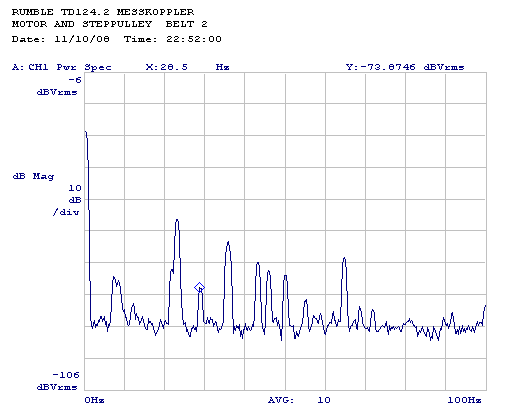

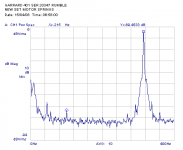

The drivetrain from the TD124 is rather complex to get a better insight I made a measurement with the messkoppler on the mainbearing without platter.

The max. frequence is 100 Hz and the vibration frequenties are clearly visible .

The next challenge is to link these different frequensies !

Step further is to make the measurement with a accellerometer to ,,bypass,, the tonearm.

The measurement with the rumble test record is limited because you get the interaction with the tonearm , cartridge etc.

Volken

The max. frequence is 100 Hz and the vibration frequenties are clearly visible .

The next challenge is to link these different frequensies !

Step further is to make the measurement with a accellerometer to ,,bypass,, the tonearm.

The measurement with the rumble test record is limited because you get the interaction with the tonearm , cartridge etc.

Volken

Attachments

Volken, interesting motor suspension set up. Can you tell us more?

Yes these are a own development seems that Thorens used them in the early days here you can see the measurements

Hanze Hifi - TD124

The drivetrain from the TD124 is rather complex to get a better insight I made a measurement with the messkoppler on the mainbearing without platter.

The max. frequence is 100 Hz and the vibration frequenties are clearly visible .

The next challenge is to link these different frequensies !

Step further is to make the measurement with a accellerometer to ,,bypass,, the tonearm.

The measurement with the rumble test record is limited because you get the interaction with the tonearm , cartridge etc.

Volken

Volken, interesting motor suspension set up. Can you tell us more?

In the "Restoring and Improving A Thorens TD-124 MKII" thread I found a couple more rumble plots from Volken. One plot of the TD124 with motor spring isolation (like in the photo), the other with rubber grommet isolation (factory method).

There probably wasn't enough discussion on this "mod" and the measurements from it. And now that I am searching for that particular post with the two plots, I can't seem to locate it. (need more coffee)

But as I recall looking at the two plots it appeared that the "spring plot" was a bit quieter than the grommet plot. Although then it might be appropriate to question if there aren't other areas of performance that might be affected by such a mod.

But this does beg comparison to the Garrard 301/401 motor isolation method which also uses springs to isolate. but that method employs springs in all the degrees of freedom that the motor has. for instance it uses springs at an angle to counteract torque force in addition to the pull of gravity. (vertical)

You know, on that TD124 thread of yours, it might be useful to organize each post made by volken. It seems that in every case he produces a measurement document to explain every question that arose in the thread. So a summary of those posts could become an important part of any method of restoration for the beast. At least I'm taking these to heart.

-Steve

Last edited:

Thanx for showing some real measurements that gives us a handle on different methods of reducing vibration.

Looking at the way the springs are touching a hard spacer, it seems practical to decouple even more by using the gel pads in some way to support the springs on both ends.

Might give some damping to the spring and should reduce higher frequency contributions.

Regards

David

Looking at the way the springs are touching a hard spacer, it seems practical to decouple even more by using the gel pads in some way to support the springs on both ends.

Might give some damping to the spring and should reduce higher frequency contributions.

Regards

David

Yes these are a own development seems that Thorens used them in the early days here you can see the measurements

Hanze Hifi - TD124

Hanze does not seem to offer these, I'd be extremely interested.. Any suggestions?

Hanze does not seem to offer these, I'd be extremely interested.. Any suggestions?

Hanze Hifi has the springs in the webshop see Thorens Motor decoupling springs

They ship to the USA too !!

Volken

Not so simple you need a decoupled measurement table otherwise you measure ambient vibrations !

Volken

Yes. When I took possession of the Minus-K platform, I thought that the isolation it afforded would make it possible to attain valid points of reference for noise measurements.

-Steve

I remember a trick of building up a thickness of coins on the arm board and gently placing the cartridge onto the stack and turning on the motor.Only valid measure of rumble is for that picked up by cartridge, thus platter must be in motion, and stylus in contact.

Check the bass speaker cones, they could be flapping around producing watt draining subsonic bass.

What about those discs that contain rumble, many did?When arm board is 400 pound block of granite this doesn't work so well. This is also basis for super heavy platters.

It all seems too much work trying to convert a cement mixer.

Some recording software can generate 1kHz test tone. And also has facility to remove one waveform from other. So one can record 1kHz test tone from test LP and remove computer/software generated waveform from recorded test tone. What remains will be noise/rumble. I guess this will work. Wouldn't it ?

Regards.

Regards.

...or if I am allowed to little unconventional thinking. How about we carefully (without damaging the stylus) move the stylus by hand on blank vinyl surface as shown in first post. Record it. This would be our noise sample. We turn on the turntable and with record spinning record the blank surface. From this recording we remove noise sample which was recorded first.

Regards.

Regards.

I like to watch a LF spectrum and levels change as a variable 4th order hi-pass filter is kicked in. I just ran a response on on old Xitel iNport usb input gizmo - it has input isolation transformers - no wonder my already rumble laden Bogen B52 sounded like a freight train - that LF peak would be about right for some 6th order vented subwoofers.

Last edited:

Thorens TD160 and Garrard 401 rumble measurement with testrecord

Old way of rumble measurement with testrecord 315hz 5,42cm/sec ref.

Thorens TD160 with HAT motor tuning cursor on the 100Hz motorvibration at -77db

Garrard 401 after motorrevision incl new motor springset also 100Hz motor vibration now on -69 db ,before revision on -55db

Volken

Old way of rumble measurement with testrecord 315hz 5,42cm/sec ref.

Thorens TD160 with HAT motor tuning cursor on the 100Hz motorvibration at -77db

Garrard 401 after motorrevision incl new motor springset also 100Hz motor vibration now on -69 db ,before revision on -55db

Volken

I did something a long time ago when I still had my turntalbe, a Thorens TD160. I removed the belt, started the turn table(the platter not turning) put a record on very gently, put the needle on the record and

then SLOWLY turned up the volume. I then very gently tapped the base, stand and so on and listed to what was coming through the speakers. Not a test of rumble when playing a record but it helped me make some mods to reduce sound that was not part of the sound coming off the record.

I guess rumble is part of the record surface that is out of our control when trying to reduce surface noise.

PeterC.

then SLOWLY turned up the volume. I then very gently tapped the base, stand and so on and listed to what was coming through the speakers. Not a test of rumble when playing a record but it helped me make some mods to reduce sound that was not part of the sound coming off the record.

I guess rumble is part of the record surface that is out of our control when trying to reduce surface noise.

PeterC.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Measuring for rumble