But a total lateral mass of 29.5 grams in (is?) not too shabby

Hello vynuhl.addict,

isn't the total lateral mass of of this type of tonearm equal to the total weight of the tonearm? Also, I would assume that the effective mass in the vertical plane is much less than it is in the horizontal plane?

What effect, if any, does that have on the quality of the sound?

Sincerely,

Ralf

Hi Ralf,

Yes, total lateral mass is the equivalent of total weight of the arm with cartridge. The lateral weight is the hardest to deal with and is also important in an air bearing design too!. The effect it has on sound is given by its ability to keep the cantilever centered, so say on an out of center disk the less mass there is to stop and traverse into an opposing direction the more likely that the stylus will remain close to center which affects stereo imaging.this has also been referred to as "the tail wagging the dog" on higher mass, and or servo controlled arms where there can be a longer delay in response to an off tangent stylus. In a nutshell, better accuracy.

Colin

Yes, total lateral mass is the equivalent of total weight of the arm with cartridge. The lateral weight is the hardest to deal with and is also important in an air bearing design too!. The effect it has on sound is given by its ability to keep the cantilever centered, so say on an out of center disk the less mass there is to stop and traverse into an opposing direction the more likely that the stylus will remain close to center which affects stereo imaging.this has also been referred to as "the tail wagging the dog" on higher mass, and or servo controlled arms where there can be a longer delay in response to an off tangent stylus. In a nutshell, better accuracy.

Colin

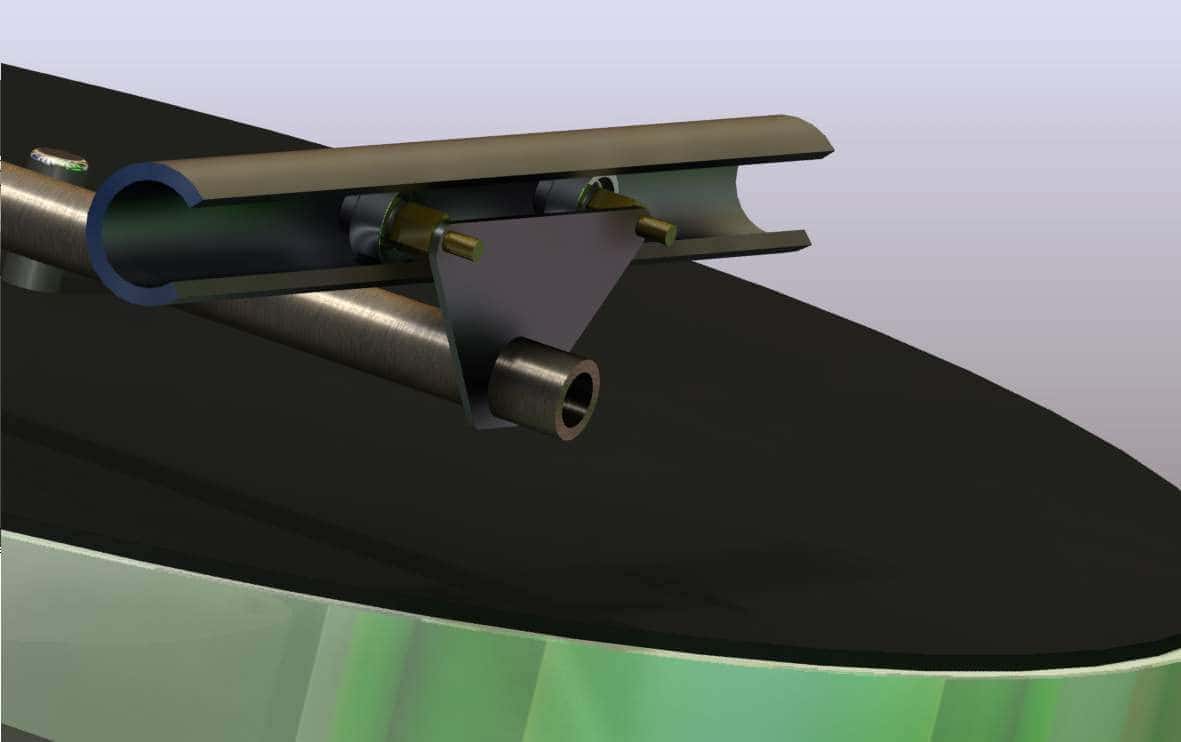

The convex shape must allow for free movement along the vertical plane. For a design where the carriage rides on the outside of the running tube, one could mount the tube to the main pillar using another roller bearing (such as larger version of those the carriage rolls on). This would theoretically allow free vertical travel of the arm wand and perhaps improve performance for higher compliance carts.

Isn't the convex shape to keep a fixed pivot point in the vertical plane for tracking warps? If they used flat edged bearings the whole assembly would rock front front edge to back as it tracked warps making it much less sensitive to warps and adding lots of noise as the flat surface of the bearing slammed into the runner.

Hi,

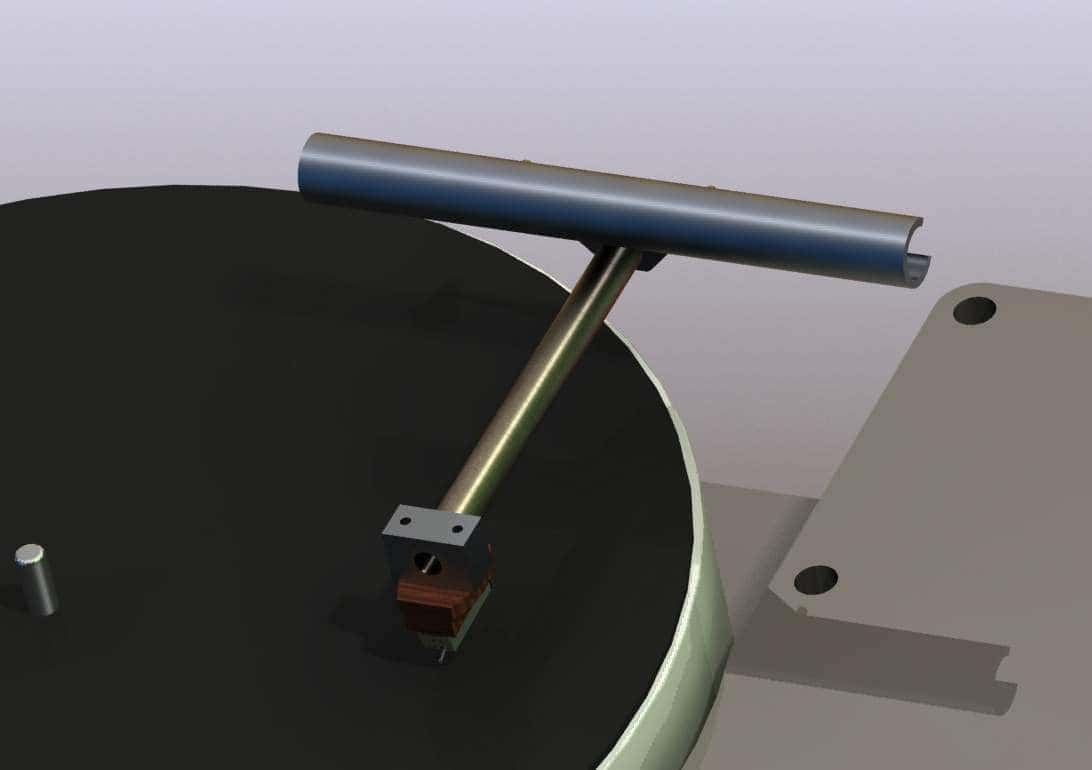

I´m no mechanical expert, but my guts feeling tells me that a framework carriage like the one shown in #93 should be advantageous over a single arm tube like in #105.

Reasoning:

The feeding force echibited by the stylus (not accounting for the perpendicular to this dragging pull due to the table´s spinning) at point A is orientated perpendicular to the single arm tube, thus exhibiting maximum torque on the midpoint B of a straight line spanning between the two bearings. Also the bending forces on the tube are maximal.

Assumed an infinitely stiff armtube/carriage this torque is translated into forces acting on the bearings parallel to the arm tube and in opposite directions at points C and D. This would push the bearings against the glass tubes wall, thereby lifting them slightly (due to the tubes shape).

Thereby it´d generate a small force in parallel to the glass tube, which then results in a movement of the bearings along the glass tubes length axis.

But most of the torque will be wasted to drive the bearing ´up the wall´.

With the framework as in #93 the bending stress within the two tubes or ribs is lower because not only will the feeding force been shared between the ribs but also will the force component perpendicular to the ribs be smaller.

The bearings will experience a force component immediately pushing in the glass tubes direction. The wasted force component pressing the bearings against the glass wand will be smaller.

I think this applies under the assumption that the points B and B" are kind of fixed, due to mass inertia of the carriage. I don´t know up to which extent this assumption holds and to which extent the assumption fails due to the moveability of points B resp. B".

If it applies, the conclusion would be that the bearings distance of the carriage for a single arm tube should be lower for higher force along the glass tube, while the conditions for a framework would be the opposite --> larger distance between the bearings.

The above lend me to the idea if it weren´t advantageous to use a flexible joint between a single arm tube and the carriage instead of a fixed one?

Is that reasonable, or am I thinking utter rubbish here?

jauu

Calvin

I´m no mechanical expert, but my guts feeling tells me that a framework carriage like the one shown in #93 should be advantageous over a single arm tube like in #105.

Reasoning:

The feeding force echibited by the stylus (not accounting for the perpendicular to this dragging pull due to the table´s spinning) at point A is orientated perpendicular to the single arm tube, thus exhibiting maximum torque on the midpoint B of a straight line spanning between the two bearings. Also the bending forces on the tube are maximal.

Assumed an infinitely stiff armtube/carriage this torque is translated into forces acting on the bearings parallel to the arm tube and in opposite directions at points C and D. This would push the bearings against the glass tubes wall, thereby lifting them slightly (due to the tubes shape).

Thereby it´d generate a small force in parallel to the glass tube, which then results in a movement of the bearings along the glass tubes length axis.

But most of the torque will be wasted to drive the bearing ´up the wall´.

With the framework as in #93 the bending stress within the two tubes or ribs is lower because not only will the feeding force been shared between the ribs but also will the force component perpendicular to the ribs be smaller.

The bearings will experience a force component immediately pushing in the glass tubes direction. The wasted force component pressing the bearings against the glass wand will be smaller.

I think this applies under the assumption that the points B and B" are kind of fixed, due to mass inertia of the carriage. I don´t know up to which extent this assumption holds and to which extent the assumption fails due to the moveability of points B resp. B".

If it applies, the conclusion would be that the bearings distance of the carriage for a single arm tube should be lower for higher force along the glass tube, while the conditions for a framework would be the opposite --> larger distance between the bearings.

The above lend me to the idea if it weren´t advantageous to use a flexible joint between a single arm tube and the carriage instead of a fixed one?

Is that reasonable, or am I thinking utter rubbish here?

jauu

Calvin

Attachments

Last edited:

easy way for you to find out is to build both. Look at the parts list for both arms, consider the complexity of the two builds. Measure the finished moving mass of booth arms. Install the same cartridge and listen. After all that you can decide but your preferential choice might not be the same as the next guy. The only opinion that counts is yours, so far as what you like the sound of. Why don't you build an arm which seems to you to be the simplest linear design for you to make and start from there? Best regards Moray James.

Which to build Moray , recommendation ..?

Slowmotion,

It's a borosilicate glass tube used for lab pipettes, glasswork, I just used a new 10ml pipette and cut it up. You can also get stock glass tube.

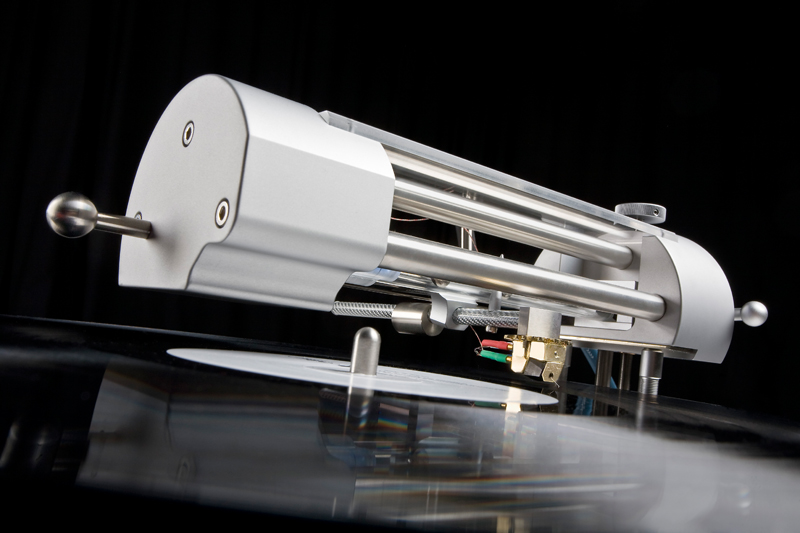

To add to the arm trials, this last carriage is the one that beats all of them, wow, vinyl playback sounds open, dynamic, and imaging to die for!!

Colin

It's a borosilicate glass tube used for lab pipettes, glasswork, I just used a new 10ml pipette and cut it up. You can also get stock glass tube.

To add to the arm trials, this last carriage is the one that beats all of them, wow, vinyl playback sounds open, dynamic, and imaging to die for!!

Colin

Attachments

Cats squirrel,

I think rubber o rings would add friction to inhibit vertical play, along with preventing a mechanical path to ground for resonance control.

Colin

I think that there would be low friction, but even a little might be beneficial. As regards the resonance, (I assume you mean of the arm wands?) if you think this would be a problem, connecting the bearings using non-compliant/non-damping materials would allow the vibrations to continue. At least the rubber o-rings would add a bit of damping. And don't forget non-compliant mounting is two way, so what is stopping vibrations coming up through the arm base into the arm?

I like the idea of the design, and I have most of the bits already, I'm just going to have to try it.

Slowmotion,

It's a borosilicate glass tube used for lab pipettes, glasswork, I just used a new 10ml pipette and cut it up. You can also get stock glass tube.

To add to the arm trials, this last carriage is the one that beats all of them, wow, vinyl playback sounds open, dynamic, and imaging to die for!!

Colin

How are you cutting the glass tube without damage ...?

Jamikl,

I've seen the u bearings, but decided to go with the four bearing arrangement since as the way it's laid out promises lowest friction and no yaw.

Resonance is low, this is shown by ultra low surface noise, and tapping the plinth which gives a deadened thump.

Cutting the glass tube:I used a file to score a line into the glass completely around the tube, then it just snaps clean.

Colin

I've seen the u bearings, but decided to go with the four bearing arrangement since as the way it's laid out promises lowest friction and no yaw.

Resonance is low, this is shown by ultra low surface noise, and tapping the plinth which gives a deadened thump.

Cutting the glass tube:I used a file to score a line into the glass completely around the tube, then it just snaps clean.

Colin

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm