Albert,

We all start off copying, and that's just fine. The whole goal of this thread was to share an idea I got working, and documented my changes along with being inspired by others ideas that have been interjected into this thread. One idea is great, but the creative input from others turn it into something even better

. One is a fool to be so stubborn as to think their idea is the end all be all and the openness to suggestions is what makes a better mousetrap.

Colin

Colin,

I totally agree n I am open to anything interesting.

May I ask What phono amp you have been using?

Albert

Hi Albert,

The phono amp I am using is one I designed loosely based off of the ctc vendetta. It is a split passive/active riaa and direct coupled. The input stage uses a fet input op amp, followed by the 2122hz pole with the rest active in the second stage using a bjt op amp. If your feeling confident with a solder iron I can pm you a diagram and op amp details. Op amp choices are important to extoll the virtues of each stage.

Colin

The phono amp I am using is one I designed loosely based off of the ctc vendetta. It is a split passive/active riaa and direct coupled. The input stage uses a fet input op amp, followed by the 2122hz pole with the rest active in the second stage using a bjt op amp. If your feeling confident with a solder iron I can pm you a diagram and op amp details. Op amp choices are important to extoll the virtues of each stage.

Colin

Hi Albert,

The phono amp I am using is one I designed loosely based off of the ctc vendetta. It is a split passive/active riaa and direct coupled. The input stage uses a fet input op amp, followed by the 2122hz pole with the rest active in the second stage using a bjt op amp. If your feeling confident with a solder iron I can pm you a diagram and op amp details. Op amp choices are important to extoll the virtues of each stage.

Colin

Colin,

Thanks for the offer. I'd love to learn something more. The design is for MM/MC?? Please do send me the schematics. You could email me as well.

Albert

Wow, this thread has grown since the last time I was through it. Some new developments as well.

Please confirm that I have correctly summarized what has transpired since the single glass tube.

1) Two 6mm Borosilicate tubes are now used side be side (no spaces)

2) Aluminum Angle used for stiffness with a dust Shield.

3) Two 4x10x4mm Bearings instead of 4 on the carraige.

4) Cartridge Shell Is a wider and taller rather than longer piece of material.

5) Other dimensions unchanged.

If so this looks like a good late summer project. With the potential of lower horizontal drag, my Lyra cartridge may be useful here. Other wise it certainly will be an improvement with the Denon 103r.

Are those ABEC9 ceramic bearings truly ABEC 9 or are they an epay scam?

Please confirm that I have correctly summarized what has transpired since the single glass tube.

1) Two 6mm Borosilicate tubes are now used side be side (no spaces)

2) Aluminum Angle used for stiffness with a dust Shield.

3) Two 4x10x4mm Bearings instead of 4 on the carraige.

4) Cartridge Shell Is a wider and taller rather than longer piece of material.

5) Other dimensions unchanged.

If so this looks like a good late summer project. With the potential of lower horizontal drag, my Lyra cartridge may be useful here. Other wise it certainly will be an improvement with the Denon 103r.

Are those ABEC9 ceramic bearings truly ABEC 9 or are they an epay scam?

Wow, this thread has grown since the last time I was through it. Some new developments as well.

Please confirm that I have correctly summarized what has transpired since the single glass tube.

1) Two 6mm Borosilicate tubes are now used side be side (no spaces)

2) Aluminum Angle used for stiffness with a dust Shield.

3) Two 4x10x4mm Bearings instead of 4 on the carraige.

4) Cartridge Shell Is a wider and taller rather than longer piece of material.

5) Other dimensions unchanged.

If so this looks like a good late summer project. With the potential of lower horizontal drag, my Lyra cartridge may be useful here. Other wise it certainly will be an improvement with the Denon 103r.

All these are What I have done so far.

I had my tonearm cable replaced with Cardas 33awg. with shield. Oh.....no hum and sound balance and wonderful, lot better than the litz wire.

Are those ABEC9 ceramic bearings truly ABEC 9 or are they an epay scam?

Finally my contribution:

I did the aligning before the tonearm wireing mount.

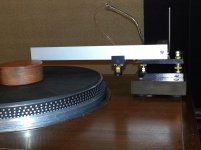

The Lenco L75 set-up on studs is a temporary solution.

Cartridge: Ortofon 2M mono with a 2M Black Shibata stylus.

I got a newsletter from Ortofon about their new 2M mono SE ( deal with Apple Records in case of the reissue of a complete Beatles mono box )

I ordered this new cartridge, but in the mean time...................I`m very,very pleased with above combo!!!!

For what I`ve heard so far............great stuff.

I`m going to spend the next week-end on fine tuning, and listening of course.

To all contributers of this Topic a big THANK YOU VERY MUCH !!!!!!!!

Hans.

p.s. completely lost in mono Jazz, for now.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

I did the aligning before the tonearm wireing mount.

The Lenco L75 set-up on studs is a temporary solution.

Cartridge: Ortofon 2M mono with a 2M Black Shibata stylus.

I got a newsletter from Ortofon about their new 2M mono SE ( deal with Apple Records in case of the reissue of a complete Beatles mono box )

I ordered this new cartridge, but in the mean time...................I`m very,very pleased with above combo!!!!

For what I`ve heard so far............great stuff.

I`m going to spend the next week-end on fine tuning, and listening of course.

To all contributers of this Topic a big THANK YOU VERY MUCH !!!!!!!!

Hans.

p.s. completely lost in mono Jazz, for now.

Last edited:

tomatamot'

Very nice work !!!! Is your arm mounted on linear bearing slide ?

no it is just like a Cantus.

An externally hosted image should be here but it was not working when we last tested it.

No, no, no, it`s Colin`s 2 rod design on an Igus Drylin* W linear guide. ( I`ve got 2, given to me by a friend )

I can see now. Very nice work!

I am going to work on my 2nd version of arm this weekend and didn't do too much because I was busy. But I finished modification of SME suspension. I built " a small Brooklyn bridge". There are two layers of suspensions now. The first layer is on racquetballs. The 2nd layer is hanging on rubber O-rings just as SME's. The arm is now on the same platform as the platter.

I am going to work on my 2nd version of arm this weekend and didn't do too much because I was busy. But I finished modification of SME suspension. I built " a small Brooklyn bridge". There are two layers of suspensions now. The first layer is on racquetballs. The 2nd layer is hanging on rubber O-rings just as SME's. The arm is now on the same platform as the platter.

Attachments

Last edited:

Lexx21,

My next carrier for a Pierre Clément mono cart. ( 38 gr. )

An externally hosted image should be here but it was not working when we last tested it.

My next carrier for a Pierre Clément mono cart. ( 38 gr. )

Well Arch Stanton non of my cantilevers ( "palette") are twisted.

Yes, with the screw and a small piece of rubber tube or heatshrink, to align the "palette".

I`ve made the space for the "palette" a little bigger ( more open ), so I can set the "palette" straight.

But I`m in a big S**t situation, lost the palette screw. ( shopping tomorrow at first )

Hans.

p.s. be carefull with that scew, d`nt turn to tight!!!!!!!!!!!!!!

Yes, with the screw and a small piece of rubber tube or heatshrink, to align the "palette".

I`ve made the space for the "palette" a little bigger ( more open ), so I can set the "palette" straight.

But I`m in a big S**t situation, lost the palette screw. ( shopping tomorrow at first )

Hans.

p.s. be carefull with that scew, d`nt turn to tight!!!!!!!!!!!!!!

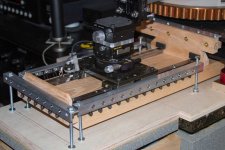

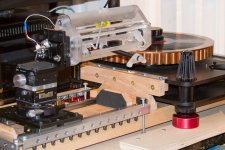

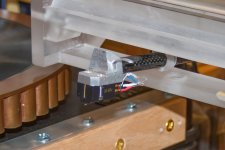

I finally finished 2nd version of diy linear tone arm. This time, I paid a lot of attention to damping. These following things are different from 1st version.

1. Arm base is on the same suspension platform as platter.

2. I tried to do uni-body. It mean to avoid loose parts and glue all supporting braces as one unified structure.

3. I used lead sheets and rubber to effectively damp unwanted resonance. Glass rail is covered by .5 mm soft lead strip and supported by 2 mm carbon fiber plates. It is very effective. The arm is deadly quiet.

4. Using a new Denon DL-103R cartridge. DL-103R works very well with this kind of diy arm. It doesn't pick any noise from the tone arm. I tapped very where on the tone arm and didn't hear any feedback from the speakers. The DL-103R has very good tracking ability as well.

5. Of course, all the dimensions of the tone arm are different from 1st version. The distance between two bearings is 60 mm now. It is 25 mm from arm pivot to center of wand. I designed 20 mm, but I have to use 25 mm due to miscalculation.

Here is a youtube video.

https://www.youtube.com/watch?v=3Y3qTb5FAlU

If I build something, I want to do it functionally and beautifully.

1. Arm base is on the same suspension platform as platter.

2. I tried to do uni-body. It mean to avoid loose parts and glue all supporting braces as one unified structure.

3. I used lead sheets and rubber to effectively damp unwanted resonance. Glass rail is covered by .5 mm soft lead strip and supported by 2 mm carbon fiber plates. It is very effective. The arm is deadly quiet.

4. Using a new Denon DL-103R cartridge. DL-103R works very well with this kind of diy arm. It doesn't pick any noise from the tone arm. I tapped very where on the tone arm and didn't hear any feedback from the speakers. The DL-103R has very good tracking ability as well.

5. Of course, all the dimensions of the tone arm are different from 1st version. The distance between two bearings is 60 mm now. It is 25 mm from arm pivot to center of wand. I designed 20 mm, but I have to use 25 mm due to miscalculation.

Here is a youtube video.

https://www.youtube.com/watch?v=3Y3qTb5FAlU

If I build something, I want to do it functionally and beautifully.

Attachments

Last edited:

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm