Hi Niffy,

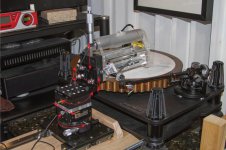

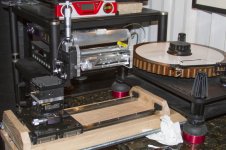

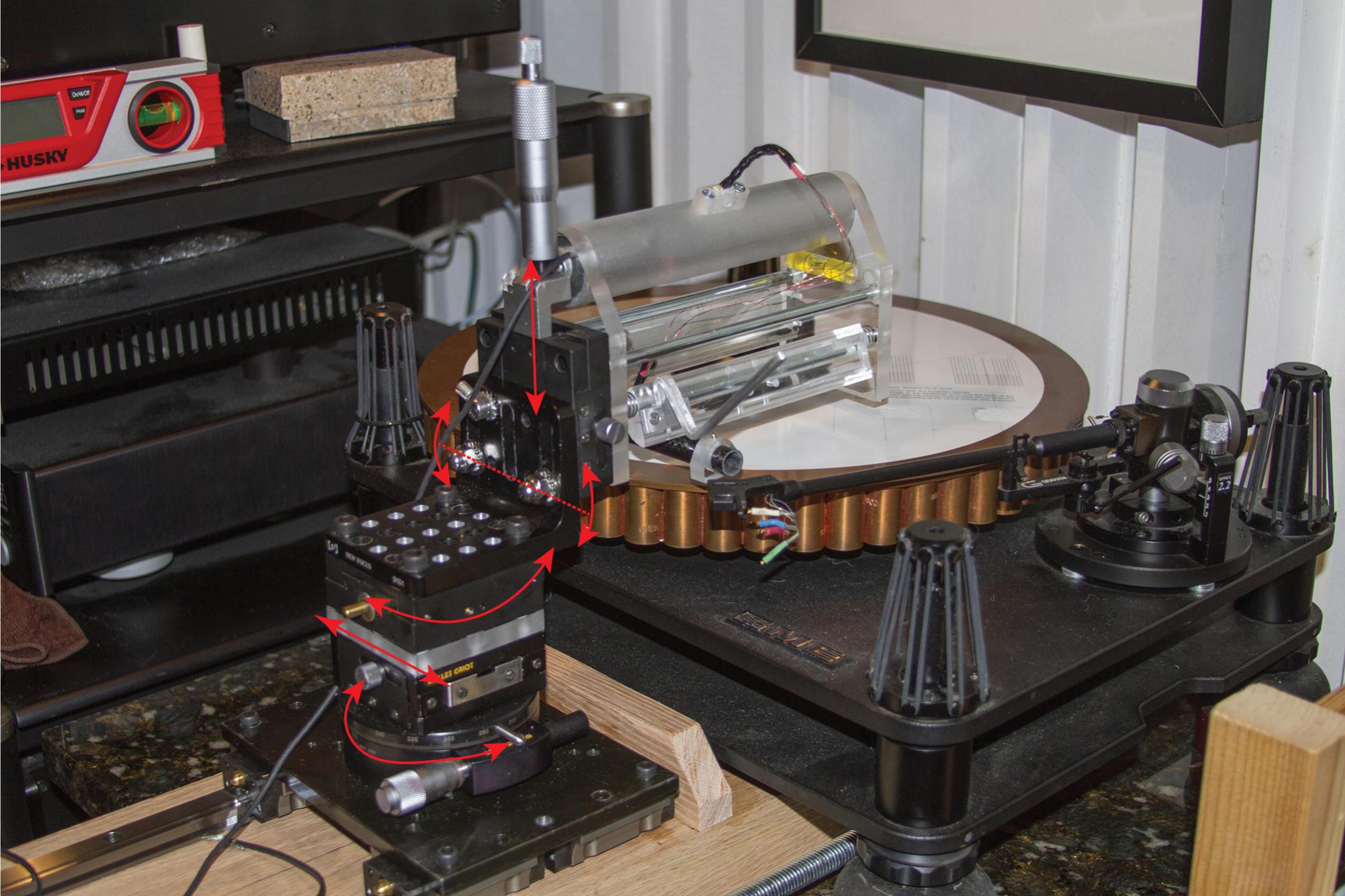

All the stages are bought off ebay. I use two micrometers. One is for height, VTA and one is for rotation.

The arm base doesn't swivel but slides. Please see attached photo. I use two linear slide rails. These rails are used in automation. It can do exact repeat action. I bought two from a surplus web site for $149.00.

I changed my mind. It is a two glass tubings and two bearings linear arm now. However, it is very easy to change the bearings and glass tracks now. I may try different designs later on. I really want to try two ceramic balls and four glass tubings as in other linear arm thread.

The deck is SME 20. I made an outer ring.

Hi AuroraB,

These stages are about $150 each on ebay. I got some cheap ones. The total cost for four stages, two linear, one rotary and one goniometer plus a angle and a base plate is $355.00. I don't have access to a machine shop except a band saw and a drill press so I think it is worth to pay more for stages.

Hi hottattoo

Thanks you!

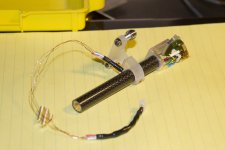

I designed my own head shell so I can adjust zenith if I want to. In the meantimes, I don't need to install cartridge on the arm. The counter weight is hiding inside the carbon fiber wand. I also made some extra weights for different cartridges. Please see photo. The wires from arm wand are made from my old Sennheiser HD600 cable. The plug attached to arm is micro mini JST 4 pin connector for computer.

All the stages are bought off ebay. I use two micrometers. One is for height, VTA and one is for rotation.

The arm base doesn't swivel but slides. Please see attached photo. I use two linear slide rails. These rails are used in automation. It can do exact repeat action. I bought two from a surplus web site for $149.00.

I changed my mind. It is a two glass tubings and two bearings linear arm now. However, it is very easy to change the bearings and glass tracks now. I may try different designs later on. I really want to try two ceramic balls and four glass tubings as in other linear arm thread.

The deck is SME 20. I made an outer ring.

Hi AuroraB,

These stages are about $150 each on ebay. I got some cheap ones. The total cost for four stages, two linear, one rotary and one goniometer plus a angle and a base plate is $355.00. I don't have access to a machine shop except a band saw and a drill press so I think it is worth to pay more for stages.

Hi hottattoo

Thanks you!

I designed my own head shell so I can adjust zenith if I want to. In the meantimes, I don't need to install cartridge on the arm. The counter weight is hiding inside the carbon fiber wand. I also made some extra weights for different cartridges. Please see photo. The wires from arm wand are made from my old Sennheiser HD600 cable. The plug attached to arm is micro mini JST 4 pin connector for computer.

Attachments

Last edited:

super10018:

The only thing you are missing is a digital read out--You could use 1 or 2 and make adjustments easier.

Digital read out is usually expensive. It will be nice to have one for VTA.

Forgot to mention that total mass of arm is 34 g.

Regards,

Jim

Super,

I look forward to you having it up and running . If there is anything I've noticed about this design is that it seems to extract every last bit of infomation from the record without smearing. It doesn't get any simpler than this, and in some respects simplicity is king. And still to top it all off it does this with ultra affordable cartridges

. If there is anything I've noticed about this design is that it seems to extract every last bit of infomation from the record without smearing. It doesn't get any simpler than this, and in some respects simplicity is king. And still to top it all off it does this with ultra affordable cartridges  .

.

Colin

I look forward to you having it up and running

Colin

Last edited:

Finally, I complete the line arm. It took me three months to plan and to get all the parts together.

I was amazed by the sound from this arm. Here are some of my experience and thoughts.

This arm works well with low and medium compliance cartridges. I tried Zyx airy 2, $3000. It totally killed the cartridge. The cartridge I am using now is Clear Audio Aurum Beta S, a $400 mm high output cartridge. It seems to me the arm works well with low priced and low or medium compliance cartridges. The arm with Aurum beats my Graham 2.2 and Zyx Airy 2 combo in term of dynamics and bass but somewhat lacks in micro dynamic and detail area. I think it is because Aurum is an mm cartridge. The diy arm also has excellent image.

For everyone who may be interested in building this arm, you need to find your own best balance of the combination for the arm. I mean wand, head shell by the word, arm here. The right balance means the all the factors; weight distribution, size and material should be in the state of right combination. I have the feeling that the arm moving mass should be little heavier than 30 grams in order to maintain good track ability. I use a cartridge weight for my VPI arm. The arm mass now is 44 grams, including cartridge. I may try not to use cartridge weight later on to reduce the arm moving mass. My arm did skip from time to time at beginning. It works fine now after I spent considerable time to adjust weight distribution.

The higher moving mass arm requires a low compliance cartridge. I checked online. Denon D-103R may be a good match for the arm since it has low compliance, 5x10-6 cm/dyne and is a low output mc cartridge.

I set VTF about 2.0 gram. However, I am not completely sure about VTF because VTF is not stable. I kind weighted VTF many times and averaged it out. VTF also changes while the arm is moving.

I used a wood stick to lightly tapped the arm wand and everywhere else including the arm base. I could hear sound only while I was tapping the arm wand. So I added four o rings on the arm wand. It helped but it didn’t completely eliminate the ringing. It may work to use insulating foam sealant to fill inside of the arm wand. But I am not sure. It is just an idea.

Here are more photos and a youtube video.

https://www.youtube.com/watch?v=zoJeAH_daEU

Jim

I was amazed by the sound from this arm. Here are some of my experience and thoughts.

This arm works well with low and medium compliance cartridges. I tried Zyx airy 2, $3000. It totally killed the cartridge. The cartridge I am using now is Clear Audio Aurum Beta S, a $400 mm high output cartridge. It seems to me the arm works well with low priced and low or medium compliance cartridges. The arm with Aurum beats my Graham 2.2 and Zyx Airy 2 combo in term of dynamics and bass but somewhat lacks in micro dynamic and detail area. I think it is because Aurum is an mm cartridge. The diy arm also has excellent image.

For everyone who may be interested in building this arm, you need to find your own best balance of the combination for the arm. I mean wand, head shell by the word, arm here. The right balance means the all the factors; weight distribution, size and material should be in the state of right combination. I have the feeling that the arm moving mass should be little heavier than 30 grams in order to maintain good track ability. I use a cartridge weight for my VPI arm. The arm mass now is 44 grams, including cartridge. I may try not to use cartridge weight later on to reduce the arm moving mass. My arm did skip from time to time at beginning. It works fine now after I spent considerable time to adjust weight distribution.

The higher moving mass arm requires a low compliance cartridge. I checked online. Denon D-103R may be a good match for the arm since it has low compliance, 5x10-6 cm/dyne and is a low output mc cartridge.

I set VTF about 2.0 gram. However, I am not completely sure about VTF because VTF is not stable. I kind weighted VTF many times and averaged it out. VTF also changes while the arm is moving.

I used a wood stick to lightly tapped the arm wand and everywhere else including the arm base. I could hear sound only while I was tapping the arm wand. So I added four o rings on the arm wand. It helped but it didn’t completely eliminate the ringing. It may work to use insulating foam sealant to fill inside of the arm wand. But I am not sure. It is just an idea.

Here are more photos and a youtube video.

https://www.youtube.com/watch?v=zoJeAH_daEU

Jim

Attachments

Last edited:

super10018:

You could try 2 fairly simple things.

1. increase the distance between the bearing as this may cut down possible twisting torsion at the cartridge.

2. make your counter weight with most of its mass close to the level of the cantilever

Your arm seems very stable in the video's. These are just some suggestions that may help. It is disappointing to hear an expensive moving coil bit the dust, since they generally sound much better overall then moving magnet cartridges. I hope you find a solution so you can get the full potential out of your arm. Again, excellent work and good luck !!!!

You could try 2 fairly simple things.

1. increase the distance between the bearing as this may cut down possible twisting torsion at the cartridge.

2. make your counter weight with most of its mass close to the level of the cantilever

Your arm seems very stable in the video's. These are just some suggestions that may help. It is disappointing to hear an expensive moving coil bit the dust, since they generally sound much better overall then moving magnet cartridges. I hope you find a solution so you can get the full potential out of your arm. Again, excellent work and good luck !!!!

Thanks for your suggestions, hottattoo!

I don't mind personally if the arm can only work well with certain cartridges. I already placed an order for Denon DL-103R. If it works, I will be happy to just use DL-103R.

One thing I find is background noise is louder than my Graham and Zyx combo. It seems to me the cartridge on the diy arm picks very dust on the surface of record and amplifies it through speakers. I have no idea why.

Anyway, I am back to the drawing board and going to design 2nd arm wand. The 1st one is a success but I would like to improve the track ability.

Regards,

Jim

I don't mind personally if the arm can only work well with certain cartridges. I already placed an order for Denon DL-103R. If it works, I will be happy to just use DL-103R.

One thing I find is background noise is louder than my Graham and Zyx combo. It seems to me the cartridge on the diy arm picks very dust on the surface of record and amplifies it through speakers. I have no idea why.

Anyway, I am back to the drawing board and going to design 2nd arm wand. The 1st one is a success but I would like to improve the track ability.

Regards,

Jim

One thing I find is background noise is louder than my Graham and Zyx combo. It seems to me the cartridge on the diy arm picks very dust on the surface of record and amplifies it through speakers. I have no idea why.

I wonder why? The record in Post 1807, is disgustingly filthy.

I wonder why? The record in Post 1807, is disgustingly filthy.

It is partly my fault. I should clean the record before I played it. Anyway, the background noise of diy arm is still louder than Graham and Zyx combo's.

One thing I have to point it out. The phase of two channels is much better than Graham and Zyx combo's by listening to the 1st and 2nd tracks of Hifi News Test LP. Musical instruments' locations are very well defined.

super,

Dimensions are critical most definately. I have set it up with a 40 mm bearing spacing and length of approx 2 5/8" from pivot to stylus tip, this seems to work well. Because of the length and weight arrangement I get no more than 1/10 tg of a gram variance when checking tracking weight. The part that makes this design work well is because of the pendulum effect vtf increases slightly on a warp which helps tracking rather than the teeter totter effect of adding a pivot to the wand.

Colin

Dimensions are critical most definately. I have set it up with a 40 mm bearing spacing and length of approx 2 5/8" from pivot to stylus tip, this seems to work well. Because of the length and weight arrangement I get no more than 1/10 tg of a gram variance when checking tracking weight. The part that makes this design work well is because of the pendulum effect vtf increases slightly on a warp which helps tracking rather than the teeter totter effect of adding a pivot to the wand.

Colin

super10018:

The obvious reason for excessive noise is excessive dust !!! I guess you figured that out. Since your ZYX cartridge failed, it is possible your cartridge became noisy as the suspension started to fail. Another possibility is excessive VTF or other stylus misalignment.

Also, give a thorough inspection to your glass rods. There may be some microscopic peaks or other flaws. Roll your glass rods on a surface plate / mirror with a strong light to see if they are very slightly bent. A good way to check for straightness is to raise one end of your flat surface a couple of thousands of an inch and watch the rods roll off. They should roll off almost as easily as a ball bearing. You will not generally feel or see small imperfections. It only takes a very small carriage restriction to ruin a cantilever suspension. Hope you find the Gremlins.

The obvious reason for excessive noise is excessive dust !!! I guess you figured that out. Since your ZYX cartridge failed, it is possible your cartridge became noisy as the suspension started to fail. Another possibility is excessive VTF or other stylus misalignment.

Also, give a thorough inspection to your glass rods. There may be some microscopic peaks or other flaws. Roll your glass rods on a surface plate / mirror with a strong light to see if they are very slightly bent. A good way to check for straightness is to raise one end of your flat surface a couple of thousands of an inch and watch the rods roll off. They should roll off almost as easily as a ball bearing. You will not generally feel or see small imperfections. It only takes a very small carriage restriction to ruin a cantilever suspension. Hope you find the Gremlins.

One thing I have to point it out. The phase of two channels is much better than Graham and Zyx combo's by listening to the 1st and 2nd tracks of Hifi News Test LP. Musical instruments' locations are very well defined.

One thing that struck and keeps on striking me with a linear arm like this. I had some here and there skip problems with the 4 bearing, but none with this version. It came down to arm level and or a record in need of cleaning. I had found that the weight needs to be placed above the cartridge and for the counterweight low slung for the most ideal tracing.

Colin

surface noise

Hi super.

I've done a bit of research into why the level of surface noise varies from arm to arm in the past. Here are my conclusions.

The answer is counterintuitive. You would expect a better arm with better resolution capabilities to pick up the "detail" of each speck of dust with greater clarity. In reality better arms have lower surface noise levels with a lot less snap, crackle and pop.

If you Google electron-microscope images of a record groove you will find lots of lovely images. Many of these show dust in the groove. From the images that have scale bars you can determine that typical dust particles are in the range of 3 to 10um across.

At an average groove velocity even a large dust particle will pass the stylus in only 1/20,000th of a second. If the record replay system was perfect this would be played as a single peek (at equivalent to 10khz). The level of this peak would be very high as groove modulation at this frequency is low due to riaa equalization.

A single peek at 10khz happens to fast to be heard.

The high amplitude rapid impact of the dust particle is like a hammer blow that sends a shock wave into the arm and deck.

What you hear as a crack is not actually the dust particle but the deck/arm ringing due to this shock wave. A better arm or at least one that controls resonance better will ring for less time and at a lower amplitude making the dust impact less audible.

Of course the same effect is occurring constantly at a lower level due to the modulation of the groove and effects sound quality.

The level of surface noise is a useful tool for determining and reducing system resonances.

You could try adding damping to the arm tube. A length of balsa dowel inserted into the arm tube would add virtually no mass and is easily removed. If I recall correctly Colin found that a piece of an ear plug, the squishy type, worked well in his arm. My approach was to build a carriage with a resonant frequency outside of the audio band, this seems to have worked well on this front as surface noise is vanishingly low.

The Graham arms have clever multilayer damping and are in my opinion some of the best arms ever made. If your diy arm is keeping up with the Graham you're definitely doing something right.

Niffy

Hi super.

I've done a bit of research into why the level of surface noise varies from arm to arm in the past. Here are my conclusions.

The answer is counterintuitive. You would expect a better arm with better resolution capabilities to pick up the "detail" of each speck of dust with greater clarity. In reality better arms have lower surface noise levels with a lot less snap, crackle and pop.

If you Google electron-microscope images of a record groove you will find lots of lovely images. Many of these show dust in the groove. From the images that have scale bars you can determine that typical dust particles are in the range of 3 to 10um across.

At an average groove velocity even a large dust particle will pass the stylus in only 1/20,000th of a second. If the record replay system was perfect this would be played as a single peek (at equivalent to 10khz). The level of this peak would be very high as groove modulation at this frequency is low due to riaa equalization.

A single peek at 10khz happens to fast to be heard.

The high amplitude rapid impact of the dust particle is like a hammer blow that sends a shock wave into the arm and deck.

What you hear as a crack is not actually the dust particle but the deck/arm ringing due to this shock wave. A better arm or at least one that controls resonance better will ring for less time and at a lower amplitude making the dust impact less audible.

Of course the same effect is occurring constantly at a lower level due to the modulation of the groove and effects sound quality.

The level of surface noise is a useful tool for determining and reducing system resonances.

You could try adding damping to the arm tube. A length of balsa dowel inserted into the arm tube would add virtually no mass and is easily removed. If I recall correctly Colin found that a piece of an ear plug, the squishy type, worked well in his arm. My approach was to build a carriage with a resonant frequency outside of the audio band, this seems to have worked well on this front as surface noise is vanishingly low.

The Graham arms have clever multilayer damping and are in my opinion some of the best arms ever made. If your diy arm is keeping up with the Graham you're definitely doing something right.

Niffy

another piont on surface noise

Stylus profile seems to make a big difference in surface noise. A fine line stylus tends to be quieter than an elliptical. I believe this is due to their smaller radius. They tend to flick larger particles out of the groove rather than riding over them. During replay the stylus will loosen a lot of dust so I always brush my records both before and after play.

Niffy

Stylus profile seems to make a big difference in surface noise. A fine line stylus tends to be quieter than an elliptical. I believe this is due to their smaller radius. They tend to flick larger particles out of the groove rather than riding over them. During replay the stylus will loosen a lot of dust so I always brush my records both before and after play.

Niffy

Colin,

The bearing space on my arm is 34 mm from center to center. The distance from pivot to stylus tip is about 1 3/4". Do you leave space between two glass tubings? Mine has space same as the thickness of a credit card. I guess it may be the cause you get less variance of VTF.

Yes. Your arm looks simple and elegant.

I am going to try to modify the counter weight and move it under the wand.

hottattoo,

I am going to check the glass tubings as you suggested.

Niffy

What you said about the background noise does make sense to me. I think the construction of my glass track needs more damping.

For arm wand, I cut a wine bottle cork(plastic foam kind) to size to insert it into the arm tube. I will try to listen later on and hope it works

The bearing space on my arm is 34 mm from center to center. The distance from pivot to stylus tip is about 1 3/4". Do you leave space between two glass tubings? Mine has space same as the thickness of a credit card. I guess it may be the cause you get less variance of VTF.

Yes. Your arm looks simple and elegant.

I am going to try to modify the counter weight and move it under the wand.

hottattoo,

I am going to check the glass tubings as you suggested.

Niffy

What you said about the background noise does make sense to me. I think the construction of my glass track needs more damping.

For arm wand, I cut a wine bottle cork(plastic foam kind) to size to insert it into the arm tube. I will try to listen later on and hope it works

Last edited:

Super,

I use 2 6mm tubes side by side, no space between, but my bearing width is 3mm. You could lengthen the arm too, this helps tracking wise along wih the lowered counterweight. I spent months honing the dimensions through much listening and tests. Another benefit seemed to be the block headshell, I tried a flat 1/8" thick headshell but this was audibly less damped through a simple finger tap with a pencil.

Colin

I use 2 6mm tubes side by side, no space between, but my bearing width is 3mm. You could lengthen the arm too, this helps tracking wise along wih the lowered counterweight. I spent months honing the dimensions through much listening and tests. Another benefit seemed to be the block headshell, I tried a flat 1/8" thick headshell but this was audibly less damped through a simple finger tap with a pencil.

Colin

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm