Thanks Warrjon, all the stuff you get done in a day, you must have longer days!Hi Mike,

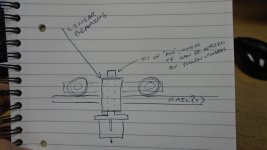

The issue I see with this design is you have a double vertical pivot. The carriage can pivot on the rail and the cartridge is attached to a vertical pivot. With 4mm rods you will need 3mm wide bearings to sit them at the correct angle on the rail. 6mm rods require 4mm bearings.

I have 3mm bearings on the list thanks, they are lighter than the 4 by a fraction as well.

Is the double vertical you see the paralelogram and swing on the rail? - if so, the idea is that the stylus is directly centred under the rails, so no pivot force is exerted

How critical is azimuth if the eye says its upright?To answer your question I suspect the distortion improvement was mainly due to being able to adjust the stylus in the groove afforded by the shallower carriage. Probably more to do with azimuth than VTA. I originally set the rail level and did not worry about checking azimuth as I machined everything to close tolerances. I didn't take into account removing and re-gluing the wheel mounting blocks.

i could adjust one wheel on the rail up and down if its critical, but more complex...........Tonight's tests will be to adjust the rail which changes azimuth to see if I can completely eradicate the distortion. If this fails I will make another carriage that has azimuth adjustment so the rail can be leveled and azimuth adjusted separately.

You could even change the direction of the parallelogram like in pic. 1 I think the balance in the hole system will improve.

And instead of the difficult to produce wheel and pin bearings , you could use the suggestion in pic. 2. This straight ball bearing is in fact the basis for the Lil casey rail, described in this thread:

My Linear Tracker (a new variation perhaps?)

By using two rails you avoid the pivoting action of just one rail.

Still thinking here Koldby, is there a post with your latest passive creation pictures i can study please, hoping to profit of your expertise and experiences as always! thanks, mike

Still thinking here Koldby, is there a post with your latest passive creation pictures i can study please, hoping to profit of your expertise and experiences as always! thanks, mike

If you ask me for the latest working TA:

post #3071

well that is a long time ago, what I am talking about now is work in progress.

Thanks

Thanks Warrjon, all the stuff you get done in a day, you must have longer days!

I have 3mm bearings on the list thanks, they are lighter than the 4 by a fraction as well.

Is the double vertical you see the paralelogram and swing on the rail? - if so, the idea is that the stylus is directly centred under the rails, so no pivot force is exerted

I think you will find the drag on the stylus will cause pivoting of the bearings on the rail. Carlo used a small CW in front of the cartridge to counter this force.

How critical is azimuth if the eye says its upright?

i could adjust one wheel on the rail up and down if its critical, but more complex...........

Depends on stylus profile. A conical stylus is in effect immune to azimuth as it is a radius. A micro line like the Jico SAS is a very fine line contact making correct azimuth more critical. I use the rail tilt to fine adjust azimuth, the amount it tilts the rail is not enough to effect tracking.

If you ask me for the latest working TA:

post #3071

well that is a long time ago, what I am talking about now is work in progress.

Thanks

Thats great, all good to see and many thanks.

My current sketch can also work under a linear roller like yours, but that seems massier on the carriage to me? - also i wonder about the balls getting out of place over time or some event being less predictable than roller bearings. i can see both types quite similar geometrically so i will do the bearings first, and i have enough glass rods to do a linear BB if it seems desirable after that.

That's great to know, so if that happens i can reconfigure slightly to put mass in the right place to achieve the same, (i expect to have spacers on the bearing mounts that would allow that) or does the drag vary enough to vary what's needed, in which case a dual rail might be necesary......I think you will find the drag on the stylus will cause pivoting of the bearings on the rail. Carlo used a small CW in front of the cartridge to counter this force.

My Ania just says eliptical, so that will probably be trial and error when i get to there!Depends on stylus profile. A conical stylus is in effect immune to azimuth as it is a radius. A micro line like the Jico SAS is a very fine line contact making correct azimuth more critical. I use the rail tilt to fine adjust azimuth, the amount it tilts the rail is not enough to effect tracking.

Thanks for provoking this thought line.I think you will find the drag on the stylus will cause pivoting of the bearings on the rail. Carlo used a small CW in front of the cartridge to counter this force.

Just comparing drawings, the length of the lever involved in the rotation/pivoting on Carlos is small, so drag rotation might be less but the mass of the parallelogram on my sketch counteracts that drag force even though its on a longer lever. I have no idea the order of magnitude, so for now that will be T&E

Now looking at miniature linear bearings for vertical movement directly under the rail.

I know they rotate as well, but if the stylus is in front of the rotation point, drag should allow self alignment in the groove should it not? Assuming of course, low horizontal friction)

Anyone tried this? Am I wasting my time going over old ground?

I know they rotate as well, but if the stylus is in front of the rotation point, drag should allow self alignment in the groove should it not? Assuming of course, low horizontal friction)

Anyone tried this? Am I wasting my time going over old ground?

Now looking at miniature linear bearings for vertical movement directly under the rail.

I know they rotate as well, but if the stylus is in front of the rotation point, drag should allow self alignment in the groove should it not? Assuming of course, low horizontal friction)

Anyone tried this? Am I wasting my time going over old ground?

Hi Apache, i may be misunderstanding the description but one key point i am aiming for is the stylus under the rail centre, and also one has to achieve tracking weight, hence the parallelogram solution, whichever orientation its in.

Maybe scribble a sketch?

With some previous arm designs, I've used fine fishing line to translate from the application point to the counterweight via bearing pulleys. I was anticipating a similar solution here.

The rail layout only shown to show where the linear bearing might sit. To do it as shown would require two rails spaced with enough clearance for the vertical bearing to traverse. Not sure I like that idea. I would possibly sit it just in front of the conventional two wheel rail and put up with any warp wow / use a clamp / not buy warped records.

<edit> D'oh. Obviously it would require a four wheel sled in order that the vertical pivoting of the two wheel design didn't occur.

The rail layout only shown to show where the linear bearing might sit. To do it as shown would require two rails spaced with enough clearance for the vertical bearing to traverse. Not sure I like that idea. I would possibly sit it just in front of the conventional two wheel rail and put up with any warp wow / use a clamp / not buy warped records.

<edit> D'oh. Obviously it would require a four wheel sled in order that the vertical pivoting of the two wheel design didn't occur.

Attachments

Last edited:

My wife can't hear it but I know it's there.

That can't be right! Normally the audiophile trope (especially when justifying £1000 speaker wire) goes something like :

"my wife came running from the kitchen shouting 'What have you changed?!'"

Last edited:

With some previous arm designs, I've used fine fishing line to translate from the application point to the counterweight via bearing pulleys. I was anticipating a similar solution here.

The rail layout only shown to show where the linear bearing might sit. To do it as shown would require two rails spaced with enough clearance for the vertical bearing to traverse. Not sure I like that idea. I would possibly sit it just in front of the conventional two wheel rail and put up with any warp wow / use a clamp / not buy warped records.

<edit> D'oh. Obviously it would require a four wheel sled in order that the vertical pivoting of the two wheel design didn't occur.

Miniature linear guides or linear bearings look to be a complicated area to research, but could be very elegant if its achieved........

You can use earphone wires. they are very good quality, thin and flexible.Many thanks again, I have found SMB bearings here and they offer them dry.

Sorry to keep asking, i know i have seen it somewhere, what is the best wiring thought currently please (at reasonable cost)?

I have used litz wires from eBay in my Schroeder clone. They are good but I have found cheap Philips earphone wires better.

You can use these for cartridge clips, gold plated and good quality

https://in.element14.com/amp-te-connectivity/66505-4/d-sub-contact-socket-28-24awg/dp/2687316

or

https://in.element14.com/norcomp/170-102-170l001/contact-crimp-receptacle-28-24awg/dp/2294211

Regards

Sachin

You can use earphone wires. they are very good quality, thin and flexible.

I have used litz wires from eBay in my Schroeder clone. They are good but I have found cheap Philips earphone wires better.

You can use these for cartridge clips, gold plated and good quality

https://in.element14.com/amp-te-connectivity/66505-4/d-sub-contact-socket-28-24awg/dp/2687316

or

https://in.element14.com/norcomp/170-102-170l001/contact-crimp-receptacle-28-24awg/dp/2294211

Regards

Sachin

Many thanks Sachin, good info to have! best, mike

i am edging closer to build and i remember reading about rail slope to centre to provide the move to centre force

Hello Mike56,

If I understand that correctly, I would not recommend doing that. It will work against you when playing even slightly eccentric records.

Sincerely,

Ralf

Hello Mike56,

If I understand that correctly, I would not recommend doing that. It will work against you when playing even slightly eccentric records.

Sincerely,

Ralf

Thanks Ralf, got that!

Miniature linear guides or linear bearings look to be a complicated area to research, but could be very elegant if its achieved........

I ordered one, complete with slider last night after talking to the supplier, who assured me that the seals can be removed easily. I need to devise a way or measuring stiction.

I'm wondering how important that is, because on the two wheel / single track version there is 'stiction' for the want of a better word, in the vertical plane anyway, and this is regarded as a positive feature as it holds the cartridge body still unless upset by significant vertical disturbance.

Anyway, I'll have a play with it and see what, if anything comes of it.

I don't think linear bearings are going to be high performance for the rail. I used 12mm industrial (read better tolerance than eBay units) on the sliding bridge and they have a fair amount of lateral twisting movement available to them. They are noisy when moving the bridge back to change LP's

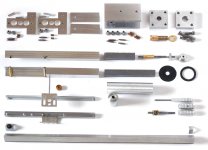

The 2 most important things to get right on the carriage and rail are starting torque (stiction) and inertia. Starting torque is obvious ( torque to get the carriage rolling) and inertia is the resistance to change in direction, carriage weight which has the largest impact on inertia needs to be matched to the cartridge.

The best example is my carriage, which is a very close copy of Niffy's did not work with my very high compliance Stanton 881s (50% higher compliance as Niffy's 2M Black), overshoot was extremely noticeable as the cantilever waggled badly on off centre pressings, distortion was audible on my Neil Diamond Stones LP. Changing the cartridge to a Technics EPC205 (same compliance as 2M Black) for the most part fixed this issue. On the same off centre pressings the EPC205 performed far better than the 881s. CL deflection is noticeable on the torture test but on Stones LP I cannot see the deflection and distortion is gone.

The 2 most important things to get right on the carriage and rail are starting torque (stiction) and inertia. Starting torque is obvious ( torque to get the carriage rolling) and inertia is the resistance to change in direction, carriage weight which has the largest impact on inertia needs to be matched to the cartridge.

The best example is my carriage, which is a very close copy of Niffy's did not work with my very high compliance Stanton 881s (50% higher compliance as Niffy's 2M Black), overshoot was extremely noticeable as the cantilever waggled badly on off centre pressings, distortion was audible on my Neil Diamond Stones LP. Changing the cartridge to a Technics EPC205 (same compliance as 2M Black) for the most part fixed this issue. On the same off centre pressings the EPC205 performed far better than the 881s. CL deflection is noticeable on the torture test but on Stones LP I cannot see the deflection and distortion is gone.

Last edited:

I don't think linear bearings are going to be high performance for the rail.

I'm looking to use one for vertical plane only (see my scrawl on the previous page), with a conventional rail. I've been drafting out some sketches and can see how it might work, and a novel (for me!) way of applying tracking force.

I'll post a retraction when I prove myself wrong

In terms of cartridges, I'm using a DL103 (very low compliance) with a spherical stylus so if alignment is slightly out it's not the end of the world, and it sounds great in my basic prototype LT too.

Last edited:

Busy to finish and match this stuff, I missed 10 discussion pages. I didn't think the corkscrew gadget could stimulate so much creativity, I will study all carefully.

Only one tip dictated by experience: keep it simple, friends. We are working on a minefield, friction > 2-3 mN begin to be problematic: little weight, few joints, less bearings (linear ones? no thanks) are the starting point

carlo

in the meantime, congratulations to Warren for the successful improvements: Great !

Only one tip dictated by experience: keep it simple, friends. We are working on a minefield, friction > 2-3 mN begin to be problematic: little weight, few joints, less bearings (linear ones? no thanks) are the starting point

carlo

in the meantime, congratulations to Warren for the successful improvements: Great !

Attachments

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm