Hello,

I'm playing with different motors for a few years now. I had a project started mainly with the target to use small 3 phase motors to have a stable and accurate drive of my belt driven TT. After a while, and after a lot of trials I gave up that way. I could not get the small 3 phase motors running stable and with low vibration. At high RPM they are fine, some I was able to drive virtually noise and vibration free, but just above ~1000 RPM. As a side effect, I have tried the 3 phase generator to drive the airpax 2 phase motor, and the result is great. The main thing is that I can tune both amplitude and phase difference to lower vibration. The needed phase shift depends on the motor. I have one with 87 degrees optimum and also the amplitude not the same at minimum vibration.

When I showed a running motor on my drive ot an old friend who is servicing high end audio for lots of years now (and builds own, and AN retailer etc.), he told he never felt an airpax running this vibration free, even, when he played with the phase capacitors. I made a 2 phase version, dedicated for 2 phase motors.

In the meantime I have one prototype at another friend who has a much higher grade analog chain, he reports good improvement and wants to own one. I have just a modified rega, he has a systemdek with a good arm etc.

The generator is based on 2 AD9954 DDS chip. Unfortunately it is not easy to get in Hungary (it was actually ~2 years ago when I bought, maybe now it is easy). The first few I got as samples (for a very different RF project), than I had to buy some, but I had to have AD to push the local distributor to sell a few piece also, not high qty. The DDS is started by a pic, than the pic goes to sleep. The output is a low pass filtered, buffered. The amplitude can be tuned by the helitrimmers, the freq and phase by the encoder (and the result can be stored in eeprom).

To get the best result, the motor could be modified also (however whom tried it so far, used it with the 110V motor without modification). On my rega I have tried 4 versions. First on 110V it is good, but at 24V I can tune much further, 12V than 6V even further. If I draw that vibration as a function of phase difference graph, the 110V is flat, not very snesitive for accurate phase diff. At 24V I can tune for much less vibration, as I got to 12V and 6V the tuning is much sharper. 6V is too sharp, and more difficult to drive. With a small amplifier it has stability problems. Now I have my motor coil made for 6V, but I go back now to 12/24V. Probably to 12V, it is easier to drive, because an old Masrhall Leach amp can drive it easy.

When I tried first, to get 110V output, I use two 3.6VA transformers.

Alos I tried a cheap class D amplifier to drive the 6V version directly. The result was not good, it seems it doesn't like the pretty inductive load, it was not stable. If I put the transformer btw the amp and the motor, it is fine, but the audio result is not that good. Better than original, but a good linear amp is much better. My friend wants to design a tube output now to drive his 110V motor, I think it is crazy, but I know different amp driving the motor sounds different at the end. I think it would be better to make a transistor amp, which is designed to drive low power, but inductive load.

If you have interest, I can share all the documentation. I will try to include some in the next posts.

ÜDV JG

I'm playing with different motors for a few years now. I had a project started mainly with the target to use small 3 phase motors to have a stable and accurate drive of my belt driven TT. After a while, and after a lot of trials I gave up that way. I could not get the small 3 phase motors running stable and with low vibration. At high RPM they are fine, some I was able to drive virtually noise and vibration free, but just above ~1000 RPM. As a side effect, I have tried the 3 phase generator to drive the airpax 2 phase motor, and the result is great. The main thing is that I can tune both amplitude and phase difference to lower vibration. The needed phase shift depends on the motor. I have one with 87 degrees optimum and also the amplitude not the same at minimum vibration.

When I showed a running motor on my drive ot an old friend who is servicing high end audio for lots of years now (and builds own, and AN retailer etc.), he told he never felt an airpax running this vibration free, even, when he played with the phase capacitors. I made a 2 phase version, dedicated for 2 phase motors.

In the meantime I have one prototype at another friend who has a much higher grade analog chain, he reports good improvement and wants to own one. I have just a modified rega, he has a systemdek with a good arm etc.

The generator is based on 2 AD9954 DDS chip. Unfortunately it is not easy to get in Hungary (it was actually ~2 years ago when I bought, maybe now it is easy). The first few I got as samples (for a very different RF project), than I had to buy some, but I had to have AD to push the local distributor to sell a few piece also, not high qty. The DDS is started by a pic, than the pic goes to sleep. The output is a low pass filtered, buffered. The amplitude can be tuned by the helitrimmers, the freq and phase by the encoder (and the result can be stored in eeprom).

To get the best result, the motor could be modified also (however whom tried it so far, used it with the 110V motor without modification). On my rega I have tried 4 versions. First on 110V it is good, but at 24V I can tune much further, 12V than 6V even further. If I draw that vibration as a function of phase difference graph, the 110V is flat, not very snesitive for accurate phase diff. At 24V I can tune for much less vibration, as I got to 12V and 6V the tuning is much sharper. 6V is too sharp, and more difficult to drive. With a small amplifier it has stability problems. Now I have my motor coil made for 6V, but I go back now to 12/24V. Probably to 12V, it is easier to drive, because an old Masrhall Leach amp can drive it easy.

When I tried first, to get 110V output, I use two 3.6VA transformers.

Alos I tried a cheap class D amplifier to drive the 6V version directly. The result was not good, it seems it doesn't like the pretty inductive load, it was not stable. If I put the transformer btw the amp and the motor, it is fine, but the audio result is not that good. Better than original, but a good linear amp is much better. My friend wants to design a tube output now to drive his 110V motor, I think it is crazy, but I know different amp driving the motor sounds different at the end. I think it would be better to make a transistor amp, which is designed to drive low power, but inductive load.

If you have interest, I can share all the documentation. I will try to include some in the next posts.

ÜDV JG

protel (or Altium or whatever  files : http://web.t-online.hu/jordangabor/DDS_LP_V2_protel.ZIP

files : http://web.t-online.hu/jordangabor/DDS_LP_V2_protel.ZIP

gerber : http://web.t-online.hu/jordangabor/dds_lp_v2.zip

!!! this is for reference, if you want to make PCB, let me generate again, it was made a year ago and I had small tunings on it.

Regards,

JG

gerber : http://web.t-online.hu/jordangabor/dds_lp_v2.zip

!!! this is for reference, if you want to make PCB, let me generate again, it was made a year ago and I had small tunings on it.

Regards,

JG

I have tried to upload an album to diyaudio, but I could not upload pictures.

Temporary, I uploaded here.

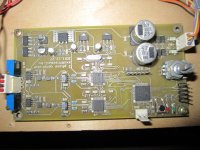

The DDS board on the right, a power amp board on the left (I do not recommend), a Leach amp under it. http://web.t-online.hu/jordangabor/IMG_1025.JPG

Close photo to the dds board : http://web.t-online.hu/jordangabor/IMG_1026.JPG

a picture of my TT and amp, oooh what a dust :-(, it is just the flash, believe me

http://web.t-online.hu/jordangabor/IMG_1027.JPG

Regards,

JG

Temporary, I uploaded here.

The DDS board on the right, a power amp board on the left (I do not recommend), a Leach amp under it. http://web.t-online.hu/jordangabor/IMG_1025.JPG

Close photo to the dds board : http://web.t-online.hu/jordangabor/IMG_1026.JPG

a picture of my TT and amp, oooh what a dust :-(, it is just the flash, believe me

http://web.t-online.hu/jordangabor/IMG_1027.JPG

Regards,

JG

JG,

Very interesting. I've been working on the same idea, but using two AD9832's. With the external phase register select of the 9832, you can control both DACs from the same SPI chip-select. One DAC is hard-wired to use one of the phase register offsets, the other isn't. When you command the DAC's to start using the same chip-select, the clocking delay is the same for both chips.

Of course the 9954 accomplishes this using the external I/O update pin to start both chips together. I just liked the simplicity and small package of the 9832.

You're a lot farther along than I am too, since you actually have it laid out and working ;-)

Bill

Very interesting. I've been working on the same idea, but using two AD9832's. With the external phase register select of the 9832, you can control both DACs from the same SPI chip-select. One DAC is hard-wired to use one of the phase register offsets, the other isn't. When you command the DAC's to start using the same chip-select, the clocking delay is the same for both chips.

Of course the 9954 accomplishes this using the external I/O update pin to start both chips together. I just liked the simplicity and small package of the 9832.

You're a lot farther along than I am too, since you actually have it laid out and working ;-)

Bill

Hello Bill,

It is not just to start it syncronized with a controlled phase shift, but the sync out > sync in also. A more simple choice could be to choose a dual DDS chip, but when I made it I could not find one with the resolution like the AD9954 (and to be honest there were some AD9954 3 phase versions before, and I had it working fine now).

I do not know the 9832, but years ago I started with the 9850 and when I tried to make a 3 phase generator, I could not make it reliable.

This 2 (and also the 3 chip version) chip generator is very stable now. Once I had it running for almost a week.

As a side project, I'm working on a vibration detector with a piezo element. I make a small and silent buffer to a microphone input. It would be good to see the vibrations on an fft graph, not just feeling it by hand. So far the best way I found is to remove the motor, hold by hand and tune the generator. That way I can feel much smaller vibration. With a sensitive sendor, we could tune it in the TT, with the belt on it and under load of the platter etc.

ÜDV JG

It is not just to start it syncronized with a controlled phase shift, but the sync out > sync in also. A more simple choice could be to choose a dual DDS chip, but when I made it I could not find one with the resolution like the AD9954 (and to be honest there were some AD9954 3 phase versions before, and I had it working fine now).

I do not know the 9832, but years ago I started with the 9850 and when I tried to make a 3 phase generator, I could not make it reliable.

This 2 (and also the 3 chip version) chip generator is very stable now. Once I had it running for almost a week.

As a side project, I'm working on a vibration detector with a piezo element. I make a small and silent buffer to a microphone input. It would be good to see the vibrations on an fft graph, not just feeling it by hand. So far the best way I found is to remove the motor, hold by hand and tune the generator. That way I can feel much smaller vibration. With a sensitive sendor, we could tune it in the TT, with the belt on it and under load of the platter etc.

ÜDV JG

Last edited:

here is the pic source code also. http://web.t-online.hu/jordangabor/main.c

Also, for reference only. If there will be interest, I will translate the hungarian comments in it, so far I was too lazy to do

JG

Also, for reference only. If there will be interest, I will translate the hungarian comments in it, so far I was too lazy to do

JG

Thanks Kevin, now I can attach the pictures and in my album also.

http://www.diyaudio.com/forums/attachment.php?attachmentid=319605&stc=1&d=1356482038

http://www.diyaudio.com/forums/attachment.php?attachmentid=319606&stc=1&d=1356482038

http://www.diyaudio.com/forums/attachment.php?attachmentid=319607&stc=1&d=1356482038

http://www.diyaudio.com/forums/attachment.php?attachmentid=319605&stc=1&d=1356482038

http://www.diyaudio.com/forums/attachment.php?attachmentid=319606&stc=1&d=1356482038

http://www.diyaudio.com/forums/attachment.php?attachmentid=319607&stc=1&d=1356482038

Attachments

Hi JG,

Looks great.. If you'd like I'll see what I can do with the earlier posts. You can attach source code, and gerber files, etc., if you zip them first. Schematics can be posted as pdf files..

Merry Christmas!

Thanks for posting this material. I think in the longer run there will be members who will find this very interesting.

Looks great.. If you'd like I'll see what I can do with the earlier posts. You can attach source code, and gerber files, etc., if you zip them first. Schematics can be posted as pdf files..

Merry Christmas!

Thanks for posting this material. I think in the longer run there will be members who will find this very interesting.

This sort of ac generator can make the motor run at correct speed for both 33 and 45 rpm without changing pulleys. Do you have an opinion on which is best, natural 33 and higher frequency to get 45 rpm or natural 45 rpm with the larger pulley and lower frequency to get 33 rpm?

I do not know. I think the first, but I do not remember why we choosed this.

I have a pulley which is made for 50Hz mains, so for 45, I use higher freq. Same for others who tried it. It would be easy to put on the 45 section of a dual pulley and slow down the control to 33, but I do not remember we tried it. I think it is just because in hand the motor run more smooth on near 50Hz than under that.

One more argument to make the vibration meter (detector).

One thing I know for fact, the Airpax is not stable with 78. It starts with help, turns the platter than, but if you stop it doesn't start without help. It is possible that if we use a bit bigger pulley, it would be stable on 33, 45 and 78 also.

Regards,

JG

I have a pulley which is made for 50Hz mains, so for 45, I use higher freq. Same for others who tried it. It would be easy to put on the 45 section of a dual pulley and slow down the control to 33, but I do not remember we tried it. I think it is just because in hand the motor run more smooth on near 50Hz than under that.

One more argument to make the vibration meter (detector).

One thing I know for fact, the Airpax is not stable with 78. It starts with help, turns the platter than, but if you stop it doesn't start without help. It is possible that if we use a bit bigger pulley, it would be stable on 33, 45 and 78 also.

Regards,

JG

One thing I know for fact, the Airpax is not stable with 78. It starts with help, turns the platter than, but if you stop it doesn't start without help. It is possible that if we use a bit bigger pulley, it would be stable on 33, 45 and 78 also.

Regards,

JG

One possible solution is to "ramp up" the frequency of the DDS. If you want to use 78, then start at 45 and then step your way up to 78 in several steps.

JL

I do not recommend. If it gets out of sync, it does not lock again without help. I think the airpax is not for that freq. I can not tell measured data, but I feel more vibration also. It is on the edge.

I think if 78 is a must, should have another diameter on the pulley (If your motor is an Airpax).

In the other hand, I have some other motors, which can do the 78 easy, for example an old Tesla motor. ... but, the problem is, on 50Hz the Airpax is much better on vibration and torq.

ÜDV JG

I think if 78 is a must, should have another diameter on the pulley (If your motor is an Airpax).

In the other hand, I have some other motors, which can do the 78 easy, for example an old Tesla motor. ... but, the problem is, on 50Hz the Airpax is much better on vibration and torq.

ÜDV JG

Increasing frequency for 78 rpm is going to need an increased drive voltage, to compensate for the effects of winding inductance and rising core losses both reducing torque

It is not obvious to me how changing frequency affects the audible noise. You have various effects going in different directions:

1 RIAA equalisation boosts the lower frequencies

2 Does the preamp have a rumble filter?

3 Higher frequencies are more audible

4 Mechanical resonances of the arm/cartridge and deck suspension

It is not obvious to me how changing frequency affects the audible noise. You have various effects going in different directions:

1 RIAA equalisation boosts the lower frequencies

2 Does the preamp have a rumble filter?

3 Higher frequencies are more audible

4 Mechanical resonances of the arm/cartridge and deck suspension

so far the best result I got is to get as close to the original levels as possible. The Airpax does not get 110V in the original setup either (at least in case of rega and systemdek). I drive it with 80-90Veff also. When I increased the drive amplitude, I got very little more torq but heat on the motor. Also, even with normal drive level, when I increased the freq to get 78rpm, with the instability, I got heat also. I think the airpax is just not capable to run in much higher freq. 45 is fine, but 78 is not.

It is very similar to what stepper motors (like this) does at too high step freq.

JG

It is very similar to what stepper motors (like this) does at too high step freq.

JG

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- 2 phase DDS signal generator to run 2 phase AC sync motors