Adding an EI isolation transformer to drop to 110V would remove a good deal of the HF noise on mains that would otherwise reach your motor. How much of a difference this would make I don't know. If you didn't ground a transformer secondary you'd also end up with a 'balanced power supply' to the motor, which might reduce the hum picked up by the cartridge and wiring (I speculate).

I had an Armageddon clone, a Valhalla and a modified Hercules all available at the same time and tested back to back and measured. The Armageddon displayed the best speed stability of all of them. Whether a listener actually prefers greater speed stability is another issue altogether. A lot of LP12 owners that I know seem to actually prefer the 'rolling' speed instability of the Valhalla.

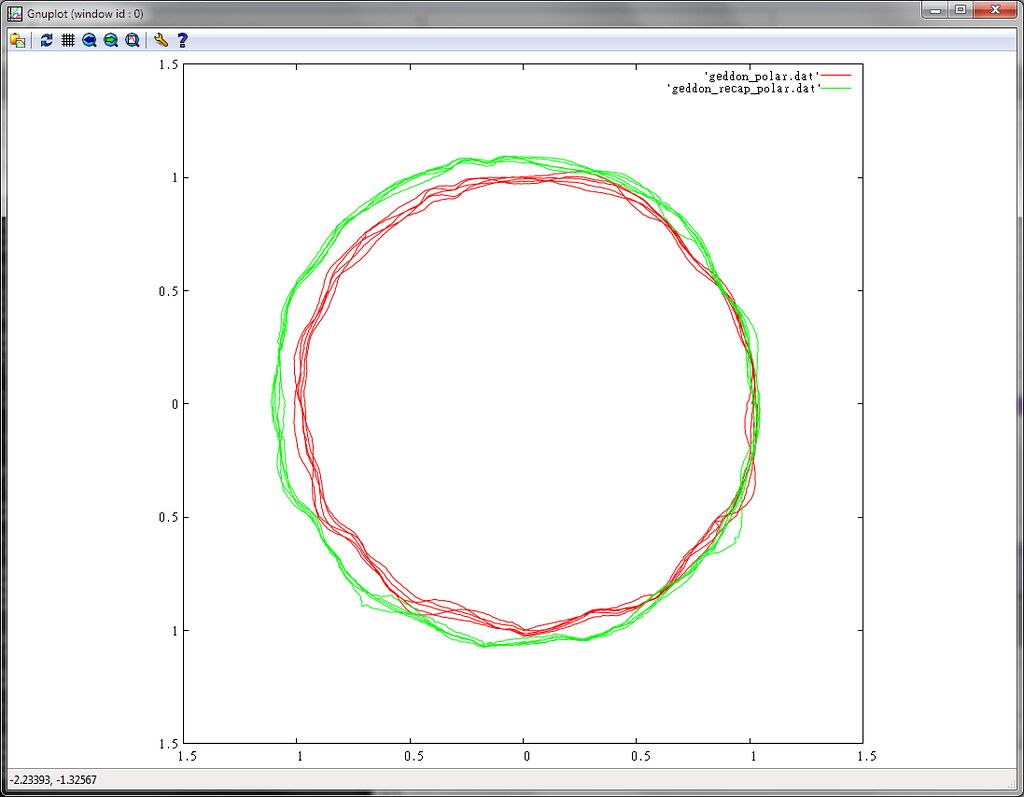

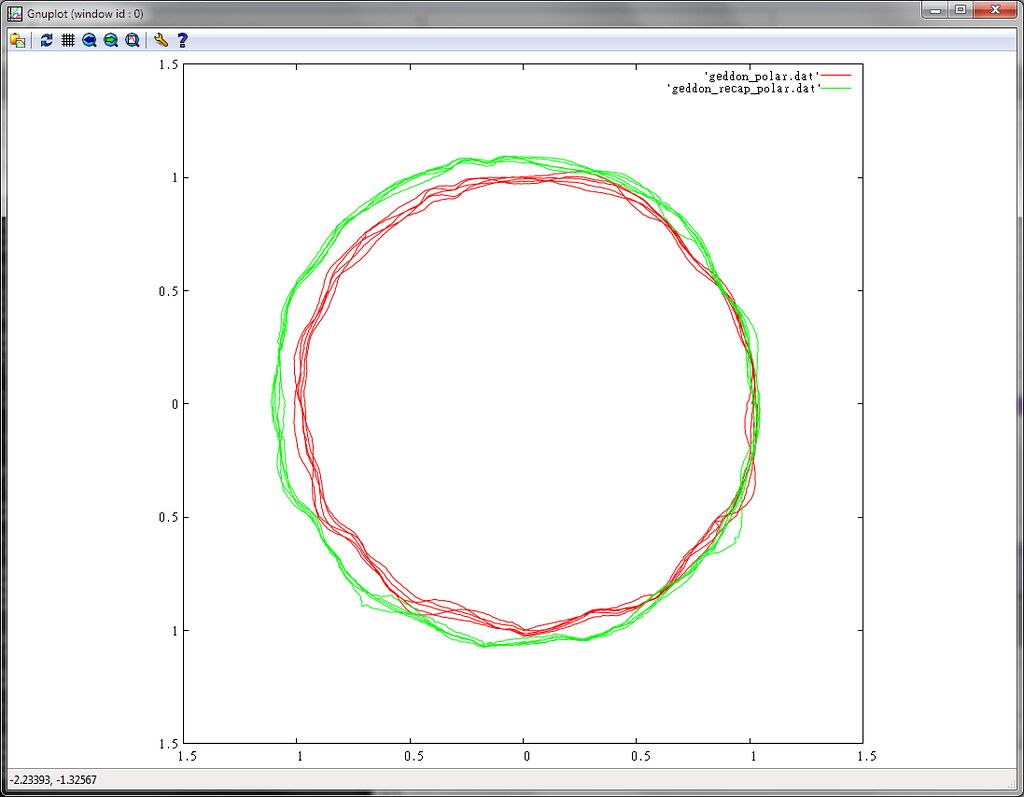

Here are two FM speed demodulations of a 3150hz test tone track. They are plotted out so that each 360 degrees of the graph equals one rotation of the platter. The same five rotations of the record are shown for each sample. Speed variation is shown as any deviation from a perfect circle. The difference between them is that the red version uses the standard 0.22uf capacitor value and the green uses 0.2uf. Nothing else was changed, the green track is marginally more accurate. The two tracks are 5 degrees out of sync.

Click for none distorted version.

Here are two FM speed demodulations of a 3150hz test tone track. They are plotted out so that each 360 degrees of the graph equals one rotation of the platter. The same five rotations of the record are shown for each sample. Speed variation is shown as any deviation from a perfect circle. The difference between them is that the red version uses the standard 0.22uf capacitor value and the green uses 0.2uf. Nothing else was changed, the green track is marginally more accurate. The two tracks are 5 degrees out of sync.

Click for none distorted version.

How did you do the plot. It looks like Linux, so Octave?

The two phases are not of equal amplitude or exact quadrature. The phase via the capacitor is usually at greater voltage than the more direct one. Small changes in capacitance have large effects, as you have plotted.

The two phases are not of equal amplitude or exact quadrature. The phase via the capacitor is usually at greater voltage than the more direct one. Small changes in capacitance have large effects, as you have plotted.

Adding an EI isolation transformer to drop to 110V would remove a good deal of the HF noise on mains that would otherwise reach your motor...

Yes, thats what I thought too, removing HF (and DC sometimes present on the mains);

to accomplish this an EI isolation transformer like you said or probably a r-core

would be best.

Regulation, regulation, regulation.

Yes, but then no resistor should be used, correct ? BTW, from your picture

in post #8 it looks like you do not use the resistor (R1, 3.3k).

... The difference between them is that the red version uses the standard 0.22uf capacitor value and the green uses 0.2uf. Nothing else was changed, the green track is marginally more accurate. The two tracks are 5 degrees out of sync.

...

Is there a way to calculate this ? I ask, because my Thorens uses 0.33uF (?)

Which transformer did you use ?

...

I haven't checked out the insides of the new Thorens TD160 MKII that I have to 'soup up'...

...but...

...does anyone know if I could benifit from ARMAGEDDON on this turntable.

...

Doesn´t the TD160 use a "wall wart" type AC adapter (16V) ?

sq225917

If you synthesise the quadrature drives in software, you could vary the nominal 90 phase shift and relative amplitudes - not done in the commercial units but easy enough to do at home.

The analogue approach probably depends on the mains waveform and I know mine varies drastically through the 24 hours as the domestic load changes.

I understood your plot correctly, It would be great if you could share how you did it.

If you synthesise the quadrature drives in software, you could vary the nominal 90 phase shift and relative amplitudes - not done in the commercial units but easy enough to do at home.

The analogue approach probably depends on the mains waveform and I know mine varies drastically through the 24 hours as the domestic load changes.

I understood your plot correctly, It would be great if you could share how you did it.

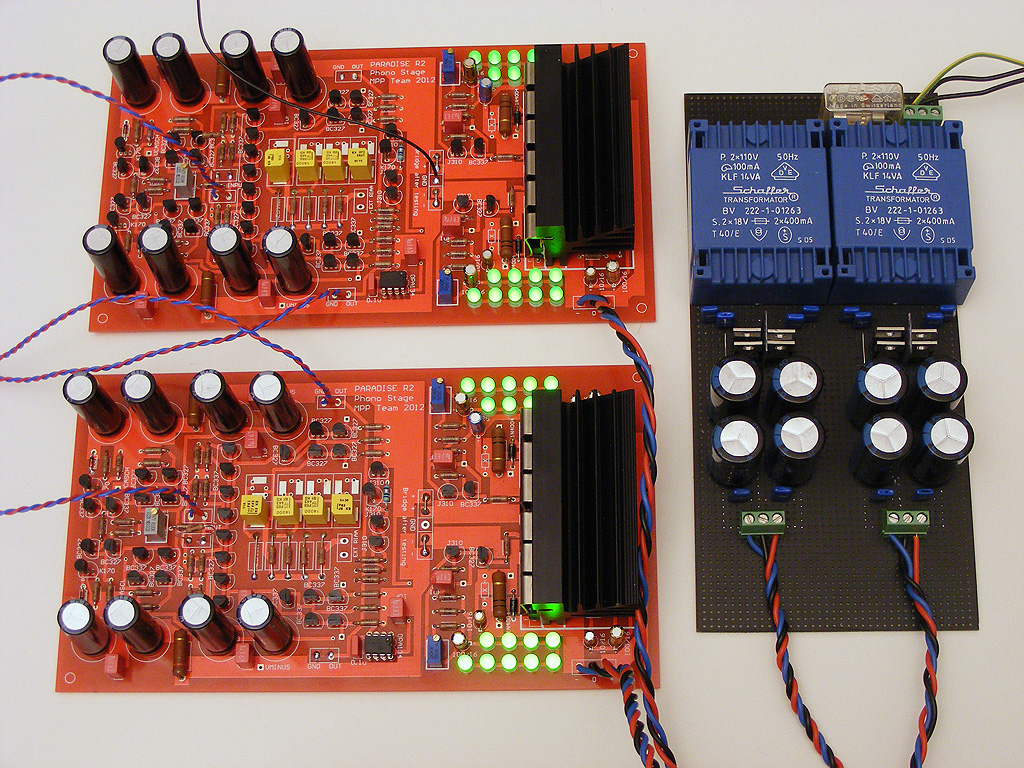

david, I also have one of these power supplies, Roehren-und-Hoeren :: Thema anzeigen - Luxusnetzteil für Synchronmotoren mal anders it has adjustable voltage and quadrature from a synthesised source. I think it's pretty much the finest AC controller you can find, and worth investigating for anyone who uses a 24v motor.

Unfortunately I can't tell you exactly how the plots are achieved as they are created by a 3rd party. Check out the 'turntable speed analysis' thread on pinkfishmedia.net Paulr does the plots.

Fortunately in the UK the mains waveform is rock solid, so the Geddon works very well. It is also much happier into a high drag bearing than most any of the electronic supplies and I find that the added load from viscous drag at the bearing does more to smooth out a deck's speed than pretty much anything else. IME replacing oil with silicon fluid on a deck equipped with an LP12 bearing assembly gives many times the improvement of jumping from a capacitor-resistor controller to the best of the commercially available psu's.

Unfortunately I can't tell you exactly how the plots are achieved as they are created by a 3rd party. Check out the 'turntable speed analysis' thread on pinkfishmedia.net Paulr does the plots.

Fortunately in the UK the mains waveform is rock solid, so the Geddon works very well. It is also much happier into a high drag bearing than most any of the electronic supplies and I find that the added load from viscous drag at the bearing does more to smooth out a deck's speed than pretty much anything else. IME replacing oil with silicon fluid on a deck equipped with an LP12 bearing assembly gives many times the improvement of jumping from a capacitor-resistor controller to the best of the commercially available psu's.

IME replacing oil with silicon fluid on a deck equipped with an LP12 bearing assembly gives many times the improvement of jumping from a capacitor-resistor controller to the best of the commercially available psu's.

Very interesting observation. My DIY TT in Corian has a simple slightly loose, bearing nylon, sleeve (about 3/8" thickness) at the top and a ruby thrust ball at the bottom. It depends on tension of the thread belt to keep the polished tool steel shaft in intimate contact with the upper bearing sleeve. This general style of bearing borrowing from the Well Tempered turntables. The motor is an old motor from AR turntables. Been very pleased with it over the years, but since my bearing well is leakproof I wonder if replacing the number 20 weight oil with silicone fluid could provide any benefits. Easy enough to try. I have silicone fluid in many viscosities from very light to very heavy, 10,000cs iirc. If you know, what viscosity did you use? Light, medium or heavy if you don't have values.

Thanks for the info, I'm looking forward to the experiment.

BillG

Hardly a compromise, choose the correct viscosity for your bearing tolerance and there are no down sides, no drop in absolute speed and only an increase in measured stability and reduced motor vibration. I use 2000cst Team Associated Silicone Differential Fluid (2,000cst) (2oz) [ASC5451] | RC Cars & Trucks - A Main Hobbies

Bill, Like anything it's easy to make a wrong decision and choose the incorrect viscosity or try it in a bearing where it simply isn't suitable due to tolerances and material choices. Your bearing sounds fine and will probably work with much higher viscosity fluid than the LP12 which is quite tight tolerance. If you use a string drive this may not be a good solution due to slippage, but with a flat belt it's fine.

Bill, Like anything it's easy to make a wrong decision and choose the incorrect viscosity or try it in a bearing where it simply isn't suitable due to tolerances and material choices. Your bearing sounds fine and will probably work with much higher viscosity fluid than the LP12 which is quite tight tolerance. If you use a string drive this may not be a good solution due to slippage, but with a flat belt it's fine.

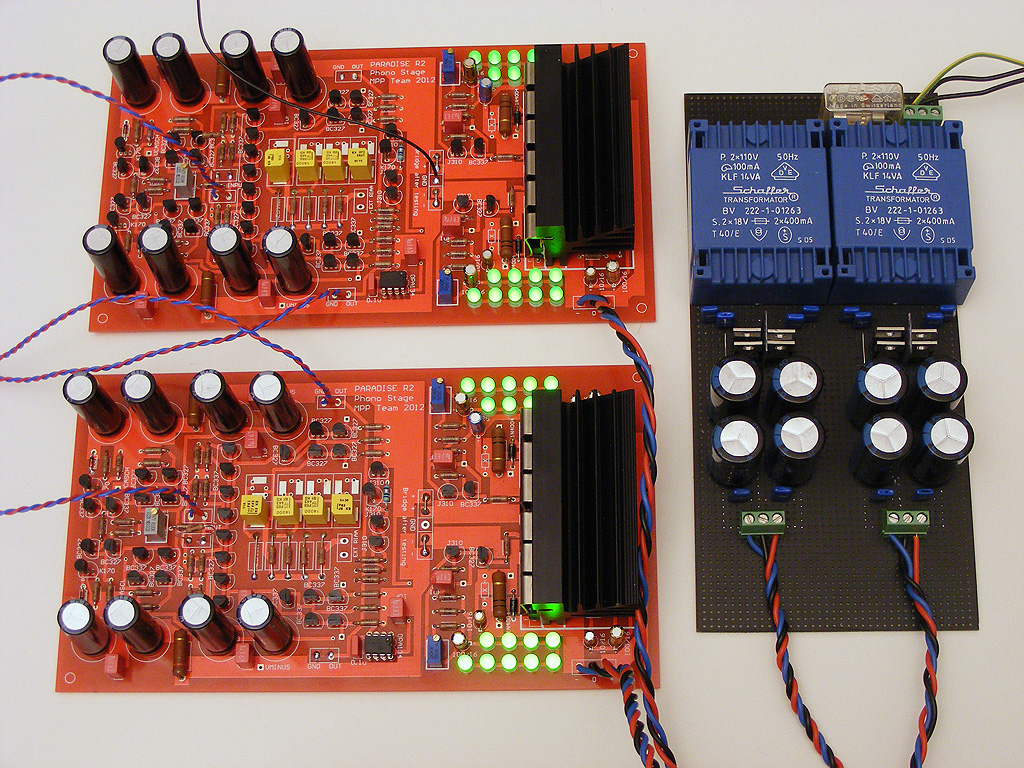

One step beyond: impatient i build up a psu with stock parts of my shelf. Works better like the lipo batteries, no hum, no noise, i´m amazed about the silence.

I think this is also the result of the shunt regulator design, thank you FWD!

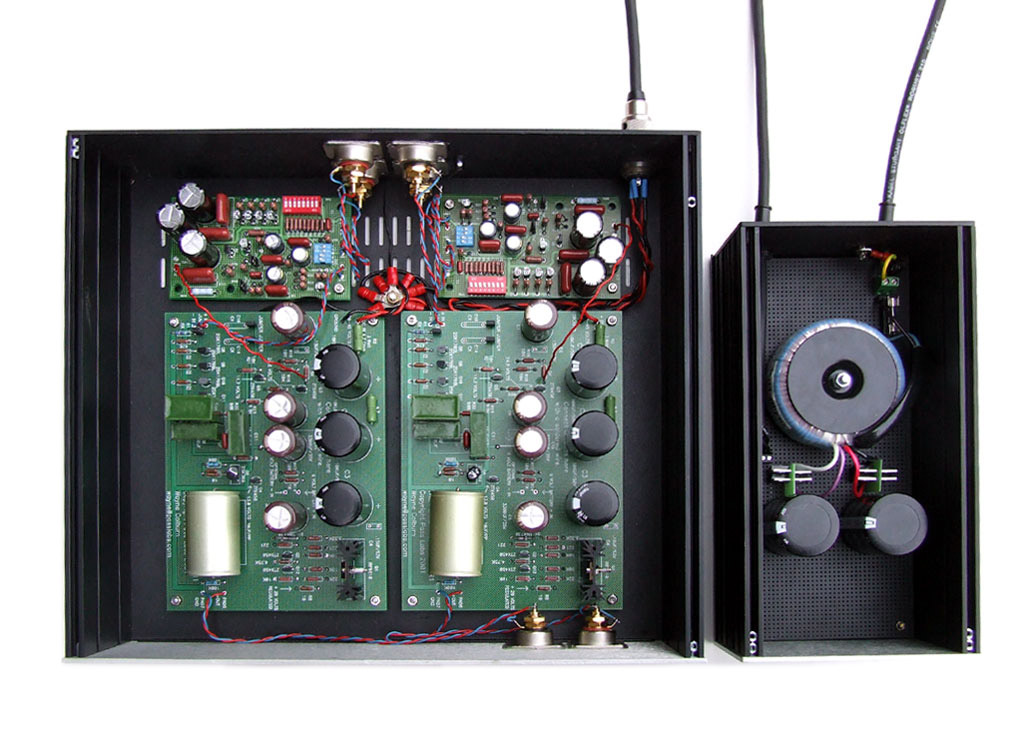

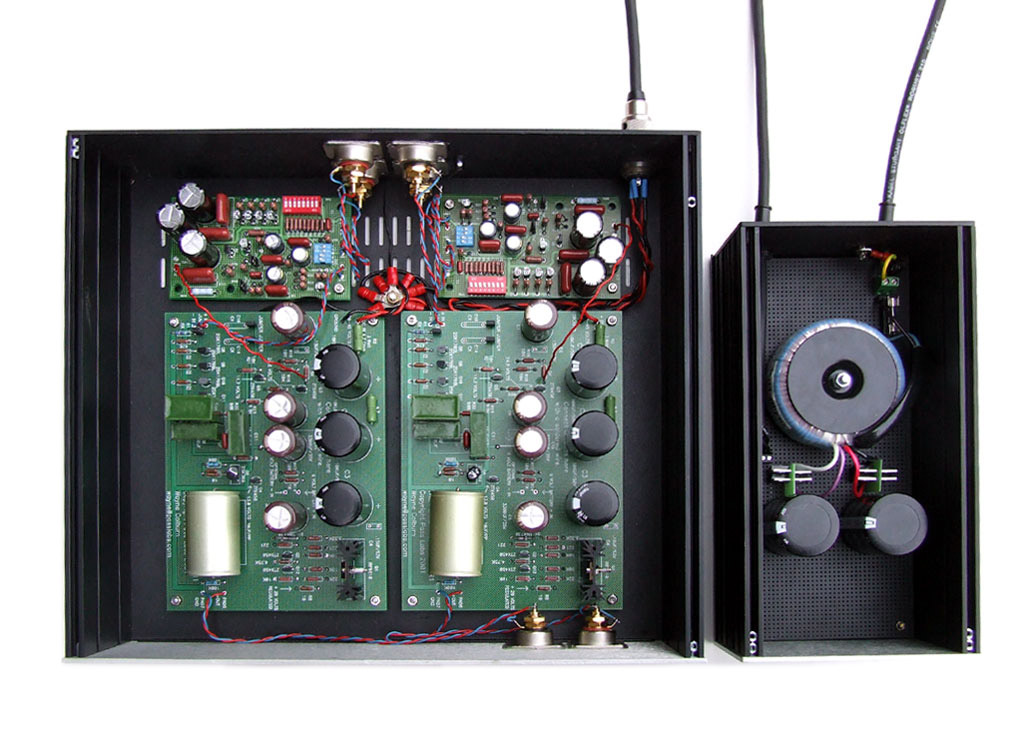

Next step: sending some bucks to italy, buying some cases. I want build it up like my sold pass pearl:

Chris

I think this is also the result of the shunt regulator design, thank you FWD!

Next step: sending some bucks to italy, buying some cases. I want build it up like my sold pass pearl:

Chris

Regardless of thread, your Pearl is fantastic!

thanks!

I hope to see your MPP when complete.

Yes, you will see it

Chris

Hardly a compromise, choose the correct viscosity for your bearing tolerance and there are no down sides, no drop in absolute speed and only an increase in measured stability and reduced motor vibration. I use 2000cst Team Associated Silicone Differential Fluid (2,000cst) (2oz) [ASC5451] | RC Cars & Trucks - A Main Hobbies

Bill, Like anything it's easy to make a wrong decision and choose the incorrect viscosity or try it in a bearing where it simply isn't suitable due to tolerances and material choices. Your bearing sounds fine and will probably work with much higher viscosity fluid than the LP12 which is quite tight tolerance. If you use a string drive this may not be a good solution due to slippage, but with a flat belt it's fine.

Thanks for the inputs. Draining out the old oil and replacing it with silicone fluid while simple and easy, is messy and not the "gee I've got five minutes let's go type of project" so, it may be a while before I can actually do it. But I would like to comment on the string slippage concern. When I first replaced the flat rubber belt with the very fine thread I did experience some slippage. After making several threads to establish the best tension, I solved the slippage problem by holding a cake of violin rosin thread against the moving thread for a minute or less. That was several years ago and no slippage or breakage has taken place. It is a highly recommended (by me) drive belt and infinitely less expensive than flat rubber belts.

Cheers and Happy New Year,

BillG

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Armageddon clone for LP12 - why such a large transformer?