Hello vinyl lovers,

I thought to share some photos of Koetsu Onyx rebuild with you.

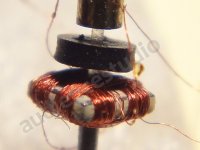

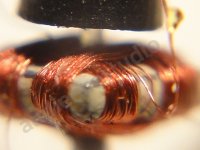

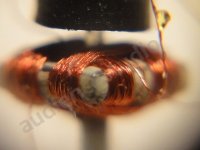

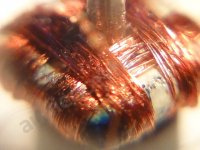

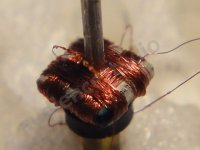

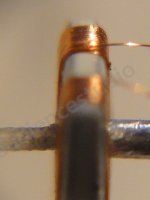

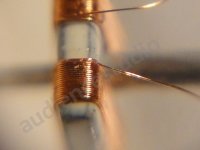

A short summary about the cartridge: I don't remember what caused the damage of the cartridge but it needed a new diamond tip, rewinding the coil and new suspension.

Once it was taken apart it was also cleaned, so this is a kind of total restoration.

I think the photos will speak for themselves.

Enjoy them

I thought to share some photos of Koetsu Onyx rebuild with you.

A short summary about the cartridge: I don't remember what caused the damage of the cartridge but it needed a new diamond tip, rewinding the coil and new suspension.

Once it was taken apart it was also cleaned, so this is a kind of total restoration.

I think the photos will speak for themselves.

Enjoy them

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Who did the rebuild and do you know what kind of rubber and glue used to bond the coil plate to it?

With ridiculous prices they have been charging for MC,s that are really the same basic structure time after time for 30 years now, this is the way to go if the rebuilder knows his stuff.

Regards

David

With ridiculous prices they have been charging for MC,s that are really the same basic structure time after time for 30 years now, this is the way to go if the rebuilder knows his stuff.

Regards

David

Who did the rebuild and do you know what kind of rubber and glue used to bond the coil plate to it?

With ridiculous prices they have been charging for MC,s that are really the same basic structure time after time for 30 years now, this is the way to go if the rebuilder knows his stuff.

Regards

David

I am in the learning phase of cartridge repair and unfortunately it is not me, who did this rebuild. It was done by my friend, who is an audio engineer and has been repairing cartridges for around 30 years. He mainly did this service for friends in his spare time.

I will post more photos of other carts as well.

Dear Randy,

The rebuild was done by my friend who is an audio engineer. I started to learn from him but as I see many years will have to pass until I learn the repair and I will have to collect the tools to be able to achieve similar service qaulity.

Unfortunately I cannot share any information about glue and rubber. This is a know-jow that my friend built up during 30 years. I hope you understand it.

The demand for cartridge repairs and upgrades is high, but there are not so many companies who can do a repair professionally. We have seen cartridges repaired by some company, but despite of the high price they charged, the coil looked horrible.

I will be posting more photos in the near future.

Congratulations for your audio equipment that you build!

Regards,

Vencel

The rebuild was done by my friend who is an audio engineer. I started to learn from him but as I see many years will have to pass until I learn the repair and I will have to collect the tools to be able to achieve similar service qaulity.

Unfortunately I cannot share any information about glue and rubber. This is a know-jow that my friend built up during 30 years. I hope you understand it.

The demand for cartridge repairs and upgrades is high, but there are not so many companies who can do a repair professionally. We have seen cartridges repaired by some company, but despite of the high price they charged, the coil looked horrible.

I will be posting more photos in the near future.

Congratulations for your audio equipment that you build!

Regards,

Vencel

Last edited:

Whoa!

How the heck did you manage to do this?

I'm thinking, parts? Where do you go for parts??

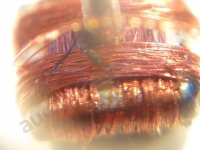

And also, it's difficult to tell, but the rewound coils look to maybe have heavier wire, and fewer turns?

Regardless, way cool.

Tell us more!!

_-_-bear

It was not me, but I hope that I will also be able to do a similar work in couple of years. Getting parts is a good question. My friend has a stock of parts but we are in contact with companies who could supply us different materials for the service.

Sorry, I cannot comment on the heavier wire and the number of turns but I am happy to upload additional photos of other cartridge repairs. Other companies are not really willing to share such photos with the audio community however I feel that they should. It should be a proof of their professionality. As you can see my friend does a very professional work so we are proud to present these photos.

Yes, I understand... the sources for the parts are closely held secrets!

Tricky stuff this cartridge rebuilding... I for one would NOT want to have to wind such thin thin wire!!! The only good part is that the wire itself ought to be fairly inexpensive since wire is often sold based upon weight more than anything else. Of course wire this thin is a 'specialty" item, so may cost a bit more...

yes, please post any other pix that you can. I am sure that everyone who is interested in vinyl will be interested.

IF you have photos of other coils wound by other *companies* (not small individuals) that you can share (with or without stating exactly which company did the work) that would be interesting.

I presume that the larger cartridge makers have machines, jewelers precision, to do the winding work, since they seem very very even and consistent.

Thanks!!

_-_-bear

Tricky stuff this cartridge rebuilding... I for one would NOT want to have to wind such thin thin wire!!! The only good part is that the wire itself ought to be fairly inexpensive since wire is often sold based upon weight more than anything else. Of course wire this thin is a 'specialty" item, so may cost a bit more...

yes, please post any other pix that you can. I am sure that everyone who is interested in vinyl will be interested.

IF you have photos of other coils wound by other *companies* (not small individuals) that you can share (with or without stating exactly which company did the work) that would be interesting.

I presume that the larger cartridge makers have machines, jewelers precision, to do the winding work, since they seem very very even and consistent.

Thanks!!

_-_-bear

Yes, I understand... the sources for the parts are closely held secrets!

Tricky stuff this cartridge rebuilding... I for one would NOT want to have to wind such thin thin wire!!! The only good part is that the wire itself ought to be fairly inexpensive since wire is often sold based upon weight more than anything else. Of course wire this thin is a 'specialty" item, so may cost a bit more...

yes, please post any other pix that you can. I am sure that everyone who is interested in vinyl will be interested.

IF you have photos of other coils wound by other *companies* (not small individuals) that you can share (with or without stating exactly which company did the work) that would be interesting.

I presume that the larger cartridge makers have machines, jewelers precision, to do the winding work, since they seem very very even and consistent.

Thanks!!

_-_-bear

I would never disclose such information who was the one to carry out such work as it would not be fare with that company.

Attachments

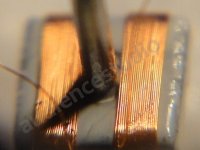

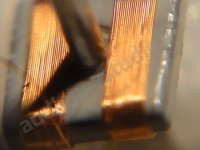

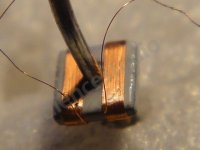

and this is how it should be done. The photos show the same piece recoiled correctly.

Attachments

-

correct-049.jpg64.1 KB · Views: 66

correct-049.jpg64.1 KB · Views: 66 -

correct-048.jpg63.8 KB · Views: 58

correct-048.jpg63.8 KB · Views: 58 -

correct-047.jpg63.3 KB · Views: 56

correct-047.jpg63.3 KB · Views: 56 -

correct-046.jpg58.5 KB · Views: 63

correct-046.jpg58.5 KB · Views: 63 -

correct-045.jpg63.3 KB · Views: 65

correct-045.jpg63.3 KB · Views: 65 -

correct-043.jpg66.6 KB · Views: 70

correct-043.jpg66.6 KB · Views: 70 -

correct-042.jpg63.6 KB · Views: 77

correct-042.jpg63.6 KB · Views: 77 -

correct-041.jpg83 KB · Views: 83

correct-041.jpg83 KB · Views: 83 -

correct-040.jpg82.1 KB · Views: 88

correct-040.jpg82.1 KB · Views: 88 -

correct-039.jpg67.6 KB · Views: 104

correct-039.jpg67.6 KB · Views: 104

Vencel

Can you tell how long original Sugano cartridge suspension would last? I have an eye on original Black MkII and Onyx. They were not played for several years (5-10) and stylus looks very good under microscope .

Rgrds, L

I might be wrong, but basically the suspension in the Sugano (long) Koetsus tend to go wrong after around 10 years. I've seen one in which the suspension rubber became like a jelly after 5 years.

The long Koetsus are rather old, so my guess would be that the suspension needs to be reaplced and if you are unlucky, then the coil will also have to be recoiled as it would be not possible to change the suspension without harming the coil.

How are the coils connected..?? I suspect the two coils with the same orientation are in series..

The brick is in soft iron, for best performance i guess silicon-strip-steet (transformer-core iron) or maybe Permadur would be the best choice. The iron core gives the B-field direction and higher Flux.

The brick is in soft iron, for best performance i guess silicon-strip-steet (transformer-core iron) or maybe Permadur would be the best choice. The iron core gives the B-field direction and higher Flux.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Koetsu Onyx rebuild