I was browsing youtube - as you do - and I came across this video which obviously was made for a TV short. Anyway, it shows the assembly of a wilson benesch TT - a very nice one at that. What I found interesting was that it clearly showed the motor they are using - see 4.08 into the video. This could be a decent motor for many DIY tables.....

The motor is from RS, cat#441-0423 250rpm synchronous motor.

thought I'd post it here, might be some good to someone....

How It's Made - turntables - YouTube

The motor is from RS, cat#441-0423 250rpm synchronous motor.

thought I'd post it here, might be some good to someone....

How It's Made - turntables - YouTube

It's a Premotec. AFAIK sold inEurope only. http://docs-europe.electrocomponents.com/webdocs/0211/0900766b802111e1.pdf

Mark is fast as lightning!

Mark is fast as lightning!

Last edited:

FYI RS will export to the US (and presumably other countries) once you set up an account.

That didn't used to be the case, and might account for why it is no longer available from Allied. (Same parent company as RS [not Radio Shack])

They are excellent motors and extremely quiet, also rather low torque so they work best with low drag main bearings and moderately heavy platters.

Stepper Motor

2 Phase Bipolar Stepper Motor 12v

What annoys me about this is the old Airpax/ Philips style motor is not much better than a central heating motor for diverter valves . I regret that Rotalink in Somerset UK do not have a retail side because they look to have good motors . ( they might have agents ) .

I was told stepper motors are similar and might just work on AC . The motor above seems rather better than an Airpax . Maybe someone knows how it might be done ?

Stepper drive is not much different to AC drive because alas the AC synchronous has nasty steps also . I have played with the Airpax a lot and don't have much time for it . I would risk conventional stepper drive control circuits . I think Nottingham Analogue said similar to this in the past ? The motor above is mostly to show price . It looks rather good and probably can run at reduced power if required .

Another source in the UK might be Microdrives in Essex UK . Give them a link to the RS part no and ask for a 250 RPM/50Hz synchronous with phase capacitor .

I have probably caused more confusion than helped so apologies in advance . Will be interested to see if this leads anywhere as the price of the recommended motor is ridiculous . For this money I would want a Papst motor ( eBay ? ) .

http://www.allaboutcircuits.com/vol_2/chpt_13/5.html

2 Phase Bipolar Stepper Motor 12v

What annoys me about this is the old Airpax/ Philips style motor is not much better than a central heating motor for diverter valves . I regret that Rotalink in Somerset UK do not have a retail side because they look to have good motors . ( they might have agents ) .

I was told stepper motors are similar and might just work on AC . The motor above seems rather better than an Airpax . Maybe someone knows how it might be done ?

Stepper drive is not much different to AC drive because alas the AC synchronous has nasty steps also . I have played with the Airpax a lot and don't have much time for it . I would risk conventional stepper drive control circuits . I think Nottingham Analogue said similar to this in the past ? The motor above is mostly to show price . It looks rather good and probably can run at reduced power if required .

Another source in the UK might be Microdrives in Essex UK . Give them a link to the RS part no and ask for a 250 RPM/50Hz synchronous with phase capacitor .

I have probably caused more confusion than helped so apologies in advance . Will be interested to see if this leads anywhere as the price of the recommended motor is ridiculous . For this money I would want a Papst motor ( eBay ? ) .

http://www.allaboutcircuits.com/vol_2/chpt_13/5.html

Last edited:

I was browsing youtube - as you do - and I came across this video which obviously was made for a TV short. Anyway, it shows the assembly of a wilson benesch TT - a very nice one at that. What I found interesting was that it clearly showed the motor they are using - see 4.08 into the video. This could be a decent motor for many DIY tables.....

The motor is from RS, cat#441-0423 250rpm synchronous motor.

thought I'd post it here, might be some good to someone....

How It's Made - turntables - YouTube

All that high performance milling and the arm is aligned by eyeball? The wires soldered with a piece of junk iron and then the downward force appears to be achieved by using an off balance arrangement (by far the most common - AND WRONG way to do it) Other than that.....

G²

Stepper conversion

The Altmann DIY Turntable

This is an excellent source of information . Hopefully someone will try this .

Nice ideas generally here for any DIY turntable . Sort of Platine Verdier in places.

The Altmann DIY Turntable

This is an excellent source of information . Hopefully someone will try this .

Nice ideas generally here for any DIY turntable . Sort of Platine Verdier in places.

Last edited:

This thread interests me and hope will help others . RS accepts orders in the UK from retail customers . I assume worldwide also . The RS 332 802 seems to be the generic version of the motor discussed and is cheaper . It is 1.7 Watts input . I think RS have the RPM wrong at 300 / 50 Hz . The Crouzet 440 385 is a more powerful motor at 2.7 Watts consumption ( not the output power of 0.3 W or whatever ) . It is generally the same mostly. Crouzet often needs running in , however they are superior I feel . Capacitors from RS or Rapid electronics UK ( 10-2696 0.22 uF 10-2698 0.33uF for the Crouzet ) .

Microdrives Essex UK will phone me back with prices . I hope they will bend the rules a bit and do retail . They have a new range coming soon . Rotalink is 200 pieces .

To me this is the Kings new suit of clothes . Why do they use this under powered motor ? It isn't a miracle of anything that I can think of . I do accept that it is a good compromise between vibration and power . However vibration can be solved .

Microdrives Essex UK will phone me back with prices . I hope they will bend the rules a bit and do retail . They have a new range coming soon . Rotalink is 200 pieces .

To me this is the Kings new suit of clothes . Why do they use this under powered motor ? It isn't a miracle of anything that I can think of . I do accept that it is a good compromise between vibration and power . However vibration can be solved .

Nigel, 0.22uf is the wrong value for the Premotec motor, you actually want 0.2uf.

The reason the Premotec motor is noisy is because it is effectively used unloaded in a turntable once it gets up to speed. In most turntables there is very little drag, so you need very little power, high torque= good is a myth, there's point using a high torque motor when it is effectively experiencing almost zero load. And you can trust me on this any free spinning turntable bearing is pretty damn close to zero load.

Apply a little drag, carefully and evenly and the premotec smooths out to something quite superb. In fact the Premotec motor is capable of incredibly high performance when handled correctly.

I currently use one with to drive my Kuzma S, with a modded bearing that has increased viscous drag. It sounds and measures better than my SME10, with its digitally controlled, 3 phase supplied, dynamically balanced, external rotor, DC motor.

Supposition tends not to be the best tool for selecting parts, you really need to work with them to find out what's capable of what level of performance, you may find some surprising results.

The reason the Premotec motor is noisy is because it is effectively used unloaded in a turntable once it gets up to speed. In most turntables there is very little drag, so you need very little power, high torque= good is a myth, there's point using a high torque motor when it is effectively experiencing almost zero load. And you can trust me on this any free spinning turntable bearing is pretty damn close to zero load.

Apply a little drag, carefully and evenly and the premotec smooths out to something quite superb. In fact the Premotec motor is capable of incredibly high performance when handled correctly.

I currently use one with to drive my Kuzma S, with a modded bearing that has increased viscous drag. It sounds and measures better than my SME10, with its digitally controlled, 3 phase supplied, dynamically balanced, external rotor, DC motor.

Supposition tends not to be the best tool for selecting parts, you really need to work with them to find out what's capable of what level of performance, you may find some surprising results.

All that high performance milling and the arm is aligned by eyeball? The wires soldered with a piece of junk iron and then the downward force appears to be achieved by using an off balance arrangement (by far the most common - AND WRONG way to do it) Other than that.....

G²

It's a unipivot, short of fouling the bearing pillar what does the alignment matter?

That motor .

If you look on the link I gave there is a recommendation to use a 90 degree phase shifted AC of low distortion . Many years ago I was asked by a friend to build a PSU for his Linn LP12 . He was recovering from cancer so I did the best job I could . I tried all the capacitors under the Sun and found it made little difference ( 0.18 to 0.24 uF ) . So I put it into a LP12 . I was not that impressed . Lets be clear by any technical standards it was perfect . I then tried different voltages to the motor which seemed promising and also different to the respective coils ( 100 and 90 V ) . Voltage was the big thing . So I deliberately made a bad version phase shift wise ( with very low distortion ) . It sounded the same . I came to the conclusion that the LP12 was brilliant at rejecting the vibration . Unfortunately it also means the LP12 is not optimum . The belt needs to be stiffer and then it would matter . Platine Verdier also spotted this . For what it is worth I still have an unmodified LP 12 and officially when someone brings it back a Garrard 401 and Naim Aro . I would love to help anyone who wants to build a turntable . For my sins I have built a few . The LP12 I have uses this motor we are discussing . I am encouraged enough to try to get the stepper I have shown working in the LP12 . I am 90% certain it will be better as it seems to be a better motor . Lets be clear the Airpax ( branded in different ways ) is not my cup of tea . However at the price I have found it at I would almost certainly recommend it as a starting point . Rega used a heat-less ballast way of doing the same using 2 x 0.22 uF . I feel that is also a good place to start . Sorry to be so dogmatic . Do try capacitors in the range I mention . Using the same make of motor you will find they all are individuals and need slightly different ones . I like the 12 V idea because even using a sound card oscilloscope you can get the phase shift correct . As a German guy said to me , even if it doesn't matter we should get right what we can . One piece of advice I can give . The Denon 103R is a cartridge worth owning . BTW this is 230 V we are playing with , be ultra careful . There are no definite recommendations for capacitors . Class X2 is at least certificated for mains use . Many recommend higher voltage types . I can not because they do not have certification . There are type Y2 and X1 which are similar . Minimum rating should be 250 V . I would use 2 in series which means doubling the values . The point made about loading the motor to get optimum vibration is excellent . Higher viscosity oil in the bearing is not so stupid if you can keep vibration down . Verdier has strong views about that . For what it's worth a 401 is slightly more my cup of tea than a Verdier . Do not confuse viscosity for friction .

If you look on the link I gave there is a recommendation to use a 90 degree phase shifted AC of low distortion . Many years ago I was asked by a friend to build a PSU for his Linn LP12 . He was recovering from cancer so I did the best job I could . I tried all the capacitors under the Sun and found it made little difference ( 0.18 to 0.24 uF ) . So I put it into a LP12 . I was not that impressed . Lets be clear by any technical standards it was perfect . I then tried different voltages to the motor which seemed promising and also different to the respective coils ( 100 and 90 V ) . Voltage was the big thing . So I deliberately made a bad version phase shift wise ( with very low distortion ) . It sounded the same . I came to the conclusion that the LP12 was brilliant at rejecting the vibration . Unfortunately it also means the LP12 is not optimum . The belt needs to be stiffer and then it would matter . Platine Verdier also spotted this . For what it is worth I still have an unmodified LP 12 and officially when someone brings it back a Garrard 401 and Naim Aro . I would love to help anyone who wants to build a turntable . For my sins I have built a few . The LP12 I have uses this motor we are discussing . I am encouraged enough to try to get the stepper I have shown working in the LP12 . I am 90% certain it will be better as it seems to be a better motor . Lets be clear the Airpax ( branded in different ways ) is not my cup of tea . However at the price I have found it at I would almost certainly recommend it as a starting point . Rega used a heat-less ballast way of doing the same using 2 x 0.22 uF . I feel that is also a good place to start . Sorry to be so dogmatic . Do try capacitors in the range I mention . Using the same make of motor you will find they all are individuals and need slightly different ones . I like the 12 V idea because even using a sound card oscilloscope you can get the phase shift correct . As a German guy said to me , even if it doesn't matter we should get right what we can . One piece of advice I can give . The Denon 103R is a cartridge worth owning . BTW this is 230 V we are playing with , be ultra careful . There are no definite recommendations for capacitors . Class X2 is at least certificated for mains use . Many recommend higher voltage types . I can not because they do not have certification . There are type Y2 and X1 which are similar . Minimum rating should be 250 V . I would use 2 in series which means doubling the values . The point made about loading the motor to get optimum vibration is excellent . Higher viscosity oil in the bearing is not so stupid if you can keep vibration down . Verdier has strong views about that . For what it's worth a 401 is slightly more my cup of tea than a Verdier . Do not confuse viscosity for friction .

Last edited:

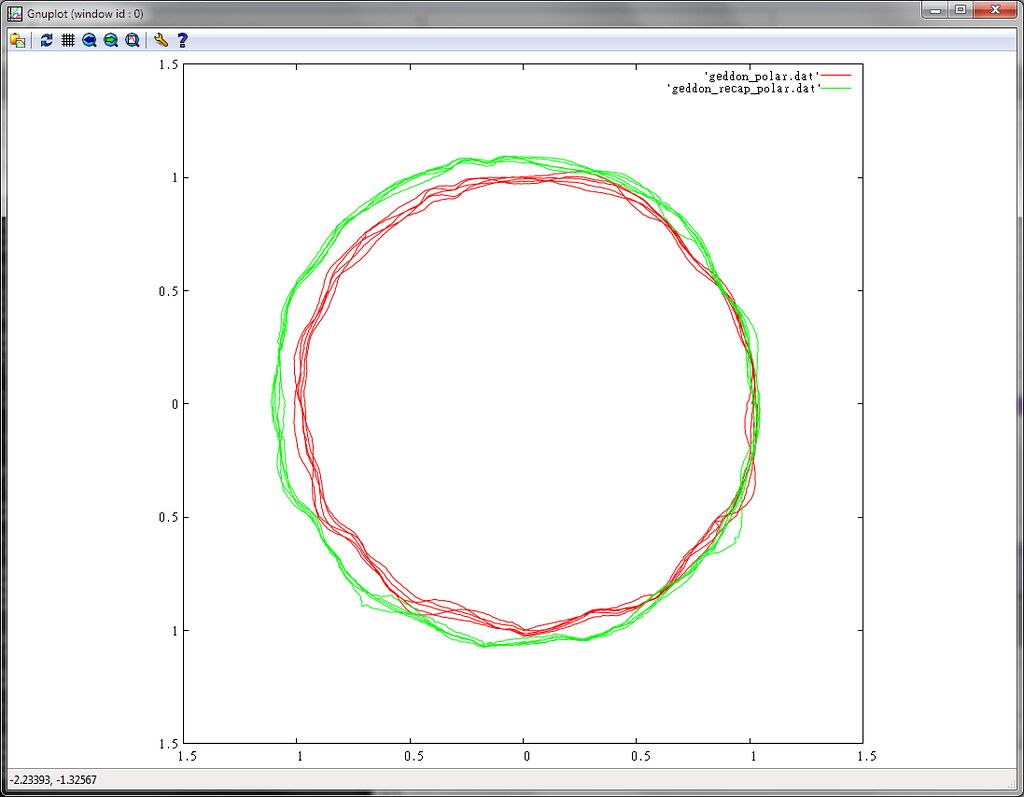

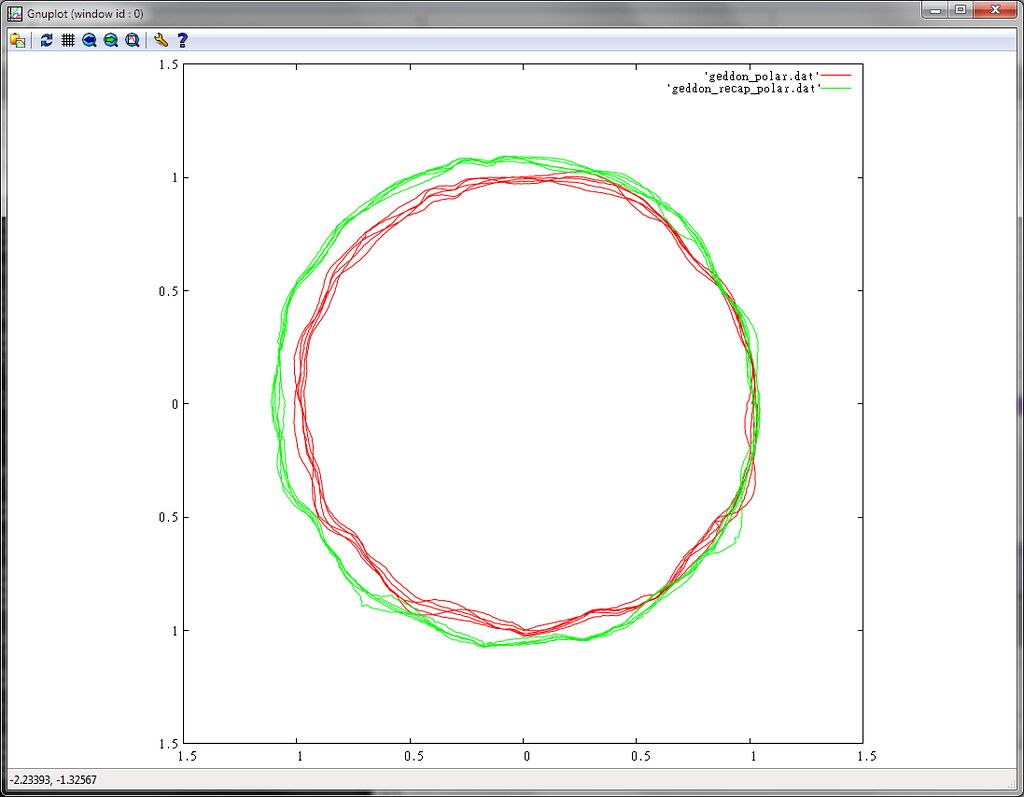

Nigel, i can only go off my own experiments and measurements, both electrical (scope etc) and actual, of the turntables RPM. I suspect I may be better equipped to get very accurate speed readings from the deck than most testers as I'm fortunate enough to have a friend who can perform 'very' accurate FFT on test tracks to give what amounts to instantaneous speed measurements and then displays them in such a way as they represent the revolution of the deck. They are in the region of a squillion times more useful than simple RMS W&F numbers. ;-)

I'm happy that the current, modded bearing and big transformer set-up that i use now provides greater speed stability than all of the readily available electronic speed controllers for Premotec style motors. Yup, I've measured them all.

I'm happy that the current, modded bearing and big transformer set-up that i use now provides greater speed stability than all of the readily available electronic speed controllers for Premotec style motors. Yup, I've measured them all.

Richard Fyneman said to solve a problem .

First define the problem

Second do a lot of thinking

Third solve the problem

I went away and did a lot of thinking . I agree with you . I know Avid use the big Crozet for their turntable .

Induction motors are good . I found none to recommend .

I did a study at Greeenwhich university which was recommended for patent on motor design ( the students did it for me ) . Basically it concluded induction is best as it has slip . Slip is useful and supports what you say . The principle was called Aeroflux . I suspend the core of the motor in a magnetic field almost like it is magic ( it's not ) . Your motor could be adapted . I can not tell you more as it belongs to someone else now . We didn't publish the design . An air bearing would be something like it .

First define the problem

Second do a lot of thinking

Third solve the problem

I went away and did a lot of thinking . I agree with you . I know Avid use the big Crozet for their turntable .

Induction motors are good . I found none to recommend .

I did a study at Greeenwhich university which was recommended for patent on motor design ( the students did it for me ) . Basically it concluded induction is best as it has slip . Slip is useful and supports what you say . The principle was called Aeroflux . I suspend the core of the motor in a magnetic field almost like it is magic ( it's not ) . Your motor could be adapted . I can not tell you more as it belongs to someone else now . We didn't publish the design . An air bearing would be something like it .

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Possible TT motor?