At the RMAF is saw a beautiful lookng turntable from Oracle. This one had a damped supsension in the vertical direction as usual and also a damping system for horizontal vibration. Basically a plunger in silicone oil. The amount of damping could be adjusted by adjusting the depth of the plunger.

I didn't expect to hear much of a difference with or without the horizontal damping. They demo'ed this feature by playing a disc with and without the damping. There was a VERY noticeable difference in 'focus' of the sound.

Like removing a veil from the front of the speakers.

Certainly something I plan to experiment with on my TD124 as soon as practically possible. I was very impressed with the demo !

Anyone else heard that demo ? Or has any comment on the effect of horizontal damping ?

I didn't expect to hear much of a difference with or without the horizontal damping. They demo'ed this feature by playing a disc with and without the damping. There was a VERY noticeable difference in 'focus' of the sound.

Like removing a veil from the front of the speakers.

Certainly something I plan to experiment with on my TD124 as soon as practically possible. I was very impressed with the demo !

Anyone else heard that demo ? Or has any comment on the effect of horizontal damping ?

Probably has something to do with why high mass plinths are popular with the TD-124...  My 124/II is in a slate plinth that weighs in excess of 80lbs, noticed a pretty significant improvement in performance when I put it in this plinth.. (More focus, lower noise floor)

My 124/II is in a slate plinth that weighs in excess of 80lbs, noticed a pretty significant improvement in performance when I put it in this plinth.. (More focus, lower noise floor)

If you are running a TD-124/I the 124/II motor mount upgrade is a significant improvement wrt to isolating motor vibration. (And these motors vibrate a lot..)

I'm curious to see what you come up with, I'm always looking for ways to further improve mine. (I have two, the second one is a 124/I)

If you are running a TD-124/I the 124/II motor mount upgrade is a significant improvement wrt to isolating motor vibration. (And these motors vibrate a lot..)

I'm curious to see what you come up with, I'm always looking for ways to further improve mine. (I have two, the second one is a 124/I)

I'll let you know how the work progresses. Mine is a TD124-MkII.

I have a new idler wheel and a belt.Hope it will reduce the little rumble I get now. Will post new info as I progress. I will certainly look at the new suspension for the motor. I did feel that it vibrates a lot.

Has anyone used a dc motor in place of the ac motor ?

Cheers.

I have a new idler wheel and a belt.Hope it will reduce the little rumble I get now. Will post new info as I progress. I will certainly look at the new suspension for the motor. I did feel that it vibrates a lot.

Has anyone used a dc motor in place of the ac motor ?

Cheers.

I'll let you know how the work progresses. Mine is a TD124-MkII.

I have a new idler wheel and a belt.Hope it will reduce the little rumble I get now. Will post new info as I progress. I will certainly look at the new suspension for the motor. I did feel that it vibrates a lot.

Has anyone used a dc motor in place of the ac motor ?

Cheers.

Since you have a 124/II you already have the better motor mounting arrangement.. I have found that geltec bushing kits sold by jec965 on eBay work quite well if you have not replaced the 45yr old bushings on your table.

No one to my knowledge has used a DC motor with a TD-124, of course that does not mean someone hasn't.. There are compelling reasons I think for not doing so which relate to keeping intact a classic table with specific performance characteristics. The eddy current brake would probably have to be disabled and speed control managed with a servo..

The 3 phase Papst Aussenlaufer motor with a Siemens 3 phase drive like the MM410 or 420 might make for a quieter set up.. I don't have one of these motors and so haven't tried this. The Papst is not quieter than an E50 on single phase power..

A heavy plinth will make this table about as quiet as any of the better current high end tables, and while not quite an SME 20 the noise performance of a properly restored and plinthed (high mass, dissipative type) TD-124 will far exceed that of your records.. (I have plenty where I can quite clearly hear the cutter rumble, some records are almost silent in this regard whilst others are far from it.) Measurements performed by others indicate that an actual improvement in rumble of 15dB or so is attainable.

Note that the condition of your main bearing is important.

Thanks for that great post. My table hasn't been used for years ! Even I haven't beeen able to use it often enough. So the botom plate on which the bearing sits could have a dent in it . This I believe is available on ebay.

But based on what you said I will first get the new plinth made and then proceed with other mods or replacement of parts.

I also have a direct drive Hitachi turntable which is relatively silent as far as rumble is concerned. It has a thick heavy platter. Been debating if I should remount that on to a solid plinth as it's own original plinth is made of MDF. This unit does sound quite nice as it is but doesn't have the resolving capability of better turntables.

But based on what you said I will first get the new plinth made and then proceed with other mods or replacement of parts.

I also have a direct drive Hitachi turntable which is relatively silent as far as rumble is concerned. It has a thick heavy platter. Been debating if I should remount that on to a solid plinth as it's own original plinth is made of MDF. This unit does sound quite nice as it is but doesn't have the resolving capability of better turntables.

Thanks for that great post. My table hasn't been used for years ! Even I haven't beeen able to use it often enough. So the botom plate on which the bearing sits could have a dent in it . This I believe is available on ebay.

But based on what you said I will first get the new plinth made and then proceed with other mods or replacement of parts.

I also have a direct drive Hitachi turntable which is relatively silent as far as rumble is concerned. It has a thick heavy platter. Been debating if I should remount that on to a solid plinth as it's own original plinth is made of MDF. This unit does sound quite nice as it is but doesn't have the resolving capability of better turntables.

Very important to overhaul the motor and replace the motor mount bushings before going very far.. See the TD-124 thread for more details..

To be honest, your question is too simplistic. Better in what way precisely? What is the resonant frequency of the suspension and what is the weight of the suspended mass, how much damping is there, is it progresive etc. etc.

What I would say is that a high mass plinth, on it's own, provides very little actual isolation.

What I would say is that a high mass plinth, on it's own, provides very little actual isolation.

Last edited:

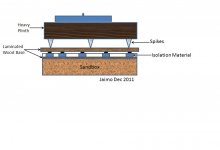

High Mass Plinth plus a compliant layer works well

I am experimenting with of adding a compliant layer of isolation under my relatively high mass 5 inch Baltic Birch plinth.

My theory is that a heavy plinth should absorb turntable (motor and record) generated vibrations and a heavy base is needed to anchor the table. A third compliant element is then needed to isolate the base and plinth.

The pic below shows my current system. Adding the Sandbox and Audio Prism Isolators has cleaned up the bottom end of the spectrum. I will continue to experiment with different isolation materials - Ginko Balls, squash balls, a bicycle inner tube etc will be tested.

I plan to use an accelerometer to document the results.

I am experimenting with of adding a compliant layer of isolation under my relatively high mass 5 inch Baltic Birch plinth.

My theory is that a heavy plinth should absorb turntable (motor and record) generated vibrations and a heavy base is needed to anchor the table. A third compliant element is then needed to isolate the base and plinth.

The pic below shows my current system. Adding the Sandbox and Audio Prism Isolators has cleaned up the bottom end of the spectrum. I will continue to experiment with different isolation materials - Ginko Balls, squash balls, a bicycle inner tube etc will be tested.

I plan to use an accelerometer to document the results.

An externally hosted image should be here but it was not working when we last tested it.

Hi jaimo,

The link to your photograph does not seem to work, at least not here.. Can you please post a picture using our server? Just go to "Advanced" and then "Manage Attachments" to upload to the server - that way it will be here for others to see into the indefinite future.

The link to your photograph does not seem to work, at least not here.. Can you please post a picture using our server? Just go to "Advanced" and then "Manage Attachments" to upload to the server - that way it will be here for others to see into the indefinite future.

Sandbox plus compliant Base

There is a definite improvement in the lower registers. Also, I did a simple tap test by placing the stylus on a stationary record with the volume turned up. There is a huge difference in feedback between tapping on the plinth (high feedback) to just about no feedback when I tap on the floor. Prior to adding the sandbox arrangement, the feedback from the floor during a "tap test" was actually quite pronounced!

This is not however a one size fits all solution as the results will vary between a suspended floor, concrete floor, plinth mass, etc, etc - also, there will be several resonant modes present and one will need to do a frequency sweep to determine the resonant frequencies and deal with these in an appropriate manner.

I will hook up an accelerometer and velocity probe and report back in the next few weeks.

Interesting approach, how well does it seem to work?

There is a definite improvement in the lower registers. Also, I did a simple tap test by placing the stylus on a stationary record with the volume turned up. There is a huge difference in feedback between tapping on the plinth (high feedback) to just about no feedback when I tap on the floor. Prior to adding the sandbox arrangement, the feedback from the floor during a "tap test" was actually quite pronounced!

This is not however a one size fits all solution as the results will vary between a suspended floor, concrete floor, plinth mass, etc, etc - also, there will be several resonant modes present and one will need to do a frequency sweep to determine the resonant frequencies and deal with these in an appropriate manner.

I will hook up an accelerometer and velocity probe and report back in the next few weeks.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- lateral vibration in turntables.......audible ?