I had to adjust the eddy current break to near maximum level now everything runs so smooth.

A good sign all the oiling of turn table parts an revision of the motor had positive effect.

It is e real pleasure to play records on the TD124 works great sounds good. Looks professional with the aluminum frame. I was very lucky to find such a nice one.

A good sign all the oiling of turn table parts an revision of the motor had positive effect.

It is e real pleasure to play records on the TD124 works great sounds good. Looks professional with the aluminum frame. I was very lucky to find such a nice one.

Last edited:

Constant speed TD124

Hi,

After a cold start the td124 is running to slow. One would aspect the speed depends on synchron motor and the 50/60hz of the main-supply this isn't the hole story I think.

Cold start? Yes in the td 124 the engine is warming-up. This temperature changes are responsible for speed variation that is what I think.

At my job I do a lot of temperature testing on switching power-supplies. The temperature rise of most medium power-supply with enclosure takes about 3 hours it follows a E-curve.

This means the E50 motor of the TD124 will run constant after 3 hours.

This morning I did the test.

After start the TT runs to slow after 2 minutes it is acceptable aft ten even better.

After one and a half hour it runs the right speed so the engine is so far in the E-curve that it end point for influence on speed so it stays constant.

That is the result of the Thorens being mechanical speed controlled and be affected by friction variation in the design.

Hi,

After a cold start the td124 is running to slow. One would aspect the speed depends on synchron motor and the 50/60hz of the main-supply this isn't the hole story I think.

Cold start? Yes in the td 124 the engine is warming-up. This temperature changes are responsible for speed variation that is what I think.

At my job I do a lot of temperature testing on switching power-supplies. The temperature rise of most medium power-supply with enclosure takes about 3 hours it follows a E-curve.

This means the E50 motor of the TD124 will run constant after 3 hours.

This morning I did the test.

After start the TT runs to slow after 2 minutes it is acceptable aft ten even better.

After one and a half hour it runs the right speed so the engine is so far in the E-curve that it end point for influence on speed so it stays constant.

That is the result of the Thorens being mechanical speed controlled and be affected by friction variation in the design.

All true, although the times you quote indicate motor service is probably needed. I assume you have not serviced the motor yet. It really, really makes a huge difference. Disassembly is comparatively easy and depending on bearing condition you can either clean and reuse them or replace them as you desire. (At minimum you must clean and completely remove the old lubricants.) I've done this on a number of TD-124 tables and once functioning nominally the TT is up to 100% of set speed in under 10 minutes from a cold start and is rock stable after that assuming an ambient of 20C or so. (Colder it will take longer) Also when completely cold it runs just a couple of % slow at worst. Take a look at my thread for information on overhauling the motor, and go here to see what is involved: http://homepage2.nifty.com/pantone/thorens/index.htm

In the previous pages you can see I did replace the bearing an felt rings and did buy a original belt. I have the eddy current break placed very close to the stepped pulley because the TT runs with very low resistance now, when I bought it it would not run slightly to slow and adjustment would not help.All true, although the times you quote indicate motor service is probably needed. I assume you have not serviced the motor yet. It really, really makes a huge difference. Disassembly is comparatively easy and depending on bearing condition you can either clean and reuse them or replace them as you desire. (At minimum you must clean and completely remove the old lubricants.) I've done this on a number of TD-124 tables and once functioning nominally the TT is up to 100% of set speed in under 10 minutes from a cold start and is rock stable after that assuming an ambient of 20C or so. (Colder it will take longer) Also when completely cold it runs just a couple of % slow at worst. Take a look at my thread for information on overhauling the motor, and go here to see what is involved: ƒg�[ƒŒƒ“ƒX THORENS model TD 124

But it cant help the motor to heat up for a longer period of time and with that being a influence on speed. Maybe when the new bearings have run in for a longer period it will change.

Last edited:

In the previous pages you can see I did replace the bearing an felt rings and did buy a original belt. I have the eddy current break placed very close to the stepped pulley because the TT runs with very low resistance now, when I bought it it would not run slightly to slow and adjustment would not help.

But it cant help the motor to heat up for a longer period of time and with that being a influence on speed. Maybe when the new bearings have run in for a longer period it will change.

I found for about the first 100hrs motor performance did change significantly, and both the weight of the oil (20wt) and the amount present is fairly critical. (Lots of oil!) I also had to adjust the eddy current brake in order to not have the table actually run too fast - this I have not resolved to my full satisfaction, but the table runs dead silent on its slate plinth so I can't really complain.

I was thinking why this direct drive sounds better then my other table's I owned.

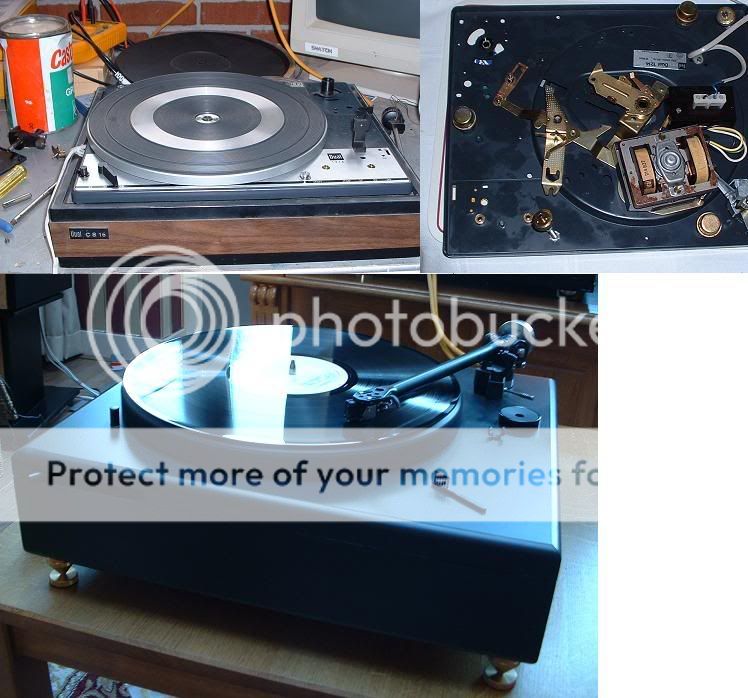

My first table dual cs16.

It had poor ceramic cartridge.

After that one I carfully selected a cs628.

When I wanted to buy it it was obsolete and I had to make a quick choice at the shop and bought a dual cs503-1 what a lousy plastic TT was that I hated it for fooling me that moment in the shop.

After that I buid my own high end table with the frame of the CS16 and a second hand RB301 and I placed van den Hul tone arm wiring.

It performed quite good but it wasn't quit enough and speed variation I could not improve.

After that one a second hand SL1700 a perfect table to adjust and use. I wanted it to use as base for the rb301 but I could not do it it was to good just how it was. I still have it.

Now with the Thorens satisfaction is coming my way after many years, I like the 60ties sturdy style. And to work with the table is some how natural I think because it is not wobbly by suspension it feels stable.

The vintage look and story is great for being a formal studio TT. It isn't just the story it performs also on high level the reproduction on the TD124 with the RB301 makes me play one record after the other.

A look at the strobe and the way it is made with a little mirror is are such nice details I love it.

Comes to me what can be the reason why the sound quality of a mass driven direct drive idler wheel does sound a bit better then the belt drive dual or direct drive technics.

I think the high mass frame plinth and platter are less sensitive for surrounding noise of the speakers and increases bas performance also the idler wheel will help damp those resonances. The idler wheel will also cause some rumble on low frequent level but that will overall be masked by the bottom noise level of the record.

My first table dual cs16.

An externally hosted image should be here but it was not working when we last tested it.

It had poor ceramic cartridge.

After that one I carfully selected a cs628.

When I wanted to buy it it was obsolete and I had to make a quick choice at the shop and bought a dual cs503-1 what a lousy plastic TT was that I hated it for fooling me that moment in the shop.

After that I buid my own high end table with the frame of the CS16 and a second hand RB301 and I placed van den Hul tone arm wiring.

It performed quite good but it wasn't quit enough and speed variation I could not improve.

After that one a second hand SL1700 a perfect table to adjust and use. I wanted it to use as base for the rb301 but I could not do it it was to good just how it was. I still have it.

Now with the Thorens satisfaction is coming my way after many years, I like the 60ties sturdy style. And to work with the table is some how natural I think because it is not wobbly by suspension it feels stable.

The vintage look and story is great for being a formal studio TT. It isn't just the story it performs also on high level the reproduction on the TD124 with the RB301 makes me play one record after the other.

A look at the strobe and the way it is made with a little mirror is are such nice details I love it.

Comes to me what can be the reason why the sound quality of a mass driven direct drive idler wheel does sound a bit better then the belt drive dual or direct drive technics.

I think the high mass frame plinth and platter are less sensitive for surrounding noise of the speakers and increases bas performance also the idler wheel will help damp those resonances. The idler wheel will also cause some rumble on low frequent level but that will overall be masked by the bottom noise level of the record.

Last edited:

coming to "grips" with idlers

Helmut,

In my case a recently "hacked" Dual 1214 with my DIY tonearm and Grado "Black" cartridge has surplanted both a Roxsan Xerxes MkI (with hot-rodded Rega RB250: Tecno weight, VTA adjuster, Teflon/Ag single piece rewire and and Ortofon MC3 turbo cart) and my Oracle Alex MkII (SME 309 magnesium, Grado Sig8 MCZ cart, SME stock Van den Hul interconnect from arm to phono stage).

In both cases the old Dual combo easily outperformed the others with superior soundstaging, pace, rythm, attack, and timing (I'll call this SPRAT). To me the control of the platter by the motor via an idler makes up for the significant performance of the old Dual.

I do love my DIY arm, but can't say that is the reason for the superior performance, The DIY arm competes favourably with my SME when mounted on the same table using the same cartridge. Differrent, but in the same league). I can only atribute the increased performance to the old idler.

Please note that the old Dual was hacked using a Dremmel tool, a small pick for "E" clips, a pair of needle-nose pliers and a n electric screw driver.

Helmut,

In my case a recently "hacked" Dual 1214 with my DIY tonearm and Grado "Black" cartridge has surplanted both a Roxsan Xerxes MkI (with hot-rodded Rega RB250: Tecno weight, VTA adjuster, Teflon/Ag single piece rewire and and Ortofon MC3 turbo cart) and my Oracle Alex MkII (SME 309 magnesium, Grado Sig8 MCZ cart, SME stock Van den Hul interconnect from arm to phono stage).

In both cases the old Dual combo easily outperformed the others with superior soundstaging, pace, rythm, attack, and timing (I'll call this SPRAT). To me the control of the platter by the motor via an idler makes up for the significant performance of the old Dual.

I do love my DIY arm, but can't say that is the reason for the superior performance, The DIY arm competes favourably with my SME when mounted on the same table using the same cartridge. Differrent, but in the same league). I can only atribute the increased performance to the old idler.

Please note that the old Dual was hacked using a Dremmel tool, a small pick for "E" clips, a pair of needle-nose pliers and a n electric screw driver.

Last edited:

Hi Stew!

As a fairly recent convert to idler drive (I now own two TD-124s) I have to say once the problems are solved with a particular table the results can be pretty compelling. Lenco tables are still incredibly undervalued and might make a worthy candidate for further investigation/tinkering at reasonable cost. Lenco Heaven here: Lenco Heaven - Forum for The Classic Lenco Idler-Drive Turntables might be of considerable interest even to non Lenco owners.

As a fairly recent convert to idler drive (I now own two TD-124s) I have to say once the problems are solved with a particular table the results can be pretty compelling. Lenco tables are still incredibly undervalued and might make a worthy candidate for further investigation/tinkering at reasonable cost. Lenco Heaven here: Lenco Heaven - Forum for The Classic Lenco Idler-Drive Turntables might be of considerable interest even to non Lenco owners.

Lencos and such...

Kevin,

yes, Lenco turntables are reputedly excellent and I have lurked over at Lenco Heaven for years but the prices are creeping up. I've had a couple of phone calls with Jean Nantais of Lenco fame, and he encouraged me to try a Dual to get my feet wet, and suggested I might be surprised.

Killing off the Oracle and Roxan was a suprise! The improvements were non-trivial. And that was with the old idler mounted on a scabbed together plinth (about as brutal as can be and not following any "recipes" for plinths, just cut ip scraps of wood).

Many undervalued changers are out there for folks who can't afford the big dogs (like me), but you often end up getting a similar bearing, platter, motor and idler system. How many old Duals are out there?

I recently picked up an old Philco console for $20. It has a VM turntable in it (a changer as most consoles had). All parts arre apparently still available for it. And it does have the really "cool" retro look similar to old McCurdy turntables. I also have an old Phillips console with an idler with similar cosmetics as the Thorens/ garrard 301, etc.

Kevin,

yes, Lenco turntables are reputedly excellent and I have lurked over at Lenco Heaven for years but the prices are creeping up. I've had a couple of phone calls with Jean Nantais of Lenco fame, and he encouraged me to try a Dual to get my feet wet, and suggested I might be surprised.

Killing off the Oracle and Roxan was a suprise! The improvements were non-trivial. And that was with the old idler mounted on a scabbed together plinth (about as brutal as can be and not following any "recipes" for plinths, just cut ip scraps of wood).

Many undervalued changers are out there for folks who can't afford the big dogs (like me), but you often end up getting a similar bearing, platter, motor and idler system. How many old Duals are out there?

I recently picked up an old Philco console for $20. It has a VM turntable in it (a changer as most consoles had). All parts arre apparently still available for it. And it does have the really "cool" retro look similar to old McCurdy turntables. I also have an old Phillips console with an idler with similar cosmetics as the Thorens/ garrard 301, etc.

It appears to me the Lenco has the idler wheel vertical causing more rumble as for the idler wheels who work horizontal. Maybe i prejudice.

Nanook what arm did you construct.

Some models are capable of really excellent rumble performance despite the vertical idler wheel. Check out that forum if curious.

of Lencos and tonearms...

The Lenco turntables have a cult following, much the same as the Thorens and Garrards.

in either case there will be some "noise" added due to an idler (and this is theoretical of course). The larger the idler wheel, the fewer RPM required of it to transfer the motor/spindle speed to the platter.

Most idlers use a bushing rather than a proper bearing. Bearings have less drag, but if sloppy can add noise.

I think if one looks at any idler wheel design, there are pluses and minuses to each. The verticle idler wheel may have an advantage, as it can be fine tuned to a specific location on a different platter if using one which has a flat bottom. Thus the oportunity to make a custom table (including a platter made of your choice of materials) may be easier to realize. Also the horizontal orientation of the motor may allow for easier fitment in a more compact plinth.

There are proponents of all:

The arm have mounted is my "kit" arm, which I have been trying to get out to folks for at least the last 6 mos. Wow, does time fly (right kevin?)!

The turntable isn't even anchored to the "plinth". Now that I know that this table has a ton of potential, I will take the time to construct a proper one from scratch, and reinforce the metal top plate , as well as fill all the little holes in it, and sand and refinish it.

The Lenco turntables have a cult following, much the same as the Thorens and Garrards.

in either case there will be some "noise" added due to an idler (and this is theoretical of course). The larger the idler wheel, the fewer RPM required of it to transfer the motor/spindle speed to the platter.

Most idlers use a bushing rather than a proper bearing. Bearings have less drag, but if sloppy can add noise.

I think if one looks at any idler wheel design, there are pluses and minuses to each. The verticle idler wheel may have an advantage, as it can be fine tuned to a specific location on a different platter if using one which has a flat bottom. Thus the oportunity to make a custom table (including a platter made of your choice of materials) may be easier to realize. Also the horizontal orientation of the motor may allow for easier fitment in a more compact plinth.

There are proponents of all:

- Garrard

- Thorens (which are a "hybrid as a belt is used to rotate an intermediate wheel)

- Lenco

- McCurdy

- EMT

- and too many others to list

The arm have mounted is my "kit" arm, which I have been trying to get out to folks for at least the last 6 mos. Wow, does time fly (right kevin?)!

The turntable isn't even anchored to the "plinth". Now that I know that this table has a ton of potential, I will take the time to construct a proper one from scratch, and reinforce the metal top plate , as well as fill all the little holes in it, and sand and refinish it.

Attachments

Last edited:

The arm have mounted is my "kit" arm, which I have been trying to get out to folks for at least the last 6 mos. Wow, does time fly (right kevin?)!

The turntable isn't even anchored to the "plinth". Now that I know that this table has a ton of potential, I will take the time to construct a proper one from scratch, and reinforce the metal top plate , as well as fill all the little holes in it, and sand and refinish it.

Stew I think this is the real DIY buy a low cost daul cs1200 series and build your own arm.

It would be good to put a well documented build of this turn table for youngsters as adults with little money to build real high end for scratch with your own hands.

At mine I had made a 8mm ax to lengten the pitch control and also the same for the speed control. It made a cool appearance.

Last edited:

well documented build

Helmuth,

Your build looks very good and I must say shows your skill and esthetic preferences, which seem to mirror mine.

A well documented build was/is the idea. I had planned on writing it up for HiFiZine.com but have since resigned my position with them (5+ years writing for Affordable$$Audio prior to their merger). I haven't decided to create my owm blog (or ezine) or see what other ezine writing opportunities exist.

I am still going to document the build and do an interview with Jean on his ideas and concepts regarding idler wheel turntables. It had always been his contention that one need not start with a Lenco or Thorens or Garrard "big dogs". There are lots of changers that could be easily modified to single play manual turntables that cost very little.

What you see in my attached picture two posts back is absolutely crude, but sounds great. Once I decide on the design of a plinth, I'll get constructing and further listening.If the initial lstening sessions arre any indication I may have an Oracle for sale.

Besides the Dual 1214, I have a Garrard Lab 80 (without idler or platter but everything else is there), and a VM, as well as a Phillips idler in nice compact console stereo from 1961, but I'd like to leave the Phillips intact if possible.

Helmuth,

Your build looks very good and I must say shows your skill and esthetic preferences, which seem to mirror mine.

A well documented build was/is the idea. I had planned on writing it up for HiFiZine.com but have since resigned my position with them (5+ years writing for Affordable$$Audio prior to their merger). I haven't decided to create my owm blog (or ezine) or see what other ezine writing opportunities exist.

I am still going to document the build and do an interview with Jean on his ideas and concepts regarding idler wheel turntables. It had always been his contention that one need not start with a Lenco or Thorens or Garrard "big dogs". There are lots of changers that could be easily modified to single play manual turntables that cost very little.

What you see in my attached picture two posts back is absolutely crude, but sounds great. Once I decide on the design of a plinth, I'll get constructing and further listening.If the initial lstening sessions arre any indication I may have an Oracle for sale.

Besides the Dual 1214, I have a Garrard Lab 80 (without idler or platter but everything else is there), and a VM, as well as a Phillips idler in nice compact console stereo from 1961, but I'd like to leave the Phillips intact if possible.

Last edited:

Helmut, and what did you do with DUAL platter? I see it differs from the original. I'm experimenting now with very similar DUAL deck, and it handles easyly both double and triple heavier platter, with no signs of drag. I will stop with 5kg weight.

DUAL idler runs surprisingly well, with no noise or rumble. At least it is lower than record floor noise...

DUAL idler runs surprisingly well, with no noise or rumble. At least it is lower than record floor noise...

Helmut, and what did you do with DUAL platter? I see it differs from the original. I'm experimenting now with very similar DUAL deck, and it handles easyly both double and triple heavier platter, with no signs of drag. I will stop with 5kg weight.

DUAL idler runs surprisingly well, with no noise or rumble. At least it is lower than record floor noise...

The metal frame was build in a heavy mdf plint. On top of that a 22mm mdf plate the platter disappears in the 22mm. Than I made a multilayer platter of felt rubber trespa mdf. To do this you need a extra long axle in the middle of the platter.

A-haa, now I understand why it looks the way it is. As for me, I've placed additional cast and machined 2,6 kg platter on the top of Dual own one , so together they are 5 kg, and also ordered extended spindle. Of course, the arm and the plinth will be replaced with something more decent.The metal frame was build in a heavy mdf plint. On top of that a 22mm mdf plate the platter disappears in the 22mm. Than I made a multilayer platter of felt rubber trespa mdf. To do this you need a extra long axle in the middle of the platter.

er...my lack of skill

Helmuth,

Your build looks very good and I must say shows your skill and esthetic preferences, which seem to mirror mine.

When I re-read this, it suggests I have your skill (which I don't). Sorry if it seemed rude, that was not the intention.

Personally, I like the Dual top plate. Does anybody know what finish (paint) was used on them. It has a very "soft" tactile feel which I quite like.

Helmuth,

Your build looks very good and I must say shows your skill and esthetic preferences, which seem to mirror mine.

When I re-read this, it suggests I have your skill (which I don't). Sorry if it seemed rude, that was not the intention.

Personally, I like the Dual top plate. Does anybody know what finish (paint) was used on them. It has a very "soft" tactile feel which I quite like.

Personally, I like the Dual top plate. Does anybody know what finish (paint) was used on them. It has a very "soft" tactile feel which I quite like.[/QUOTE]

As to DUAL paint, apart from aesthetics, it also has remarkable damping property. Even chipper models with iron stamped platter, that is covered with that paint, are not ringing at all. I think that paint is a reason, why DUAL idler runs so surprisingly quiet.

As to DUAL paint, apart from aesthetics, it also has remarkable damping property. Even chipper models with iron stamped platter, that is covered with that paint, are not ringing at all. I think that paint is a reason, why DUAL idler runs so surprisingly quiet.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- TD124 mk1 RB301 new plinth and service