Dave, can you tell me why the belt drive tt's are better?

Execution counts, but belt-drives have the HUGE advantage of not having the motor directly connected to the platter/record.

dave

First I must tell you that I'm here for pleasure, to learn and if there is such possibility it to be usable and valuable to give some of my miserable knowledge to someone.

Second that I must tell you is that my conversational English in aspect of normal friendly talk between people is somehow retarded... I am a great fan of you, MJK and all other power members here and i wouldn't even try to argue with you! If it sounds like I'm questioning you or as if I'm arguing - know that it isn't so!

or as if I'm arguing - know that it isn't so!

It is obvious that the monster turn table systems are all using a belt drive system, so probably the last 1 or 5% bit of quality and realism can be achieved with a belt drive.

But there must be some scientific grounds for that?

Let's try like that:

Is it true that belt drive has advantage only if it's plater is heavy enough?

Reason for question:

In order a belt drive to beat DD with only moving part the plater, it should beat the 0.01% to 0.035% possible speed deviation.

Effect of the heavy plater:

It acts like a flywheel so the belt only adds the torque lost to friction with the stylos, the bearing and the air. The bigger the flywheel mass the bigger is the proportion between it's stored to lost torque. And the bigger is it's resistance to belt fluctuations.

So the result would be that the plater is acting as self propelled rather than driven - a natural effect of that is the stable speed.

Is this reasoning a valid one?

But my point is that if we get two turntables wit equal low mass platers - say 2 kilograms the DD would be preferable over belt drive, because at that low mass the resistance of the stylos would be transferred and transformed directly into belt tension... But this would be system with spring and varying weight and no damper! The weight (friction transformed into tension force) is not one and the same and additionally the spring (belt elasticity) is not linear. So we would get oscillations at certain frequencies...

Most DD systems are made with a kind of pacemaker which makes them naturally stable... The next inductance in the motor stator is activated not only based on time, but based on a trigger so the motor can work with increased torque but without increasing it's speed.

If deviation in the speed is detected this is not cured by throttling the engine, but rather by increasing the current fed to the inductances without increasing the pace. It's the same like driving on a level road in 4th gear at 50 mph and doing the same on a steep road - the engine PRM are the same, only the throttle position is different.

And if there are three triggers and three sensors then you get the speed measured 9 times per revolution so the controls can increase and decrease the torque 9 times per revolution and roughly 18 times per second.

With a belt drive you have a transmission with certain elasticity - and thus a two way lag - the belt drive must rely on heavier plater and statistics accumulation - it's controls ought to gather enough date in order to decide that there is a certain tendency for advance or retard.

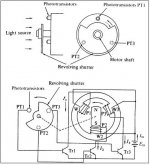

See attached principle drawing. - it explains why the controls are not based on permanent corrections but rather on a constant pace... Even with the highest speeds of reaction if the system was naturally unstable the speed would oscillate all the time at random. And then you would need a read ahead buffer which is aware of the current speed in order to reproduce a speed corrected sound... but that would corrupt the whole idea of turntable...

What an interesting thought I had

So my conclusion is that there is a very great probability that a belt drive is better than direct drive in the end as an absolute answer. But BD is only better only with a considerably heavy plater. And let's not forget that a BD has much more moving parts than a DD, so everything must be really much more accurate and expensive... For instance the motor has to have balanced rotor otherwise it would induce vibrations in the belt and even it they never reach the stylus they will for sure make the friction in the motor spool higher...

So for a reasonable price the better choice is DD.... for me at least.

And apart of the above off-topic I would be happy to know some tricks for cleaning of dirty record, because I have plenty of them :lol:

My cleaning kit is Stanton - probably the most ordinary one and it seems that it's velvet brush doesn't absorb enough dust because after a couple of turns on the initial dry brushing it cleans the record, but the dust is gathered on a line on the record instead on the brush :lol: and I have to blow it off :lol: and the cleaning solution smells like soap water to me...

Second that I must tell you is that my conversational English in aspect of normal friendly talk between people is somehow retarded... I am a great fan of you, MJK and all other power members here and i wouldn't even try to argue with you! If it sounds like I'm questioning you

or as if I'm arguing - know that it isn't so!

or as if I'm arguing - know that it isn't so!It is obvious that the monster turn table systems are all using a belt drive system, so probably the last 1 or 5% bit of quality and realism can be achieved with a belt drive.

But there must be some scientific grounds for that?

Let's try like that:

Is it true that belt drive has advantage only if it's plater is heavy enough?

Reason for question:

In order a belt drive to beat DD with only moving part the plater, it should beat the 0.01% to 0.035% possible speed deviation.

Effect of the heavy plater:

It acts like a flywheel so the belt only adds the torque lost to friction with the stylos, the bearing and the air. The bigger the flywheel mass the bigger is the proportion between it's stored to lost torque. And the bigger is it's resistance to belt fluctuations.

So the result would be that the plater is acting as self propelled rather than driven - a natural effect of that is the stable speed.

Is this reasoning a valid one?

But my point is that if we get two turntables wit equal low mass platers - say 2 kilograms the DD would be preferable over belt drive, because at that low mass the resistance of the stylos would be transferred and transformed directly into belt tension... But this would be system with spring and varying weight and no damper! The weight (friction transformed into tension force) is not one and the same and additionally the spring (belt elasticity) is not linear. So we would get oscillations at certain frequencies...

Most DD systems are made with a kind of pacemaker which makes them naturally stable... The next inductance in the motor stator is activated not only based on time, but based on a trigger so the motor can work with increased torque but without increasing it's speed.

If deviation in the speed is detected this is not cured by throttling the engine, but rather by increasing the current fed to the inductances without increasing the pace. It's the same like driving on a level road in 4th gear at 50 mph and doing the same on a steep road - the engine PRM are the same, only the throttle position is different.

And if there are three triggers and three sensors then you get the speed measured 9 times per revolution so the controls can increase and decrease the torque 9 times per revolution and roughly 18 times per second.

With a belt drive you have a transmission with certain elasticity - and thus a two way lag - the belt drive must rely on heavier plater and statistics accumulation - it's controls ought to gather enough date in order to decide that there is a certain tendency for advance or retard.

See attached principle drawing. - it explains why the controls are not based on permanent corrections but rather on a constant pace... Even with the highest speeds of reaction if the system was naturally unstable the speed would oscillate all the time at random. And then you would need a read ahead buffer which is aware of the current speed in order to reproduce a speed corrected sound... but that would corrupt the whole idea of turntable...

What an interesting thought I had

So my conclusion is that there is a very great probability that a belt drive is better than direct drive in the end as an absolute answer. But BD is only better only with a considerably heavy plater. And let's not forget that a BD has much more moving parts than a DD, so everything must be really much more accurate and expensive... For instance the motor has to have balanced rotor otherwise it would induce vibrations in the belt and even it they never reach the stylus they will for sure make the friction in the motor spool higher...

So for a reasonable price the better choice is DD.... for me at least.

And apart of the above off-topic I would be happy to know some tricks for cleaning of dirty record, because I have plenty of them :lol:

My cleaning kit is Stanton - probably the most ordinary one and it seems that it's velvet brush doesn't absorb enough dust because after a couple of turns on the initial dry brushing it cleans the record, but the dust is gathered on a line on the record instead on the brush :lol: and I have to blow it off :lol: and the cleaning solution smells like soap water to me...

Attachments

Last edited:

There are many schools of thought wrt belt-drive tables. Low mass, high mass platters, both have their pluses & minuses, belts can be stretchy or not. Execution is important.

Direct drives have the motor directly attached to the record... that is a VERY serious negative. And any speed stability scheme is subject to hunt & peck (same is true of belt-drives with the same kind of motor controllers)... it all comes down to execution.

In the end you have to listen to it and choose your compromises. And to my ear, you can get a better sounding belt-drive for less. A belt drive is certainly a whole lot simplier.

Just yesterday, a friend brought over a CD he had burned... he commented that it sounded kinda flat & uninvolving. I said, it sorta sounds like a typical DD. Turns out it was a digital capture using a big Pioneer DD.

dave

Direct drives have the motor directly attached to the record... that is a VERY serious negative. And any speed stability scheme is subject to hunt & peck (same is true of belt-drives with the same kind of motor controllers)... it all comes down to execution.

In the end you have to listen to it and choose your compromises. And to my ear, you can get a better sounding belt-drive for less. A belt drive is certainly a whole lot simplier.

Just yesterday, a friend brought over a CD he had burned... he commented that it sounded kinda flat & uninvolving. I said, it sorta sounds like a typical DD. Turns out it was a digital capture using a big Pioneer DD.

dave

Come on!

You're obsessed!

You're obsessed!

There must be a reason.

I might have a TT from less than a week, but for sure the sound is not flat. Much more holographic than CD.

Maybe DVD Audio comes close, but not quite. With a friend we listened to DVD-a version of This Is It when it was released when Michael Jackson died, not my kind of music, but the second best after my TT as SQ, stage and imaging for sure. Speakers were Fostex 12x in horns.

You're obsessed!

You're obsessed!There must be a reason.

I might have a TT from less than a week, but for sure the sound is not flat. Much more holographic than CD.

Maybe DVD Audio comes close, but not quite. With a friend we listened to DVD-a version of This Is It when it was released when Michael Jackson died, not my kind of music, but the second best after my TT as SQ, stage and imaging for sure. Speakers were Fostex 12x in horns.

Come on!You're obsessed!

There must be a reason.

How many times do i have to answer that question?

In a belt-drive, platter/bearing are separate from the motor. In a DD the motor is directly connected to the platter/bearing. Consider how small the squiggles on a record are and how even a tiny amount of motor vibration can completely bury the lowest level information on a record.

dave

Can you demonstrate this by measuring the noise and rumble from a few DD TT's and compare them to some BD TT's? It appears you're saying a DD TT inherently creates much more noise, and also implying that a DD TT's motor generates the same amount of noise as does a BD TT's motor. I'd like to see the evidence.How many times do i have to answer that question?

In a belt-drive, platter/bearing are separate from the motor. In a DD the motor is directly connected to the platter/bearing. Consider how small the squiggles on a record are and how even a tiny amount of motor vibration can completely bury the lowest level information on a record.

dave

I'd like too, but first would like to know some DIY tricks about cleaning of records.

And I can't imagine what might be the difference when in the Technics for instance the only moving part is the plater itself as it is integrated with the motor rotor (thy magnet is just bolted to it) - so the same ad BD - only one bearing and a shaft.

Think the trick must be elsewhere. Probably the way the two systems handle resistance from the sylus - the lever through which the torque is acting is longer in DD's - so this equals an overdrive gear, and in BD not only the pulley radius is smaller (shorter lever), but further the gear is lowering=more torque - better dealing with hill climbing and more controlled descent

- the lever through which the torque is acting is longer in DD's - so this equals an overdrive gear, and in BD not only the pulley radius is smaller (shorter lever), but further the gear is lowering=more torque - better dealing with hill climbing and more controlled descent  (guess who has an old Jeep with AMC straight six

(guess who has an old Jeep with AMC straight six  )

)

p.s. why everyone in the speaker sections is so scientific and why the same people in the source sections are showing signs of superstition?

And I can't imagine what might be the difference when in the Technics for instance the only moving part is the plater itself as it is integrated with the motor rotor (thy magnet is just bolted to it) - so the same ad BD - only one bearing and a shaft.

Think the trick must be elsewhere. Probably the way the two systems handle resistance from the sylus

p.s. why everyone in the speaker sections is so scientific and why the same people in the source sections are showing signs of superstition?

T101,

There is a lot of good material on cleaning at Vinyl Engine. First issue is the cleaning solution...you can spend a fortune for commercial stuff but most recommend a mix of distilled water & isopropyl alcohol, with some debate over the addition of a small amount of surfactant like a mild detergent. For the first cleaning of grungy records I find it works best to rig up a trough a little deeper than 6" (the distance from record edge to center hole) fill to about 3.5" (90 mm) deep. place a 1/4" (6.3 mm) shaft through the center hole & submerge the album on edge in the solution allowing it to soak a while then slowly rotate to the next section while brushing back solution to keep label dry. Once they are clean something simple like a Discwaher brush with same solution works fine for pre-play cleaning.

There is a lot of good material on cleaning at Vinyl Engine. First issue is the cleaning solution...you can spend a fortune for commercial stuff but most recommend a mix of distilled water & isopropyl alcohol, with some debate over the addition of a small amount of surfactant like a mild detergent. For the first cleaning of grungy records I find it works best to rig up a trough a little deeper than 6" (the distance from record edge to center hole) fill to about 3.5" (90 mm) deep. place a 1/4" (6.3 mm) shaft through the center hole & submerge the album on edge in the solution allowing it to soak a while then slowly rotate to the next section while brushing back solution to keep label dry. Once they are clean something simple like a Discwaher brush with same solution works fine for pre-play cleaning.

That a Technics SL1200 has a good motor is without question.

That is not to say that its bearing, tonearm, PSU, and isolation peformance are state of the art. A lot of the mechanical \ electrical shortcomings of the SL1200 can be overcome with aftermarket modifications. But the most important thing is what the deck is supported on.

I spent many years setting up these decks in nightclubs, and the difference between a good setup and a poor one is massive. Get it right and you can transform the performance (and the nightclub)

That is not to say that its bearing, tonearm, PSU, and isolation peformance are state of the art. A lot of the mechanical \ electrical shortcomings of the SL1200 can be overcome with aftermarket modifications. But the most important thing is what the deck is supported on.

I spent many years setting up these decks in nightclubs, and the difference between a good setup and a poor one is massive. Get it right and you can transform the performance (and the nightclub)

Just yesterday, a friend brought over a CD he had burned... he commented that it sounded kinda flat & uninvolving. I said, it sorta sounds like a typical DD. Turns out it was a digital capture using a big Pioneer DD.

He must have borrowed my Linn LK1, flat and uninvolving describes it perfectly.

jeff

The only thing about Linn that ever impressed me was their marketing.

Dishonest and bordering on the fraudulent yes but also impressive.

Their products have always been largely underwhelming. Including the LP12 which is basically a bolt-for-bolt copy of a Thorens discontinued the year before the LP12s first release. And then there were their endless 'upgrades', all things you got as standard with the better Thorens models like stiffer springs etc but even with those you have problems fitting the Dynavector arm which was a Thorens factory option.

Sadly it was pretty much only Linn who could ride out the drop in TT sales after cds hit the market but then they were a subsidiary of Britains second largest defense contractor and didn't have to rely on HiFi sales to survive.

Dishonest and bordering on the fraudulent yes but also impressive.

Their products have always been largely underwhelming. Including the LP12 which is basically a bolt-for-bolt copy of a Thorens discontinued the year before the LP12s first release. And then there were their endless 'upgrades', all things you got as standard with the better Thorens models like stiffer springs etc but even with those you have problems fitting the Dynavector arm which was a Thorens factory option.

Sadly it was pretty much only Linn who could ride out the drop in TT sales after cds hit the market but then they were a subsidiary of Britains second largest defense contractor and didn't have to rely on HiFi sales to survive.

Guys, don't tell anyone about Linn! :lol: because a friend of mine also Diy-er recently bought three 50 watt stereo Linn amps and a passive preamp also Linn. :lol:

The passive preamp got beaten on phono by my 100$ Behringer VMX100 DJ mixer :lol: and the difference wasn't barely there! No! The sound with the Linn was hugely worse!

I have some bad news for me! It seems that I have to throw out my Pioneer 417 receiver. With everything the same I tried with the 417 and Tannoy Sensys dc-2, the tannoys have proven themselves, but such a really flat and dull sound I haven't expected! Maybe it needs repair.

So now I have a problem, my best source, amp and preamp and speakers are in three different places :lol:

By the way how does the height of the tonearm alter the sound?

The passive preamp got beaten on phono by my 100$ Behringer VMX100 DJ mixer :lol: and the difference wasn't barely there! No! The sound with the Linn was hugely worse!

I have some bad news for me! It seems that I have to throw out my Pioneer 417 receiver. With everything the same I tried with the 417 and Tannoy Sensys dc-2, the tannoys have proven themselves, but such a really flat and dull sound I haven't expected! Maybe it needs repair.

So now I have a problem, my best source, amp and preamp and speakers are in three different places :lol:

By the way how does the height of the tonearm alter the sound?

Stereo and imaging are back. I sorted the problem with the sound quality, it was due to a degraded receiver entrance and due to inappropriate bi-amp and bi-wire connections. Strangely the difference was not so obvious with CD as a source, it seems that a TT is a more demanding source.

Now I have yet another observation the membranes of the low range drivers are making constant lazy back and forward motions with considerable amplitude that don't produce sound. From what I've read this is normal with TT's and older records. It seems that only drivers with soft suspension are prone to that, the Goldwood 18 inch all mighty does not seem to show any such signs.

I cleaned several records, but the velvet brush only gathers the dust and dirt (which is quite allot on some records) in one place and does not pick it up, the dirt just remains in a line on ore radius of the record which means that this brush makes it travel through the grooves all the time. - kinda abrasive this seems to me.

And there are no instructions on how to clean the brush itself...

Definitely will make a DIY cleaning of some sort and will report. The results of that cleaning are clearly audible, so a tougher cleaning should be better.

Also I'll be building an OB with 15 in Eminence and a full range because the 18 Goldwoods just don't fit in my living room.

Best regards to all!

Now I have yet another observation the membranes of the low range drivers are making constant lazy back and forward motions with considerable amplitude that don't produce sound. From what I've read this is normal with TT's and older records. It seems that only drivers with soft suspension are prone to that, the Goldwood 18 inch all mighty does not seem to show any such signs.

I cleaned several records, but the velvet brush only gathers the dust and dirt (which is quite allot on some records) in one place and does not pick it up, the dirt just remains in a line on ore radius of the record which means that this brush makes it travel through the grooves all the time. - kinda abrasive this seems to me.

And there are no instructions on how to clean the brush itself...

Definitely will make a DIY cleaning of some sort and will report. The results of that cleaning are clearly audible, so a tougher cleaning should be better.

Also I'll be building an OB with 15 in Eminence and a full range because the 18 Goldwoods just don't fit in my living room.

Best regards to all!

One thing with 1200s is that the rubber mat is an essential part of the overall damping.

Replacing these with slip mats as is usual in clubs will make them a lot worse.

For cleaning records you can make your own cleaning fluid from reverse osmosis water (used for aquariums), isopropyl alcohol and a drop of the wetting agent that was used in photo laboratories when we still used film. Not sure about the ratios, found it on the web a long time ago. It dries without any residue but wipe them dry with a lint-free cloth as used for polishing car wax.

Replacing these with slip mats as is usual in clubs will make them a lot worse.

For cleaning records you can make your own cleaning fluid from reverse osmosis water (used for aquariums), isopropyl alcohol and a drop of the wetting agent that was used in photo laboratories when we still used film. Not sure about the ratios, found it on the web a long time ago. It dries without any residue but wipe them dry with a lint-free cloth as used for polishing car wax.

PS: The good thing about your excessive cone movement is that the arm/cartridge resonance is below audibility threshold as it should be, the bad thing is that your phono pre amp should contain a steep high pass filter to stop these from getting into the power amp but apparently it doesn't.

Ofcource it doesn't - it's a $100 Behringer, but otherwise it sounds great and on my OB "18 H frame system it outperformed a Linn phono pre-amp, which as I understand is not a considerable achievement.

The problem with the sound now is due to the receiver and speakers at my home - when I listen with headphones it's the same as in my other place...

The problem with the sound now is due to the receiver and speakers at my home - when I listen with headphones it's the same as in my other place...

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- First Turntable For Me? Technics-1200?