Thanks, all. I have obtained a few 2mm silicon nitride balls for this job. My back-up is a Papst from my collection.

Kal

Thought I should mention the Papst on single phase power generates more vibration than the E50 unless you can power it with 3 phase power in which case it should run smooth as glass, and be significantly quieter. It is certainly a great looking motor.. (More torque too..)

The other thing to bear in mind is that if you wish to use the stroboscope you will need a tiny step-up transformer to provide the 220V - 240V the lamp requires or you will need to find a lamp that functions well on 120V..

Well, none of the Papst motors I have are the one that Thorens used as a replacement for the E-50. They are all newer and run very smoothly with single-phase although I have rigged up a quadrature generator to make it even better.

My power for the Papst would be external with all the rest of the Thorens intact, so why would I need to make any accommodations for the strobe?

All said, I hope not to have to go this route.

My power for the Papst would be external with all the rest of the Thorens intact, so why would I need to make any accommodations for the strobe?

All said, I hope not to have to go this route.

Well, none of the Papst motors I have are the one that Thorens used as a replacement for the E-50. They are all newer and run very smoothly with single-phase although I have rigged up a quadrature generator to make it even better.

My power for the Papst would be external with all the rest of the Thorens intact, so why would I need to make any accommodations for the strobe?

All said, I hope not to have to go this route.

Hi Kal,

Perhaps you don't have the Papst Aussenlaufer type motors as these are genuine 3 phase, not quadrature motors. (They were also used in some rek-o-cut tables) I was a bit skeptical but was able to verify that this is in fact the case. (Mark Kelly and others have written extensively about this subject..) Polyphase power is required to make them run at their highest performance levels. Quadrature motors of course are very much easier to deal with, so I will keep my fingers crossed if you have to use one of these.

There are replacement motor windings available for the E50 from a variety of sources so there is almost no reason you couldn't get the original motor running again no matter how messed up it is. Old motors even show up on eBay with some regularity.

The neon lamp in the strobe runs of off one of the stator windings in the E50 using the highest voltage tap. On 120V the motor provides roughly 240V to the neon lamp, that fact is what predicated my comment. 120V Papst Aussenlaufer motors which is what I thought you had don't provide the additional winding required.

Your comments on the modern Papst motor have me wondering whether there might in fact be a motor out there better than the old Aussenlaufer and E50...

Last edited:

I have quite a few but the one that will physically fit in the TD-124 chassis is a quadrature motor. It is the same one that has been used in the original Wilson-Benesch turntable.Hi Kal,

Perhaps you don't have the Papst Aussenlaufer type motors as these are genuine 3 phase, not quadrature motors. (They were also used in some rek-o-cut tables) I was a bit skeptical but was able to verify that this is in fact the case. (Mark Kelly and others have written extensively about this subject..) Polyphase power is required to make them run at their highest performance levels. Quadrature motors of course are very much easier to deal with, so I will keep my fingers crossed if you have to use one of these.

I know. Just lining up my options.There are replacement motor windings available for the E50 from a variety of sources so there is almost no reason you couldn't get the original motor running again no matter how messed up it is. Old motors even show up on eBay with some regularity.

Thanks. Understood.The neon lamp in the strobe runs of off one of the stator windings in the E50 using the highest voltage tap. On 120V the motor provides roughly 240V to the neon lamp, that fact is what predicated my comment. 120V Papst Aussenlaufer motors which is what I thought you had don't provide the additional winding required.

Sure but it also has to fit.Your comments on the modern Papst motor have me wondering whether there might in fact be a motor out there better than the old Aussenlaufer and E50...

Kal

Hello all.

I just thought I'd chime in and say that this looks like a fun project. And not too terribly expensive.

Here's my current Lp spinner:

This is a project from a couple of years ago. I've tried a few different tonearms and cartridges. The Zeta tonearm that is pictured is my current choice. Dynamic, slammy, yet very nicely detailed. I'm using a Uwe bodied DL103R with SS retip. The armboard was cut from Gabon Ebony. It might be a good choice for the Zeta.

Meanwhile here are some notes I've made on the breed.

MK II double grommet motor suspension is a definite upgrade over the original single grommet motor suspension. For those with a mk1, it is worthwhile to make the conversion.

The 'non-magnetic' platter was optional even on the mk1 models. Look close at the platter used on the TD135 and realize that this is the same platter offered as the 'non-magnetic option' only it was adapted to fit the larger TD124 14mm bearing. Also, the non-mag platter was cast from a zinc alloy with a product name called Zamac. If you want an exact chemical composition of the alloy this can easily be found via google. Not aluminum. There never was an aluminum platter for the TD124, any mark.

20 wt seems to be the magic viscosity for motor and bearing, but other folks use different oils and weights and report different findings. Me, I'm a traditionalist. 20 wt turbine oil for me.

Belts have become a thorny issue on all of the vintage Thorens models. In the case of the belt drive models like the Td150/160/125 etc, the current belt offered by Thorens Export does function correctly. This I have found through my own use. It is the aftermarket belts that tend to be too wide, too thick, wrong length and will over-tension the motor....causing excessive motor vibes to enter the motor plate. But....... on the TD124 I have had better luck using aftermarket belts. Example, the TD124 spec belt offered at Elex-Atelier seems to work well enough over the 60 hz pulley. Caution....it could very well be too tight over the 50 hz pulley. Width and thickness on that belt seems close to right. This observation I make after seeing 1/2 dozen TD124 models pass through my hands and observing which belts were on them when I received them. The Elex-Atelier belt is comparable to the thinnest/skinniest of belts I've seen. And that is likely closest to what works. Too tight = motor vibes. Too loose = pulley slip

Thanks for the feedback on the so-called Thorens belt being offered for the TD124 by Thorens Export. I'll save the money. $35.00 for a belt indeed. Just a glorified rubber band. We deserve better. Like maybe a nice ground belt of just the right width, length, thickness and elasticity. Is anybody listening....!

Did not know that the MkII E50 motor was 15 watt. The mk1 is rated at 10 watt. That could provide some additional, um, thrust...

The TD124 does indeed play quiet.....when the drivetrain is 100% that is. Not only is it pacey, dynamic and slammy, but it also can sound refined and detailed. Perhaps not detailed and airy in the same league as the better belt drives, but it does the authority and slam that they just can't do.

On the other hand, with a gunked up motor, rubber-caked pulley crown, tired belt, sloppy platter bearing, bent outer platter shell, it will indeed fail to deliver.

Mine's pretty close to 100%, so I'm keeping it.

-Steve

I just thought I'd chime in and say that this looks like a fun project. And not too terribly expensive.

Here's my current Lp spinner:

This is a project from a couple of years ago. I've tried a few different tonearms and cartridges. The Zeta tonearm that is pictured is my current choice. Dynamic, slammy, yet very nicely detailed. I'm using a Uwe bodied DL103R with SS retip. The armboard was cut from Gabon Ebony. It might be a good choice for the Zeta.

Meanwhile here are some notes I've made on the breed.

MK II double grommet motor suspension is a definite upgrade over the original single grommet motor suspension. For those with a mk1, it is worthwhile to make the conversion.

The 'non-magnetic' platter was optional even on the mk1 models. Look close at the platter used on the TD135 and realize that this is the same platter offered as the 'non-magnetic option' only it was adapted to fit the larger TD124 14mm bearing. Also, the non-mag platter was cast from a zinc alloy with a product name called Zamac. If you want an exact chemical composition of the alloy this can easily be found via google. Not aluminum. There never was an aluminum platter for the TD124, any mark.

20 wt seems to be the magic viscosity for motor and bearing, but other folks use different oils and weights and report different findings. Me, I'm a traditionalist. 20 wt turbine oil for me.

Belts have become a thorny issue on all of the vintage Thorens models. In the case of the belt drive models like the Td150/160/125 etc, the current belt offered by Thorens Export does function correctly. This I have found through my own use. It is the aftermarket belts that tend to be too wide, too thick, wrong length and will over-tension the motor....causing excessive motor vibes to enter the motor plate. But....... on the TD124 I have had better luck using aftermarket belts. Example, the TD124 spec belt offered at Elex-Atelier seems to work well enough over the 60 hz pulley. Caution....it could very well be too tight over the 50 hz pulley. Width and thickness on that belt seems close to right. This observation I make after seeing 1/2 dozen TD124 models pass through my hands and observing which belts were on them when I received them. The Elex-Atelier belt is comparable to the thinnest/skinniest of belts I've seen. And that is likely closest to what works. Too tight = motor vibes. Too loose = pulley slip

Thanks for the feedback on the so-called Thorens belt being offered for the TD124 by Thorens Export. I'll save the money. $35.00 for a belt indeed. Just a glorified rubber band. We deserve better. Like maybe a nice ground belt of just the right width, length, thickness and elasticity. Is anybody listening....!

Did not know that the MkII E50 motor was 15 watt. The mk1 is rated at 10 watt. That could provide some additional, um, thrust...

The TD124 does indeed play quiet.....when the drivetrain is 100% that is. Not only is it pacey, dynamic and slammy, but it also can sound refined and detailed. Perhaps not detailed and airy in the same league as the better belt drives, but it does the authority and slam that they just can't do.

On the other hand, with a gunked up motor, rubber-caked pulley crown, tired belt, sloppy platter bearing, bent outer platter shell, it will indeed fail to deliver.

Mine's pretty close to 100%, so I'm keeping it.

-Steve

Hi Steve,

Very nice table.. I've been working on mine for a little over a month now after it sat for a few weeks waiting for the replacement/upgrade parts to arrive. All I can say is I have found my little bit of audio nirvana.. It's in daily use now, I suspect in a short period of time I will have put more hours on it than the original owner..

It's in daily use now, I suspect in a short period of time I will have put more hours on it than the original owner..

I am planning on a slate plinth in the not too distant future. Future plans include the Schopper platter to replace the Zamac alloy platter. (I'm guilty I knew about this and referred to it as AL anyway, I had understood it was a zinc alloy, but conveniently forgot.) This platter really rings like a bell, and in the mean time I will probably try to damp it just a little.

Interestingly I find I prefer the oem mat to the two aftermarket ones I have tried. Something was lost in this case seemingly the leading edge of transients, and a lot of HF detail.

I'm somewhat amused by the fact that this turntable has a "warm up time" as it does not run at exactly the set speed until it is warmed up, in fact when very cold it cannot even be adjusted to run at the correct speed although it is very close, once warm it is dead on and has lots of adjustment range. I have found that once properly set warm it will come back to the correct speed without the need for readjustment so I just don't worry about it.. The heavy lubricant is definitely the culprit here, some brag that their platters spin for 90 seconds or more, mine manages around 45 seconds with 20wt oil in the main bearing. Lighter oils would increase that but might result in more bearing noise, mine is unworn and very tight..

I'm still waiting for the turntablebasics belt to show up, their published measurements are closer to my belt than any of the others I have looked at. They are very slow, and don't apparently respond to email, but people have good things to say about their belts.

I wish I had picked up a TD-124 a number of years ago, I came very close to abandoning vinyl because nothing I tried sounded close to right. This table was actually promised to me nearly 9yrs ago, and had I known what I was waiting for I would have been chomping at the bit rather more than I have, although the last week of wait was a bit agonizing..

Very nice table.. I've been working on mine for a little over a month now after it sat for a few weeks waiting for the replacement/upgrade parts to arrive. All I can say is I have found my little bit of audio nirvana..

I am planning on a slate plinth in the not too distant future. Future plans include the Schopper platter to replace the Zamac alloy platter. (I'm guilty I knew about this and referred to it as AL anyway, I had understood it was a zinc alloy, but conveniently forgot.) This platter really rings like a bell, and in the mean time I will probably try to damp it just a little.

Interestingly I find I prefer the oem mat to the two aftermarket ones I have tried. Something was lost in this case seemingly the leading edge of transients, and a lot of HF detail.

I'm somewhat amused by the fact that this turntable has a "warm up time" as it does not run at exactly the set speed until it is warmed up, in fact when very cold it cannot even be adjusted to run at the correct speed although it is very close, once warm it is dead on and has lots of adjustment range. I have found that once properly set warm it will come back to the correct speed without the need for readjustment so I just don't worry about it.. The heavy lubricant is definitely the culprit here, some brag that their platters spin for 90 seconds or more, mine manages around 45 seconds with 20wt oil in the main bearing. Lighter oils would increase that but might result in more bearing noise, mine is unworn and very tight..

I'm still waiting for the turntablebasics belt to show up, their published measurements are closer to my belt than any of the others I have looked at. They are very slow, and don't apparently respond to email, but people have good things to say about their belts.

I wish I had picked up a TD-124 a number of years ago, I came very close to abandoning vinyl because nothing I tried sounded close to right. This table was actually promised to me nearly 9yrs ago, and had I known what I was waiting for I would have been chomping at the bit rather more than I have, although the last week of wait was a bit agonizing..

Last edited:

re: slate. Yes. There is something about the slate that works really well as a TT plinth material. I have also tried a slate armboard, but using a different tonearm from what I use now. Interesting material.

re: Schopper non-mag platter. Please keep us posted on how this works out for you when you do make the plunge. They say it is a Grey iron with a high graphite content. Probably very messy to machine, with lots of fine black dust getting all over the shop.....but as a platter, excellent stable material for the job. The Schopper product looks very good in the photos.

re: warm up time.

Mine too. Although it improved dramatically after the motor overhaul. And after I switched to 20 wt. lube. At this point I have close to correct speed in about 4 - 6 platter rpms on a cold start. Takes about a minute for the speed to lock in stable. In summer anyway. Winter room temperature is about 4 - 6 degrees cooler and that does cause the TT to take just a few more seconds to get up to speed. Still, it is quite good compared to what it was before I worked on it.

I don't worry too much about coast down times. Although I think I measured it on my first TD124 rebuild when I had replaced bushings and thrust. In the 40 to 60 second range. The funny thing is that a platter bearing with somewhat worn bushings will allow even longer coast down times than one that is operating with spec-correct clearances and lube viscosity.

I'll be interested to find out how that TT basics belt conforms to the needs of the Td124. An inexpensive belt that meets the requirements would be very welcome over here.

I also play a belt drive TT in the same system. Kind of like having a different TT for different records kind of thing.

This one doesn't have the authority or ability to cause the drums to leap out of the speakers the same way the TD124 does, but it is quite punchy, absolutely pitch correct with excellent 'prat'. Toe tappin', feet moving pace.....and it handles the delicate bits of classical music with a little more grace and definition. With these two players..., one doing one thing better, the other doing a different thing better,... I'm pretty happy......for now.

-Steve

re: Schopper non-mag platter. Please keep us posted on how this works out for you when you do make the plunge. They say it is a Grey iron with a high graphite content. Probably very messy to machine, with lots of fine black dust getting all over the shop.....but as a platter, excellent stable material for the job. The Schopper product looks very good in the photos.

re: warm up time.

Mine too. Although it improved dramatically after the motor overhaul. And after I switched to 20 wt. lube. At this point I have close to correct speed in about 4 - 6 platter rpms on a cold start. Takes about a minute for the speed to lock in stable. In summer anyway. Winter room temperature is about 4 - 6 degrees cooler and that does cause the TT to take just a few more seconds to get up to speed. Still, it is quite good compared to what it was before I worked on it.

I don't worry too much about coast down times. Although I think I measured it on my first TD124 rebuild when I had replaced bushings and thrust. In the 40 to 60 second range. The funny thing is that a platter bearing with somewhat worn bushings will allow even longer coast down times than one that is operating with spec-correct clearances and lube viscosity.

I'll be interested to find out how that TT basics belt conforms to the needs of the Td124. An inexpensive belt that meets the requirements would be very welcome over here.

I also play a belt drive TT in the same system. Kind of like having a different TT for different records kind of thing.

This one doesn't have the authority or ability to cause the drums to leap out of the speakers the same way the TD124 does, but it is quite punchy, absolutely pitch correct with excellent 'prat'. Toe tappin', feet moving pace.....and it handles the delicate bits of classical music with a little more grace and definition. With these two players..., one doing one thing better, the other doing a different thing better,... I'm pretty happy......for now.

-Steve

Last edited:

I'll keep my fingers crossed on that belt, but after no response to email and waiting 2 1/2 weeks I'm a little concerned. I'm going to keep looking for other sources that offer comparable belts.

The Thorens belt was a major disappointment, and I'll only use it if the original 43yr old belt gives up - which in daily use over the last few week has not yet shown any signs of excessive stretching or other causes of concern.

You touched on the controversy surrounding the belts on this table. It is a major concern until I locate a supply of acceptable belts. I'll be sure to share anything I find out. I'm keeping my fingers crossed as this is the one potential fly in the ointment..

LF noise from bad belts and other noise sources in this table could be a serious problem considering the fact that my system plays down to 30Hz and resolves well. I can hear hints of record cutter rumble on a recording I am currently listening to for example.. It's a budget Mercury Wing recording of Respighi's Pines and Fountains of Rome. The Chesky reissue of an RCA LSC recording of the same music (different orchestra and venue) has no such noise. Actually this is a fairly dreadful recording - wondering why I am listening to it as I write this.. I won't be playing the other side..

It's much warmer here today, and the TT came up to speed very quickly when I turned it on. Generally it takes just one revolution to come up to within a couple of % or less of set speed, and then the table has to warm up the rest of the way for it to be dead on. Tyoically this takes about 5 - 10 minutes depending on ambient temperature.

I am still impressed by the very low noise floor, presumably the gel motor mounts and bushings are helping here. The only thing I hear is tracing noise, the noise floor whilst undoubtedly not as low as the SME 20/2 it replaced is far lower apparently than the noise levels on the disks themselves. I am not aware of any increase in noise levels at all, although I can no longer make that comparison.

I have only this table, and will work to demonstrably improve it over time, without hopefully compromising its characteristic sound as this is evidently what I like about it. Clearly a great synergy between it, the arm, and the cartridge as well as the rather strange electronics driving my equally unusual speaker system. (Some Japanese audiophiles would probably recognize this system as somewhat familiar, if not the results. Sort of a happy accident actually.)

I expect reports will continue on a regular basis for a while, and I will definitely write all about the Schopper platter experience when I get it. Much penny scraping will be required..

Your other TT looks quite nice as well.

The Thorens belt was a major disappointment, and I'll only use it if the original 43yr old belt gives up - which in daily use over the last few week has not yet shown any signs of excessive stretching or other causes of concern.

You touched on the controversy surrounding the belts on this table. It is a major concern until I locate a supply of acceptable belts. I'll be sure to share anything I find out. I'm keeping my fingers crossed as this is the one potential fly in the ointment..

LF noise from bad belts and other noise sources in this table could be a serious problem considering the fact that my system plays down to 30Hz and resolves well. I can hear hints of record cutter rumble on a recording I am currently listening to for example.. It's a budget Mercury Wing recording of Respighi's Pines and Fountains of Rome. The Chesky reissue of an RCA LSC recording of the same music (different orchestra and venue) has no such noise. Actually this is a fairly dreadful recording - wondering why I am listening to it as I write this.. I won't be playing the other side..

It's much warmer here today, and the TT came up to speed very quickly when I turned it on. Generally it takes just one revolution to come up to within a couple of % or less of set speed, and then the table has to warm up the rest of the way for it to be dead on. Tyoically this takes about 5 - 10 minutes depending on ambient temperature.

I am still impressed by the very low noise floor, presumably the gel motor mounts and bushings are helping here. The only thing I hear is tracing noise, the noise floor whilst undoubtedly not as low as the SME 20/2 it replaced is far lower apparently than the noise levels on the disks themselves. I am not aware of any increase in noise levels at all, although I can no longer make that comparison.

I have only this table, and will work to demonstrably improve it over time, without hopefully compromising its characteristic sound as this is evidently what I like about it. Clearly a great synergy between it, the arm, and the cartridge as well as the rather strange electronics driving my equally unusual speaker system. (Some Japanese audiophiles would probably recognize this system as somewhat familiar, if not the results. Sort of a happy accident actually.)

I expect reports will continue on a regular basis for a while, and I will definitely write all about the Schopper platter experience when I get it. Much penny scraping will be required..

Your other TT looks quite nice as well.

Last edited:

One way to revive, or extend, the life of an old belt is to soak the thing in boiling water for a few minutes.

I am not so sure about using talcum powder in this application with the TD124. Although I have tried it with no obvious effect. I think the suggestion about using talcum powder on a clean belt comes from the suspended sub-chassis belt-drive crowd that were worried about having too much belt 'stick' and the associated 'slap' that might come about on the unloaded side of the pulley. All just conjecture. No one has proven this mythology that I know of. Folklore.

re: LF noise. My speakers will just barely reproduce 30hz notes. Example, the continuous organ pedal note in the opening bars of Also Sprach Zarathustra. Thinking of the Bohm/BSO performance as was used in the 2001 A Space Odyssey Sound Track Lp. Although other performances get enough ooomph into this part of it. Thinking of the Reiner/CSO performance that I have on a MOFI Lp. Point is... on this piece my system will reproduce this note...although not to the same gut rattling intensity that I first heard when in the Bagdad Theater on NE Stark street Portland, Oregon 1969. Now there is a hi-fi memory that sticks with me. Magnetic film audio played through VOT gear in the appropriate auditorium. I suspect records can't manage this.

The TD124 plays this cleanly, and with more authority than any other deck I've had in here. I'm sure the arm and cartridge and phono stage play into this. The other observation is that I hear no obvious LF noise while playing this.

I don't have the Merc record you mention. I do have some records that exhibit some rumble that most likely exists within the lathe lacquer master itself. Older 1950's recordings. From time to time this has been of some concern to me until I was able to demonstrate, as you did, that the home system does not rumble by playing a different record at the same volume level and listening for it.

I'm still using the belt that I sourced from Elex. Although they get $25.00 for that belt. It would be nice if we could source the same exact belt for a much lower price. Worth experimenting for.

re: motor grommets.

I've tried three different materials in TD124 motor grommets.

The ones you get from Mirko (sq38s on ebay)...which appear close to rubber in hardness/texture.

The FD81 kit from Schopper (Octave Audio-USA is the NA distributor/dealer).

And the silicone gel grommets from Vibration-Mounts.com. I assume it is the latter grommets that are being offered by the other ebay seller, jec965 These can also be sourced directly from Vibration Mounts. btw.

In this group of three, I prefer the FD81 kit from Schopper. That grommet is some sort of poly (urethane?) material that is midway between rubber and the silicone gel in hardness. I think it provides just the right amount of stiffness/versus vibration dampening for this application. The result being a 'perceived better sense of pace correctness when compared to the silicone gel bushings. I 'intuit' that the silicone gel bushings allow the motor to twist and squirm a little too much under the torque loading of operation. Of course this is not measured in any way. Just my observation based on using and listening. And that is why I choose not to use these for the near term.

(disclaimer. I am not affiliated in any way with the above three. And I would buy from any of them should they have the parts I need)

Other notes: Silicon Ceramic Bearing Balls are commonly sourced from Boca Bearing in Florida. Probably, the best prices on these are had from them. Cheaper than McMaster-Carr. Easy to deal with online and I have experienced fast shipping from them.

-Steve

I am not so sure about using talcum powder in this application with the TD124. Although I have tried it with no obvious effect. I think the suggestion about using talcum powder on a clean belt comes from the suspended sub-chassis belt-drive crowd that were worried about having too much belt 'stick' and the associated 'slap' that might come about on the unloaded side of the pulley. All just conjecture. No one has proven this mythology that I know of. Folklore.

re: LF noise. My speakers will just barely reproduce 30hz notes. Example, the continuous organ pedal note in the opening bars of Also Sprach Zarathustra. Thinking of the Bohm/BSO performance as was used in the 2001 A Space Odyssey Sound Track Lp. Although other performances get enough ooomph into this part of it. Thinking of the Reiner/CSO performance that I have on a MOFI Lp. Point is... on this piece my system will reproduce this note...although not to the same gut rattling intensity that I first heard when in the Bagdad Theater on NE Stark street Portland, Oregon 1969. Now there is a hi-fi memory that sticks with me. Magnetic film audio played through VOT gear in the appropriate auditorium. I suspect records can't manage this.

The TD124 plays this cleanly, and with more authority than any other deck I've had in here. I'm sure the arm and cartridge and phono stage play into this. The other observation is that I hear no obvious LF noise while playing this.

I don't have the Merc record you mention. I do have some records that exhibit some rumble that most likely exists within the lathe lacquer master itself. Older 1950's recordings. From time to time this has been of some concern to me until I was able to demonstrate, as you did, that the home system does not rumble by playing a different record at the same volume level and listening for it.

I'm still using the belt that I sourced from Elex. Although they get $25.00 for that belt. It would be nice if we could source the same exact belt for a much lower price. Worth experimenting for.

re: motor grommets.

I've tried three different materials in TD124 motor grommets.

The ones you get from Mirko (sq38s on ebay)...which appear close to rubber in hardness/texture.

The FD81 kit from Schopper (Octave Audio-USA is the NA distributor/dealer).

And the silicone gel grommets from Vibration-Mounts.com. I assume it is the latter grommets that are being offered by the other ebay seller, jec965 These can also be sourced directly from Vibration Mounts. btw.

In this group of three, I prefer the FD81 kit from Schopper. That grommet is some sort of poly (urethane?) material that is midway between rubber and the silicone gel in hardness. I think it provides just the right amount of stiffness/versus vibration dampening for this application. The result being a 'perceived better sense of pace correctness when compared to the silicone gel bushings. I 'intuit' that the silicone gel bushings allow the motor to twist and squirm a little too much under the torque loading of operation. Of course this is not measured in any way. Just my observation based on using and listening. And that is why I choose not to use these for the near term.

(disclaimer. I am not affiliated in any way with the above three. And I would buy from any of them should they have the parts I need)

Other notes: Silicon Ceramic Bearing Balls are commonly sourced from Boca Bearing in Florida. Probably, the best prices on these are had from them. Cheaper than McMaster-Carr. Easy to deal with online and I have experienced fast shipping from them.

-Steve

Hey Steve,

Actually the talcum powder recommendation comes straight from Thorens, it is mentioned on p.14 of the MKII owner's manual and is recommended to help quiet the table.

Interesting comments on the motor bushings - i'm pretty happy with the gel ones for the moment, but I'll revisit this at some point out of curiosity.. I'll spring for the Schopper kit at some point. The mounts JEC965 sells are sourced from Japan and don't appear to be similar to anything I could find at Vibration Mounts, but OTOH I only spent a couple of minutes browsing their site. I can say they seem extremely effective and have no negative effect I can hear.

I've found that the little Bren1 record clamp I purchased does very good things in terms of bass authority, things just sound a little better delineated than without. The other benefit of course is that it doesn't interfere with my cartridge and headshell. No interference with clutch operation - I wouldn't be without at this point. I recommend it..

Table is very quiet. The disc I mentioned has other problems as well as the rather significant level of rumble that seems to have been recorded on it. Seems like a bad reissue, audible distortion at times, and an overall glassiness to the sound. Competent Orchestra (Minnesota) and a big name conductor.. Shame, it is now in the tbd bin (to be disposed)..

I'll check out Boca bearing..

Actually the talcum powder recommendation comes straight from Thorens, it is mentioned on p.14 of the MKII owner's manual and is recommended to help quiet the table.

Interesting comments on the motor bushings - i'm pretty happy with the gel ones for the moment, but I'll revisit this at some point out of curiosity.. I'll spring for the Schopper kit at some point. The mounts JEC965 sells are sourced from Japan and don't appear to be similar to anything I could find at Vibration Mounts, but OTOH I only spent a couple of minutes browsing their site. I can say they seem extremely effective and have no negative effect I can hear.

I've found that the little Bren1 record clamp I purchased does very good things in terms of bass authority, things just sound a little better delineated than without. The other benefit of course is that it doesn't interfere with my cartridge and headshell. No interference with clutch operation - I wouldn't be without at this point. I recommend it..

Table is very quiet. The disc I mentioned has other problems as well as the rather significant level of rumble that seems to have been recorded on it. Seems like a bad reissue, audible distortion at times, and an overall glassiness to the sound. Competent Orchestra (Minnesota) and a big name conductor.. Shame, it is now in the tbd bin (to be disposed)..

I'll check out Boca bearing..

Last edited:

Vibration Mounts eStore Cylindrical Rubber Anti Vibration Mounts Rubber Neoprene Urethane Sorbothane Silicone Gel Ring Mounts

The above link should match up to photos of the motor grommets in your photos.

As we try different grommets, it becomes possible to compare the effects. Basically, any of the ones currently available to us will be an improvement over the 40 yr old melted ones that we typically see prior to beginning a project. At least there is a choice.

The ones from Mirko work well too. They are the firmest/hardest of the three types I've tried. Using a stethoscope, these seem to keep the vibes out of the chassis as well as any of the others. I'd imagine one would have to get more serious about measurements, by electronic means with recorded values, before we could really know which ones work the best. And it might be useful to measure wow/flutter as well as rumble while making these comparisons.

I've also been using new replacement idler wheels from Mirko. These aren't perfect, but they do have fresh rubber, new bronze bushings and spin concentric. I have found, in the three Mirko idlers that I have tried, that it is necessary to adjust height of the idler wheel to match the step pulley lands. Or in the case of the MkII, it is easy to adjust vertical position of the step pulley to match up to the idler wheel.

But the results have been audibly better in my experiences. 40 yr old idler rubber versus new idler rubber....with fresh bronze bushings.

-Steve

The above link should match up to photos of the motor grommets in your photos.

As we try different grommets, it becomes possible to compare the effects. Basically, any of the ones currently available to us will be an improvement over the 40 yr old melted ones that we typically see prior to beginning a project. At least there is a choice.

The ones from Mirko work well too. They are the firmest/hardest of the three types I've tried. Using a stethoscope, these seem to keep the vibes out of the chassis as well as any of the others. I'd imagine one would have to get more serious about measurements, by electronic means with recorded values, before we could really know which ones work the best. And it might be useful to measure wow/flutter as well as rumble while making these comparisons.

I've also been using new replacement idler wheels from Mirko. These aren't perfect, but they do have fresh rubber, new bronze bushings and spin concentric. I have found, in the three Mirko idlers that I have tried, that it is necessary to adjust height of the idler wheel to match the step pulley lands. Or in the case of the MkII, it is easy to adjust vertical position of the step pulley to match up to the idler wheel.

But the results have been audibly better in my experiences. 40 yr old idler rubber versus new idler rubber....with fresh bronze bushings.

-Steve

FD81 kit from Schopper

Steve,

Schopper sells their long motor mounts/bushing kit for about $200. That's a lot of money. Someone on ebay sells the longer MKII motor rods for $125 or BO but no bushings. Do you know if Schopper sells only the motor mount bushings? If not, where can they be sourced? I currently have the gels on my MkI motor. Your observations and comments on their possible behavior got me thinking.

Thanks,

David

Steve,

Schopper sells their long motor mounts/bushing kit for about $200. That's a lot of money. Someone on ebay sells the longer MKII motor rods for $125 or BO but no bushings. Do you know if Schopper sells only the motor mount bushings? If not, where can they be sourced? I currently have the gels on my MkI motor. Your observations and comments on their possible behavior got me thinking.

Thanks,

David

Vibration Mounts eStore Cylindrical Rubber Anti Vibration Mounts Rubber Neoprene Urethane Sorbothane Silicone Gel Ring Mounts

The above link should match up to photos of the motor grommets in your photos.

<snip>

-Steve

Hi Steve,

I looked after your post referencing Vibration Mounts and the "Metric Spring Mounts" are the closest, but they aren't quite the same. Here is a link (currently down, wasn't a couple of weeks ago) to the manufacturer: http://www.geltec.co.jp/english/product/pro_02.htm It is the A2 type formulation.. V10261MA2 is the part number for these bushings, and currently it is not available using the search tool at vibration mounts. The appearance is a quite bit different too. They are a more squared off than the parts shown and don't have the collar either.

Mirko's idlers are somewhat controversial, but I was thinking at some point i would probably spring for one of these although for the moment the original seems to work fine.

The cold weather motor performance is a bit concerning. Can't wait for it to get really cold here as I expect the motor will then not start at all..

I guess I should expect this with a table that sat unused for 4 decades..

Our power here is a badly clipped sinewave, so bad in fact that 120V decorative neon lamps don't work here at all without a step up transformer. Line voltage measures over 118Vrms all the time, but the waveform is distorted - thinking this might have impact on start up torque.

I employ voltage regulation in all of my electronics so as long as they don't drop the performance of my signal chain is not affected. I only noticed the issue when my wife complained that some of our neon lamps no longer worked and i investigated - this was after some of the transformers in our neighborhood were replaced with modern ones. (Apparently the new ones run on the verge of core saturation or perhaps are saturating on the peak..) The waveform is bad at all times of the day..

I'm going to order a belt from Octave Audio as I would expect given their TD-124 expertise that this belt fits and runs quietly. Hopefully this is not the same as the Thorens belt I purchased recently from Thakker which clearly has an issue.

Last edited:

Steve,

Schopper sells their long motor mounts/bushing kit for about $200. That's a lot of money. Someone on ebay sells the longer MKII motor rods for $125 or BO but no bushings. Do you know if Schopper sells only the motor mount bushings? If not, where can they be sourced? I currently have the gels on my MkI motor. Your observations and comments on their possible behavior got me thinking.

Thanks,

David

The bushings are expensive enough that it might make sense to get the kit if you are going for the long motor mount kit..

Several sellers offer alternative bushings to Schopper on eBay..

Octave Audio has the bushings separately here:

Octave Audio - Motor-Damping-Set FD 81

These are the Schopper parts..

Mirko sells a similar but not identical part.. (See Steve's post for more on this)

Kevinkr,

Thanks for the link. They are $50 for 6 grommets.

The gel grommets would cost about $30 to $50 for 6. I may spend the bucks on the Octave's to compare them with the gels

One more question Kevinkr, after you rebuilt your motor, how hot does it get? On my rebuilt motor, it gets so hot I can not leave my finger on the housing for more a second or so. It is very quiet and holds its speed with no problems.

Thanks,

David

Bolt Mounts – Silicone Gel Type

Thanks for the link. They are $50 for 6 grommets.

An externally hosted image should be here but it was not working when we last tested it.

The gel grommets would cost about $30 to $50 for 6. I may spend the bucks on the Octave's to compare them with the gels

An externally hosted image should be here but it was not working when we last tested it.

One more question Kevinkr, after you rebuilt your motor, how hot does it get? On my rebuilt motor, it gets so hot I can not leave my finger on the housing for more a second or so. It is very quiet and holds its speed with no problems.

Thanks,

David

Bolt Mounts – Silicone Gel Type

Last edited:

Steve,

Schopper sells their long motor mounts/bushing kit for about $200. That's a lot of money. Someone on ebay sells the longer MKII motor rods for $125 or BO but no bushings. Do you know if Schopper sells only the motor mount bushings? If not, where can they be sourced? I currently have the gels on my MkI motor. Your observations and comments on their possible behavior got me thinking.

Thanks,

David

Hi David.

Mirko (sq38s) is the one on Ebay selling a MKII upgrade kit. His kit includes the grommets, clips and washers for $125. I have purchased a few of these kits and they install and work fine. It is definitely a savings over the 200 dollar Schopper kit. Although Schopper, I think, has a more interesting set of grommets.

Initially I had purchased just the grommet kit only from Schopper (# FD81) when I wanted to try one of those Papst Aussenlauffer motors on my TD124. I didn't like the sound of the TT with the Aussenlauffer motor and went back to the E50, but then purchased a MKII conversion kit from Mirko to update my MK1 motor suspension. That is why I have an extra 6 grommets around.

I have also installed a couple of MKII conversion kits on TD124 players for other people. The machining on the posts is good. The grommets, clips and washers fit correctly.

Hi Steve,

I looked after your post referencing Vibration Mounts and the "Metric Spring Mounts" are the closest, but they aren't quite the same. Here is a link (currently down, wasn't a couple of weeks ago) to the manufacturer: http://www.geltec.co.jp/english/product/pro_02.htm It is the A2 type formulation.. V10261MA2 is the part number for these bushings, and currently it is not available using the search tool at vibration mounts. The appearance is a quite bit different too. They are a more squared off than the parts shown and don't have the collar either.

ƒg�[ƒŒƒ“ƒX THORENS model TD 124

re: above link. I remember studying the above page and another page he made showing his motor overhaul. He referenced Geltec Co. as the source for his silicon gel bushings. So I made contact with Geltec.co in Japan by email and got a reply from one of their sales people. They are the ones who directed me to vibration mounts as the outlet in North America for their silicone gel bushing product. At one time I was able to source the A2 silicon gel from Vibration Mounts. Here's a cross section view of the bushing as it would be used on the TD124:

An externally hosted image should be here but it was not working when we last tested it.

The compliance factor of the bushing is indicated by the part number that either ends in numeral 1 or numeral 2. So we would choose part number:

V10Z61MA2 that has an ID of .16 inches. The brass collar is removed from the id before using. Obviously these bushings weren't exactly designed for our application, but seem to fit up well enough. I did mention that I'm not exactly crazy about using these bushings?!!

re: powder on belt in the mkII manual.

Ahhh. So Thorens themselves were perpetuating that myth..

re: motor heat and motor vibes.

A freshly assembled motor tends to run extra warm until the upper and lower motor bearings are in optimal alignment. This I have found through my own trial and error. The better the alignment, the cooler it runs. Also, the quicker the TT comes up to speed.

I do run a freshened motor in for a week or thereabouts, then re-align the bushings again. This seems to result in a very stable, quiet and reasonably cool running motor.

I"ve been using 20 wt lube for a couple of years and prefer it year around.

re: platter mats.

I've been using the original rubber mat after cleaning the thing in the kitchen sink using warm water and suds and soft brush. Then pouring boiling water over the rubber mat to further soften it. Seems to freshen it up a bit. I have also used auxiliary mats on top of the rubber mat in order to distance the moving coil cartridge above the iron platter. After a time I found that with the cartridges I'm using (DL 103R, Shelter 501-II, Ortofon Jubilee) that there wasn't any problem with the magnet pulling the cartridge down toward the platter. This I tested using a vtf scale at various points along the arc path. So I stopped using the auxiliary mat and found that there is indeed a sharper dynamic and better low frequency authority available by simply using the original mat. IN my case, noise floor is still quite low and not noticeable.

That much said, I do feel that there is room for someone to develop a better mat for this TT. IT is just that the mat will need to be of the kind that fits exactly like the original. That is it is clamped into place by the 45 adapter/collar.

-Steve

Last edited:

Kevinkr,

<snip>

One more question Kevinkr, after you rebuilt your motor, how hot does it get? On my rebuilt motor, it gets so hot I can not leave my finger on the housing for more a second or so. It is very quiet and holds its speed with no problems.

Thanks,

David

@ David

It ran quite hot for the first few hours after the rebuild, and is still rather uncomfortable to the touch after an hour or so of operation, although not nearly as hot. My line voltage averages 118V..

Steve's comments about bearing alignment are spot on, I also found this to be quite true.

Noting that I have not tried this: The turntable is normally set to the 100V - 120V setting for North America, in the event that your line is constantly and appreciably higher than this you might want to try the 125 - 150V motor tap instead. Note that torque will probably be reduced to some extent, and the calibration of the eddy current brake might not allow you to run at the proper speed. Might also affect some of that drive the TT is noted for. Try at own risk, and don't mess with the eddy current brake calibration when the motor and table is cold!

@ Steve

Interesting comments/conclusions on the mat. I have reluctantly (maybe not so reluctantly) come to the conclusion that the stock mat is pretty good if not quite perfect. I think I am getting used to its colorations, and for the moment I find it satisfactory. I'd be very interested in hearing about further insights in this area if you have them. Again both Mirko and Schopper offer replacement mats, so far I have not been able to find any evidence as to whether or not they sound better than the stock mat. Your suggestions for mat reconditioning sound good, and I think I might give the boiling water idea a try as well. (I did the rest as you did)

I have noted that Schopper sells an "improved" top platter and am mildly curious as to whether it in any way improves on the original - mine is perfect so there is no impetus to replace it.

FWIW I think I will try the Schopper motor isolation mounts at some point, so far I have not had any issues with the current ones. Based on measurements however I did install the big end of the geltec bushing on the motor end and the little one (which is tiny) in the groove on the top of the chassis. The second bushing IIRC was installed with the same orientation, but I think this is not critical. I did not observe any more deflection of the motor assembly with the belt installed than I did with the older bushings which have not hardened up, but probably aren't ideal either. (I still have them) One thing of note is that the motor height might not be absolutely identical with the stock bushings and I did end up tweaking the motor pulley height slightly in order to make sure it and the intermediate pulley line up properly. I'm of mixed feelings about this, but I haven't noted any problems either.

With regard to the talc issue my suspicion is that it would be of some benefit with the very stiff modern Thorens CB965 replacement belt in reducing the noise made as the belt enters and leaves the circumference of the intermediate pulley as in theory it should reduce the belt adhesion as it leaves the end of the pulley.. This is of course a complete swag as I haven't tried it yet.

One thing I think I haven't emphasized is that I really appreciate the fact the magnetic fields from the motor do not interfere with the cartridge at any point during play. This was a huge problem with the TD-125 towards the inner half of a record and was the one reason why ultimately I decided after quite a few years of use that it was unsatisfactory, listening to a properly running TD-124 provided lots of other justifications beyond this..

Last edited:

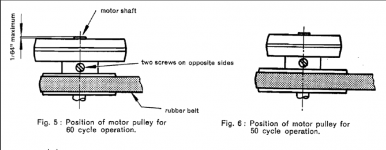

Touching further on the motor pulley alignment issue I have attached a capture of the Thorens TD-124 MKII owner's manual (p.7) on pulley alignment. Note that they indicate that the pulley may be seated as much as 1/64" below the top of the shaft..

The two decks I have looked at (both MKII) had pulleys mounted with the shaft recessed by 1/10" or more. (Not disturbed since built)

What is important is that belt rides on the center of both pulleys..

When (re)installing the pulley tighten the black grub screw first and then the silver one.

The two decks I have looked at (both MKII) had pulleys mounted with the shaft recessed by 1/10" or more. (Not disturbed since built)

What is important is that belt rides on the center of both pulleys..

When (re)installing the pulley tighten the black grub screw first and then the silver one.

Attachments

Last edited:

Touching further on the motor pulley alignment issue I have attached a capture of the Thorens TD-124 MKII owner's manual (p.7) on pulley alignment. Note that they indicate that the pulley may be seated as much as 1/64" below the top of the shaft..

The two decks I have looked at (both MKII) had pulleys mounted with the shaft recessed by 1/10" or more. (Not disturbed since built)

What is important is that belt rides on the center of both pulleys..

When (re)installing the pulley tighten the black grub screw first and then the silver one.

Right. What is important is that the belt rides on the center of both pulleys. Although it will unless there is a really large height misalignment between the driving and driven pulley crowns. The crowned shape of the pulleys tends to retain the belt on crown center.

The 1/64th maximum feature is probably given as a general rule of thumb. Much lower and the pulley scrapes against that thin aluminum dust cover. A recessed shaft would indicate that the pulley is seated higher on the shaft than is shown in the illustration--- and is within that dimensional tolerance. Ideally, both the driving and driven pulley crowns will share the same plane.

All of this will come into play as one tinkers around with adjusting the step pulley and idler wheel alignment when one changes to a different idler wheel.

-Steve

The turntablebasics belt came today and measured more or less similarly to the Thakker belt, except that it is 0.030" thick and appears if anything to be somewhat less pliant than the Thakker. I haven't run the new belt yet so I will report back when I do. I'm in no rush to do it.

- Home

- Source & Line

- Analogue Source

- Restoring and Improving A Thorens TD-124 MKII