On no!That will raise the price of secondhand LT-5Vs and will limit my supply of spare parts!

For lots of different turntables......

Sheesh.

this picture in my head

Think torque, total momentum of the three bronze masses is always zero.

(things would be different if the masses would be engine pistons, 3 and 4 cilinder engines are basically inferior)

Last edited:

the latest bookie on turntables overhere,

The one by Richard de Gruyl? Can you recommend it? Does it go as far as discussing DIY tables and arms?

Thanks

LAST EPISODE

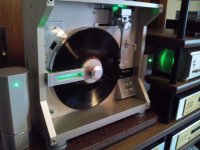

Before taking it home, i took careful measurements for a 3 cm thick granite base.

I decided on African red granite with a surface of 70 X 30 cm.

I handpicked the piece to be cut and it was in my hands ready and polished

within the week.

A wooden shelf on the right side of the turntable had to be cut in a semicircle way

so that one motor could fit in-space in my rack is limited!

With a jig that i use for cutting frames for loudspeakers it was an easy job...Done!

I spent a whole afternoon leveling my audio rack to perfection!

The turntable had adjustable feet but i would prefer leaving them in an up-tight position.

Finally everything was ready...

With the help of two friends (that i ordered to take off their rings,watches and buckled belts)

the main body was placed on a MDF board and then to the back seat of a car with me stabilizing it.

Rest of the parts (motors,cups,PS,plexi covers) were packaged separately and placed in the trunk.

I am unlucky enough to live on the second floor with no elevator...

It is a very hard job to lift something so massive for two floors in mid summer.

We were soaking wet when we arrived on my apartment.

I just placed it there and left the final setting for the next morning.

I hardly slept...

It was Sunday morning and after having a cup of coffee, i started the setting up.

It took me an hour to measure the exact places of the chassis and two motors.

The belts rotate so close together that the two motors need absolutely perfect placing

so that they don't rub to each other.

Check of individual speeds:With the front double pot at middle position i dialed the perfect

33 and 45 speeds on each motor just by adjusting the master trimmer on the boards.

Then they both could be tailored with the front double trimmer.Done!

After another check on the leveling of the chassis it was time to set the tonearm right.

First i had to regulate a small rotating weight whithin the major arm weight,

so that the arm is aiming straight down to the center of the earth...

When this was set, with another screw at the side of the arm's base

i set the arms sensors so that they know where the "0" tracking error point is.

With my new headshell loaded with my trusty Van den Hul Condor and my favorite record on the plater

(Elly Ameling sings Bel canto) it was time to rotate the round micro-metric weight

on the face of the arm until it was absolutely parallel to the record.

That is point "0" on the tracking weight.I turned it to a 1.35 grams and double checked it with my digital scale.

Done!

A quick listen through the earphones to dial in the arms "taming" on the back said that things were looking promising...

It was time to close the back after a thorough cleaning and dusting off.

With the soft rubber flange attached, i had a nice,non rattling ,secure fit...Done...

Turned on the system for a thorough listen...

Started from Elly Ameling,to Dire Straits,to Daniel Lanois,to JJ Cale, to ZZtop,to Patricia Barber...

Heaven...

Construction details:Two years planning,prototyping,gathering donor tables and figuring out solutions for my "special needs".

Almost two years actually building this thing, from the moment of ordering the first CNC pieces till the Sunday

that it was in my home playing.

Around 50 trips (that's a lot of gas) to the CNC shop for discussing on CAD files,material selection,metal cutting

and finishing.

Around 900 euro for the three donor tables plus LT-1 tonearm plus Sony headshell(one LT-5V kept untouched)

Around 500 euro for prepping/painting material.

Around 100 euro for the inox screws/washers etc used in every phase of the assembling.

Around 100 euro for silicone sheets in various thicknesses.

A cool 3500 euro for CNC work, metals cost,bushing treatment,platter/subplatter balancing.

Around 200 euro for power/signal cables and termination.

Around 150 euro for Plexiglas covers.

Some hair lost /some went gray...

The table was weighted with the plexi in place and was found 67.5 kilos

The rotating mass (with a 180 gr record playing) is 6.2 kilos

Each motor tower (with motor) was weighted at 13.5 kilos

The PS box is 9.5 kilos.

The granite plate is another 24.5 kilos

Was it worth the cost and personal attention?

Yes!

Would i do it again?

Nope!

Before taking it home, i took careful measurements for a 3 cm thick granite base.

I decided on African red granite with a surface of 70 X 30 cm.

I handpicked the piece to be cut and it was in my hands ready and polished

within the week.

A wooden shelf on the right side of the turntable had to be cut in a semicircle way

so that one motor could fit in-space in my rack is limited!

With a jig that i use for cutting frames for loudspeakers it was an easy job...Done!

I spent a whole afternoon leveling my audio rack to perfection!

The turntable had adjustable feet but i would prefer leaving them in an up-tight position.

Finally everything was ready...

With the help of two friends (that i ordered to take off their rings,watches and buckled belts)

the main body was placed on a MDF board and then to the back seat of a car with me stabilizing it.

Rest of the parts (motors,cups,PS,plexi covers) were packaged separately and placed in the trunk.

I am unlucky enough to live on the second floor with no elevator...

It is a very hard job to lift something so massive for two floors in mid summer.

We were soaking wet when we arrived on my apartment.

I just placed it there and left the final setting for the next morning.

I hardly slept...

It was Sunday morning and after having a cup of coffee, i started the setting up.

It took me an hour to measure the exact places of the chassis and two motors.

The belts rotate so close together that the two motors need absolutely perfect placing

so that they don't rub to each other.

Check of individual speeds:With the front double pot at middle position i dialed the perfect

33 and 45 speeds on each motor just by adjusting the master trimmer on the boards.

Then they both could be tailored with the front double trimmer.Done!

After another check on the leveling of the chassis it was time to set the tonearm right.

First i had to regulate a small rotating weight whithin the major arm weight,

so that the arm is aiming straight down to the center of the earth...

When this was set, with another screw at the side of the arm's base

i set the arms sensors so that they know where the "0" tracking error point is.

With my new headshell loaded with my trusty Van den Hul Condor and my favorite record on the plater

(Elly Ameling sings Bel canto) it was time to rotate the round micro-metric weight

on the face of the arm until it was absolutely parallel to the record.

That is point "0" on the tracking weight.I turned it to a 1.35 grams and double checked it with my digital scale.

Done!

A quick listen through the earphones to dial in the arms "taming" on the back said that things were looking promising...

It was time to close the back after a thorough cleaning and dusting off.

With the soft rubber flange attached, i had a nice,non rattling ,secure fit...Done...

Turned on the system for a thorough listen...

Started from Elly Ameling,to Dire Straits,to Daniel Lanois,to JJ Cale, to ZZtop,to Patricia Barber...

Heaven...

Construction details:Two years planning,prototyping,gathering donor tables and figuring out solutions for my "special needs".

Almost two years actually building this thing, from the moment of ordering the first CNC pieces till the Sunday

that it was in my home playing.

Around 50 trips (that's a lot of gas) to the CNC shop for discussing on CAD files,material selection,metal cutting

and finishing.

Around 900 euro for the three donor tables plus LT-1 tonearm plus Sony headshell(one LT-5V kept untouched)

Around 500 euro for prepping/painting material.

Around 100 euro for the inox screws/washers etc used in every phase of the assembling.

Around 100 euro for silicone sheets in various thicknesses.

A cool 3500 euro for CNC work, metals cost,bushing treatment,platter/subplatter balancing.

Around 200 euro for power/signal cables and termination.

Around 150 euro for Plexiglas covers.

Some hair lost /some went gray...

The table was weighted with the plexi in place and was found 67.5 kilos

The rotating mass (with a 180 gr record playing) is 6.2 kilos

Each motor tower (with motor) was weighted at 13.5 kilos

The PS box is 9.5 kilos.

The granite plate is another 24.5 kilos

Was it worth the cost and personal attention?

Yes!

Would i do it again?

Nope!

Attachments

-

Photo0261.jpg168.6 KB · Views: 449

Photo0261.jpg168.6 KB · Views: 449 -

Photo0257.jpg175.9 KB · Views: 429

Photo0257.jpg175.9 KB · Views: 429 -

Photo0258.jpg188.1 KB · Views: 425

Photo0258.jpg188.1 KB · Views: 425 -

Photo0262.jpg169.1 KB · Views: 412

Photo0262.jpg169.1 KB · Views: 412 -

Photo0264.jpg165.9 KB · Views: 383

Photo0264.jpg165.9 KB · Views: 383 -

Photo0267.jpg194.6 KB · Views: 160

Photo0267.jpg194.6 KB · Views: 160 -

Photo0269.jpg217 KB · Views: 187

Photo0269.jpg217 KB · Views: 187 -

Photo0270.jpg197.1 KB · Views: 187

Photo0270.jpg197.1 KB · Views: 187 -

Photo0271.jpg183.5 KB · Views: 175

Photo0271.jpg183.5 KB · Views: 175 -

Photo0272.jpg189 KB · Views: 158

Photo0272.jpg189 KB · Views: 158

Classic feelings after a major project.Was it worth the cost and personal attention?

Yes!

Would i do it again?

Nope!

Well done.

I am thinking of doing something similar on a AKAI GX747 reel to reel machine.

Don't you think it would look great next to my LT?

I think that would be cool, but I'm wondering if you're not just a glutton for punishment.

However, you've done a superb job on the turntable and I have no doubt that you would approach the Akai in the same intelligent, methodical and comprehensive manner.

I'm sure that I'm not the only person here that would be following your progress if you decide to take on a R2R tapedeck!

Again, great work on the turntable...

Best Regards,

TerryO

I am thinking of doing something similar on a AKAI GX747 reel to reel machine.

Don't you think it would look great next to my LT?

Go-on.Do it.

When you do it as well as you did the Mitsu,it has to be regarded as a Homage.

Thanks for the encouragement!The only thing i'm not short of, is future plans.

A BIG speaker is next, complete with line arrays for ribbon tweeters and planar mids plus two 10" TL loaded woofers.

Active xover and 1000 Watts from five amps (two SS monos,two tube monos,one tube stereo) powering it.

Until Christmas i will have a separate diy space in the attic of my clinic and things will run much more smoothly from then on...

Of course i will post any new projects with the same meticulous manner.

A BIG speaker is next, complete with line arrays for ribbon tweeters and planar mids plus two 10" TL loaded woofers.

Active xover and 1000 Watts from five amps (two SS monos,two tube monos,one tube stereo) powering it.

Until Christmas i will have a separate diy space in the attic of my clinic and things will run much more smoothly from then on...

Of course i will post any new projects with the same meticulous manner.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- My last turntable!