This is just a feeler to see if anyone has a subchassis for this TT. I inherited it and while I love it, it has a badly warped subchassis. I can't see dropping 660$ for Oracle's replacement when in good condition this table is worth 500$-600$. I already have the subchassis relieved and epoxied so it is almost flat and true but with the added weight from the epoxy (1lb?)I am having trouble getting the suspension dialed in. I have installed the maintenance kit but I may have to order the next stronger springs to get it dialed in with the epoxied subchassis.

Thx in advance, Den

Thx in advance, Den

how to warp a sub-chassis...

Really? I have an old Alex and have never experienced this. A wooden sub-chassis such as those made for the Roksan Xerxes ("upgrade plinth") could be made pretty easily though. If too light in weight, mass can always be added.

A couple of things come to mind as perhaps a way of "fixing" your warped sub-chassis:

The idea is to relieve the (possible) cracks, and give someplace for the cracks to end.

If the sub-chassis is relieved in this manner, then all that maybe required is removal of the bearing, and a build up of the area surrounding the bearing with body filler. It will have to be sanded to level. Or use shim stock to correct any mis-alignment.

Adding a pound of epoxy in whatever distribution that is needed to effect a repair is not suitable, as the ability to correct for the weight of it may require more work than is practical.

On second thoughts maybe a Roksan style plinth may make a pretty reasonable replacement. If need be replace the aluminium with steel plate.

Really? I have an old Alex and have never experienced this. A wooden sub-chassis such as those made for the Roksan Xerxes ("upgrade plinth") could be made pretty easily though. If too light in weight, mass can always be added.

A couple of things come to mind as perhaps a way of "fixing" your warped sub-chassis:

- peel off the finish on the sub-chassis

- get the piece magnafluxed or X-rayed to check for cracks

- mark any cracks using a paint marker

- drill both ends of the cracks

- fill drilled holes with epoxy or body filler.

The idea is to relieve the (possible) cracks, and give someplace for the cracks to end.

If the sub-chassis is relieved in this manner, then all that maybe required is removal of the bearing, and a build up of the area surrounding the bearing with body filler. It will have to be sanded to level. Or use shim stock to correct any mis-alignment.

Adding a pound of epoxy in whatever distribution that is needed to effect a repair is not suitable, as the ability to correct for the weight of it may require more work than is practical.

On second thoughts maybe a Roksan style plinth may make a pretty reasonable replacement. If need be replace the aluminium with steel plate.

Too late. I snapped off the bent ear. So, I should rephrase...the sub chassis WAS warped, now is in two pieces.

I will either mill a new one out of 1/2 inch aluminum plate, or MDF. I think MDF would have better absorbsion properties, but would warp itself in time. So, a dampened aluminum would need to be used.

I have lots of projects on my plate and this wasn't supposed to be one of them.

C

I will either mill a new one out of 1/2 inch aluminum plate, or MDF. I think MDF would have better absorbsion properties, but would warp itself in time. So, a dampened aluminum would need to be used.

I have lots of projects on my plate and this wasn't supposed to be one of them.

C

Baltic Birch and Aluminium...

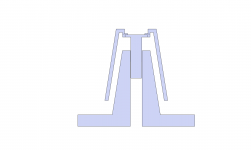

The Xerxes upgrade plinth handles a platter and arm of similar weight. I would try one made of that. The thickness is 25.5mm total, the BB is 18mm, the aluminium skins are 2.5 mm each.

If you don't like the suspension, you can do as some have done on Thorens tables: heater hose "springs". I know the suspension on my Alex has always been a real sore spot for me. The "fix" for the Alex MkII suspension is the addition of PTFE "sliders" on the suspension "posts". This is simply a poor solution (as made by Oracle themselves).

A remake using their parts, but a completely new plinth would then make sense. Hope you don't have a Prelude arm. A real POS...

The Xerxes upgrade plinth handles a platter and arm of similar weight. I would try one made of that. The thickness is 25.5mm total, the BB is 18mm, the aluminium skins are 2.5 mm each.

If you don't like the suspension, you can do as some have done on Thorens tables: heater hose "springs". I know the suspension on my Alex has always been a real sore spot for me. The "fix" for the Alex MkII suspension is the addition of PTFE "sliders" on the suspension "posts". This is simply a poor solution (as made by Oracle themselves).

A remake using their parts, but a completely new plinth would then make sense. Hope you don't have a Prelude arm. A real POS...

No, I don't believe I would have that problem in my spring towers. There is ample clearance all around.

I'm going to make a sub-chassis template out of 3/4" mdf, then router out the final in aluminum. I will add resonance barriers and breaks all through the template to deaden it. It will be thick enough to afford wide voids that I'll fill with a rubbery substance of some sort.

What do you think?

C

btw, I have/had a Grace tonearm. It was horrifically damaged in transit.

I'm going to make a sub-chassis template out of 3/4" mdf, then router out the final in aluminum. I will add resonance barriers and breaks all through the template to deaden it. It will be thick enough to afford wide voids that I'll fill with a rubbery substance of some sort.

What do you think?

C

btw, I have/had a Grace tonearm. It was horrifically damaged in transit.

regarding changing the sub-chassis

Personally I would avoid hollowing anything out of the aluminium, and filling it. Unless the "hollowed" portion is at least as thick as the original. Once filled with whatever goo you use, I'd skin the top of the sub-chassis as well, and adjust for a change in the thickness of the new sub-chassis. As I stated before, I think the idea of using BB ply and skinning it with aluminium has proven effective in other turntables.

Personally I would avoid hollowing anything out of the aluminium, and filling it. Unless the "hollowed" portion is at least as thick as the original. Once filled with whatever goo you use, I'd skin the top of the sub-chassis as well, and adjust for a change in the thickness of the new sub-chassis. As I stated before, I think the idea of using BB ply and skinning it with aluminium has proven effective in other turntables.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- In need of a subchassis for my Oracle Alexandria Mk II