I am going to either build or buy a new plinth for my Thorens TTs and wondered if a high mass one like the ones for Lencos would work,

i.e. plywood and veneer

This is in Cherry

This is in Rosewood Venner 17kg

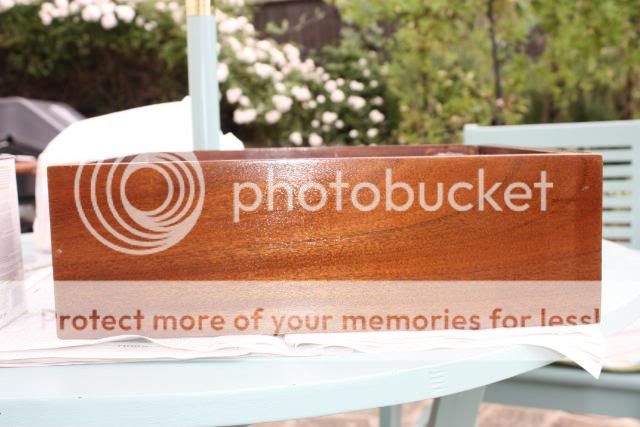

Here is a hollow box plinth in Santos Rosewood

Here is a solid ply and Rosewood veneer

here's a solid one with a TD150

layers-of-beauty - gallery

or would it have to be the simple box frame?

Here is the traditional plinth in solid mahogany from the same guy

Can anyone explain what type would or wouldn't work and why?

I have no commercial interest or link with the above company apart from thinking about buying one of their plinths.

Any advice welcome

Thanks

i.e. plywood and veneer

This is in Cherry

An externally hosted image should be here but it was not working when we last tested it.

This is in Rosewood Venner 17kg

An externally hosted image should be here but it was not working when we last tested it.

Here is a hollow box plinth in Santos Rosewood

An externally hosted image should be here but it was not working when we last tested it.

Here is a solid ply and Rosewood veneer

An externally hosted image should be here but it was not working when we last tested it.

here's a solid one with a TD150

layers-of-beauty - gallery

An externally hosted image should be here but it was not working when we last tested it.

or would it have to be the simple box frame?

Here is the traditional plinth in solid mahogany from the same guy

An externally hosted image should be here but it was not working when we last tested it.

Can anyone explain what type would or wouldn't work and why?

I have no commercial interest or link with the above company apart from thinking about buying one of their plinths.

Any advice welcome

Thanks

Suspended tables like the Thorens TD150/160 don't seem to get the "high mass" treatment like other "non suspended" tables like the TD124, SP10, GL75 etc. This is based on personal observation, not on actual experience building plinths. It could be that all turntables benefit from "high mass" plinths, just suspended tables less so.

I've seen some lovely lower mass plinths lately for the TD150, built from layers of Baltic Birch, and then painted with high gloss automotive lacquer. I do love the look of wood though, especially on an older "classic" table.

Take a look through the Thorens_Gallery

Jeff

I've seen some lovely lower mass plinths lately for the TD150, built from layers of Baltic Birch, and then painted with high gloss automotive lacquer. I do love the look of wood though, especially on an older "classic" table.

Take a look through the Thorens_Gallery

Jeff

High mass plinths are not very common with suspended TTs. Not sure why, must be the Linn "philosophy"  . Still, years ago i built a slate plinth for a TD150 and it turned out great. The TD125 which in my eyes and ears is a better tt than the LP12 is high mass. And so are the Prestige and Reference.

. Still, years ago i built a slate plinth for a TD150 and it turned out great. The TD125 which in my eyes and ears is a better tt than the LP12 is high mass. And so are the Prestige and Reference.

I tried for years to try to tame turntables for dance music.

If you want to know what works try putting your turntable in front of a 6KW efficient PA!

For me high mass wins, but the most important thing is the support. It pains me to see someone spend all that time making a turntable, and then sticking it on a resonant cabinet.

The best support I have found is a braced wall mounted shelf. The wall should of course be solid. The referencing of the turntable to such an imovable object is what makes the difference.

I have experience of nightclubs, back in the Vinyl only days, where the simple addition of 2 brick piers, One under each turntable, referenced to solid foundations, totally transformed the fortunes of the club. All of a sudden the punters had tunes that they could dance to. Very soon the club was full every weekend

If you want to know what works try putting your turntable in front of a 6KW efficient PA!

For me high mass wins, but the most important thing is the support. It pains me to see someone spend all that time making a turntable, and then sticking it on a resonant cabinet.

The best support I have found is a braced wall mounted shelf. The wall should of course be solid. The referencing of the turntable to such an imovable object is what makes the difference.

I have experience of nightclubs, back in the Vinyl only days, where the simple addition of 2 brick piers, One under each turntable, referenced to solid foundations, totally transformed the fortunes of the club. All of a sudden the punters had tunes that they could dance to. Very soon the club was full every weekend

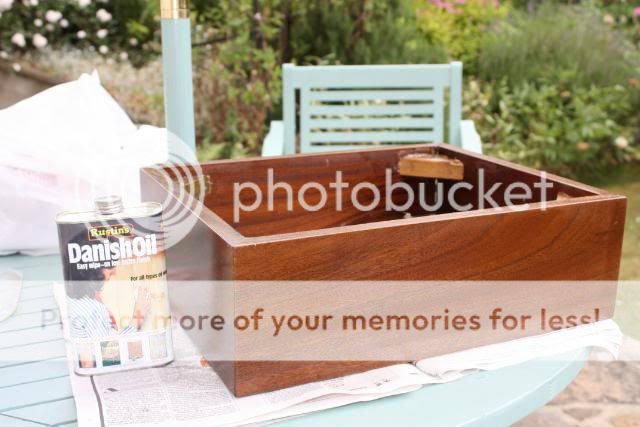

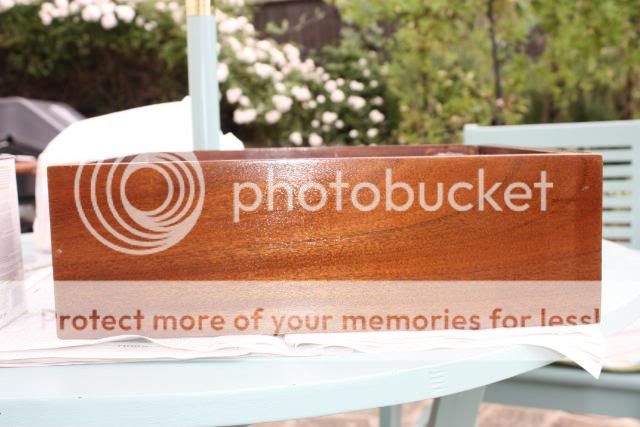

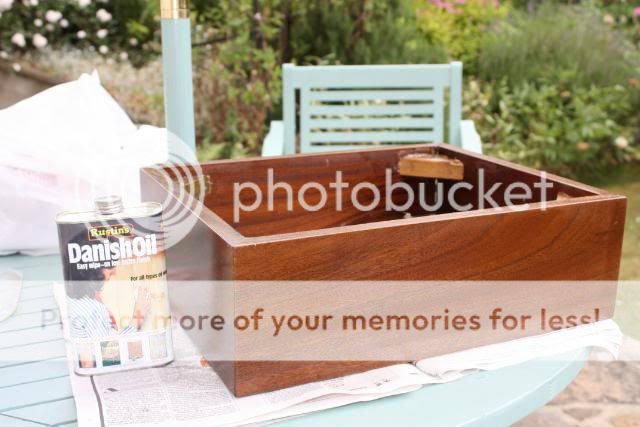

Here's the update,

I have emailed Russ for a quote on a cherry plinth, as that seems to be my favourite wood.

Meanwhile I have put together a solid 140mm African Walnut plinth as I wanted to give it a go anyway. I wished I had purchased American Walnut as its a lighter wood, but hey ho I am going to use it with a TD 160MKIIB that I will build with parts from ebay.

I am going to use it with a TD 160MKIIB that I will build with parts from ebay.

I a not a woodworker and have very limited tools and experience. The hardest thing is the mitred joints, I just can't get them as good as a factory or professional would. I did try using 'plastic wood' to fill in the gaps but its been a big mistake to be honest, I will never use it again.

Anyway comments appreciated, I have used Danish Oil to finish and am up to

3 coats now rubbing with 000 grade wire wool in between.

Any advice on finishing and the corners would be appreciated.

I have bought some rega planar 3 rubber feet of ebay as the majotiy opinion seemed to be rubber over spikes.

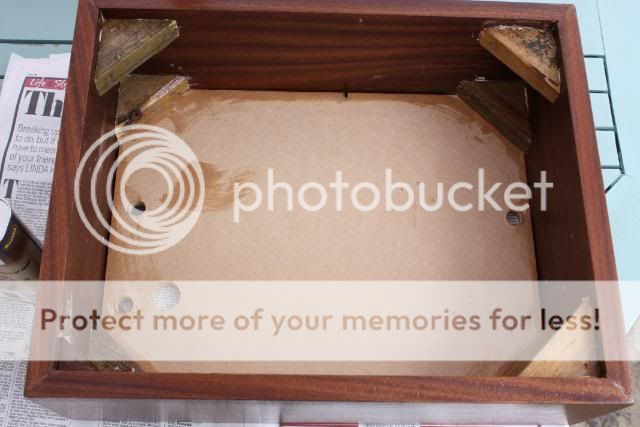

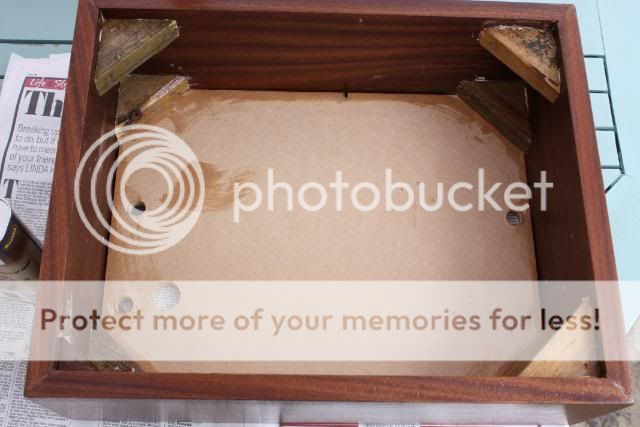

I have used an 18mm piece of MDF for the base.

Look forward to comments and advice

I have emailed Russ for a quote on a cherry plinth, as that seems to be my favourite wood.

Meanwhile I have put together a solid 140mm African Walnut plinth as I wanted to give it a go anyway. I wished I had purchased American Walnut as its a lighter wood, but hey ho

I a not a woodworker and have very limited tools and experience. The hardest thing is the mitred joints, I just can't get them as good as a factory or professional would. I did try using 'plastic wood' to fill in the gaps but its been a big mistake to be honest, I will never use it again.

Anyway comments appreciated, I have used Danish Oil to finish and am up to

3 coats now rubbing with 000 grade wire wool in between.

Any advice on finishing and the corners would be appreciated.

I have bought some rega planar 3 rubber feet of ebay as the majotiy opinion seemed to be rubber over spikes.

I have used an 18mm piece of MDF for the base.

Look forward to comments and advice

Last edited:

I a not a woodworker and have very limited tools and experience.

At least you are not camera-shy

I found replacing the stock plinth on my TD-125 with a considerably heavier one made a huge difference for the better particularly in terms of the bass.. Overall noise floor seemed to drop slightly as well.

I am beginning to doubt that even a csd (constrained layer damping) plinth would be overkill for a good suspended table. The motor board is usually directly coupled to the plinth and the heavier plinth should act as a more effective sink for low frequency motor vibration IMHO..

I am beginning to doubt that even a csd (constrained layer damping) plinth would be overkill for a good suspended table. The motor board is usually directly coupled to the plinth and the heavier plinth should act as a more effective sink for low frequency motor vibration IMHO..

I found replacing the stock plinth on my TD-125 with a considerably heavier one made a huge difference for the better particularly in terms of the bass.. Overall noise floor seemed to drop slightly as well.

I am beginning to doubt that even a csd (constrained layer damping) plinth would be overkill for a good suspended table. The motor board is usually directly coupled to the plinth and the heavier plinth should act as a more effective sink for low frequency motor vibration IMHO..

Thorens has always believed in high mass suspended designs,especially on their top of the line ,models.Even today their top of the line TD550 is such a design.The TD125 has its mass too compared to TD150,160 etc..........

Here is the plinth with my TD166MKII in African Walnut

I have just done a strait transplant without any mods for now, as I want to get it fully working, and modify it over time. I already have some parts ready to go such as metal inner platter to replace the composite one.

I fired up the TT and was immediately struck by the level of base in the music however the left channel is much quieter than the right one so that everything sounds as though its coming from the right. Any ideas? Its not the amp as I have swapped back and forth between my Systemdek IIX and the problem lies with the Thorens.

It has a Nagaoka MP-11 cartridge on the original arm, could it be a knackered cartridge near the end of its life?

Here are the pictures

I had a bit of a disaster assembling when I scratched the front of the plinth and will need to sort that out

and will need to sort that out

I have the plinth sitting on 3 rubber Rega Planner 3 feet I bought off ebay

As I mentioned the base is preety deep and musical much deeper than my Systemdek IIX

I have just done a strait transplant without any mods for now, as I want to get it fully working, and modify it over time. I already have some parts ready to go such as metal inner platter to replace the composite one.

I fired up the TT and was immediately struck by the level of base in the music however the left channel is much quieter than the right one so that everything sounds as though its coming from the right. Any ideas? Its not the amp as I have swapped back and forth between my Systemdek IIX and the problem lies with the Thorens.

It has a Nagaoka MP-11 cartridge on the original arm, could it be a knackered cartridge near the end of its life?

Here are the pictures

I had a bit of a disaster assembling when I scratched the front of the plinth

I have the plinth sitting on 3 rubber Rega Planner 3 feet I bought off ebay

As I mentioned the base is preety deep and musical much deeper than my Systemdek IIX

TD150/SME3009 renovation experience

I'm almost through the renovation of my TD150(MkII)/SME3009(MkII-Improved) combo, and had the lef/right imbalance problem in the past as well. That proved to be the cartridge worn out, probably years ago, but then I didn't have anything decent behind my "inherited" tt to really notice. Since I've also replaced the entire wire loom, headshell and headshell connection. The guys from Moth group have been very helpful in getting spare parts (see British Audio Products Online - High end Audio Accessories, Hardware, Turntables and spares). In fact, I can heartily recommend their Incognito silver wire loom (straight from the cartridge to the pre-amp!) and SRM Thorens enhancement kit, with several rubber enhancements. Big fun to try them out one by one and judge the difference...

I've got one question in general, as I've given up on trying to make my own new plinth. As I've got a feeling the turntable would benifit greatly from a much more solid plinth than the old cheapo low density fibre one now, though I wouldn't go as far as a slate, as you see for the rim and direct drive models. Anyone knows where I could get a decent wooden plinth these days?

Anyone who knows the inner dimensions of an LP12 plinth, as those seem to be around plentyful? maybe I can adapt one ...

I'm almost through the renovation of my TD150(MkII)/SME3009(MkII-Improved) combo, and had the lef/right imbalance problem in the past as well. That proved to be the cartridge worn out, probably years ago, but then I didn't have anything decent behind my "inherited" tt to really notice. Since I've also replaced the entire wire loom, headshell and headshell connection. The guys from Moth group have been very helpful in getting spare parts (see British Audio Products Online - High end Audio Accessories, Hardware, Turntables and spares). In fact, I can heartily recommend their Incognito silver wire loom (straight from the cartridge to the pre-amp!) and SRM Thorens enhancement kit, with several rubber enhancements. Big fun to try them out one by one and judge the difference...

I've got one question in general, as I've given up on trying to make my own new plinth. As I've got a feeling the turntable would benifit greatly from a much more solid plinth than the old cheapo low density fibre one now, though I wouldn't go as far as a slate, as you see for the rim and direct drive models. Anyone knows where I could get a decent wooden plinth these days?

Anyone who knows the inner dimensions of an LP12 plinth, as those seem to be around plentyful? maybe I can adapt one ...

Pro and cons of high mass / low mass plinths

Light plinths will vibrate more easily but they will

store less energy (due to the low mass) and therefore

have a much shorter decay time.

The suspension is tuned to a low resonant frequency and

thus isolates the turntable from vibrations with a compareably

short decay.

Heavy plinths will not resonate that easily but _if_ they

eventually do they store more energy (larger moving mass)

and will have a longer decay wich will counteract the

isolation effect of the suspension.

A heavier plinth with a suspended turntable will not give

you "better" bass but probably more but less precise bass.

In short this is why almost all experienced manufacturers

of suspended turntables (Linn, Thorens etc.) do _not_ use

heavy plinth.

If you use a high mass plinth the you could abandon the

suspension at all but use _really_ a lot of mass with high density then

(like Micro Seiki or the likes).

Low / high mass turntables have been a controversial subject

since they exist, so probably many won´t agree with what I wrote...

Light plinths will vibrate more easily but they will

store less energy (due to the low mass) and therefore

have a much shorter decay time.

The suspension is tuned to a low resonant frequency and

thus isolates the turntable from vibrations with a compareably

short decay.

Heavy plinths will not resonate that easily but _if_ they

eventually do they store more energy (larger moving mass)

and will have a longer decay wich will counteract the

isolation effect of the suspension.

A heavier plinth with a suspended turntable will not give

you "better" bass but probably more but less precise bass.

In short this is why almost all experienced manufacturers

of suspended turntables (Linn, Thorens etc.) do _not_ use

heavy plinth.

If you use a high mass plinth the you could abandon the

suspension at all but use _really_ a lot of mass with high density then

(like Micro Seiki or the likes).

Low / high mass turntables have been a controversial subject

since they exist, so probably many won´t agree with what I wrote...

Hallo Georg,

Thanks for a comprehensive reply!

As odd as it may sound, having owned the Thorens for over 20 years, I'm quite new to the details of tt design and all the controversies entailed ...

I can see where you're comming from on the low mass, low density plinth in a suspended design. For a while I was tempted to buy a completely new tt & arm, but the more I looked around and listened, I got convinced the old style heavy platter & suspension gave me the sound that I like. Looking at the plinth from resonance freq perspective, I can see the advantages of keeping it like that, so very likely I'll stay with that.

In the meantime I've figured out an LP12 plinth fits the TD150 in depth (305mm - most importantly) and is only ~3cm wider (400mm vs 375), which is easily covered by an extra inset next to the armboard. And you can get an LP12 plinth for €50~€70 on eBay ... can't do any better to give it a try ;-)

Thanks for a comprehensive reply!

As odd as it may sound, having owned the Thorens for over 20 years, I'm quite new to the details of tt design and all the controversies entailed ...

I can see where you're comming from on the low mass, low density plinth in a suspended design. For a while I was tempted to buy a completely new tt & arm, but the more I looked around and listened, I got convinced the old style heavy platter & suspension gave me the sound that I like. Looking at the plinth from resonance freq perspective, I can see the advantages of keeping it like that, so very likely I'll stay with that.

In the meantime I've figured out an LP12 plinth fits the TD150 in depth (305mm - most importantly) and is only ~3cm wider (400mm vs 375), which is easily covered by an extra inset next to the armboard. And you can get an LP12 plinth for €50~€70 on eBay ... can't do any better to give it a try ;-)

And you can get an LP12 plinth for €50~€70 on eBay ... can't do any better to give it a try ;-)

If you go this route, make sure it has the corner braces, as the early one's didn't.

jeff

The LP12 ones I saw now on eBay don't have the corner braces (had picked that comment up from somewhere already), but as I'll need to do some small modifications to the internal supports anyway by the looks of it, I can easily add the corner braces as well. It's the fit of the corners on the main plinth that daunt me for making my own  .

.

Anyway, I think I'll do it step by step and judge the differences by ear. The only way to go with serious audio in my book: it needs to sound good to these ears

And the mat I haven't got to yet. That's another tweak down the road, just as the feet, although the stock ones on the LP12 plinth may be sufficient. In that respect I think a complete "base" would be better, but better still heavy duty wall-mounting. Now it sits on a solid oak cabinet set on a concrete floor (covered by low density laminate wood flooring with a 1mm cork underfloor - that really did the trick over tiles )

)

Anyway, I think I'll do it step by step and judge the differences by ear. The only way to go with serious audio in my book: it needs to sound good to these ears

And the mat I haven't got to yet. That's another tweak down the road, just as the feet, although the stock ones on the LP12 plinth may be sufficient. In that respect I think a complete "base" would be better, but better still heavy duty wall-mounting. Now it sits on a solid oak cabinet set on a concrete floor (covered by low density laminate wood flooring with a 1mm cork underfloor - that really did the trick over tiles

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Thorens TD150/160/166 plinth solid or hollow