Hello everyone,

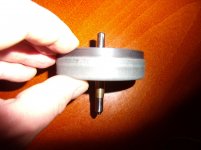

The direct drive motor for my Micro DQX 1000 needs repair .

The reason being that the spindle is very lightly bended .

The platter makes small waves when benchmarked to a straight line.

Please, have in mind that this is not a spindle only.

It is a rotor with a round magnet attached to it.

I was foolish enough to take the spindle/rotor to a metal working shop to try to make it straight.

And they did thei rbest and used only wood and hit it very lightly on the one side but the effect is anyway not good as now there is even some friction .

This metal is soft.

Ordered the Van Den Hul spindle oil to try.

In short, need a new motor or a new rotor (the spindle and attached magnet ).

Highly appreciate if anyone can advise from where I can obtain it orwhat else if anything I can do.

The direct drive motor for my Micro DQX 1000 needs repair .

The reason being that the spindle is very lightly bended .

The platter makes small waves when benchmarked to a straight line.

Please, have in mind that this is not a spindle only.

It is a rotor with a round magnet attached to it.

I was foolish enough to take the spindle/rotor to a metal working shop to try to make it straight.

And they did thei rbest and used only wood and hit it very lightly on the one side but the effect is anyway not good as now there is even some friction .

This metal is soft.

Ordered the Van Den Hul spindle oil to try.

In short, need a new motor or a new rotor (the spindle and attached magnet ).

Highly appreciate if anyone can advise from where I can obtain it orwhat else if anything I can do.

Can you show a picture of the rotor or the whole assembly? It is possible that Micro Seiki outsourced their motor from other manufacturer and you might be able to find the same motor or parts from a turntable of another brand. I know many Yamaha models used JVC motors such as the on in the PX2 and PX3 are identical motors in many JVC turntables. And list the motor model number.

The wavy rotation may not have to do with a bent spindle or bearing shaft. If you were able to rotation the bearing smoothly then it wasn't the bearing shaft's problem. It is possible the bronze taper sleeve that fit into the platter hole is dented or had uneven surface. I had something like that happened to me before and I took the shaft out and clamped it to a drill and sand papered the bronze sleeve and solved the problem but your hammering the spindle could only make it worse.

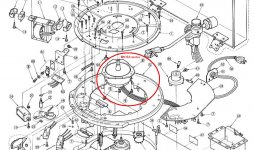

That motor looks familiar. It's very similar to the JVC QL-5 but the motor model is M935A.

Partstore.com has JVC motors for sale you can perhaps ask them about this motor model.

The flange is different from the QL-5 but the other parts look similar. Here are some pictures from a repair in Japan.

Some pictures of the higher model QL-7 in disassembled form. Different motor but spindle is similar.

Even if the rotor on the QL-5 is the same, there's no guarantee the taper spindle will fit the Micro-Seiki platter. I hope all these information helps.

That motor looks familiar. It's very similar to the JVC QL-5 but the motor model is M935A.

Partstore.com has JVC motors for sale you can perhaps ask them about this motor model.

The flange is different from the QL-5 but the other parts look similar. Here are some pictures from a repair in Japan.

Some pictures of the higher model QL-7 in disassembled form. Different motor but spindle is similar.

Even if the rotor on the QL-5 is the same, there's no guarantee the taper spindle will fit the Micro-Seiki platter. I hope all these information helps.

An externally hosted image should be here but it was not working when we last tested it.

Attachments

Last edited:

In my case there is no tolerance where the platter joins the spindle.

Unfortunately the spindle was/is bended.

I guess it had been carried with the platter left on and it is a heavy platter.

Made a mistake last night above about the exact motor designation.

The correct one is: JVC S74-94V-I

Unfortunately the spindle was/is bended.

I guess it had been carried with the platter left on and it is a heavy platter.

Made a mistake last night above about the exact motor designation.

The correct one is: JVC S74-94V-I

Directdriver,

Partsstore were unable to tell me which other motors does the spindle they have fit.

The motor I am looking for JVC S-74-94V-I does not appear in their database.

Besides that they said that they do not ship overseas and I better contact JVC directly.

This is quite reasonable but I doubt that there will be any support from JVC in respect of this long time ago discontinued product.

In short, I haven't progressed much .

Will try JVC ...

Regards,

Aleko

Partsstore were unable to tell me which other motors does the spindle they have fit.

The motor I am looking for JVC S-74-94V-I does not appear in their database.

Besides that they said that they do not ship overseas and I better contact JVC directly.

This is quite reasonable but I doubt that there will be any support from JVC in respect of this long time ago discontinued product.

In short, I haven't progressed much .

Will try JVC ...

Regards,

Aleko

Directdriver,

Latest findings are:

The spindle appears to be absolutely straight.

This is good news so far.

Possibly the bearing is a little worn.

The magnet - brass insert joint is not very stable which creates unbalanced rotation of the magnet.

The QL5 motor is different.

Best regards,

Aleko

Latest findings are:

The spindle appears to be absolutely straight.

This is good news so far.

Possibly the bearing is a little worn.

The magnet - brass insert joint is not very stable which creates unbalanced rotation of the magnet.

The QL5 motor is different.

Best regards,

Aleko

Aleko: "The magnet - brass insert joint is not very stable which creates unbalanced rotation of the magnet."

Perhaps you can replace just the brass ring salvage from beater table with similar motor structure? I used to have a QL-5 I bought for dirt cheap. I salvaged the tonearm and sold the rest. I wish there's another JVC model that uses the same motor as in the DQX-1000. Good luck!

.

Have been offered a motor for Victor TT101.

JVC TT-101 Owners Manual, Service Manual, Schematics, Free Download | Vinyl Engine

The spindle looks similar and the motor has a servo control.

But cannot ask the seller to dismantle it just in order to see the model designation inside.

It is up to me to check if it will fit or not.

This site explains some similarities between those TTs:

Micro Seiki DDX-1000 on TVK

A TT with the same motor seems to be the Marantz Esotec TT Marantz Tt 1000 on TVK

JVC TT-101 Owners Manual, Service Manual, Schematics, Free Download | Vinyl Engine

The spindle looks similar and the motor has a servo control.

But cannot ask the seller to dismantle it just in order to see the model designation inside.

It is up to me to check if it will fit or not.

This site explains some similarities between those TTs:

Micro Seiki DDX-1000 on TVK

A TT with the same motor seems to be the Marantz Esotec TT Marantz Tt 1000 on TVK

The motor from the JVC TT-101 is NOT the same as the one in your Micro-Seiki. I am a fan of JVC turntables and quite familiar with their models. Although I don't own one but many DD fans consider TT-101 one of the best direct-drive turntables ever made. I still have a dozen JVC tables. All later day JVC turntables, from late 70's to early 80's, used coreless ironless motors. In fact majority of Japanese turntable manufacturers switched to coreless motors, with the exception of Denon. Your motor is from a core motor before the coreless era. The TT-101 is the motor unit from the integrated turntable QL-10. When the TT-101 first came out it was the exact same price as the Technics SP-10Mk2. Personally, if given the opportunity to buy a TT-101 or QL-10, I would not hesitate to buy that over any Technics products. Technics maybe the darling of vintage DD these days and I have owned all of them(except the SP10Mk3) and none sound better than my JVC tables. Yes, the TT-101 is my dream table.

What you need to concentrate on is to find models before JVC switched to coreless motor, that is, anything before 1977. Consider the DQX-1000 has no quartz lock, it would have to be before 1975, that is, anything before "QL" in the name.

What you need to concentrate on is to find models before JVC switched to coreless motor, that is, anything before 1977. Consider the DQX-1000 has no quartz lock, it would have to be before 1975, that is, anything before "QL" in the name.

DDriver

I have one of these Ql-10/TT101 tables that was stored for 20 years. After pulling it out and setting it up, one signature it has it a lack of detail overall, not bad, just not anywhere close to my SOTA star vacuum.

Thinking about it a little bit, that motor has way to much torque and you can feel the pulsing or cogging if you remove the platter and feel the rotation of the spindle. This has to affect the stylus in a negative way. The cast alu/platter and mat are way to light to dampen those pulses. I have tried a heavier acrylic job but no success.

Is there a way to lessen this cogging like the Goldmund does on their DD model?

There's enough electronics underneath this to power a small city!

The other features are nice, fast startup and stopping, readout etc. but who cares if it doesn,t compete with a belt drive?

Regards

David

I have one of these Ql-10/TT101 tables that was stored for 20 years. After pulling it out and setting it up, one signature it has it a lack of detail overall, not bad, just not anywhere close to my SOTA star vacuum.

Thinking about it a little bit, that motor has way to much torque and you can feel the pulsing or cogging if you remove the platter and feel the rotation of the spindle. This has to affect the stylus in a negative way. The cast alu/platter and mat are way to light to dampen those pulses. I have tried a heavier acrylic job but no success.

Is there a way to lessen this cogging like the Goldmund does on their DD model?

There's enough electronics underneath this to power a small city!

The other features are nice, fast startup and stopping, readout etc. but who cares if it doesn,t compete with a belt drive?

Regards

David

AVWERK: "Is there a way to lessen this cogging like the Goldmund does on their DD model?"

Your motor might need lubrication after 20 years. Some Goldmund turntables used JVC motors, too.

.

DDriver,

I have sent the motor to a nice gentleman in Germany for repair.

Will report the result later here.

Partsstore have motors M935A, M938Q, others.

MO936F does not appear in their database so they cannot check which other motor model matches it.

AVWERK, I think that you may try to use copper mat on top of the platter

to reduce cogging .

I have sent the motor to a nice gentleman in Germany for repair.

Will report the result later here.

Partsstore have motors M935A, M938Q, others.

MO936F does not appear in their database so they cannot check which other motor model matches it.

AVWERK, I think that you may try to use copper mat on top of the platter

to reduce cogging .

Here are some photos of a motor taken from Micro Seiki DD-8.

The model is JVC MC936B2.

The one on the DQX 1000 I am looking for is MC936F.

The control electronics is different but the motor unit looks very similar.

I may buy it to use the rotor and the bearing.

The size of the spindle is the same, looks that it will fit the DQX 1000 platter.

http://picasaweb.google.co.jp/108054183575317063202/DD8MOtorOnly#

The model is JVC MC936B2.

The one on the DQX 1000 I am looking for is MC936F.

The control electronics is different but the motor unit looks very similar.

I may buy it to use the rotor and the bearing.

The size of the spindle is the same, looks that it will fit the DQX 1000 platter.

http://picasaweb.google.co.jp/108054183575317063202/DD8MOtorOnly#

Last edited:

Micro Seiki DQX-1000 - motor

Hi Tom,

No, not yet.

Turned out to be a time consuming task.

I am still waiting.

The good part here is that in the meantime my nice daughter

has been growing . She is 4 months old now.

So I haven't realy been able to play much records at home anyway .

Sometime soon I hope ....

Thank you for thinking of me.

Best regards,

Aleko

Hi Tom,

No, not yet.

Turned out to be a time consuming task.

I am still waiting.

The good part here is that in the meantime my nice daughter

has been growing . She is 4 months old now.

So I haven't realy been able to play much records at home anyway .

Sometime soon I hope ....

Thank you for thinking of me.

Best regards,

Aleko

Micro Seiki DQX-1000 - motor

Hi everyone,

I am reporting that the issue has been solved successfully.

I purchased one JVC MC936B2 motor from Japan.

In fitted in place and works exactly as the original MC936F.

Even the Quartz Lock works .

The stator looks exactly the same, the rotor seems a bit different.

Thanks to everyone who participated, especially DirectDriver .

Best to all

Aleko

Hi everyone,

I am reporting that the issue has been solved successfully.

I purchased one JVC MC936B2 motor from Japan.

In fitted in place and works exactly as the original MC936F.

Even the Quartz Lock works .

The stator looks exactly the same, the rotor seems a bit different.

Thanks to everyone who participated, especially DirectDriver .

Best to all

Aleko

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Micro Seiki DQX 1000 - motor