There has to be a way to get that 90 degrees on a stylus without the damn air pump!!

I don't want to go off track in other tonearm threads so I decided to start a new thread focusing on the discussion and design ideas for pivot style tonearms that can attain tangential tracking, a pivot linear tracker if you will. Sounds like an oxymoron but it can be done.

To be brief, most tangential tracking tonearms are typically air-bearing tonearms that allows the stylus glide across the radius in almost frictionless manner to simulate how a record is cut on a lathe. Other means of this gliding action can be also achieve via linear bearings like rollers on a rod or bushing on a rod, etc... Some concept arms even suggest using floating opposing magnets. The flaw of such tonearm is that the horizontal mass is enormous regardless of bearing quality, low friction or no friction. It limits the choices of stylus, depending on its compliance. And the use of an air pump is not for everyone to say the least - a personal pet peeve of mine. The genre of electronic servo detection pseudo-tangential trackers like the Rabco tracking across the record in tiny little arcs constantly self correcting its way to the end of the record is not part of this discussion here. Anyway, this thread is NOT about the above tonearms. We want to talk about pivot tonearms that can track tangentially by changing stylus angle simultaneously.

The best examples are actually currently available in production. By now, many people have heard of the Thales tonearm from Switzerland. It is a pivot style tonearm with an extra pivot at the headshell area right above the stylus. The changing angle is always 90 degree to the radius because it is part of a triangle that is inside a semi-circle that adheres to the Thales theorem, that is, "Thales discovered that the circumferential angle subtended by a triangle in a semicircle is always a right angle. As a result, the half circle above the hypotenuse of a right-angled triangle is called the Thales Circle."

http://www.tonarm.ch/kommentare/thaleskreis_e.html

6moons industryfeatures: Thales

.

.

With the basis of the Thales Circle, the designer Micha Huber devised a tonearm that can track any point inside the semi-circle always 90 degrees to the center of the record, voila a linear tracking tonearm that pivots without any linear motion. Genius! The tonearm appears to be executed with quality construction and precise worthy of a Swiss watch. So far it is the ONLY tonearm on the market that is capable of 100% geometric accuracy in maintaining tangency, at a price,of course, as it sells for, I believe, 6000 €.

.

.

Visually, it has the look of a Rube Goldberg device but looking closely, everything seems to have its specific function for good reason. I don't want to write a white paper on the Thales design but for those who are interested in examining it more closely, feel free to explore its website. But this tonearm does give a good example of the objective here.

.

Thales will introduce a new tonearm named "Simplicity" that looks simpler and elegant and even though it is not 100% accurate in geometry but it reduces the tracking error to a maximum of 0.008°! Pretty damn good in my book.

.

.

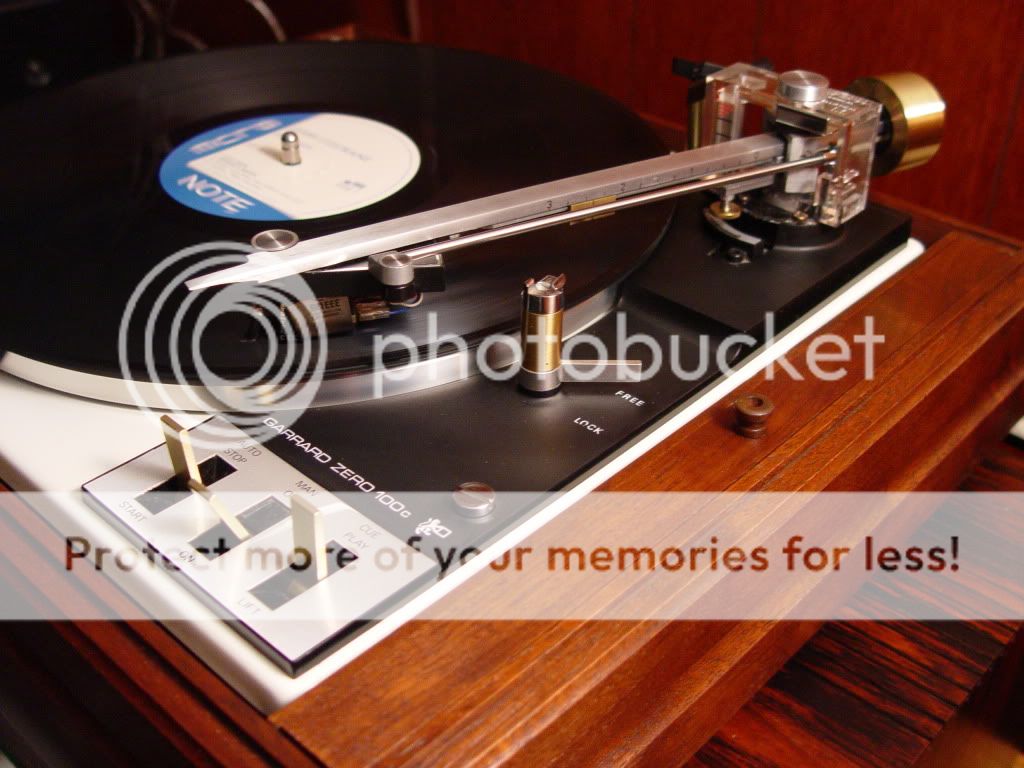

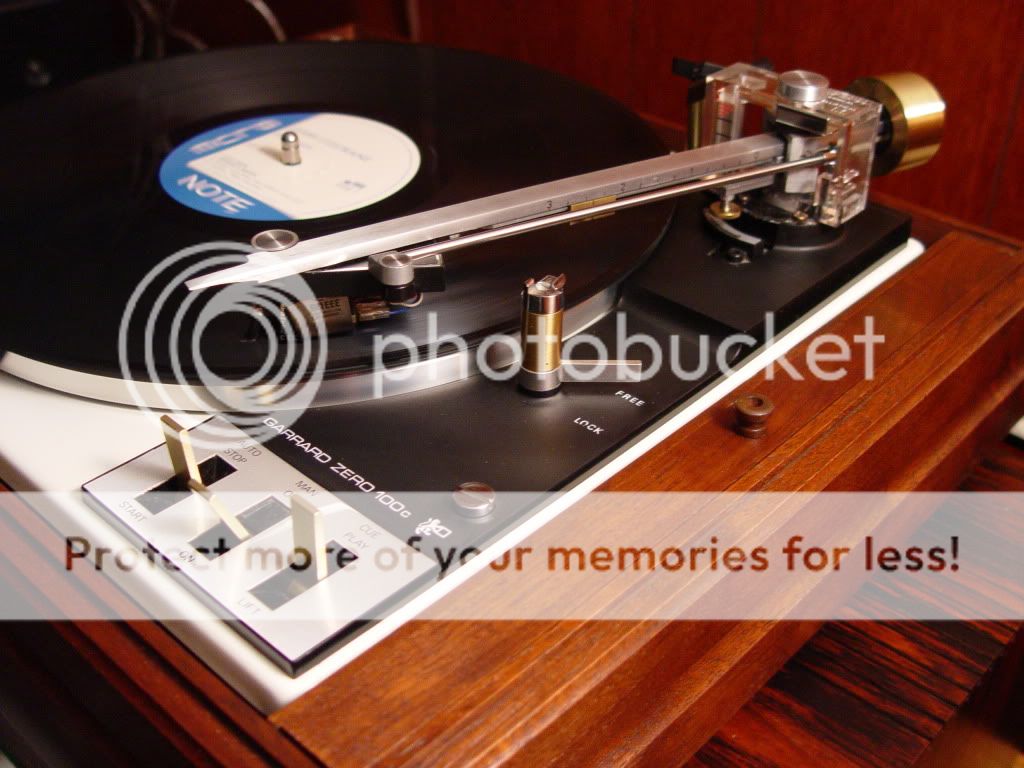

There are historical predecessors of such design and one can find that in the classic Garrard Zero 100.

.

.

.

And the Burne-Jones arms.

.

.

.

One can also find examples in contemporary designs like the RS Labs RS-A1 arm with a pivoting headshell.

.

.

.

"Prototype of the 'Bajulaz' tonearm on a TD-124. It was designed by Ing. Bajulaz to overcome the geometry problems of the conventional tonearms, but allegedly it wasn't so good for the new stereo cartridges and therefore never went in production."

.

.

I will continue to upload more pictures and present ideas to stimulate discussions and, hopefully, inspire the DIY spirit.

.

I don't want to go off track in other tonearm threads so I decided to start a new thread focusing on the discussion and design ideas for pivot style tonearms that can attain tangential tracking, a pivot linear tracker if you will. Sounds like an oxymoron but it can be done.

To be brief, most tangential tracking tonearms are typically air-bearing tonearms that allows the stylus glide across the radius in almost frictionless manner to simulate how a record is cut on a lathe. Other means of this gliding action can be also achieve via linear bearings like rollers on a rod or bushing on a rod, etc... Some concept arms even suggest using floating opposing magnets. The flaw of such tonearm is that the horizontal mass is enormous regardless of bearing quality, low friction or no friction. It limits the choices of stylus, depending on its compliance. And the use of an air pump is not for everyone to say the least - a personal pet peeve of mine. The genre of electronic servo detection pseudo-tangential trackers like the Rabco tracking across the record in tiny little arcs constantly self correcting its way to the end of the record is not part of this discussion here. Anyway, this thread is NOT about the above tonearms. We want to talk about pivot tonearms that can track tangentially by changing stylus angle simultaneously.

The best examples are actually currently available in production. By now, many people have heard of the Thales tonearm from Switzerland. It is a pivot style tonearm with an extra pivot at the headshell area right above the stylus. The changing angle is always 90 degree to the radius because it is part of a triangle that is inside a semi-circle that adheres to the Thales theorem, that is, "Thales discovered that the circumferential angle subtended by a triangle in a semicircle is always a right angle. As a result, the half circle above the hypotenuse of a right-angled triangle is called the Thales Circle."

http://www.tonarm.ch/kommentare/thaleskreis_e.html

6moons industryfeatures: Thales

.

An externally hosted image should be here but it was not working when we last tested it.

.

With the basis of the Thales Circle, the designer Micha Huber devised a tonearm that can track any point inside the semi-circle always 90 degrees to the center of the record, voila a linear tracking tonearm that pivots without any linear motion. Genius! The tonearm appears to be executed with quality construction and precise worthy of a Swiss watch. So far it is the ONLY tonearm on the market that is capable of 100% geometric accuracy in maintaining tangency, at a price,of course, as it sells for, I believe, 6000 €.

.

An externally hosted image should be here but it was not working when we last tested it.

.

Visually, it has the look of a Rube Goldberg device but looking closely, everything seems to have its specific function for good reason. I don't want to write a white paper on the Thales design but for those who are interested in examining it more closely, feel free to explore its website. But this tonearm does give a good example of the objective here.

.

Thales will introduce a new tonearm named "Simplicity" that looks simpler and elegant and even though it is not 100% accurate in geometry but it reduces the tracking error to a maximum of 0.008°! Pretty damn good in my book.

.

An externally hosted image should be here but it was not working when we last tested it.

.

There are historical predecessors of such design and one can find that in the classic Garrard Zero 100.

.

.

.

And the Burne-Jones arms.

.

An externally hosted image should be here but it was not working when we last tested it.

.

.

One can also find examples in contemporary designs like the RS Labs RS-A1 arm with a pivoting headshell.

.

.

.

"Prototype of the 'Bajulaz' tonearm on a TD-124. It was designed by Ing. Bajulaz to overcome the geometry problems of the conventional tonearms, but allegedly it wasn't so good for the new stereo cartridges and therefore never went in production."

.

An externally hosted image should be here but it was not working when we last tested it.

.

I will continue to upload more pictures and present ideas to stimulate discussions and, hopefully, inspire the DIY spirit.

.

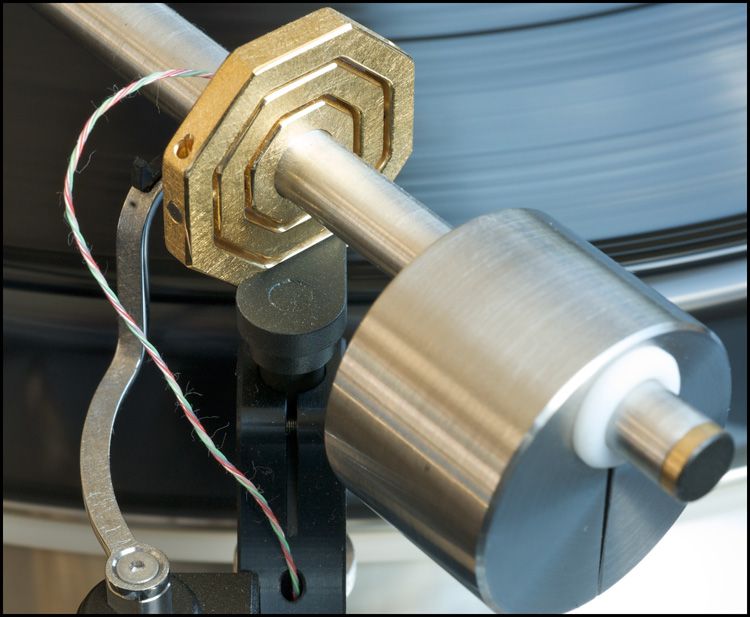

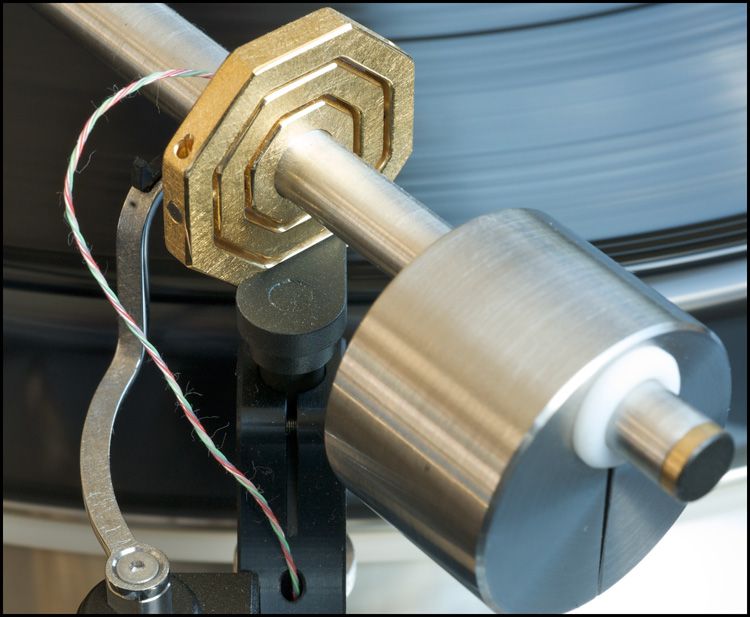

More Thales tonearm pictures.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

An externally hosted image should be here but it was not working when we last tested it.

.

An externally hosted image should be here but it was not working when we last tested it.

.

An externally hosted image should be here but it was not working when we last tested it.

.

An externally hosted image should be here but it was not working when we last tested it.

.

.

.

.

.

.

.

.

.

An externally hosted image should be here but it was not working when we last tested it.

.

.

.

The above is a diagram of the working of the Thales arm. Now, if I eliminate the arm from M to C completely, what is left is the triangle inside the semi-circle that C is always tangent to A. The hitch is that we have to come up with a design to allow the distance between to B to C to change about couple inches. In this case, there's no need for any pivot or bearing at the headshell area at all, just a straight wand. We can have a fixed arm length and the arm's base sit on some linear motion bearing or a tricycle platform that can move front and back and the middle wheel to steer the tricycle in a curved track that allows the arm to be tangent to A at all time. Essentially an assembly that allows pivoting and linear motion at the same time.

Look at picture below and I hope this makes sense.

.

An externally hosted image should be here but it was not working when we last tested it.

.

Arm in motion

.

.

.

.

.

.

An externally hosted image should be here but it was not working when we last tested it.

.

.

IMHO, all mechanical nightmares that probably introduce as many problems as they cure. Here's what I've been thinking about, but have yet to build. Pivoted tone arms are highly developed and work well, but I think that offset introduces forces that cause more trouble than can be fixed with anti-skate mechanisms, not to mention the obvious problem of getting the angle right at only two points. Rotating the head of an offset arm is not the answer! You must eliminate the offset. So, keep the standard tonearm, remove the offset and make it a bit longer. Now, just drive the pivot assembly along the back of the turntable in a track. Servo it, probably photoelectrically, but don't try for perfection. Let the tonearm do what it was designed to do. Try for silence and smoothness on the drive. I'm not sure what the best drive method would be, maybe a lead screw and DC motor, maybe a thin thread and drum drive or even a linear motor track. This is basically an electronic forum, so moving the pivot under motor control shouldn't be too difficult. The angular error will be very small even if the pivot location is off a couple mm- no human can align a cartridge that close regardless of what they claim. Maybe line the track with Teflon tape and/or make it a V-way for better stability. IMHO again, any system that tries for a rigid coupling between the tone arm and track (like air bearing arms) creates a horizontal mass problem that's completely unnecessary. The arm in this design can be a unipivot or whatever you like.

Conrad

Conrad

Last edited:

I think that offset introduces forces that cause more trouble than can be fixed with anti-skate mechanisms

I agree. I think many audiophiles prefer the sound of linear trackers is, perhaps, due to the elimination of offset angle and anti-skating in pivot arms.

Rotating the head of an offset arm is not the answer! You must eliminate the offset.

I don't know if you are referring to the Thales arm or the other above arms but all the arms I mentioned earlier does NOT have an offset angle and the stylus is NOT tracking with overhang, since it is pivoting in an arc the headshell towards the spindle it is constantly rotating in tangent and there is not skating force created, therefore NO antiskating mechanism is needed.

keep the standard tonearm, remove the offset and make it a bit longer. Now, just drive the pivot assembly along the back of the turntable in a track. Servo it, probably photoelectrically, but don't try for perfection.

What you are suggesting is really ending up with a servo tonearm like the Rabco or the Goldmund. And that's not what I have in mind and as I said at the beginning of this thread that I don't want to resort to motor or air pump. What I want is to think to come up with something geometrically clever and simple at the same time. That's where the creativity comes in.

However, just to indulge you for a second, I have thought of something along similar line is to create a gliding armboard that allows a conventional pivot arm to work as is but to servo correct the microscopic out of tangent arcs via motor and sensors. There are linear motion guides and bushings out there that have no slops that are quiet and smooth such as products from THK. Not all pivot arms are good candidates to be mounted on such motorized gliding armboard because some arms have offset headshells that are not suitable for this operation and arms with J-shaped or S-shaped armwands make matters worse. But the worse is the kind with offset bearings at the pivot point. Looking through available modern tonearms to find a good candidate for such experiment, one must find an arm with straight wand, no offset headshell, and no offset bearings. And the best arm I can think of right now is the Clearaudio Satisfy arm because it has a rotatable headshell, straight armwand, no offset bearings. And one can easily defeat the antiskating mechanism. The arm itself is visually quite elegant looking too.

I think the rotatable headshell allows for experimenting with adding a pivot point about the stylus to turn it into an RS Labs RS-A1 type of arm. Just a thought.

.

.

.

.

Last edited:

.

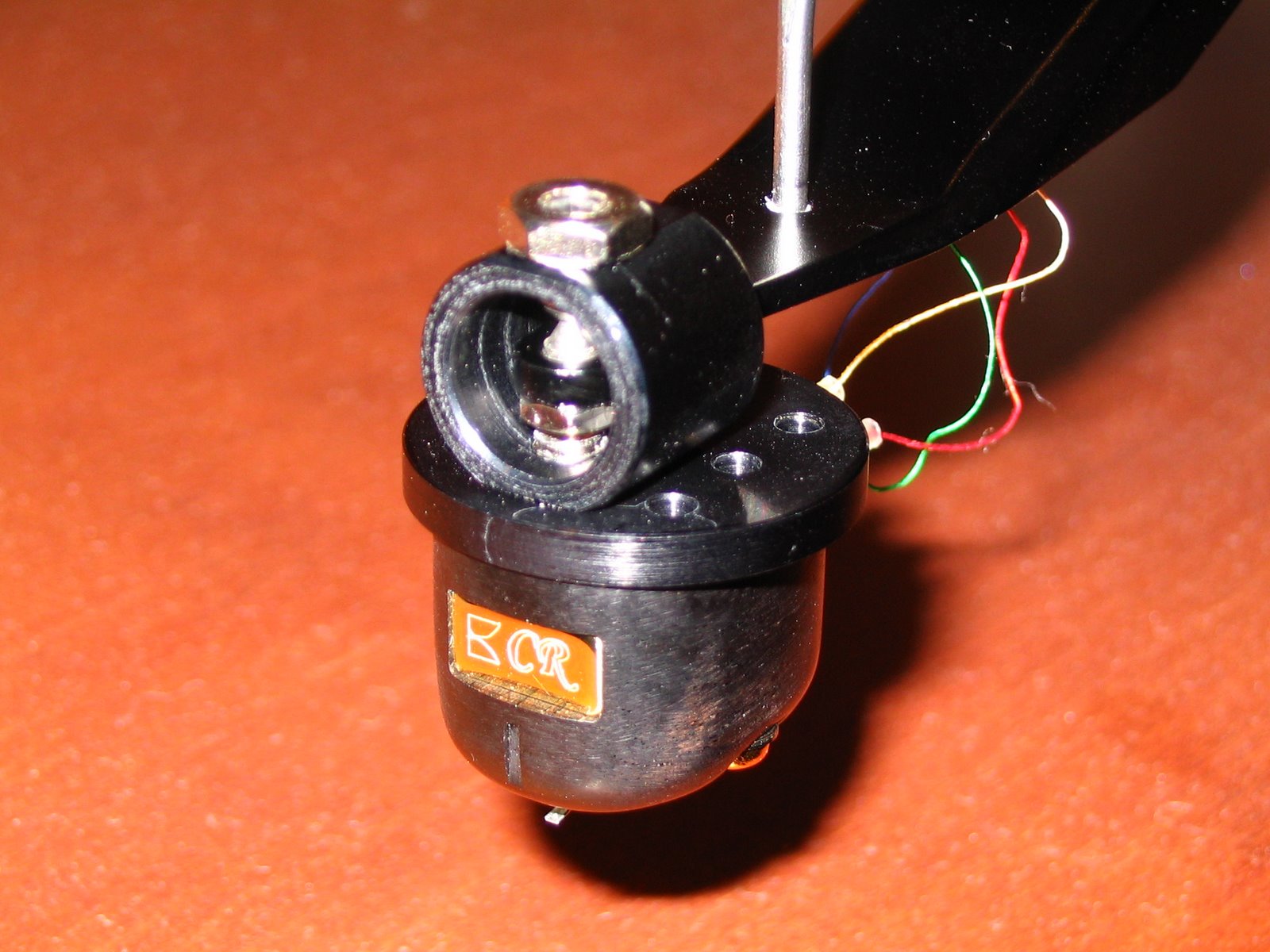

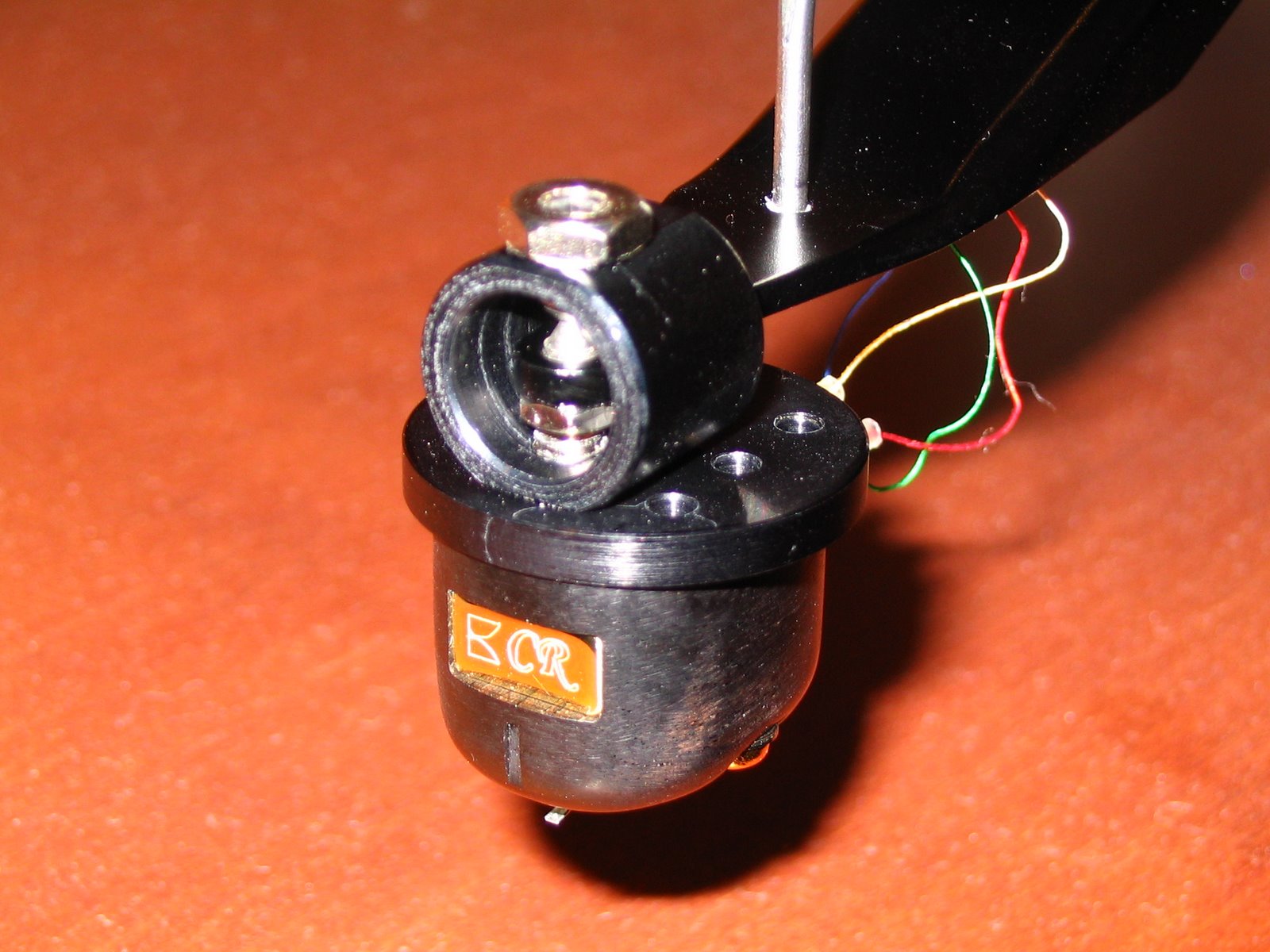

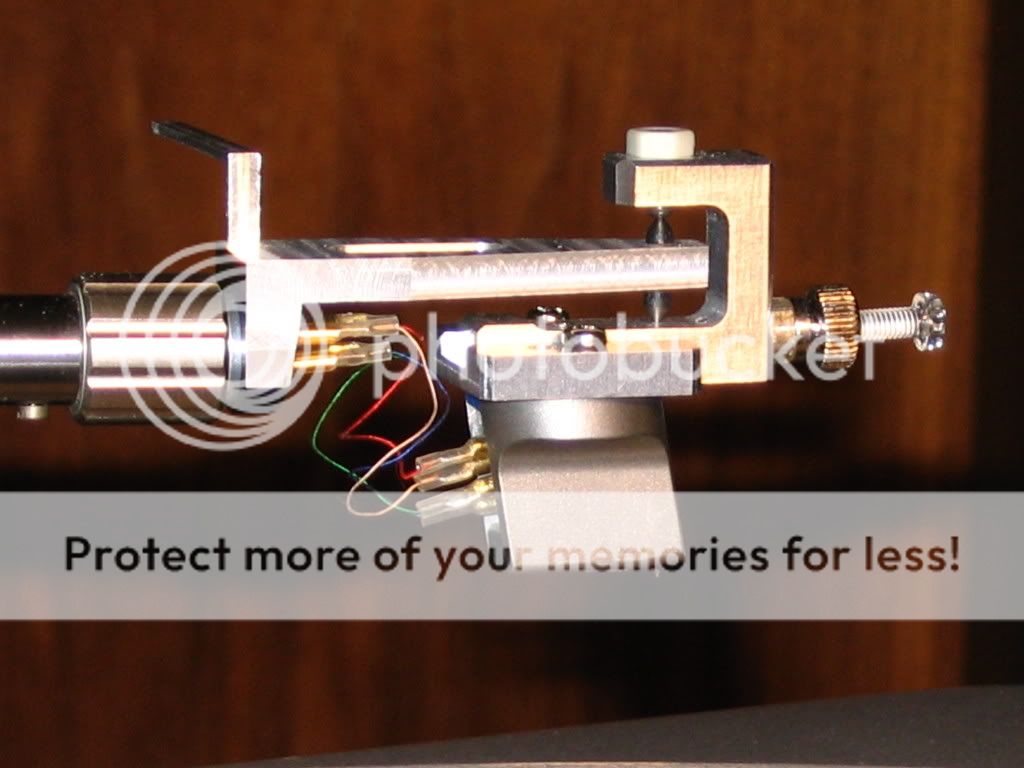

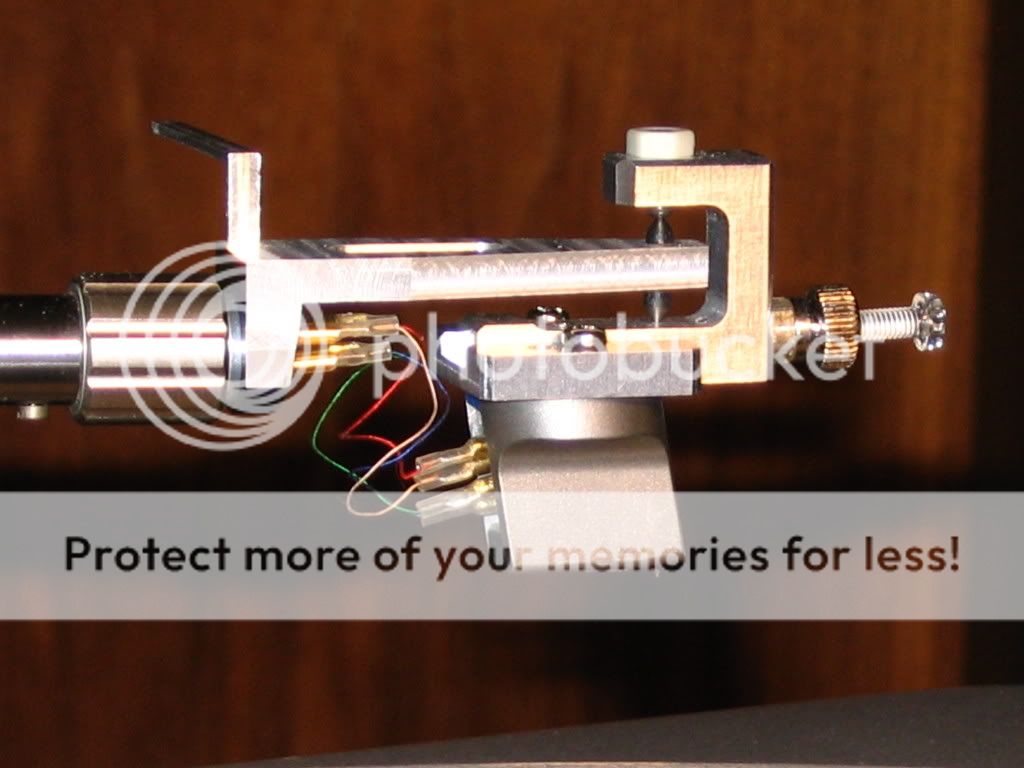

Some images of pivoting headshell from RS Labs. Without any guiding mechanism, I do not believe just by having a pivot headshell will give us less tracking error but this is just for showing how a pivot mechanism can be implemented on a headshell, no more no less.

.

.

.

.

Some images of pivoting headshell from RS Labs. Without any guiding mechanism, I do not believe just by having a pivot headshell will give us less tracking error but this is just for showing how a pivot mechanism can be implemented on a headshell, no more no less.

.

.

.

.

.

Some patents on how to pivot the headshell:

Pivot headshell patented by Wolf

.

.

Pivot headshell patented by Van Eps

.

.

Some patents on how to pivot the headshell:

Pivot headshell patented by Wolf

.

An externally hosted image should be here but it was not working when we last tested it.

.

Pivot headshell patented by Van Eps

.

An externally hosted image should be here but it was not working when we last tested it.

.

Garrard Zero style tonearm patented by Klein

.

An externally hosted image should be here but it was not working when we last tested it.

.

More discussion of linear tracking arm from Yosh in Japan.

http://www7a.biglobe.ne.jp/~yosh/lineartrack.htm via Google Translate

.

http://www7a.biglobe.ne.jp/~yosh/lineartrack.htm via Google Translate

.

Sorry, my dial-up can't deal with so many large images! If you draw a line, or at least a vertical plane, through the stylus/cartridge and it doesn't intersect the arm pivot, you've got forces you don't want. For example, I believe the Zero 100 generates skating force. Most of the arms I saw above don't appear to meet that criteria either. The problems of making decent tiny bearings for a mechanically compensated design are overwhelming (I work with that sort of thing every day), and dragging a big mass around isn't a starter for me, thus my view on driving the pivot support in a track. Yes, it's a bit like the old Rabco, but IMO those designs didn't have a good pivoted arm to begin with. Obviously you want a straight arm and I wouldn't bother with trying to use what's available, as making an excellent straight arm isn't overly difficult. Again, look at what people have built in terms of uni-pivots. If you own a small lathe, any design is within your grasp.

CH

CH

.

More interesting quasi-tangential pivot arm, this time with strings.

.

.

.

More interesting quasi-tangential pivot arm, this time with strings.

.

An externally hosted image should be here but it was not working when we last tested it.

.

An externally hosted image should be here but it was not working when we last tested it.

.

.

One of the earliest patents that are conscious of the Thales circle in designing a tangential tonearm.

http://www.freepatentsonline.com/2516565.pdf - Patent by Guy

.

One of the earliest patents that are conscious of the Thales circle in designing a tangential tonearm.

http://www.freepatentsonline.com/2516565.pdf - Patent by Guy

An externally hosted image should be here but it was not working when we last tested it.

.

I love a neat mechanism and that one's quite ingenious. Still, to beat my dead horse, if the arm pivot is fixed, and if the cartridge tracks tangentially, skating forces will be generated at all but one point. Ain't no escape from that simple geometry problem via mechanical means, at least that I can think of. IMHO, because of dynamic disturbances like record warp and off center spindle holes, any skating force (and its compensation, if used) sets off cantilever and arm motions (or maybe cantilever offsets to the coils) that are more serious detractors of sound than the tracing error we're trying to correct. FWIW, though people find it an interesting curiosity today, I remember when the Zero 100 was in production, knowledgeable people had a very low opinion of its actual performance. Recently, I designed an air bearing arm system and was nearly ready to fabricate it. Though I was able to get the mass quite low, in the final analysis I didn't see any way for it to properly handle a high compliance cartridge and real world (read imperfect) records. Thus my interest in alternate methods.

CH

CH

if the arm pivot is fixed, and if the cartridge tracks tangentially, skating forces will be generated at all but one point. Ain't no escape from that simple geometry problem via mechanical means

I agree with many things you said. First, on this thread I am trying to make it the most comprehensive gathering of information on this genre and to generate an interest or at least an awareness of the possibility of such device. Personally it's really an intellectual exercise because I already have enough toys to play with in my own audio system, including some servo linear trackers.

I'm glad that you pointed out about the issue when the arm pivot is fixed. Even though the many examples I posted are mostly about pivoting at the headshell, the solution and the idea I have in mind is to move the base, not the headshell. Again, if you look the Thales circle, I want to make the arm to be B to C, so there is no need for offset angle at the headshell at all. I want to separate vertical bearing independent of the horizontal bearing. What I need to do is to come up with a mechanism at the arm base area that allows the arm to swing and shift front and back on a track to create a virtual that can extend and shorten according to the swing motion.

Imagine the Dynavector arm without the offset angle, then you might get an idea of what I am talking about. The Dyna arm has two sections, one arm is purely for horizontal movement and at the end of that is another extended arm purely for vertical movement. Now, just think along the same line in a tangential arm that has a mechanism that allows for guiding. Imagine the effective length is 10" and the actual arm for vertical is about 7" so the track is only 3". After all, a servo motorized arm will require a track anyway but why not take advantage of pivot motion that can inherently allow for guiding the front and back motion. Imagine the Clearaudio Satisfy arm without offset angle at the headshell, and its base is on two rolling ball bearings on a track that pivots and when the arm swings to the spindle the arm base shift forward on the track maintains a Thales triangle inside a semi-circle. I might need to spend some time on some drawings to illustrate my point.

Again, I agree that skating force due to offset is bad for sound. The more I can minimize or eliminate it the better. Thanks for indulging me. I look forward to owning a small lathe one day. 🙂

P.S. Sorry to hear that you had to abandon your air-bearing project. Perhaps you might look into the Cantus tonearm in another thread that might inspire you to try a mechanical linear tracker.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

.

Found a rare image of the actual Van Eps tonearm. very cool looking but looks massive.

.

.

Found a rare image of the actual Van Eps tonearm. very cool looking but looks massive.

.

An externally hosted image should be here but it was not working when we last tested it.

.

Conrad Hoffman: "keep the standard tonearm, remove the offset and make it a bit longer. Now, just drive the pivot assembly along the back of the turntable in a track. Servo it, probably photoelectrically, but don't try for perfection. Let the tonearm do what it was designed to do. Try for silence and smoothness on the drive. I'm not sure what the best drive method would be, maybe a lead screw and DC motor, maybe a thin thread and drum drive or even a linear motor track. This is basically an electronic forum, so moving the pivot under motor control shouldn't be too difficult."

Looks like someone in 1981 Wireless World was thinking along similar lines. I wish I can find the complete article.

.

Attachments

DD,

This is very interesting to me. Thanks for this thread.😎

I don't like the idea of an air pump either.

I need to do some more research on these mechanical issues with this type of arm, will post some drawings after some more thinking.

Here is a link to a design not covered in your thread yet.

Equipment for playing gramophone records and method of operation thereof

have you seen this before and what do you think about it?

I am currently working on a diy tt design,even though I don't have a clue about all the technical aspects of such a project. It will be quite some time until anything is realized.

jim

This is very interesting to me. Thanks for this thread.😎

I don't like the idea of an air pump either.

I need to do some more research on these mechanical issues with this type of arm, will post some drawings after some more thinking.

Here is a link to a design not covered in your thread yet.

Equipment for playing gramophone records and method of operation thereof

have you seen this before and what do you think about it?

I am currently working on a diy tt design,even though I don't have a clue about all the technical aspects of such a project. It will be quite some time until anything is realized.

jim

max426: "Here is a link to a design not covered in your thread yet. www.freepatentsonline.com/4344168 have you seen this before and what do you think about it?"

I never saw that one before. Fascinating! I still can't decipher all the idea from the drawings yet. I need to read further but looks like instead of pivoting the headshell, it's pivoting and moving the armbase. I think it's on the right track similar to what I have in mind. Thanks for alerting me this design.

What I have in mind recently is along similar line. If you look at the Thales semi-circle, the headshell need not to be offset if we can change the effective length simultaneously moving across the arc. In any pivot arm, the swinging is a radius of a circle and we don't want to do that. If we can come up with a mechanism that change the length the cartridge can remain tangent drawing a line to the spindle. Let's say we have an armature that's 10" from the mounting to the spindle to form an 10" effective length arm but the armwand that carries the cartridge is only about 7" so we have about 3" sliding to do and this can be achieve via guiding rails for forward motion and swinging motion in essentially a tricycle platform where the armtube sits. Please look at the crude drawing and I hope it gets the idea across.

It might look complicated by it's actually quite simple. One can implement all the pivot arm concepts we learn in the past into this and the tricky part is the linear motion bearing, the tricycle mechanism. I am constantly thinking ways to reduce parts count and mass. The advantage of this over the Thales tonearm is that there's no pivoting headshell and no bearing near the cartridge, no vibration. Geometrically less ambiguous. Low vertical mass since the arm is only 7" long. Horizontal mass is a touch higher than typical pivot arm and it's similar to the Dynavector. The downside is that we have to rely on linear bearing which can result in high friction. An all pivot approach is doable if we use a parallelogram but that requires many pivot bearings and linkages - I will have to think about that for another project. Since I don't have a small lathe for me to experiment with physical objects, I just have to continue to headbang myself. Sometimes it hurts my brain, but as a masochist it can be quite fun. 🙂

Thank you for your interest.

.

Attachments

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms