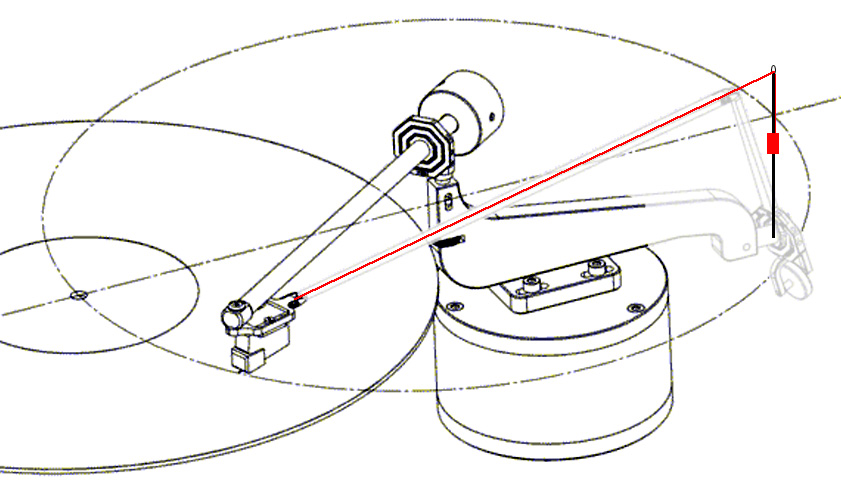

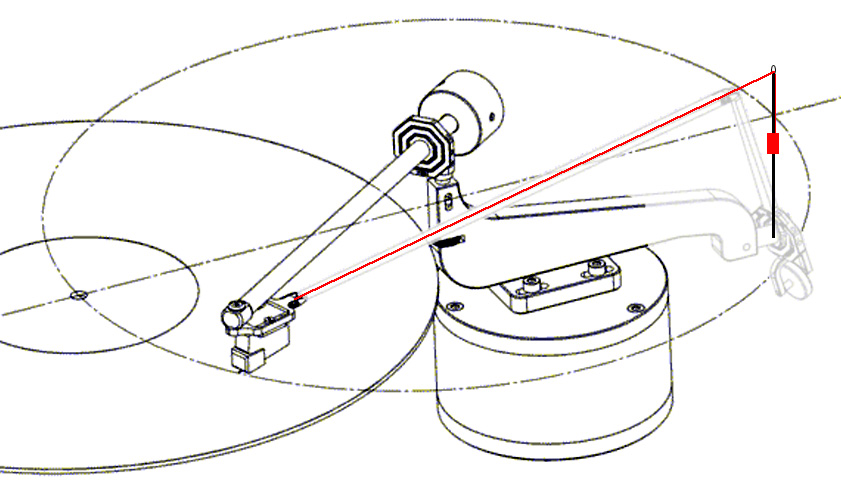

The pivot at the red arrow is stationary and at the blue area follows the slot or linear bearing as the arm moves across the record?

Sorry for the confusing drawing. The arm in the picture is a side view and fail to convey the tricycle idea. Just imagine all three wheels are V-groove or U-groove bearings. I drew another crude drawing. Essentially we have a track with two paralleled rods and in front of it we have a curved rod that can guide the arm and for the cartridge to move inside the Thales semi-circle.

Idea #1 is the tricyle idea above.

Idea #2 is to dispense the third wheel and replace it with a attaction magnet to follow a curved track right below the parallel track without being touched.

Idea #3 is to dispense the third wheel and replaced it with a guiding arm that pivots, which is probably what you have in mind. But to be precise geometrically the pivot has to have a cam system as a circular pivot will not preserve tangency at the cartridge. To get this curve the right shape, you have to plot it out on paper depending on where you want the place the arm between the pivot-to-spindle distance. Unless a geometry genius can show me a way to do it pivotally. The Thales arm does the guiding at the headshell which is what we want to avoid.

Of course one can make the tricycle independent of the arm wand to have a stable platform and then add a twin spike pivot on the arm wand for vertical movement. Since we have two wheels already can give us vertical movement, I thought why not use them. The arm assembling with twin spikes on the tricycle resembles the Ladegaard arm idea.

The curved rail is a brute force way of preserving tangency but still simple enough.

Another note is that the longer the effective length, the shorter the linear motion needs to travel. For a 12" arm the linear motion bearing only need to travel about 2 inches. I think 10" is a good compromise.

I hope this makes sense. Thanks again for your interest and feel free to comment and add ideas.

Attachments

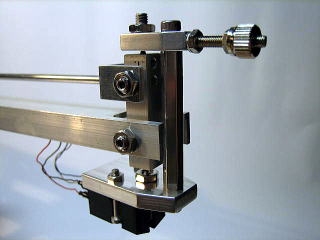

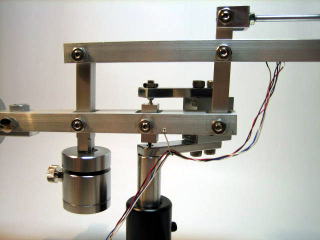

I think this Robert Van Eps designed tonearm would benefit from using unipivot bearing for each armwand. It begs for it as it will simplify the design without the disadvantage of unipivot as the dual armwands would take out the azimith rocking. Conceptually similar to Thales Simplicity arm. If the geometry is figured out I believe the Van Eps arm using unipivot bearings have the potential to sound the best of the lot.

.

.

.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

.

.

Another picture of the new Thales Simplicity arm in action in a three-arm turntable at the recent 2010 Munich Show. It certainly looks more practical than the two arms of the Original model. Simplicity is correct!

To be honest, I fail to understand why the Original model has to be done such way that's so awkward to install for most turntable. Surely, one can design a guiding arm without being position so low. I am sure there are other ways to handle that. Well, at least the Simplicity sounds like a self critique.

.

Another picture of the new Thales Simplicity arm in action in a three-arm turntable at the recent 2010 Munich Show. It certainly looks more practical than the two arms of the Original model. Simplicity is correct!

To be honest, I fail to understand why the Original model has to be done such way that's so awkward to install for most turntable. Surely, one can design a guiding arm without being position so low. I am sure there are other ways to handle that. Well, at least the Simplicity sounds like a self critique.

.

More interesting patents:

http://www.freepatentsonline.com/3476394.pdf by R. W. Birch 1969

http://www.freepatentsonline.com/4580258.pdf by Dinsdale and Birks 1986

.

http://www.freepatentsonline.com/3476394.pdf by R. W. Birch 1969

An externally hosted image should be here but it was not working when we last tested it.

http://www.freepatentsonline.com/4580258.pdf by Dinsdale and Birks 1986

An externally hosted image should be here but it was not working when we last tested it.

.

Here are some Exel files for download from a Japanese fellow who is like a mad scientist of all things analog. Fascinating stuff as he analyzes and calculates tracking error on these novel ideas including the Thales tonearm.

http://www7a.biglobe.ne.jp/~yosh/sitemap.htm --- sitemap, some text in Japanese

http://www7a.biglobe.ne.jp/~yosh/auto-offsetting%20arms.xls ---- Download

http://www7a.biglobe.ne.jp/~yosh/moving%20pivots.xls --- Download

http://www7a.biglobe.ne.jp/~yosh/sitemap.htm --- sitemap, some text in Japanese

http://www7a.biglobe.ne.jp/~yosh/auto-offsetting%20arms.xls ---- Download

http://www7a.biglobe.ne.jp/~yosh/moving%20pivots.xls --- Download

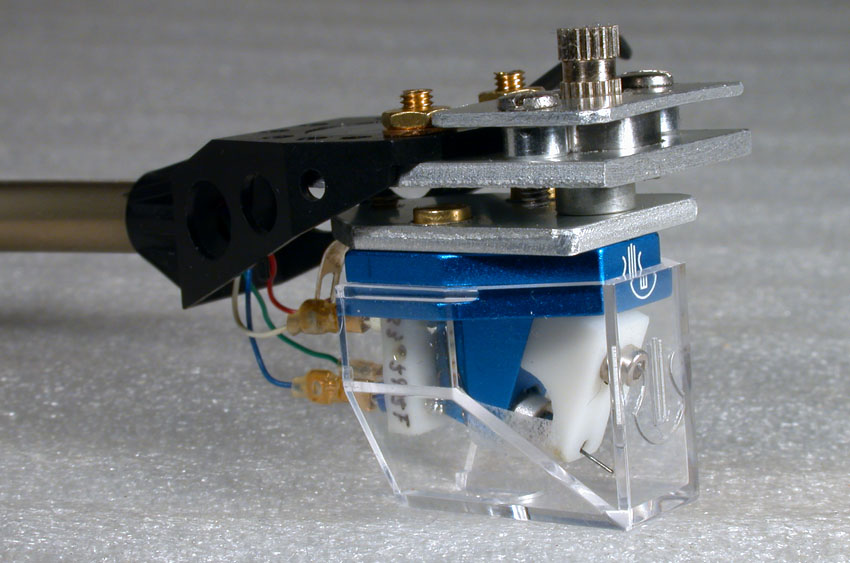

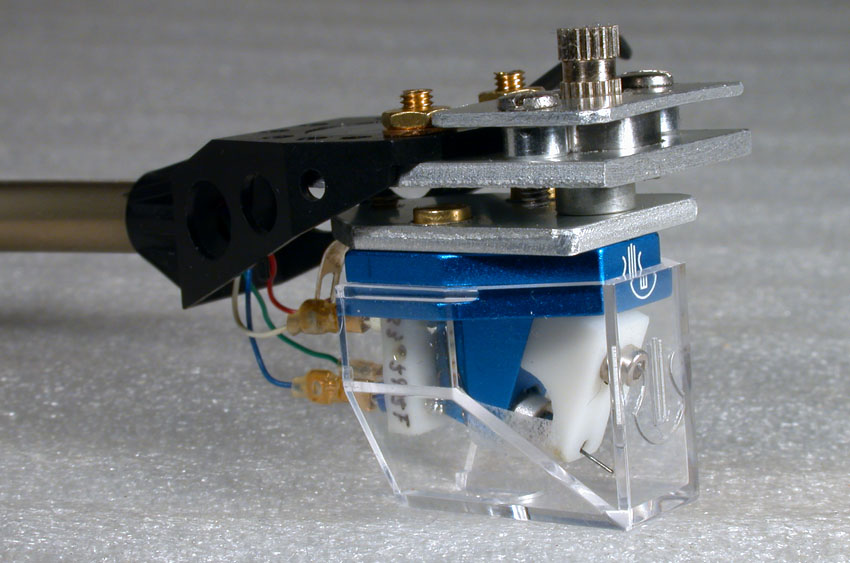

More rotary headshell, diy style.

www.chukai.ne.jp/~stail/kaiten.html

The above pictures suggested to me that the best and easiest tonearm for this kind of mod is the Clearaudio Satisfy tonearm:

.

www.chukai.ne.jp/~stail/kaiten.html

The above pictures suggested to me that the best and easiest tonearm for this kind of mod is the Clearaudio Satisfy tonearm:

.

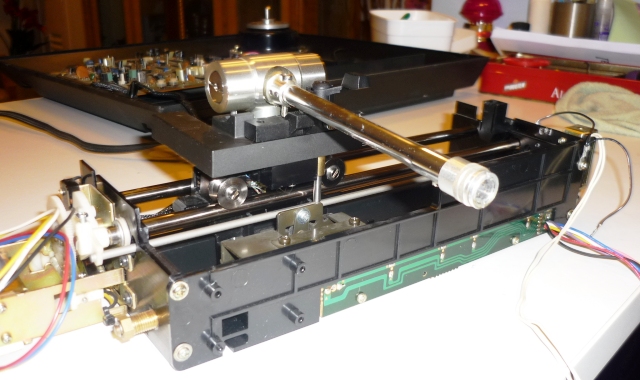

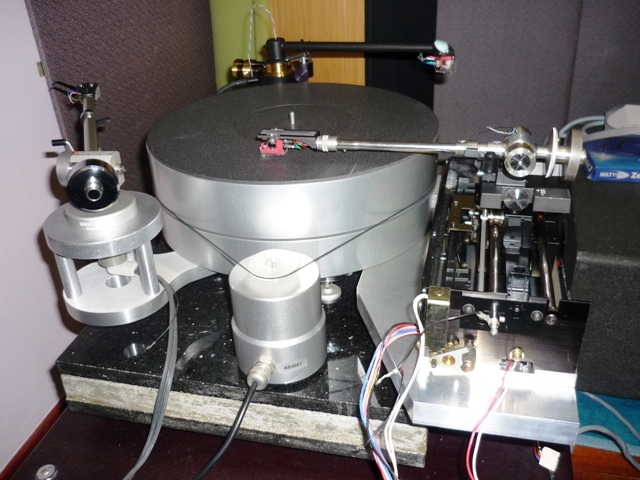

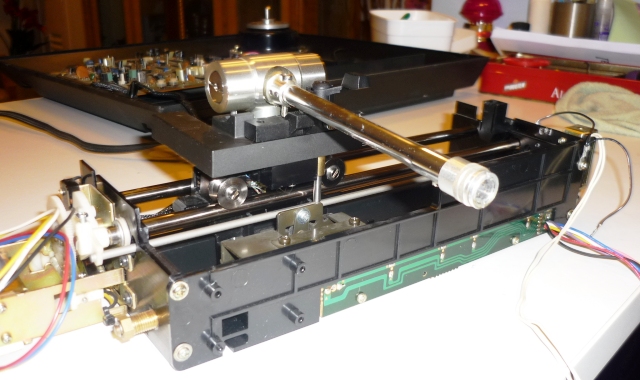

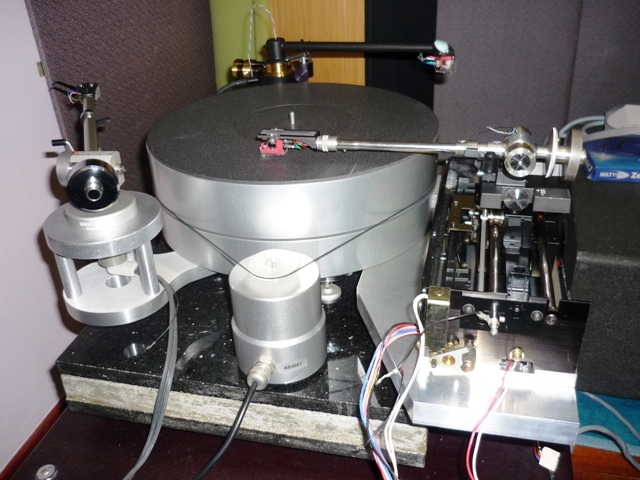

That's not a tone arm - that's a steam engine!

Simplicity is best when it comes to arms, and has been pointed out, the real driver for parallel trackers is the elimination of bias force. Mind you, the cost of that elimination is high. I wondered about parallel trackers and air pumps then gave up when I discovered how noisy even the quiet ones were.

It's a very pretty steam engine, though.

Simplicity is best when it comes to arms, and has been pointed out, the real driver for parallel trackers is the elimination of bias force. Mind you, the cost of that elimination is high. I wondered about parallel trackers and air pumps then gave up when I discovered how noisy even the quiet ones were.

It's a very pretty steam engine, though.

Attachments

EC8010: "Simplicity is best when it comes to arms, and has been pointed out, the real driver for parallel trackers is the elimination of bias force. Mind you, the cost of that elimination is high. I wondered about parallel trackers and air pumps then gave up when I discovered how noisy even the quiet ones were."

Yes, simplicity is the best but much engineering is to start with complex design and then pare it down to the essentials. I want to figure out a way that is hopefully clever and yet simple to deal with in a tonearm design. If by adding an extra pivot point(s) can minimize anti-skating force and lower tracking error it might not still be worth it and is still simpler than using air bearing. As stated in my opening post, I want to pick people's brain by not using air bearing or even mechanical parallel designs. The topic is to use a pivot design without resorting to linear motion designs like rails and air bearings. I believe much innovation hasn't been exhausted yet.

Of course, the above example is just an extreme case of doing too much but I still appreciate the designer trying new things. One wouldn't appreciate simplicity until a complex issue is thought through. Once again, this is purely an intellectual exercise and for fun. Apparently I haven't really generated much interest. But it's not going to stop me from trying and I will keep marching to my own beat.

It's still more fruitful than talking about cables. 🙂

Active motorized servo tonearms are not the genre I am talking about in this post but they are still interesting.

I used to own several of those and I still have a couple spare arms laying around. Perhaps I should put them to good use. The arm's construction was over complicated and it's the only servo arm that the armtube moves laterally left AND right because the armbase is part of a linear motor; most other arms pivots and moves laterally to the left in only one direction. With so much tiny movement, the bearing quality was not that good. I took it apart just to salvage the motor and platter as stand alone direct drive turntable. It's a clever design but unfortunately the whole thing sits on a flimsy plastic wobbly suspended platform. It's certainly cheaper than a Goldmund T3 arm! I think the Yamaha PX-2 is probably another candidate for this kind of experiment.

Thanks for sharing. Here are the rest of the pictures in this forum post:

.

I used to own several of those and I still have a couple spare arms laying around. Perhaps I should put them to good use. The arm's construction was over complicated and it's the only servo arm that the armtube moves laterally left AND right because the armbase is part of a linear motor; most other arms pivots and moves laterally to the left in only one direction. With so much tiny movement, the bearing quality was not that good. I took it apart just to salvage the motor and platter as stand alone direct drive turntable. It's a clever design but unfortunately the whole thing sits on a flimsy plastic wobbly suspended platform. It's certainly cheaper than a Goldmund T3 arm! I think the Yamaha PX-2 is probably another candidate for this kind of experiment.

Thanks for sharing. Here are the rest of the pictures in this forum post:

.

Last edited:

It's still more fruitful than talking about cables. 🙂

Absolutely. And you're providing huge entertainment with all those big pictures of unusual arms.

An externally hosted image should be here but it was not working when we last tested it.

Arm design incorporating Burne Jones' Thales circle concept and Dynavector's split planes concept.

I actually built a prototype of this but didn't take any decent photos. This design fails for the usual reason: the complexity of the bearings creates excess friction or excess play (or both).

Currently working on a new version incorporating a new concept which seems to avoid this problem. Need more round tuits.

Don't forget Rabco!

their arm was on a track run by a motor that was turned on via thin wire contacts but the arm still pivoted, thus the contacts. So it crabbed across the record.

My friend Al and I back in about 1973-4 built a radically upgraded modifcation of it - he still uses his. We built precision bearings and fabricated a lightweight arm for it. He still uses his, it works great.

I used a phototransistor and light source to trigger mine...

It was kewl.

Maybe I can get him to post a jpeg of his.

_-_-bear

their arm was on a track run by a motor that was turned on via thin wire contacts but the arm still pivoted, thus the contacts. So it crabbed across the record.

My friend Al and I back in about 1973-4 built a radically upgraded modifcation of it - he still uses his. We built precision bearings and fabricated a lightweight arm for it. He still uses his, it works great.

I used a phototransistor and light source to trigger mine...

It was kewl.

Maybe I can get him to post a jpeg of his.

_-_-bear

Hi!

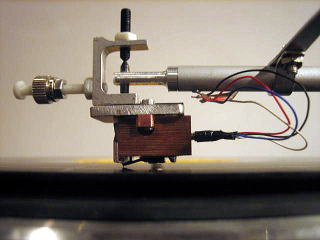

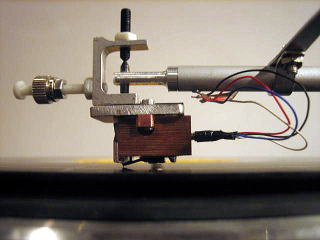

Here's an arm I've built for my Neumann PA2(the original arm has a pivot to spindle distance of only 185mm) that fits this thread:

European Triode Festival 2009/hb/DSC_0501

Essentially based on the Thales circle but allowing for the headshell to rotate like the RS Labs(within the confines of the tensioning thread). Much less complex than the Thales arm and working extremely well. Skating compensation decreases with decreasing offset angle (when moving towards the spindle). Skating compensation is determined by the (lead shot)weight(s) at the end of the string.

I showed it publicly after getting permission from Micha Huber whose new arm is an exercise in combing mechanical complexity with elegant detail solutions(the skating compensation is waaay cool!)

Cheers,

Frank Schröder

Here's an arm I've built for my Neumann PA2(the original arm has a pivot to spindle distance of only 185mm) that fits this thread:

European Triode Festival 2009/hb/DSC_0501

Essentially based on the Thales circle but allowing for the headshell to rotate like the RS Labs(within the confines of the tensioning thread). Much less complex than the Thales arm and working extremely well. Skating compensation decreases with decreasing offset angle (when moving towards the spindle). Skating compensation is determined by the (lead shot)weight(s) at the end of the string.

I showed it publicly after getting permission from Micha Huber whose new arm is an exercise in combing mechanical complexity with elegant detail solutions(the skating compensation is waaay cool!)

Cheers,

Frank Schröder

Mark Kelly: "Arm design incorporating Burne Jones' Thales circle concept and Dynavector's split planes concept. This design fails for the usual reason: the complexity of the bearings creates excess friction or excess play (or both). Currently working on a new version incorporating a new concept which seems to avoid this problem."

Thanks so much for sharing!! That's very close to what I have in mind, the split planes concept is the way to go. By separating the vertical and horizontal movements independently ease up the geometric issue considerably. My biggest problem with the Thales (Original model not the Simplicity) tonearm is that it has geometric issue on the vertical plane as the stylus angle is constantly changing in reference to the main arm (which is NOT part of the Thales triangle only compounds the problem) and not a good thing when encounter warped records. The split planes concept also helps not having a moving part right above the cartridge! The B&J design has too many pivot bearings and it's no surprise that it doesn't work well. I have abandoned the idea of using linear motion bearings in my previous posts. I believe it can be simpler and only having two pivots to make the geometry close to be tangential. Most arms of this genre requires at least 4 pivot points like a tetragon.

Thanks again for sharing and this is very encouraging. I look forward to the new design. The day we won't see air pumps will be soon. 🙂

.

berlinta: "Essentially based on the Thales circle but allowing for the headshell to rotate like the RS Labs(within the confines of the tensioning thread). Much less complex than the Thales arm and working extremely well. Skating compensation decreases with decreasing offset angle (when moving towards the spindle). Skating compensation is determined by the (lead shot)weight(s) at the end of the string."

Hi Frank, that's brilliant!!

It reminds me of that mysterious tonearm I posted earlier that uses two strings. But yours is even simpler by having a single constantly tensioned string that compensates the skating force. Two birds one stone!

I always wonder if the Thales guiding mechanism can be simpler. I thought of an idea by using long light round rod with teflon sleeve and it goes in between a vertical tuning fork like mechanism that can pivot so it guides and forces the cartridge to be inside the Thales circle and provides low friction. One can even add a u-groove bearing in between the tuning fork to ease the linear motion. But the mass of the rod will change at different points of the record and changing the effective mass. Hmm... no free lunch.

How does it sound compare to your regular arm?

I found more pictures of the arm and I hope you don't mind more people get to see them.

DSC_0295.jpg - & - DSC_0293.jpg - & - DSC_0210.jpg - & - DSC_0501.jpg

.

bear: "We built precision bearings and fabricated a lightweight arm for it. He still uses his, it works great. I used a phototransistor and light source to trigger mine..."

Of course, I haven't forgotten about the Rabco, as it is the granddaddy of motorized servo linear tonearm. I still have two faulty ones laying around. The Rabco arm works pretty well but is hindered by its bearing quality and flimsy armtube. I look forward to seeing pictures of you and your friend's modification. I want to salvage the motor and servo mechanism to make a sliding base so one can mount a conventional pivot arm like a Rega on it to improve the bearing. There's no need to reinvent the wheel on the tonearm part, we just need a suitable motorized gliding base with sensor for mounting an arm. Most arm of such genre cheap out on the arm part after they spent all the resource on the motor and electronics.

Once again, the genre of arms I am talking about is to exclude motors and air pumps, hence the title "pivot tangential arms." But I am still curious about the pictures.

.

modified Thales

Someone is thinking along similar lines in another forum. Very articulate and many good pictures, including showing how Frank's string tensioned pivoting headshell works and the making of a DIY pivot headshell on an SME Type3 arm.

Italian forum postings - ansaht.altervista.org/phpBB2/viewtopic.php?t=135 - "The brilliant Thales"

.

.

.

Someone is thinking along similar lines in another forum. Very articulate and many good pictures, including showing how Frank's string tensioned pivoting headshell works and the making of a DIY pivot headshell on an SME Type3 arm.

Italian forum postings - ansaht.altervista.org/phpBB2/viewtopic.php?t=135 - "The brilliant Thales"

.

.

.

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms