This one is foam and fiber glass with 5/16 Masonite inside to attach the parts - AR platter and bearing, BIC motor, and DIY tensioned string arm. Sort of a musical surfboard. It works well even though the materials are improbable and not for everyone. I wanted a unique shape, but there sure is something fine about the classic simplicity and proportions of Jason's bamboo Lenco.

Jim - Thanks for posting #17. Great information and a lot to think about.

Jim - Thanks for posting #17. Great information and a lot to think about.

Attachments

Doug your table looks beautiful almost like a concrete or stone plinth very interesting effect. Any more pictures under the hood? I really like your treatment of the top of the plinth, what material did you use for that?

I am sure that bamboo would make a fine plinth material but it sure is hard on carbide cutting tools.

I am sure that bamboo would make a fine plinth material but it sure is hard on carbide cutting tools.

Moray,

Here are the innards in all their glory. The straps to the motor are neoprene. The BIC is noisy, but the neoprene isolates it completely. I use neoprene for the platter mat, too. The drive pulley is wood with washers top and bottom. Entirely by coincidence, a 3/4" hole saw with a 1/4" guide bit made the pulley. Just luck with that one. The platter and arm don't float like they did in the original AR. The entire outside of the plinth is foam and fiber glass. The dark matte grey on the top is Rust-o-leum spray can paint. They've introduced a new line I really like. It holds up to use and cleaning very well. I'm glad you like the polished stone look. That's what I was going for, although the red accent is a little more prominent than I intended.

Here are the innards in all their glory. The straps to the motor are neoprene. The BIC is noisy, but the neoprene isolates it completely. I use neoprene for the platter mat, too. The drive pulley is wood with washers top and bottom. Entirely by coincidence, a 3/4" hole saw with a 1/4" guide bit made the pulley. Just luck with that one. The platter and arm don't float like they did in the original AR. The entire outside of the plinth is foam and fiber glass. The dark matte grey on the top is Rust-o-leum spray can paint. They've introduced a new line I really like. It holds up to use and cleaning very well. I'm glad you like the polished stone look. That's what I was going for, although the red accent is a little more prominent than I intended.

Attachments

Jim - Thanks for posting #17. Great information and a lot to think about.

My pleasure Doug!

Take nothing I say as gospel; just use it as a guide to let your ears decide what is right...

Doug: nice job on the plinth very professional looking job.

I rather like the red effect it almost looks like a blood stone.

I have seen some very interesting effects generated in colored concrete by adding either fine steel wool, brass wool or copper wool. This yields a very nice colored marble effect with the steel producing iron oxide (rust red) the brass makes a blueish oxide and the copper is green. When the outer surface is polished the look is very unique. I have seen steel and brass wool but have never come across copper wool perhaps it was hand made for the application. I saw this in a concrete design book decades ago.

I rather like the red effect it almost looks like a blood stone.

I have seen some very interesting effects generated in colored concrete by adding either fine steel wool, brass wool or copper wool. This yields a very nice colored marble effect with the steel producing iron oxide (rust red) the brass makes a blueish oxide and the copper is green. When the outer surface is polished the look is very unique. I have seen steel and brass wool but have never come across copper wool perhaps it was hand made for the application. I saw this in a concrete design book decades ago.

Lengthen Infinity Black Widow Tonearm!!!

djn! Please give some details about how you lengthened the Infinity Black Widow Tonarm. I just bought one with the specific idea to lengthen it. I didn't think anyone else had tried it. I have access to some very high quality carbon fiber kite spars and carbon fishing rod blanks that look very similar to yours. Would be very excited to hear from you how you did it. One of my main questions is whether the factory carbon arm is glued or somehow screwed into the aluminum pivot mount?

Thanks in advance !!!

!!!

djn! Please give some details about how you lengthened the Infinity Black Widow Tonarm. I just bought one with the specific idea to lengthen it. I didn't think anyone else had tried it. I have access to some very high quality carbon fiber kite spars and carbon fishing rod blanks that look very similar to yours. Would be very excited to hear from you how you did it. One of my main questions is whether the factory carbon arm is glued or somehow screwed into the aluminum pivot mount?

Thanks in advance

Djn

Very nice marble work!

Since granite/marble is very stable, your next project (should you decide to accept it Mr. phelps) would be an a platter and integrated base honed to float it on air.

I have made one out of aluminum and one out of marble would be even better.

Very original design there!

2 big thumbs up

Regards

David

Very nice marble work!

Since granite/marble is very stable, your next project (should you decide to accept it Mr. phelps) would be an a platter and integrated base honed to float it on air.

I have made one out of aluminum and one out of marble would be even better.

Very original design there!

2 big thumbs up

Regards

David

djn! Please give some details about how you lengthened the Infinity Black Widow Tonarm. I just bought one with the specific idea to lengthen it. I didn't think anyone else had tried it. I have access to some very high quality carbon fiber kite spars and carbon fishing rod blanks that look very similar to yours. Would be very excited to hear from you how you did it. One of my main questions is whether the factory carbon arm is glued or somehow screwed into the aluminum pivot mount?

Thanks in advance!!!

I used carbon fiber kite spars like you have. What was left of the original aluminum wand left of the stub had an OD the exact same size as the ID on the carbon tube so it is a tight fit with no glue are screw needed. I made the headshell out of an aluminum bolt that I put in the drill press and shaped with an angle grinder.

Djn

Very nice marble work!

Since granite/marble is very stable, your next project (should you decide to accept it Mr. phelps) would be an a platter and integrated base honed to float it on air.

I have made one out of aluminum and one out of marble would be even better.

Very original design there!

2 big thumbs up

Regards

David

Thanks much David. floating a marble platter would be a sight to see. I'll have to think on that for a while.

Avincenty,

Very nice traditional plinth. Did you do anything with the Lenco top plate? Further pictures available?

I documented the build in the Lenco Heaven forum.

build link

Alfredo

research

Hi all

Stumbled across this thread. Seems to have wandered a bit from the original post, but I thought I'd share a link to a page I found a while ago when I was considering tearing apart my HW-19 and building a new plinth that might mimic an Aries or HR-X.

plinths - Audio qualia

I haven't moved on it yet, and I can't say anything about the definitive nature of the data presented, but I thought it was interesting and have been hoping to apply it to a plinth for a VPI Super Platter and bearing that I managed to get my hands on a few years ago.

Kevin

Hi all

Stumbled across this thread. Seems to have wandered a bit from the original post, but I thought I'd share a link to a page I found a while ago when I was considering tearing apart my HW-19 and building a new plinth that might mimic an Aries or HR-X.

plinths - Audio qualia

I haven't moved on it yet, and I can't say anything about the definitive nature of the data presented, but I thought it was interesting and have been hoping to apply it to a plinth for a VPI Super Platter and bearing that I managed to get my hands on a few years ago.

Kevin

Slate

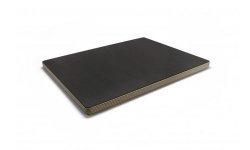

I'm using Slate now but I'm going to try this cutting board.

Hi,

I am planning to build a new plinth for my turntable. I would like to know the best medium for the plinth.

>> Wood.

>> MDF.

>> Granite.

>> Combination.

Please comment...

Best regards,

Bins.

I'm using Slate now but I'm going to try this cutting board.

Attachments

But why?

Isn't slate the Holy Frail for idlers? As I understand it ,the TD124 is a belt/idler hybrid. Regarding the use of a cutting board, I think that it looks like one that is very suitable for a plinth. I think it will look quite good. It's just the cost compared to using Baltic Birch ply (if easily available). I suppose if you can afford slate, then you can afford whatever you wish ; . At least there would be no issues finishing it as the melamine surface looks very good.

The use of cutting boards as plinths works because many are of suitable materials, and look good as purchased. They need no extra work to [put a finish on them either.The one pictured seems to be surfaced with melamine or similar. Be patient drilling into the melamine, use an awl or small pointed machinist's punch to start the centre of a drill hole and then a small bit. Once a small hole is established go to your final size. And support the backside of the cutting board to avoid any tear outs. The use of a drill press is pretty much a given, but if not put the cutting board on a piece of scrap.

I'm using Slate now but I'm going to try this cutting board.

Isn't slate the Holy Frail for idlers? As I understand it ,the TD124 is a belt/idler hybrid. Regarding the use of a cutting board, I think that it looks like one that is very suitable for a plinth. I think it will look quite good. It's just the cost compared to using Baltic Birch ply (if easily available). I suppose if you can afford slate, then you can afford whatever you wish ; . At least there would be no issues finishing it as the melamine surface looks very good.

The use of cutting boards as plinths works because many are of suitable materials, and look good as purchased. They need no extra work to [put a finish on them either.The one pictured seems to be surfaced with melamine or similar. Be patient drilling into the melamine, use an awl or small pointed machinist's punch to start the centre of a drill hole and then a small bit. Once a small hole is established go to your final size. And support the backside of the cutting board to avoid any tear outs. The use of a drill press is pretty much a given, but if not put the cutting board on a piece of scrap.

Last edited:

chopping boards made of slatted bamboo are very good. I use one under my Lenco, and I'm working on a plinth that uses flooring strips, also made of slatted bamboo, with cork and a damping compound I've developed. I'll post pics and measurements when I have finalised the design.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Custom made turntable plinth...