The 115 VAC Crouzet uni-directional synchronous motor without type number has only one phase (only two instead normally four leads and no phase shift cap necessary)

The "ON" direction isn't clear - both directions are possible. To get always the right direction, an internal mechanism is present to determine the right direction.

About

Crouzet Automatismes - Accueil

isn't to find replacement

I want to know a replacement type - Thank you very much

The "ON" direction isn't clear - both directions are possible. To get always the right direction, an internal mechanism is present to determine the right direction.

About

Crouzet Automatismes - Accueil

isn't to find replacement

I want to know a replacement type - Thank you very much

Attachments

It is, as you say, a synchronous motor. Probably 24 pole. If it does 250rpm, then it's definitely 24 pole. If so, you could replace it with the ubiquitous Philips/Premotec motor now distributed by McLennan. You'll need to add a phasing capacitor, but that's hardly a problem. Your more important problem is whether the shaft diameter is the same.

I know McLennan - it is a good delivery source for the motors inside by different models from Linn (LP-12 and AXIS). There are 250 RPM necessary.It is, as you say, a synchronous motor. Probably 24 pole. If it does 250rpm, then it's definitely 24 pole. If so, you could replace it with the ubiquitous Philips/Premotec motor now distributed by McLennan. You'll need to add a phasing capacitor, but that's hardly a problem. Your more important problem is whether the shaft diameter is the same.

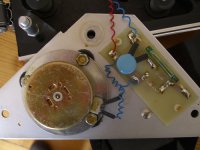

The motor here runs with approximately 580-610 RPM, because the belt is on the outsite of the platter edge (see photo and the milled groove for the belt) and not at a small inner platter like Linn.

Mechtex had overtaken this Crouzet model? How I do Removing Pressing Parts ?

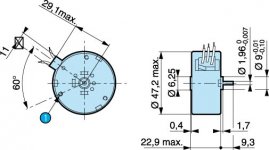

I have discover the right order code of Crouzet: "82 330 582" (82330582)

and some informations about data and some delivery sources:

http://www.crouzet.com/FILIALES/catalogue_web/pdf/ENG/ndb15_eng.pdf

Crouzet | Steuergeräte | Antriebstechnik | AC Motoren | Eine Phase, 240V_6153648_Normal Module |82 330 582

Crouzet Automatismes - Micro-motors - Synchronous motors - Direct drive single direction synchronous motors - 82330582-0.42 Watts

Crouzet Automatismes - Mikromotoren - Synchronmotoren - Ferritsynchronmotoren, 1 Drehrichtung - 82330582-0,42 W

Antriebstechnik & Automatisierung - Ferritsynchronmotor, Rechtslauf, 8 mNm, 82330582 82330582

it seems, Mechtex offer the same motor:

Permanent magnet synchronous electric motors (PMSM) - 600 rpm - MECH-TEX-MFG-CO - Synchronous electric motor: Brushless motor

Mech - Tex

http://www.mechtex.com/pdf/syn_motors/MT6.pdf

But now new questions come to me:

How do I remove the pressing part (motor pulley carrier) sitting on the shaft?

And which tools I need for repressing this part on the new motor?

In the attachement photos from this motor modell inside in the "Golden Shadow"

I have discover the right order code of Crouzet: "82 330 582" (82330582)

and some informations about data and some delivery sources:

http://www.crouzet.com/FILIALES/catalogue_web/pdf/ENG/ndb15_eng.pdf

Crouzet | Steuergeräte | Antriebstechnik | AC Motoren | Eine Phase, 240V_6153648_Normal Module |82 330 582

Crouzet Automatismes - Micro-motors - Synchronous motors - Direct drive single direction synchronous motors - 82330582-0.42 Watts

Crouzet Automatismes - Mikromotoren - Synchronmotoren - Ferritsynchronmotoren, 1 Drehrichtung - 82330582-0,42 W

Antriebstechnik & Automatisierung - Ferritsynchronmotor, Rechtslauf, 8 mNm, 82330582 82330582

it seems, Mechtex offer the same motor:

Permanent magnet synchronous electric motors (PMSM) - 600 rpm - MECH-TEX-MFG-CO - Synchronous electric motor: Brushless motor

Mech - Tex

http://www.mechtex.com/pdf/syn_motors/MT6.pdf

But now new questions come to me:

How do I remove the pressing part (motor pulley carrier) sitting on the shaft?

And which tools I need for repressing this part on the new motor?

In the attachement photos from this motor modell inside in the "Golden Shadow"

Attachments

Last edited:

Removing a pulley isn't usually too difficult. It's doing it without bending the motor shaft that's tricky. Of course, if you know you won't use the motor again, that's not a problem. People used to use spoons as levers, but I never liked that technique. What might work nicely would be some improvised jacks. An M4 threaded spacer with a hexagonal headed bolt going into it would expand as the bolt was undone. If you had three of these evenly spaced under the pulley, you could ease it off by undoing each of the bolts a little at a time.

For putting pulleys onto motors, I've used my drilling machine. Put a piece of steel under the motor shaft (to support it), and a larger piece of wood to hold the motor square, adjust the chuck so that the jaws disapppear inside, and then use the chuck to drive the pulley gently onto the motor shaft.

For putting pulleys onto motors, I've used my drilling machine. Put a piece of steel under the motor shaft (to support it), and a larger piece of wood to hold the motor square, adjust the chuck so that the jaws disapppear inside, and then use the chuck to drive the pulley gently onto the motor shaft.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- CROUZET-Motor for Transrotor Turntable Model "Hydraulic" - Replacement?