This is a message that was sent to me:

“I was thinking about your thread suspension idea and I like it a lot. I was wondering if you used a mono filament thread like a polyester or nylon fishing line? I thought of a twist on this idea to build a linear arm. The horizontal bearing would be two paralleled and tensioned threads spread apart by some small distance. The vertical bearing would be a horizontal thread held in a small “U” shaped frame to which a small plate is clamped to the tread and from which are mounted two small hollow steel tubes that would make up the tonearm assembly. So the tone arm can rotate on the tensioned thread in the “U” channel and the “U” channel would have small groves on the underside which registered to and slide upon the two horizontal filaments. I hope that this makes sense. The tonearm rotates on the short thread and that assembly slides upon the two parallel threads. Let me know what you think about this idea. Thanks for posting your thought provoking idea. Best regards Moray James.”

The thread I used is described in post #5

My bearing is build based on believing that tensioned string solidly connected to the wand can drain out (into the post) vibrations induced in the wand by stylus, so these vibrations don’t get back to cartridge. Like in tight gimbal bearing but without the noise caused by friction. In your proposed model wand assembly slides loosely on 2 parallel threads which is opposite to what I believe. There are reports from air suspended linear arm builders that lowering air pressure (which lowers solidity of coupling between wand assembly and support) lowers sound dynamics, bass quality and output.

It will work but it is hard to say how it will sound.

Marek

“I was thinking about your thread suspension idea and I like it a lot. I was wondering if you used a mono filament thread like a polyester or nylon fishing line? I thought of a twist on this idea to build a linear arm. The horizontal bearing would be two paralleled and tensioned threads spread apart by some small distance. The vertical bearing would be a horizontal thread held in a small “U” shaped frame to which a small plate is clamped to the tread and from which are mounted two small hollow steel tubes that would make up the tonearm assembly. So the tone arm can rotate on the tensioned thread in the “U” channel and the “U” channel would have small groves on the underside which registered to and slide upon the two horizontal filaments. I hope that this makes sense. The tonearm rotates on the short thread and that assembly slides upon the two parallel threads. Let me know what you think about this idea. Thanks for posting your thought provoking idea. Best regards Moray James.”

The thread I used is described in post #5

My bearing is build based on believing that tensioned string solidly connected to the wand can drain out (into the post) vibrations induced in the wand by stylus, so these vibrations don’t get back to cartridge. Like in tight gimbal bearing but without the noise caused by friction. In your proposed model wand assembly slides loosely on 2 parallel threads which is opposite to what I believe. There are reports from air suspended linear arm builders that lowering air pressure (which lowers solidity of coupling between wand assembly and support) lowers sound dynamics, bass quality and output.

It will work but it is hard to say how it will sound.

Marek

This just reminds me of the "well tempered tonearm" by Bill Firebaugh (sp?). I really liked his business practice but not the arm. Every change in level meant a different drag load on the stylus which pulled on the arm a very slightly different amount which resulted in pitch shift at the front of every note. This effect drove me crazy! I could not handle it and made my skin want to jump off my body. Suppose being overly sensitive to FM which is the big can this type of distortion fits in. Singing springs in tonearms was my next big annoyance. -cheers

Recently, while I was listening to some Bach sonatas, I heard distortion during string crescendo passages. Sound familiar, Marek? The string - on my suspension, not the instruments - had stretched and loosened.

After I retightened the string, the distortion mostly disappeared confirming, for me, that Marek's theory that tensioned string carries resonances to the frame where it's damped. But that leaves the problem of where the resonance originated. There are plenty of suspects. This arm was pretty much thrown together with whatever was on the bench at the time so the type of string, wand material, cartridge, and counter-weight design all need to be re-examined. Marek's find that additional weight at the head shell is helpful is a good starting point. Beyond that, despite my allergy to math, I'd like this to get a little more formal and check out more about effective mass and the causes/cures of resonance.

Before I built this arm, I was considering a tensioned string linear arm. My idea was to use glass beads for the sliding surface, but after buying beads and sliding them on string, teflon insulated wire, and guitar string, I decided there was too much friction/noise and I wasn't sure about how to avoid/damp the noise and string resonances.

Regardless, I urge Moray James to go ahead with developing his idea and reporting back. I hope my experience was misleading and he comes up with something viable.

After I retightened the string, the distortion mostly disappeared confirming, for me, that Marek's theory that tensioned string carries resonances to the frame where it's damped. But that leaves the problem of where the resonance originated. There are plenty of suspects. This arm was pretty much thrown together with whatever was on the bench at the time so the type of string, wand material, cartridge, and counter-weight design all need to be re-examined. Marek's find that additional weight at the head shell is helpful is a good starting point. Beyond that, despite my allergy to math, I'd like this to get a little more formal and check out more about effective mass and the causes/cures of resonance.

Before I built this arm, I was considering a tensioned string linear arm. My idea was to use glass beads for the sliding surface, but after buying beads and sliding them on string, teflon insulated wire, and guitar string, I decided there was too much friction/noise and I wasn't sure about how to avoid/damp the noise and string resonances.

Regardless, I urge Moray James to go ahead with developing his idea and reporting back. I hope my experience was misleading and he comes up with something viable.

Doug thanks I appreciate your support, projects such as this can take on a life of their own. I only wish that I had a fraction of the DIY talent that I see most every day in these forums. I would be most interested in seeing any pictures you might have of your arm projects linear or pivoted.

Moray,

You're welcome.

Post 14 in this thread.

Edison said something about "90% perspiration and 10% inspiration." I've noticed that persistence, inquisitiveness, and a willingness to royally screw up seem to really count in DIY. Oh, yeah, and a penchant for hanging out in and with the weird.

You're welcome.

Post 14 in this thread.

Edison said something about "90% perspiration and 10% inspiration." I've noticed that persistence, inquisitiveness, and a willingness to royally screw up seem to really count in DIY. Oh, yeah, and a penchant for hanging out in and with the weird.

Sumadioguy,

I am saddened that my tonearm reminds you of an unpleasant experience.

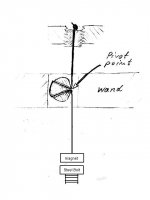

I only saw a picture of “well tempered tonearm” and I don’t like the design. My tonearm is mechanically different. My bearing is practically a unipivot. I am not sure what to call the bearing of “well tempered” – a floating swing? My string is under tension, it is solidly anchored to the support above and below the wand and string’s horizontal movement and vibration is limited. My antiskate force is adjustable and proportional to skating force. I use different materials etc. And don’t forget that my tonearm is home made, not for sale but free to be copied for any reason.

I don’t hear the singing of the spring, you might. With your experience, you probably could calculate resonance and without building anything find out if the spring sings in audible frequency. I prefer to build my toys and if they sound good to me I share the design.

Doug,

I use test LP to check mechanical resonance of the tonearm with given cartridge, so far I was only a couple of grams off the target. Sound waves behavior in the wand and other parts of the tonearm is a different matter - unless you have lab equipment you have to trust your ears. The only “complicated” calculation I did was the effect of different distance between magnets’ gap and string attachment point on stiffness of the Schroeder type bearing, but that does not apply to our designs.

Moray,

I also was dreaming about linear arm, it was string suspended unipivot mounted on brass bearings sliding on two stainless steel bars. The wand assembly was motorized and wand was pivoting only to compensate for crooked records.

Marek

I am saddened that my tonearm reminds you of an unpleasant experience.

I only saw a picture of “well tempered tonearm” and I don’t like the design. My tonearm is mechanically different. My bearing is practically a unipivot. I am not sure what to call the bearing of “well tempered” – a floating swing? My string is under tension, it is solidly anchored to the support above and below the wand and string’s horizontal movement and vibration is limited. My antiskate force is adjustable and proportional to skating force. I use different materials etc. And don’t forget that my tonearm is home made, not for sale but free to be copied for any reason.

I don’t hear the singing of the spring, you might. With your experience, you probably could calculate resonance and without building anything find out if the spring sings in audible frequency. I prefer to build my toys and if they sound good to me I share the design.

Doug,

I use test LP to check mechanical resonance of the tonearm with given cartridge, so far I was only a couple of grams off the target. Sound waves behavior in the wand and other parts of the tonearm is a different matter - unless you have lab equipment you have to trust your ears. The only “complicated” calculation I did was the effect of different distance between magnets’ gap and string attachment point on stiffness of the Schroeder type bearing, but that does not apply to our designs.

Moray,

I also was dreaming about linear arm, it was string suspended unipivot mounted on brass bearings sliding on two stainless steel bars. The wand assembly was motorized and wand was pivoting only to compensate for crooked records.

Marek

Directdriver,

You missed my point - I wanted both ends of the string solidly attached to the support!

I don’t like patented designs, because then you have to bury your toys with you to avoid a patent attorney showing up on the widow’s doorstep...

I am busy growing food now in my veggie garden, but when spring is over I will make my second tonearm; I already thought out different vertical geometry for it.

Marek

You missed my point - I wanted both ends of the string solidly attached to the support!

I don’t like patented designs, because then you have to bury your toys with you to avoid a patent attorney showing up on the widow’s doorstep...

I am busy growing food now in my veggie garden, but when spring is over I will make my second tonearm; I already thought out different vertical geometry for it.

Marek

You missed my point - I wanted both ends of the string solidly attached to the support! I don’t like patented designs, because then you have to bury your toys with you to avoid a patent attorney showing up on the widow’s doorstep...

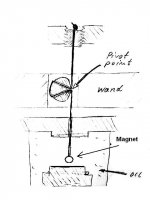

I was not criticizing your design, Marekst. I think your design is brilliant and it inspired me to come up with something different - and if I ever want to build a DIY tonearm, I might try that. It was just a variation of the same theme, really. If you have to attach the string to a spring, it is already a compliant system so instead of spring, the string is attached to a magnet and by varying the gap the tension changes. This scheme I drew up in the picture is not the patented Schroeder - after all there's an extra string above the magnet so it's very different - and no one is making a commercial product out of it so I don't worry about it. I was not asking you to make an arm out of my drawing, just contributing idea to the discussion on here. Isn't this what the forum is about? Why so defensive? Anyway, good luck with your future projects.

.

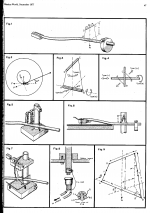

Attachments

Directdriver,

I welcome all contributions. However, I believe that using magnet to tension the string is in fact an essence of Schroeder invention. I may be wrong. You can ask him or a patent lawyer. I put my design in public domain so it can be copied for any reason whatsoever. Changing my drawing with my handwriting on it and posting it, is just not right. It can be confusing and misleading to others. It might even get somebody in trouble. You do not have to make a commercial product; Frank has every right and promised to act on a single, home made clone sold.

Marek

I welcome all contributions. However, I believe that using magnet to tension the string is in fact an essence of Schroeder invention. I may be wrong. You can ask him or a patent lawyer. I put my design in public domain so it can be copied for any reason whatsoever. Changing my drawing with my handwriting on it and posting it, is just not right. It can be confusing and misleading to others. It might even get somebody in trouble. You do not have to make a commercial product; Frank has every right and promised to act on a single, home made clone sold.

Marek

Marekst,

Ah, I see you are objecting to the drawing! I completely did not think of that. I apologize and I am sorry for vandalizing your invention. I was trying to suggest an idea and instead of describing it in words I was just trying to illustrate it in drawing. I should have made an original drawing but I was lazy so I am paying the price here. Again, I apologize.

Even if Frank is here, I am confident that the use of magnet here is indeed different from his design. Besides, there are already multiple posts on Schroeder clones that Frank himself participates in the thread - the posts are still active and lively discussions abound - and giving advices to people wanting to make a DIY unit for themselves as long as they don't sell it. I am not selling tonearm and I am not even making one so I don't worry.

Before the Schroder arm, there was the Well Tempered arm. Basically there's nothing original about a string hanging tonearm but the inventiveness comes in the way how the arm is stabilized, the same thing with unipivot arms like the Graham Phantom, Basis Vector, Continuum Copperhead, et al - using magnet in the Phantom case and using ball bearing in the case of the Vector and Copperhead. Frank's design uses a magnet DIRECTLY attaches to the bottom of the armwand and as you pointed out, it's geometrically more ambiguous because the magnetic pulling force is a pivoting AREA not a single point but I believe Frank does it for a reason for his design - to shift the pivot point slightly in case of warp record to create a dynamic geometric relationship.

Before I saw your design I was thinking along the same line that I prefer to have a single bearing point like a uni-pivot tonearm and simply thought of tying the bottom string snugly to the bottom support. To have constant tension on the bottom string, one needs some kind of compliant material and, in your case, a spring works well. And I just thought a magnet would do the trick too, and I think a rubber band might work also. I also think by using sheer weight will work as one can hang a hefty sliding rod vertically. This is where the invention comes in and those who have more ideas, feel free to chime in.

If I may, let me articulate the essence of this design that is layered in the following and think of each physical component placed vertically from top to bottom:

Hanger

String (top)

Armwand

String (bottom)

Stabilizing & compliant material(spring, rubber band, magnet, etc..)

The key is that all movements, vertically and horizontally pivot at a single point. What is above and below the arm pivot are both attached to a string. The top string is stabilized by gravity and the bottom string is tensioned by a spring or magnet. Of course to make the bottom string more precisely placed, it is best to let it pass through a tiny slot as your design have done.

Sorry that I may have repeated what you already illustrated in your post, the above is simply thinking out loud. But it's a fun mental exercise.

Thanks again for sharing your idea with the DIY community and I am sorry for abusing your drawing and I wish I am allowed to edit out the drawings but I cannot see the EDIT button so I will be more sensitive in the future.

Happy project building!

.

Ah, I see you are objecting to the drawing! I completely did not think of that. I apologize and I am sorry for vandalizing your invention. I was trying to suggest an idea and instead of describing it in words I was just trying to illustrate it in drawing. I should have made an original drawing but I was lazy so I am paying the price here. Again, I apologize.

Even if Frank is here, I am confident that the use of magnet here is indeed different from his design. Besides, there are already multiple posts on Schroeder clones that Frank himself participates in the thread - the posts are still active and lively discussions abound - and giving advices to people wanting to make a DIY unit for themselves as long as they don't sell it. I am not selling tonearm and I am not even making one so I don't worry.

Before the Schroder arm, there was the Well Tempered arm. Basically there's nothing original about a string hanging tonearm but the inventiveness comes in the way how the arm is stabilized, the same thing with unipivot arms like the Graham Phantom, Basis Vector, Continuum Copperhead, et al - using magnet in the Phantom case and using ball bearing in the case of the Vector and Copperhead. Frank's design uses a magnet DIRECTLY attaches to the bottom of the armwand and as you pointed out, it's geometrically more ambiguous because the magnetic pulling force is a pivoting AREA not a single point but I believe Frank does it for a reason for his design - to shift the pivot point slightly in case of warp record to create a dynamic geometric relationship.

Before I saw your design I was thinking along the same line that I prefer to have a single bearing point like a uni-pivot tonearm and simply thought of tying the bottom string snugly to the bottom support. To have constant tension on the bottom string, one needs some kind of compliant material and, in your case, a spring works well. And I just thought a magnet would do the trick too, and I think a rubber band might work also. I also think by using sheer weight will work as one can hang a hefty sliding rod vertically. This is where the invention comes in and those who have more ideas, feel free to chime in.

If I may, let me articulate the essence of this design that is layered in the following and think of each physical component placed vertically from top to bottom:

Hanger

String (top)

Armwand

String (bottom)

Stabilizing & compliant material(spring, rubber band, magnet, etc..)

The key is that all movements, vertically and horizontally pivot at a single point. What is above and below the arm pivot are both attached to a string. The top string is stabilized by gravity and the bottom string is tensioned by a spring or magnet. Of course to make the bottom string more precisely placed, it is best to let it pass through a tiny slot as your design have done.

Sorry that I may have repeated what you already illustrated in your post, the above is simply thinking out loud. But it's a fun mental exercise.

Thanks again for sharing your idea with the DIY community and I am sorry for abusing your drawing and I wish I am allowed to edit out the drawings but I cannot see the EDIT button so I will be more sensitive in the future.

Happy project building!

.

Last edited:

Marek,

I hope you enjoy whatever endeavors you take up now. You made valuable contributions here and I appreciated our discussions about what I've come to think of as "soft suspension" tonearms. For now, I'm going to be checking out string materials and damping methods. I replaced the string on my tonearm with monofilament, which is pretty springy, but I'm not convinced yet that, in my arrangement, that's necessarily a problem. I still like the sound I'm getting. I've got some much less stretchy high tech braid that I'll use to try to make some comparisons.

EC8010,

I came across pictures you posted back a ways of an arm you'd built. Beautiful work. Thanks for posting the Bizarrm article. The author seems quite comfortable with the torsional displacements I was concerned about.

I hope you enjoy whatever endeavors you take up now. You made valuable contributions here and I appreciated our discussions about what I've come to think of as "soft suspension" tonearms. For now, I'm going to be checking out string materials and damping methods. I replaced the string on my tonearm with monofilament, which is pretty springy, but I'm not convinced yet that, in my arrangement, that's necessarily a problem. I still like the sound I'm getting. I've got some much less stretchy high tech braid that I'll use to try to make some comparisons.

EC8010,

I came across pictures you posted back a ways of an arm you'd built. Beautiful work. Thanks for posting the Bizarrm article. The author seems quite comfortable with the torsional displacements I was concerned about.

Doug: do you still have your version of the linear arm that you built? If so I would be keen to see some pictures of it and perhaps discuss its merits and any issues that you had with it. I think that a thread linear could be an interesting and simple project to diy. Did you use a single thread for both the vertical and horizontal motion? I had thought that two or three threads for the horizontal track would spread the weight load over multiple threads. There is only so much tension that could be applied to a horizontal thread in a simple design like this and so my thought for three. I had been thinking of using a mono filament thread rather than a steel wire thinking that the plastic thread would self damp better than piano wire or such. Marek may be right that solid metal knife edge tracks might be necessary to make things work properly. Regards.

Moray,

I apologize - I didn't make myself clear about the linear arm. It was just a thought experiment and didn't get much past buying buying the beads, trying them on different wires and strings and trying some inexpensive bearings - ball and slider - on different rods and troughs. None of that seemed promising so I went on to the string suspension normal arm I wound up posting. Nylon or bronze bearings on polished steel rods - in this case, something cannibalized from a very cheap linear tracker - might have led to something, but I didn't follow up. I couldn't convince myself the assembly wouldn't grab and stutter. My recent experience with the stretchiness of monofilament makes me wonder about how well it could be tensioned, but the heavier stuff >20# might work especially if you parallel three strings. I think you're right about the damping qualities of plastic compared to wire. Teflon insulation over steel might work. It would be easy to make a U frame and do tests and you could use it as a test bed for working out the number of strings and their arrangements. Almost every time I've started hacking some idea into reality, there have been "aha" moments - both positive and negative - that have been rewarding in themselves, kept me out of dead ends, or have lead to eventual solutions.

I was just about to ask an insulting question about whether you'd looked at other linears, but had the sense to check first and found some of your earlier posts. You've obviously put a lot of thought into this.

I hope you carry out your ideas and post the results - I'd really like to see what you come up with.

I apologize - I didn't make myself clear about the linear arm. It was just a thought experiment and didn't get much past buying buying the beads, trying them on different wires and strings and trying some inexpensive bearings - ball and slider - on different rods and troughs. None of that seemed promising so I went on to the string suspension normal arm I wound up posting. Nylon or bronze bearings on polished steel rods - in this case, something cannibalized from a very cheap linear tracker - might have led to something, but I didn't follow up. I couldn't convince myself the assembly wouldn't grab and stutter. My recent experience with the stretchiness of monofilament makes me wonder about how well it could be tensioned, but the heavier stuff >20# might work especially if you parallel three strings. I think you're right about the damping qualities of plastic compared to wire. Teflon insulation over steel might work. It would be easy to make a U frame and do tests and you could use it as a test bed for working out the number of strings and their arrangements. Almost every time I've started hacking some idea into reality, there have been "aha" moments - both positive and negative - that have been rewarding in themselves, kept me out of dead ends, or have lead to eventual solutions.

I was just about to ask an insulting question about whether you'd looked at other linears, but had the sense to check first and found some of your earlier posts. You've obviously put a lot of thought into this.

I hope you carry out your ideas and post the results - I'd really like to see what you come up with.

Last edited:

Ha a lot of thinking has gone into lots of bad designs I don't suppose mine are any different. But yes I have put some considerable time into the thought process. There are a horde of simple and elegant linear design ideas in the US patents dating back to the Forties. Would be nice to find a Teflon coated steel wire but Teflon has a habit of flowing under pressure so placing it under tension might result in some weird things happening to the coating. There are lots of Teflon coated copper wires but I don't imagine you could keep them tensioned without stretching but they might prove useful for a proof of concept. I am thinking that something along the lines of dead simple might just get the job done. Lots of times over thinking things can get in the way and high tech is not always the solution but it does make for good marketing spin. After helping Nanook build a $3.00 ball point pen unipivot arm one night and watching painfully how long it spun in a circle on the pivot made of an acorn nut only to see it drift backward a degree or so after it stopped moving around I was blown away as to how well low tech can work. A unipivot like this on a sled riding on horizontally stretched mono filament threads might work a treat. There are so many was to skin the cat (just a figure of speech I like cats). But I do like your horizontal thread suspension and it could be pre tensioned to off set resonances by adding some amount of twist to the thread when mounting the arm wand. Not enough to throw things off but enough to prevent a structural resonance in the suspension in the vertical plane. Lots to think about. Hope to see your continued input as more comments makes for a wider view of things. Sometimes even the strangest of comments can trigger some useful ideas. Regards.

Moray,

"Skin a cat" to cat gut to violin string or some such? High tension capable and much deader than guitar/piano. I tried CAT 5 teflon coated wire, but I don't think it's strong enough although the teflon was quiet and damped the copper. For the steel wire, I was thinking of something like teflon spaghetti rather than something that would stretch as the steel was tensioned.

I've been trying to figure out off-setting, counter-balancing twists in the string, but no real luck so far. At some point diminishing returns start to kick in. And, at this point Spousal Project Tolerance is getting a little strained. Fortunately, she likes the sound the arm's producing, too, so I'm OK for a bit longer.

"Skin a cat" to cat gut to violin string or some such? High tension capable and much deader than guitar/piano. I tried CAT 5 teflon coated wire, but I don't think it's strong enough although the teflon was quiet and damped the copper. For the steel wire, I was thinking of something like teflon spaghetti rather than something that would stretch as the steel was tensioned.

I've been trying to figure out off-setting, counter-balancing twists in the string, but no real luck so far. At some point diminishing returns start to kick in. And, at this point Spousal Project Tolerance is getting a little strained. Fortunately, she likes the sound the arm's producing, too, so I'm OK for a bit longer.

Cat gut is strong but not near as strong as a mono filament. That also was my line of thought and a mono filament will take a twist to generate some reverse tension far more effectively than a stranded thread will. That might get you where you want with a little differential off set in the tension on the thread or filament so that up and down motion cannot get itself off on some resonance related to the mass of the arm. Kind of a self built in damping. This could also be used in a design like Marek"s for anti skate purposes. It might get a little tweaky but who knows until you try it out.

Say aint that the way it's always been 'what have you done for me today?" a man has always got to "produce" to keep a woman happy. Well you are still getting that job done so you are ahead of me on that score. Back to the mono filament, the larger the diameter the more effectively you will be able to "torque" it up so maybe you need a thicker filament. Fishing lines are your most available and least expensive source that I can think of. Time to go fishing Doug. Who knows what you might catch? Regards.

Say aint that the way it's always been 'what have you done for me today?" a man has always got to "produce" to keep a woman happy. Well you are still getting that job done so you are ahead of me on that score. Back to the mono filament, the larger the diameter the more effectively you will be able to "torque" it up so maybe you need a thicker filament. Fishing lines are your most available and least expensive source that I can think of. Time to go fishing Doug. Who knows what you might catch? Regards.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- DIY tensioned string suspended tonearm