It's definetely a useful app note for the equations but I think you'd be far better off with the circuits and parts used in their AN-1651 app note, available here-

Audio App Notes

CH

Audio App Notes

CH

LT1028 better than LT1115 better than LM833Hi,

The Linear Technology LT1115 is also being used in phono stages. See the attached file. Which one will be better (when compared to National LM833 implementation) ?

Best regards,

Bins.

Hi,

What about the RETRO from twisted pear audio ? (We have got a thread here for this at: http://www.diyaudio.com/forums/twis...fully-symetrical-phono-stage-riaa-filter.html)

Please suggest.

Best regards,

Bins.

What about the RETRO from twisted pear audio ? (We have got a thread here for this at: http://www.diyaudio.com/forums/twis...fully-symetrical-phono-stage-riaa-filter.html)

Please suggest.

Best regards,

Bins.

I like balanced and instrumentation amps, but you have to compare the actual measured performance of that design vs. some other design. I believe (could be wrong) that differential amp systems like that one are at an inherent noise disadvantage over single ended. Other benefits may make up for it. IMO, the performance of the LME opamps is so good that only a fairly complex discrete design can compete with it. It is, however, a high speed part and poorly laid out or poorly bypassed, it won't do its best. The commercial instrumentation amps I've seen don't come close on noise and distortion, but I haven't used 'em all.

CH

CH

for good background on designing riaa stages using opamps, you would be hard pressed to do a lot better than studying pages 6.11-6.27 of this handbook from Analog Devices: http://www.analog.com/static/import... Amp Applications Book (PDF)/P2 Ch6_final.pdf and the errata: http://www.analog.com/library/analogDialogue/archives/39-05/Web_Errata.pdf

mlloyd1

mlloyd1

Last edited:

Hi CH,

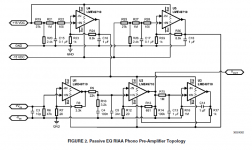

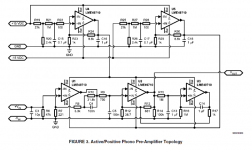

1. In the LME4910 application note (AN-1651), there are two types of designs specified - Passive EQ and Active/Passive EQ (Hybrid EQ). The overall DC gain for the fully passive EQ design is 74dB and 70dB for the active/passive EQ design. Which one will be better ?

2. In the cartridge loading portion of the schematics, the capacitance used is 10pF. Will that be enough ? (In the cartridge loading theory it is stated as 100pF for MC and 300pF for MM)

Best regards,

Bins.

1. In the LME4910 application note (AN-1651), there are two types of designs specified - Passive EQ and Active/Passive EQ (Hybrid EQ). The overall DC gain for the fully passive EQ design is 74dB and 70dB for the active/passive EQ design. Which one will be better ?

2. In the cartridge loading portion of the schematics, the capacitance used is 10pF. Will that be enough ? (In the cartridge loading theory it is stated as 100pF for MC and 300pF for MM)

Best regards,

Bins.

Attachments

I've always used active, but a good argument can be made for passive as well. Frankly, I probably couldn't tell the difference if the curves matched. Active probably has a noise advantage, and I might be able to hear that. Or not.

You should adjust the loading to suit your particular cartridge. Remember, the turntable cables are part of the load, so the preamp load can often be quite low and still have the total correct. Some cartridges are load sensitive, others are not. My moving magnet Ortofon OM series is almost completely immune to load changes.

CH

You should adjust the loading to suit your particular cartridge. Remember, the turntable cables are part of the load, so the preamp load can often be quite low and still have the total correct. Some cartridges are load sensitive, others are not. My moving magnet Ortofon OM series is almost completely immune to load changes.

CH

Hi CH,

Thanks for your reply. I am going for the Active/Passive model (Hybrid). All the resistors will be metal film with 0.1 % tolerance and all the capacitors will be of polypropylene with a maximum tolerance limit of 5%.

1. What should be the required DC voltage rating for the resistors & caps ?

2. What should be the required power rating for the resistors & caps ?

Best regards,

Bins.

Thanks for your reply. I am going for the Active/Passive model (Hybrid). All the resistors will be metal film with 0.1 % tolerance and all the capacitors will be of polypropylene with a maximum tolerance limit of 5%.

1. What should be the required DC voltage rating for the resistors & caps ?

2. What should be the required power rating for the resistors & caps ?

Best regards,

Bins.

There isn't too much to think about when choosing ratings for solid state preamps. A good rule is that caps should be rated for the maximum supply differential, plus a safety factor. Say you use +/-15VDC. Use 35V caps as a minimum. 1/4W MF resistors are what I use. If it were surface mount you'd worry more about power ratings, but for the values in a preamp it's rarely a problem. I like polypropylenes unless I can get polystyrenes- they both sound good. I do, however, select my caps for value and match them to 1% or better from channel to channel. Resistors too, but I start with 1%. I want my RIAA perfect and I want the channels to match as closely as possible. Depending on what you have to test with, you might also want to build a little test box containing a reverse RIAA network. That will give you flat response, making testing easier. Various plans if you search- I use the one with the extra time constant.

(BTW, proper engineering requires one to calculate the worst case power dissipation for every part, and the worst case voltage drop. Print out a schematic, figure out how much and how little voltage could possibly be on each end of each resistor, subtract the two and apply ohms law. As I said, it's almost never an issue in a preamp, but the exercise is an important habit to get into. Include situations like the output being short circuited and the input getting a 15VDC connection from some other failed piece of equipment.)

Best,

CH

(BTW, proper engineering requires one to calculate the worst case power dissipation for every part, and the worst case voltage drop. Print out a schematic, figure out how much and how little voltage could possibly be on each end of each resistor, subtract the two and apply ohms law. As I said, it's almost never an issue in a preamp, but the exercise is an important habit to get into. Include situations like the output being short circuited and the input getting a 15VDC connection from some other failed piece of equipment.)

Best,

CH

Last edited:

Well, the LT1028 is superior to any LME I've heard even as a unity gain DAC buffer, then I guess all the more so in a phono stage...I like balanced and instrumentation amps, but you have to compare the actual measured performance of that design vs. some other design. I believe (could be wrong) that differential amp systems like that one are at an inherent noise disadvantage over single ended. Other benefits may make up for it. IMO, the performance of the LME opamps is so good that only a fairly complex discrete design can compete with it. It is, however, a high speed part and poorly laid out or poorly bypassed, it won't do its best. The commercial instrumentation amps I've seen don't come close on noise and distortion, but I haven't used 'em all.

CH

Well, you're getting your information from some joker on the internet, but FWIW...

I suspect the LT1028 could be better at DAC buffer duty, but I tried it in my preamp and didn't think it was as good as the LME chips. We're talking really subtle stuff here, maybe only stuff of the mind, so I think the jury is out and will remain out forever. Remember, I'm the guy who doesn't think the OPA-627 is as good as the LME parts either. Or, any other popular "audiophile" IC.

Note that the Nat app note circuit goes to great lengths with buffered power. I didn't do that. IMO, if you can hear differences between power supplies, there is something wrong with your physical layout, or something insufficient about your bypass scheme. Trace and wire routing in a preamp is critical to getting the lowest hum/noise and since the LME amps are very fast, they also need proper bypassing. I get my best results with small film caps located near the chips. Something like 0.1 to 0.47 uF works well. Film caps (Mylar or Panasonic mystery film) have good performance up into the MHz if you keep the leads and traces very short. Somewhere on the board should be 100 to 1000 uF as well. Nothing exotic, just decent low esr electrolytics.

I installed a switch to insert resistors in the supply lines (up to 100 ohms) and found that with a properly laid out and bypassed pre board, the extra resistance made no detectable difference. Thus, I can't put much credence in claims about the supply being critical- it's several inches away at best, so HF performance is provided by the bypass caps, not the supply. It should be well regulated, but LM317 and its negative cousin are fine. Transformer hum induced in the chassis can be an issue, so the chassis ground point is critical. There should be a single tie point to the chassis, and that should be right at the lowest level input. The inputs, however, should be isolated from the chassis and the ground wired to the pre board, which is then wired back to the tie point. You want no power currents flowing in signal grounds- ever! A (pc based) spectrum analyzer is really handy to figure this stuff out.

I suspect the LT1028 could be better at DAC buffer duty, but I tried it in my preamp and didn't think it was as good as the LME chips. We're talking really subtle stuff here, maybe only stuff of the mind, so I think the jury is out and will remain out forever. Remember, I'm the guy who doesn't think the OPA-627 is as good as the LME parts either. Or, any other popular "audiophile" IC.

Note that the Nat app note circuit goes to great lengths with buffered power. I didn't do that. IMO, if you can hear differences between power supplies, there is something wrong with your physical layout, or something insufficient about your bypass scheme. Trace and wire routing in a preamp is critical to getting the lowest hum/noise and since the LME amps are very fast, they also need proper bypassing. I get my best results with small film caps located near the chips. Something like 0.1 to 0.47 uF works well. Film caps (Mylar or Panasonic mystery film) have good performance up into the MHz if you keep the leads and traces very short. Somewhere on the board should be 100 to 1000 uF as well. Nothing exotic, just decent low esr electrolytics.

I installed a switch to insert resistors in the supply lines (up to 100 ohms) and found that with a properly laid out and bypassed pre board, the extra resistance made no detectable difference. Thus, I can't put much credence in claims about the supply being critical- it's several inches away at best, so HF performance is provided by the bypass caps, not the supply. It should be well regulated, but LM317 and its negative cousin are fine. Transformer hum induced in the chassis can be an issue, so the chassis ground point is critical. There should be a single tie point to the chassis, and that should be right at the lowest level input. The inputs, however, should be isolated from the chassis and the ground wired to the pre board, which is then wired back to the tie point. You want no power currents flowing in signal grounds- ever! A (pc based) spectrum analyzer is really handy to figure this stuff out.

Hello CH,

I am going for the LME4910 hybrid model. All the resistors will be 250mW 200V DC 0.1% Metal Film and all the capacitors will be 200V DC polypropylene 5%.

Do you have any suggestions for the 15V DC supply ?

Best regards,

Bins.

You can get some of PerAnders "Sjostrom" regulator boards or the Jung-Didden Super Regulator from Old Colony Sound -- see the super regulator thread. (For the error amp I like the AD797 or LT1028...but I haven't tried out the National Chips on his boards. FWIW, some folks really like the TO-5 cases for the National Chips.)

I've built an RIAA amp "Dead bug" style -- with the chips flat on their backs. The citing of Walt Jung's article on RIAA amplifiers in his "Operational Amplifier Handbook" is a must read.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Phono preamplifier using OPAMPS.