It's just made of laminated MDF with nothing done particularly precisely or nicely, but I just want to come away with something marginally functional.

I used parts from a rekokut K-33H (platter, motor, bearing) that I had been hanging on to for a while and an SME Series III I had. Still have no idea what cartridge I will use, I have a nice Shure V15 III stylus but no cartridge, and a couple of other MM carts around. Not sure what the best match would be for the arm.

I hope to have it completed before this weekend's AKfest (audiokarma), or as completed as a PVC and MDF turntable can be.

I used parts from a rekokut K-33H (platter, motor, bearing) that I had been hanging on to for a while and an SME Series III I had. Still have no idea what cartridge I will use, I have a nice Shure V15 III stylus but no cartridge, and a couple of other MM carts around. Not sure what the best match would be for the arm.

I hope to have it completed before this weekend's AKfest (audiokarma), or as completed as a PVC and MDF turntable can be.

Looks like we both had about the same idea for a turntable. It looks great. The only diffenrece is I used 5 layers of 3/4" mdf for mine, but with the Rek-O-Kut platter on top it will probably come out to be the same. Progress looks great! Can't wait to see the final product.

dnewma04 said:I have a nice Shure V15 III stylus but no cartridge

I think i have a body with no stylus.

dave

The ROK bearing isn't the last word in precision and maybe a bit noisier than some better bearings on the market. The shaft is 1/2" and has a spiral groove in it to pull up the lubricant. I would guess that if I machined a new housing with some precision oilite sleeves and a proper thrust plate, it would make a very very good bearing. The platter needs some damping added, it's rather bell like if you tap on it.

I should have it hooked up by tonight with some luck.

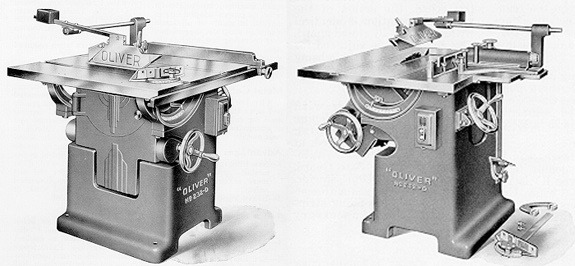

The table saw is a nice one. I have an Oliver 232-D, but I'm saving up for a nice fence for it. In the mean time, the inlaw's Craftsmen suits me just fine.

I should have it hooked up by tonight with some luck.

The table saw is a nice one. I have an Oliver 232-D, but I'm saving up for a nice fence for it. In the mean time, the inlaw's Craftsmen suits me just fine.

throw out the MDF....

it sucks the life out of music.

I know I've almost flogged this point to death, but...

try a nice hardwood. The ROK turntables apparently like the high mass approach. As a minimum, buy my fave, Baltic Birch plywood. Relatively easy to get. Relatively inexpensive.

Or consider any of the denser hardwoods, such as walnut, cherry, etc.

stew

it sucks the life out of music.

I know I've almost flogged this point to death, but...

try a nice hardwood. The ROK turntables apparently like the high mass approach. As a minimum, buy my fave, Baltic Birch plywood. Relatively easy to get. Relatively inexpensive.

Or consider any of the denser hardwoods, such as walnut, cherry, etc.

stew

I think I would be afraid of it moving. In that I mean that with temperature and humidity, wood moves. Good furniture is all made to allow for expansion. A wood bearing would not allow for that motion at all.

On the other hand, I know that some pumps, specifically for water, user ironwood bearings. I did some testing at the NREL labs in Ottawa. In their hydro lab, they have a pump like that. When it started you heard the metal shaft drag on the wood for the first couple revolutions. Once the water started flowing, it was silent and smooth as could be. So, I don't have a definitive answer to that idea, only some thoughts on it

On the other hand, I know that some pumps, specifically for water, user ironwood bearings. I did some testing at the NREL labs in Ottawa. In their hydro lab, they have a pump like that. When it started you heard the metal shaft drag on the wood for the first couple revolutions. Once the water started flowing, it was silent and smooth as could be. So, I don't have a definitive answer to that idea, only some thoughts on it

The show was a success, I installed a A&R cambridge P77 cartridge that I had on hand and it was a great match for the low mass SME arm.

If the MDF is sucking the life out of the music, I didn't hear it nor would I want to add more life to the music. It sounded quiet, natural, and in some ways, I preferred it to my Oracle Delphi/SME V/VDH 2 turntable, especially in terms of bass impact.

It's certainly not going to compare to my bigger project, but it does sound damn good as it is.

If the MDF is sucking the life out of the music, I didn't hear it nor would I want to add more life to the music. It sounded quiet, natural, and in some ways, I preferred it to my Oracle Delphi/SME V/VDH 2 turntable, especially in terms of bass impact.

It's certainly not going to compare to my bigger project, but it does sound damn good as it is.

dnewma04..if you prefer it to your Oracle...

you may very well have a sick Delphi...or not. We all have our own listener biases.

There could be a number of factors with your preference compared to the Delphi. Which Delphi? Which VDH, MM2 or MC Two special?

regarding the use of hardwood and Baltic Birch plywood. There is a reason that (almost universally ) the big dog Thorens, and Garrard re-builders and re-plinth folks use it...it simply sounds better.

In no way are my comments meant to devalue your experiences, but you do owe it to yourself to go buy a sheet of 1/2" or 3/4" BB ply once you have settled on the cosmetic portion of your design. You will not be disappointed.

The biggest hassle with BB ply is the difficulty finishing it. It can be a bear to stain , so paint or some sort of top coat finish (glazes etc) may be the best you can do, or of course veneer.

Regardless, your project is quite inspiring and I look forward to any further developments and updates that you provide.

stew

you may very well have a sick Delphi...or not. We all have our own listener biases.

There could be a number of factors with your preference compared to the Delphi. Which Delphi? Which VDH, MM2 or MC Two special?

regarding the use of hardwood and Baltic Birch plywood. There is a reason that (almost universally ) the big dog Thorens, and Garrard re-builders and re-plinth folks use it...it simply sounds better.

In no way are my comments meant to devalue your experiences, but you do owe it to yourself to go buy a sheet of 1/2" or 3/4" BB ply once you have settled on the cosmetic portion of your design. You will not be disappointed.

The biggest hassle with BB ply is the difficulty finishing it. It can be a bear to stain , so paint or some sort of top coat finish (glazes etc) may be the best you can do, or of course veneer.

Regardless, your project is quite inspiring and I look forward to any further developments and updates that you provide.

stew

I didn't take your comments as trying to devalue my system, I knew the content of your message would inevitably be expressed by someone. For every MDF fan, there is at least one plywood fan. I had MDF scrap, so it's what I used, part of the project was to see what I could built quickly and inexpensively. Outside of the arm, I have approximately 25.00 invested in the table so far. Paint, when it comes time to spray it will kill that budget, though.

I don't think the Delphi is ailing, it's been semi-recently tuned up, the cart is a the VDH Two, HOMC cart. It sounds great, but there seemed to be an advantage in bass with this project. The Two is much more detailed than the A&R Cambridge P77, so the mids/highs were marginally better with the Delphi.

When I build my "real" DIY turntable, it will be made of epoxy granite, aluminum, PVC and acrylic for various parts. Vacuum platter, inverted magnetic bearing, Mark Kelly controller.

If i do have some spare BB or MGP laying around in the future, I may give it a try. Who knows, maybe I'll prefer it, maybe not.

Thanks for the feedback, in any case.

I don't think the Delphi is ailing, it's been semi-recently tuned up, the cart is a the VDH Two, HOMC cart. It sounds great, but there seemed to be an advantage in bass with this project. The Two is much more detailed than the A&R Cambridge P77, so the mids/highs were marginally better with the Delphi.

When I build my "real" DIY turntable, it will be made of epoxy granite, aluminum, PVC and acrylic for various parts. Vacuum platter, inverted magnetic bearing, Mark Kelly controller.

If i do have some spare BB or MGP laying around in the future, I may give it a try. Who knows, maybe I'll prefer it, maybe not.

Thanks for the feedback, in any case.

devalue my system...

yes, thanks for realizing there is no other desire other to make suggestions. Seems almost every time I make a comment, folks take it as an attach instead of in the spirit it was given...

my comments about BB are simply that--- just comments

I look forward to your project continuing and any possible updates that you provide,

thanks

stew

yes, thanks for realizing there is no other desire other to make suggestions. Seems almost every time I make a comment, folks take it as an attach instead of in the spirit it was given...

my comments about BB are simply that--- just comments

I look forward to your project continuing and any possible updates that you provide,

thanks

stew

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Practice run at a DIY turntable