Hi,

I am currently designing a belt driven turntable and the motor I am planning to use is an 24 pole AC sync motor running at 250 RPM on 50 Hz. The motor will be driving an acrylic-wood combination platter weighing around 4 Kg via a silk thread.

The motor specification sheet states that the detent torque value is 60 gm-cm and the running torque value is 240 gm-cm. It also states that the HVT value is 2.0 KV (motor voltage>40V) or 0.6 KV (motor voltage<40V) for 1 min. I would like to know whether this motor is OK or not.

Best regards,

Bins.

I am currently designing a belt driven turntable and the motor I am planning to use is an 24 pole AC sync motor running at 250 RPM on 50 Hz. The motor will be driving an acrylic-wood combination platter weighing around 4 Kg via a silk thread.

The motor specification sheet states that the detent torque value is 60 gm-cm and the running torque value is 240 gm-cm. It also states that the HVT value is 2.0 KV (motor voltage>40V) or 0.6 KV (motor voltage<40V) for 1 min. I would like to know whether this motor is OK or not.

Best regards,

Bins.

mark, and binspaul

really what I am looking for is a replacement for a Premotec 9904-111-31302 as found in an Ariston RD11 (not an "S"). I have been posting in "help revive Ariston RD11s" thread. This motor issue just came up.

Maybe it's just me, but I am having some problems finding a replacement. I can try a DC type if need be, but isn't my table...so...

Mark, Altmann uses and promotes the use of steppers for turntable use if driven by a proper signal..(and the proper stepper is used...)

really what I am looking for is a replacement for a Premotec 9904-111-31302 as found in an Ariston RD11 (not an "S"). I have been posting in "help revive Ariston RD11s" thread. This motor issue just came up.

Maybe it's just me, but I am having some problems finding a replacement. I can try a DC type if need be, but isn't my table...so...

Mark, Altmann uses and promotes the use of steppers for turntable use if driven by a proper signal..(and the proper stepper is used...)

binspaul said:Mark: I think it is not a stepper motor. Can you explain me how you arrived at that statement ?

Detent Torque

Hi,

What is your opinion on the below given AIRPAX motor ? Is this one a good motor for using in a turntable ?

The motor details are as follows:

The motor technical details can be accessed at the link: http://www.farnell.com/datasheets/330534.pdf

Best regards,

Bins.

What is your opinion on the below given AIRPAX motor ? Is this one a good motor for using in a turntable ?

The motor details are as follows:

MOTOR, 240VAC, 250RPM, NO EARS

Centres, Fixing:60.2mm

Current Rating:16mA

Diameter, External:51mm

Diameter, Fixing Hole:3.5mm

Diameter, Shaft:3mm

Length / Height, External:25mm

Length, Shaft:8.2mm

Power Consumption:3.5W

Speed, No Load:250rpm

Temp, Op. Max:60°C

Temp, Op. Min:-20°C

Torque:20N-m

Voltage, Operating Nom:240V

The motor technical details can be accessed at the link: http://www.farnell.com/datasheets/330534.pdf

Best regards,

Bins.

Try here:

http://www.hurstmfg.com/hurstmfg/qseries.jsp?series=Series+A,+AB+Direct+Drive+Synchronous+Motor

These are very decent motors, and used by VPI among others. They'll ship direct from the factory, and the price is a reasonable US$60 (approximately).

-Richard

http://www.hurstmfg.com/hurstmfg/qseries.jsp?series=Series+A,+AB+Direct+Drive+Synchronous+Motor

These are very decent motors, and used by VPI among others. They'll ship direct from the factory, and the price is a reasonable US$60 (approximately).

-Richard

Hello,

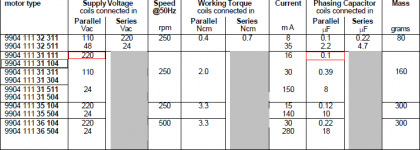

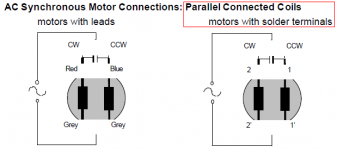

I am having an AIRPAX AC Sync. motor (9904-111-31104) with me and I would like to use it for my custom turntable. It is stated in the first page of the manual that the motor works in the parallel mode (220 VAC using a 0.1uF phasing capacitor). The motor I am having is the one with solder terminals (totally 4).

Can someone help me in identifying the correct terminals and the right way to connect it ?

Best regards,

Binu Paul.

I am having an AIRPAX AC Sync. motor (9904-111-31104) with me and I would like to use it for my custom turntable. It is stated in the first page of the manual that the motor works in the parallel mode (220 VAC using a 0.1uF phasing capacitor). The motor I am having is the one with solder terminals (totally 4).

Can someone help me in identifying the correct terminals and the right way to connect it ?

Best regards,

Binu Paul.

Attachments

Hi,

I think 0.22uF is for the 990411131813 model. Please see the attached image for the 990411131104 specification details (220V AC Supply). Also, How can we identify the correct terminals (The connections and the terminals are not clear in the 990411131104 specification sheet) ?

Best regards,

Bins.

I think 0.22uF is for the 990411131813 model. Please see the attached image for the 990411131104 specification details (220V AC Supply). Also, How can we identify the correct terminals (The connections and the terminals are not clear in the 990411131104 specification sheet) ?

Best regards,

Bins.

If your place have 50hz mains, use 0.22uF for phasing cap. If not mistaken 0.1uf is for 60hz mains (USA, Japan and others)

Attachments

Try here:

Hurst Motors - Your place to find BLDC, Permanent Magnet DC Stepper and AC Synchronous

These are very decent motors, and used by VPI among others. They'll ship direct from the factory, and the price is a reasonable US$60 (approximately).

-Richard

While digging around different threads, I stumbled across this one. Very interesting stuff.

Not knowing anything about motor ratings, what are the minimum mN-M torque requirements. Found a few on the site Richard posted and they ar indeed quite reasonable priced. One is rated at 19.1 nM-m, I presume it depends on how heavy the platter is? If VPI uses them, how bad could they be? AND, how much of a difference is a DC motor going to make in a DIY turntable project? There are premade solutions out there that are DC motors and variable speed controllers for ~$200 on the low end and on up from there.

Bins, I'm watching you because we're both making a version of the Schroeder tonearm.

Ron

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Help required for choosing an AC sync motor for a belt driven turntable.