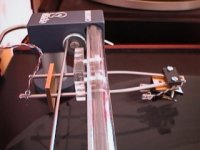

would like to hear your comments on a unipivot Vs an arm such as the opus 3 Cantus as shown in the picture attached. Kind of like a rolling knife edge arrangement. Since you have a lot of experience with unipivots I was curious to hear your comments.

Also I wondered if you might comment on an idea I just had about a Cantus style arm. Getting roller or ball in cup bearings to work properly in a design like this might be tricky and I fear they might end up sliding instead of rolling. So I thought why not a couple of solid balls and let the carriage or trolley slide in both the horizontal as well as in the vertical (rotational) plane. I dont think that the friction would be all that bad do you? Just thinking out loud here and as I don't have any construction experience with an arm such as this would appreciate your thoughts. There does not seem to be a lot of surface tension or traction for a steel roller bearing on the inside of a curved glass tube so my fear of the assemby just sliding rather than rolling. Thanks.

PS: comments from others would be most welcome also.

Also I wondered if you might comment on an idea I just had about a Cantus style arm. Getting roller or ball in cup bearings to work properly in a design like this might be tricky and I fear they might end up sliding instead of rolling. So I thought why not a couple of solid balls and let the carriage or trolley slide in both the horizontal as well as in the vertical (rotational) plane. I dont think that the friction would be all that bad do you? Just thinking out loud here and as I don't have any construction experience with an arm such as this would appreciate your thoughts. There does not seem to be a lot of surface tension or traction for a steel roller bearing on the inside of a curved glass tube so my fear of the assemby just sliding rather than rolling. Thanks.

PS: comments from others would be most welcome also.

Attachments

I don't suppose you can find a better picture? I can't quite see what's going on. I can see that it's a parallel tracker, but the bearing is difficult to see. Is that because it's really just a cylinder floating in liquid?

I've seen parallel trackers that worked by having a pair of pulleys with V-cuts in them running along a knife edge. They worked, but I can't help feel that dirt and wear would cause problems very quickly. Of course, as a DIY project, you might not feel that's a problem. Bear in mind that not only are some records eccentric, but variable pitch (to pack more music in at a decent level) means that an arm needs to be able to move easily from side to side; if it can't you're using up valuable linear excursion in the cartridge. I doubt if solid balls would give you low enough friction in your proposed idea.

There's a reason why most DIY arms are unipivots - they're very forgiving of indifferent construction (I made my first arm in a double period at school). Conversely, parallel trackers are really difficult to make. Having said that, there has been some excellent lateral thinking in a number of DIY designs, particularly the Paul Ladegaard (probably spelt incorrectly) with the air bearing made of bits of aluminium angle.

I've seen parallel trackers that worked by having a pair of pulleys with V-cuts in them running along a knife edge. They worked, but I can't help feel that dirt and wear would cause problems very quickly. Of course, as a DIY project, you might not feel that's a problem. Bear in mind that not only are some records eccentric, but variable pitch (to pack more music in at a decent level) means that an arm needs to be able to move easily from side to side; if it can't you're using up valuable linear excursion in the cartridge. I doubt if solid balls would give you low enough friction in your proposed idea.

There's a reason why most DIY arms are unipivots - they're very forgiving of indifferent construction (I made my first arm in a double period at school). Conversely, parallel trackers are really difficult to make. Having said that, there has been some excellent lateral thinking in a number of DIY designs, particularly the Paul Ladegaard (probably spelt incorrectly) with the air bearing made of bits of aluminium angle.

Not to rain or your thought parade, but I think that if you were to use caged or fixed balls instead of a ball bearing assembly the arm would not work at all.

Without a predisposed axis to the bearing, the sideways load at the stylus would want to pivot the arm about whichever bearing has greater friction. The other bearing climbing the wall of the tube until it offers more resistance than the first bearing. At some point they will have walked up the tube to a point where the arm assembly will break-free and start rolling along (maybe).

Even if your record and stylus survive the first test of the prototype, you'll not find the herky-jerky path of the arm convincingly hi-fi.

Do the Opus3 bearings have a knife edge on their perimeter, or are they just the usual cylindrical shape? I can't find a good pic on the net.

Without a predisposed axis to the bearing, the sideways load at the stylus would want to pivot the arm about whichever bearing has greater friction. The other bearing climbing the wall of the tube until it offers more resistance than the first bearing. At some point they will have walked up the tube to a point where the arm assembly will break-free and start rolling along (maybe).

Even if your record and stylus survive the first test of the prototype, you'll not find the herky-jerky path of the arm convincingly hi-fi.

Do the Opus3 bearings have a knife edge on their perimeter, or are they just the usual cylindrical shape? I can't find a good pic on the net.

here is another picture...

if you down load these two pictures to your computer and open using Windows Picture and Fax Viewer you can easily use the enlarge feature to get a better look at the bearings inside of the glass tube. You might have to take a step back from your screen to get things to focus properly but this works for me on my small 17 inch LCD screen.

if you down load these two pictures to your computer and open using Windows Picture and Fax Viewer you can easily use the enlarge feature to get a better look at the bearings inside of the glass tube. You might have to take a step back from your screen to get things to focus properly but this works for me on my small 17 inch LCD screen.

Attachments

Ah yes, the old back away an the pixels disappear trick. I still can't tell if they're knife edged or just plain cylinders. What do you see?

The reason I asked has to do with the Opus3's warp riding ability. If the bearings have a knife edge, the arm will rock on the knife edges for any up and down movement. If they are just run of the mill cylindrical shaped bearings, then they will have two points of contact per bearing and will have to slide up and down the tube to track warps.

The reason I asked has to do with the Opus3's warp riding ability. If the bearings have a knife edge, the arm will rock on the knife edges for any up and down movement. If they are just run of the mill cylindrical shaped bearings, then they will have two points of contact per bearing and will have to slide up and down the tube to track warps.

Attachments

Hi Moray,

trying to follow you guys here because I inherited a large collection and have nothing to play it on.

Totally OT - I apologize

but how do you adjust the weight on that arrangement? Does that wooden block slide back and forth?

I've always worried about the noise from rolling bearings like the linear trackers, especially when you consider eccentricity and warp. Following the cutting tools rate is easy.

Are these implementations "state of the art" in roller bearing technology?

Can't help thinking this is a lot like jitter

trying to follow you guys here because I inherited a large collection and have nothing to play it on.

Totally OT - I apologize

but how do you adjust the weight on that arrangement? Does that wooden block slide back and forth?

I've always worried about the noise from rolling bearings like the linear trackers, especially when you consider eccentricity and warp. Following the cutting tools rate is easy.

Are these implementations "state of the art" in roller bearing technology?

Can't help thinking this is a lot like jitter

Iain thanks for joining in...

I have not used one of these arms but I assume as you do that the rectangular plate at the rear slides forwards and back along the arm tubes for counterbalance and down force. This arm was inspired by the famous Lou Souther arm, Lou sold the rights to Clearaudio. The Cantus was designed to be an improvement over the Souther arm and was designed by Bo Hansson who was an importer of the Souther arm. I have not heard the Cantus yet but I have spoken with two people who both perfer it over the Souther arm. I can say with personal knowledge that the Souther arm is the most impressive arm that I have ever seen when it comes to tracking (no pivoted arm can match it) and it is still after more than twenty years the finest arm I have ever heard. So you can understand my interest in the Cantus. I think that Bo may well have taken the best and made it better. The cantus is a very clever design clean simple functional and affordable.

I have not used one of these arms but I assume as you do that the rectangular plate at the rear slides forwards and back along the arm tubes for counterbalance and down force. This arm was inspired by the famous Lou Souther arm, Lou sold the rights to Clearaudio. The Cantus was designed to be an improvement over the Souther arm and was designed by Bo Hansson who was an importer of the Souther arm. I have not heard the Cantus yet but I have spoken with two people who both perfer it over the Souther arm. I can say with personal knowledge that the Souther arm is the most impressive arm that I have ever seen when it comes to tracking (no pivoted arm can match it) and it is still after more than twenty years the finest arm I have ever heard. So you can understand my interest in the Cantus. I think that Bo may well have taken the best and made it better. The cantus is a very clever design clean simple functional and affordable.

Moray,

I tried replying to you email, but it bounced. Here's what I sent:

Putting the rollers inside a tube (where they won't get dirty) is a clever idea, and overcomes one of my main objections to ball race parallel trackers. However, I'm always nervous about noise in bearings. Unipivots can reduce the problem by putting their entire weight on one bearing, but I still prefer to use a soft bearing (PTFE) to avoid rattle - I've never really been happy with traditional "cone and ball race" unipivots. I don't know why, but it seems to me that there needs to be a little compliance somewhere between the cartridge body and the turntable bearing. The advantage of a parallel tracker is the elimination of the bias force requirement, but to get that you really need stunningly low lateral friction. Because of that, I'm uneasy about rollers, even though a number of people have proved it can be done. To me, the most elegant solution is the air bearing made of two concentric cylinders. I'm sorry I can't give you a more helpful response.

I tried replying to you email, but it bounced. Here's what I sent:

Putting the rollers inside a tube (where they won't get dirty) is a clever idea, and overcomes one of my main objections to ball race parallel trackers. However, I'm always nervous about noise in bearings. Unipivots can reduce the problem by putting their entire weight on one bearing, but I still prefer to use a soft bearing (PTFE) to avoid rattle - I've never really been happy with traditional "cone and ball race" unipivots. I don't know why, but it seems to me that there needs to be a little compliance somewhere between the cartridge body and the turntable bearing. The advantage of a parallel tracker is the elimination of the bias force requirement, but to get that you really need stunningly low lateral friction. Because of that, I'm uneasy about rollers, even though a number of people have proved it can be done. To me, the most elegant solution is the air bearing made of two concentric cylinders. I'm sorry I can't give you a more helpful response.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Ping EC8010 ....