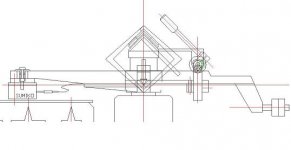

I am thinking about building an Air bearing tangent tonearm. Apart from several commercial versions there don't appear to be many DIY versions.

I have found Trans-fi's evolution and terminator series which appear to have developed from Poul Ladegaards diy versions. They appear relatively straight forward and from images on the web it should not be to hard to reverse engineer.

Are there any other options out there?

Has anyone built Poul's version and can offer me some handy pointers? Do and don't etc.

Thanks

Neil

I have found Trans-fi's evolution and terminator series which appear to have developed from Poul Ladegaards diy versions. They appear relatively straight forward and from images on the web it should not be to hard to reverse engineer.

Are there any other options out there?

Has anyone built Poul's version and can offer me some handy pointers? Do and don't etc.

Thanks

Neil

I have built both versions.

My advice is build a 'terminator' style arm if your going to build one.

No harder and much better results.

just read poul's site, look at vics pics and have a go

Main advice is.

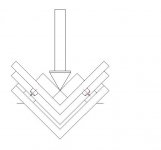

The manifold and the carrier need to match perfectly.

Dont use 2 pieces of the same angle as internal and external angles will be different.

When shopping for angle go through them all untill you find 2 bits that match the best, as perfectly as possible. Make the manifold from one piece and the carrier from the other.

Before you drill holes, lap the 2 pieces of angle together. Put a mild abrasive between the 2 pieces of angle and rub them together.

Toothpaste will do fine

When making the holes for the manifold, dont drill right through, use tape and punch the 0.3mm holes.

Drill most of the way through the angle and drill the 0.3mm holes.

You will need a small pin chuck twist drill and be carefull! 0.3mm drill bits snap easy! I got 7-8 holes out of each drill bit.

Thats about it. I use a hard walled smoothing tank, seems to work better.

With the terminator style arm, make the arm tube really short.

Get the pivot point in the middle of the arm tube, seems to work better.

I lashed mine together in a day. I always planned to re-build a nice neat version but it sounds so good i havent bothered yet.

Be prepared to say goodby to 'normal' pivoted arms, these are MUCH better imo!!

My advice is build a 'terminator' style arm if your going to build one.

No harder and much better results.

just read poul's site, look at vics pics and have a go

Main advice is.

The manifold and the carrier need to match perfectly.

Dont use 2 pieces of the same angle as internal and external angles will be different.

When shopping for angle go through them all untill you find 2 bits that match the best, as perfectly as possible. Make the manifold from one piece and the carrier from the other.

Before you drill holes, lap the 2 pieces of angle together. Put a mild abrasive between the 2 pieces of angle and rub them together.

Toothpaste will do fine

When making the holes for the manifold, dont drill right through, use tape and punch the 0.3mm holes.

Drill most of the way through the angle and drill the 0.3mm holes.

You will need a small pin chuck twist drill and be carefull! 0.3mm drill bits snap easy! I got 7-8 holes out of each drill bit.

Thats about it. I use a hard walled smoothing tank, seems to work better.

With the terminator style arm, make the arm tube really short.

Get the pivot point in the middle of the arm tube, seems to work better.

I lashed mine together in a day. I always planned to re-build a nice neat version but it sounds so good i havent bothered yet.

Be prepared to say goodby to 'normal' pivoted arms, these are MUCH better imo!!

Yes, upside down with a short arm.

he has a website for his sales, http://www.trans-fi.com/terminatortonearm.htm

A friend of mine has one, i met him after i built mine.

Vics ones he sells are very good, well made too.

All depends how much you like DIY.

he has a website for his sales, http://www.trans-fi.com/terminatortonearm.htm

A friend of mine has one, i met him after i built mine.

Vics ones he sells are very good, well made too.

All depends how much you like DIY.

"Terminator" disappoints

My experience with "terminator" style arm is just opposite to your's. It has a major drawback: very poor stability lengthwise. It rocks easily back and forth on its slider when touched with finger, since it has immence torque moment for applied force, hanging way below " lift force" application point. I heard "elephant steps behind the scene" - very low fq artefacts on record amplitude peaks, when sylus drag varies significantly and probably causes arm rocking and even touching rail.

Good thing about this design is lower arm mass due to shorter arm: I had 100 gramm arm+slider mass vs. 130 gramm for conventional design. I tend to attribute slightly better details retrieval I heard to it. On the other hand, short arm is more suscetible to VTA/VTF changes on warped records. And lastly bare alu angle rail hanging above record looks not exactly good aestetically and makes records change inconvinient and sometines dangerous for the record.

So in the end I abandoned "terminator" and went back to conventional Ladegaard.

My experience with "terminator" style arm is just opposite to your's. It has a major drawback: very poor stability lengthwise. It rocks easily back and forth on its slider when touched with finger, since it has immence torque moment for applied force, hanging way below " lift force" application point. I heard "elephant steps behind the scene" - very low fq artefacts on record amplitude peaks, when sylus drag varies significantly and probably causes arm rocking and even touching rail.

Good thing about this design is lower arm mass due to shorter arm: I had 100 gramm arm+slider mass vs. 130 gramm for conventional design. I tend to attribute slightly better details retrieval I heard to it. On the other hand, short arm is more suscetible to VTA/VTF changes on warped records. And lastly bare alu angle rail hanging above record looks not exactly good aestetically and makes records change inconvinient and sometines dangerous for the record.

So in the end I abandoned "terminator" and went back to conventional Ladegaard.

Interesting.

What exactly do you mean by rocks back and forwards? Do you mean the slider rocks on the manifold?

If so, thats either too much air, or the slider is not perfectly matched to the manifold.

I find the VTF is much more stable, VTA will change more but none of my records are badly warped enough for this to matter.

Ive had no isses with it being in the way to change records, i guess it depends how high the manifold is.

personaly, i like the slightly 'industrial' look

What exactly do you mean by rocks back and forwards? Do you mean the slider rocks on the manifold?

If so, thats either too much air, or the slider is not perfectly matched to the manifold.

I find the VTF is much more stable, VTA will change more but none of my records are badly warped enough for this to matter.

Ive had no isses with it being in the way to change records, i guess it depends how high the manifold is.

personaly, i like the slightly 'industrial' look

I found using the same piece of angle for carrier and manifold doesnt work as the internal and external angles will be different. The angle is thicker at the corner and thins towards the edge.

When i built my first couple of ladegaard arms i used to get the rocking as the air gap would be thicker at the bottom of the V.

I found there are 2 ways to get a good match, go through all the angle to find 2 that fit together, or lap them together. Lapping will only work if there already pretty much perfect.

If you hold the manifold/carrier up to the light and look at the end, you shouldnt be able to see ANY daylight.

I never managed to get a good match using the same piece of angle, although i know VIC does and his arms are fine.

maybe it depends on who manufactured the angle? Maybe B&Q's stuff isnt that high a quality.

I dunno, but if you get rocking, i bet mismatched angle is to blame, they really do have to be 100% perfect!

When i built my first couple of ladegaard arms i used to get the rocking as the air gap would be thicker at the bottom of the V.

I found there are 2 ways to get a good match, go through all the angle to find 2 that fit together, or lap them together. Lapping will only work if there already pretty much perfect.

If you hold the manifold/carrier up to the light and look at the end, you shouldnt be able to see ANY daylight.

I never managed to get a good match using the same piece of angle, although i know VIC does and his arms are fine.

maybe it depends on who manufactured the angle? Maybe B&Q's stuff isnt that high a quality.

I dunno, but if you get rocking, i bet mismatched angle is to blame, they really do have to be 100% perfect!

livemusic...

I am a little confused by your diagram and your explanation.

M:=F Xr , where M is actually torque, a vector . It follows the RHR in vector mathematics. The torque created by a (relatively) large F and a large r could , in fact , move the arm "backwards" if there is enough movement permitted by an imprecise gap between the carrier and the stationary portion of the arm, or the gap is large.

I suspect that graeme uk is on the correct path to answering the "rocking " question.

Maybe my neurons are misfiring across the synaptic gap in my brain, in which case please ignore any comments I make.

stew

I am a little confused by your diagram and your explanation.

M:=F Xr , where M is actually torque, a vector . It follows the RHR in vector mathematics. The torque created by a (relatively) large F and a large r could , in fact , move the arm "backwards" if there is enough movement permitted by an imprecise gap between the carrier and the stationary portion of the arm, or the gap is large.

I suspect that graeme uk is on the correct path to answering the "rocking " question.

Maybe my neurons are misfiring across the synaptic gap in my brain, in which case please ignore any comments I make.

stew

Match between slider and manyfold may definitely be improved for any ready made angle profiles; I will try lapping. But anyway, all other factors being the same, the rocking moment is order of magnitude bigger for terminator arm. I have rised a bit a point of contact between the arm knife and slider (two tiny bronze prisms are glued to the slider), such as it lays in the same horizontal plane with the air nozzles placed in the middle of slider bottom surfaces; so the rocking moment is virtually non-existent.

Attachments

I started out with Vic's conventional Ladergaard and now have the Terminator. The only time I've heard "elephant steps" is with the conventional arm when there was too much air pressure. The Terminator is very insensitive to air pressure levels and works like a dream. It's a significant step up from the conventional Ladegaard type arm that Vic originally produced - which was very good indeed.

If the inverted arm is causing "elephant steps" then there's something wrong but it's either something Vic has got around or never experienced.

If the inverted arm is causing "elephant steps" then there's something wrong but it's either something Vic has got around or never experienced.

graeme uk said:Get the pivot point in the middle of the arm tube, seems to work better.

So the pivot point should be at about 3" & not at the 4" mark as in Vic's terminator pics? In what ways is it better?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- DIY Air bearing tangent tone arm