Schroeder antiskating

It appears that the twist in the thread applies the antiskating.

If you look at the materials on the Shroeder website, in the owner instructions, he shows how the curled knob at the top of the arm pillar, which captures the string, has an inner hex screw. The inner screw appears to set the spacing between the magnets and larger kurled screw applies twist to the monofilament line applying antiskating.

Or at least that's how it looks

Mike

It appears that the twist in the thread applies the antiskating.

If you look at the materials on the Shroeder website, in the owner instructions, he shows how the curled knob at the top of the arm pillar, which captures the string, has an inner hex screw. The inner screw appears to set the spacing between the magnets and larger kurled screw applies twist to the monofilament line applying antiskating.

Or at least that's how it looks

Mike

Re: effective mass...

I don't know how to calculate effective mass. My plan for my DIY arm is to 'reverse engineer' it empirically by using the HiFi News and Record Review test record to determine the resonance and, then, calculate the effective mass based on that. But, this is an after-the-fact approach and I haven't performed it yet. Based on my experiences (BTW, my arm is very different - it's a linear air-bearing arm), I got very lucky.

Regarding magnetic field strength, I would think that the stronger the better would apply (as long as the string could handle it, of course).

Paul Ebert

ticovski said:Another (two) questions:

How to calculate effective mass of tonearm, any formula;

and how much of the force do we need in between magnets (5, 10, 15... kg)

I don't know how to calculate effective mass. My plan for my DIY arm is to 'reverse engineer' it empirically by using the HiFi News and Record Review test record to determine the resonance and, then, calculate the effective mass based on that. But, this is an after-the-fact approach and I haven't performed it yet. Based on my experiences (BTW, my arm is very different - it's a linear air-bearing arm), I got very lucky.

Regarding magnetic field strength, I would think that the stronger the better would apply (as long as the string could handle it, of course).

Paul Ebert

I asked the same question some time ago and got a very thorough reply from Dice45 and Jeremy Epstein:effective massHow to calculate effective mass of tonearm

At the time I made an excel-sheet to do the calculations but I am afraid to have lost it

. Sorry.

. Sorry.Re: effective mass...

I had pretty much planned to do as the same as Paul and just take a shot in the dark - but the question did cross my mind. I figured that if I looked hard enough on the web, and in my old references I could probably find something on the subject of tonearm mass.

In any case, the carbon fiber set-up looks like the least amount of work and will thus result in the least amount of dissapointment if it doesn't work out

I figured the wood arms could come later.

Mike

I had pretty much planned to do as the same as Paul and just take a shot in the dark - but the question did cross my mind. I figured that if I looked hard enough on the web, and in my old references I could probably find something on the subject of tonearm mass.

In any case, the carbon fiber set-up looks like the least amount of work and will thus result in the least amount of dissapointment if it doesn't work out

I figured the wood arms could come later.

Mike

eff mass again

Thank you for the link Peter,

I read reffering postings a few times and have some understanding about effective mass now, but don`t understand what is final formula. If you accidentally find your excel sheet I would appreciate if you would send me a copy. Otherwise I don`t see how to do calcs. I like to know what I am doing.

Thank you,

Ticovski

Thank you for the link Peter,

I read reffering postings a few times and have some understanding about effective mass now, but don`t understand what is final formula. If you accidentally find your excel sheet I would appreciate if you would send me a copy. Otherwise I don`t see how to do calcs. I like to know what I am doing.

Thank you,

Ticovski

Re: Re: effective mass...

Hi Paul,

I have a Schroeder No.1 tonearm (even wrote the test report for http://www.tnt-audio.com), and can tell you that the magnets of the Schroeder tonearm have about 10kgs attracting force.

regards,

Hartmut from Munich

Paul Ebert said:

Regarding magnetic field strength, I would think that the stronger the better would apply (as long as the string could handle it, of course).

Hi Paul,

I have a Schroeder No.1 tonearm (even wrote the test report for http://www.tnt-audio.com), and can tell you that the magnets of the Schroeder tonearm have about 10kgs attracting force.

regards,

Hartmut from Munich

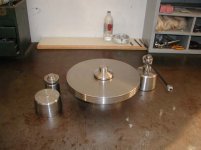

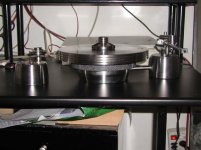

DIY Turntables and Schroeder tonearm clone.

Here are some pics of my DIY Turntables and Schroeder tonearm clone. I'll post some more detail pics as soon as i get my digital camera back (Did you heard that Chris? ).

).

Meanwhile, anyone want details of the cosntruction feel free to mail me.

Regards

Konstantin

ktzivleris@hotmail.com

Here are some pics of my DIY Turntables and Schroeder tonearm clone. I'll post some more detail pics as soon as i get my digital camera back (Did you heard that Chris?

).

).Meanwhile, anyone want details of the cosntruction feel free to mail me.

Regards

Konstantin

ktzivleris@hotmail.com

An externally hosted image should be here but it was not working when we last tested it.

Attachments

Konstantin's Klone

WOW! That is beautiful work.

I think many here will be interested in the actual machining plans in terms of how the magnets are connected to the base and arm

As a side note to Hartmut, I recieved my magents yesterday - although very strong, they dont seem to have 10KGs of attraction. One set, about 8mm wide and 6mm tall could lift about 2KG. Ones about 12 X 10 mm - I could not seperate with hand strength.

Konstantin, any comments or advice about the magnets you used?

Regards

Mike

WOW! That is beautiful work.

I think many here will be interested in the actual machining plans in terms of how the magnets are connected to the base and arm

As a side note to Hartmut, I recieved my magents yesterday - although very strong, they dont seem to have 10KGs of attraction. One set, about 8mm wide and 6mm tall could lift about 2KG. Ones about 12 X 10 mm - I could not seperate with hand strength.

Konstantin, any comments or advice about the magnets you used?

Regards

Mike

Magnets

Thanks K,

I just got a few generic neodymium samples off eBay to experiment on. I assumed that there would be different grades but hadn't gotten that far yet.

Did you drill through your arm magnet to mount it?

It has been suggested here that drilling in these magnets is quite challenging.

Mike

Thanks K,

I just got a few generic neodymium samples off eBay to experiment on. I assumed that there would be different grades but hadn't gotten that far yet.

Did you drill through your arm magnet to mount it?

It has been suggested here that drilling in these magnets is quite challenging.

Mike

Mike,

There is absolutely no way to drill these magnets without destroy them. Neodymium is Very hard but is also very corrosive and even if you drill them you will take of some of the hard Chromium they have on the surface to prevent corrosion. What you can do is to order predrilled magnets as i did. 6mm X 6mm rod with a 1.5mm hole in the middle.

Regards

There is absolutely no way to drill these magnets without destroy them. Neodymium is Very hard but is also very corrosive and even if you drill them you will take of some of the hard Chromium they have on the surface to prevent corrosion. What you can do is to order predrilled magnets as i did. 6mm X 6mm rod with a 1.5mm hole in the middle.

Regards

I can get varius predrilled Neoymium magnets here in Scandinavia, from 10x3mm to 16-20-35 mm dia and 3.5 to 5.5 mm thickness, holding strengts are listed from appx. 0.8 to 3o kg for the largest..

Has anyone made some seriuos thoughts on what strength would be the optimum...??

What kind of wire, in terms of stiffness..??

Antiskating would be a combination of wire stiffness and magnet, or just by the magnet pull vs. distance..??

Has anyone made some seriuos thoughts on what strength would be the optimum...??

What kind of wire, in terms of stiffness..??

Antiskating would be a combination of wire stiffness and magnet, or just by the magnet pull vs. distance..??

Magnet strength - clarification??

Mr B.,

Note that Hartmut said that his original model Schroeder's magnets have 10KG of holding force. The newest Schroeder Reference arm apparently has more powerful magnets. Konstantin's magnets are grade N40 - the grades go up to N50.

I have not been able to figure out yet if the holding strength is the same number quoted by magnet manufacturers as the "coercive force", i.e., KOe. If so this would seem to be a generic holding force for the grade of magnet as opposed to the actual holding force for a magnet sized for our work here.

Can someone with a physics or other suitable background, help us here?

Mike

Mr B.,

Note that Hartmut said that his original model Schroeder's magnets have 10KG of holding force. The newest Schroeder Reference arm apparently has more powerful magnets. Konstantin's magnets are grade N40 - the grades go up to N50.

I have not been able to figure out yet if the holding strength is the same number quoted by magnet manufacturers as the "coercive force", i.e., KOe. If so this would seem to be a generic holding force for the grade of magnet as opposed to the actual holding force for a magnet sized for our work here.

Can someone with a physics or other suitable background, help us here?

Mike

MAGGIES...

Hi,

Could do but it would take me several pages.

Try to use a search engine such as Google and type in magnet strength.

You'll find numerous sites giving you all the theory.

Cheers,

Hi,

Can someone with a physics or other suitable background, help us here?

Could do but it would take me several pages.

Try to use a search engine such as Google and type in magnet strength.

You'll find numerous sites giving you all the theory.

Cheers,

Magnet strength

Hi Frank,

I generally try to get the info on the web, as you suggest, before making an open inquiry. Even looked in a couple of physics textbooks. I did not find an answer to the question asked above in either venue.

What manufacturers of neodyium magnets generally do not list is a "lifting strength" number analogous to the number quoted by Hartmut.

Of course, the easy answer is simply to follow Konstantin and get reasonably sized magnets in grades at or above N40.

BTW: Schroeder's patent can be accessed here:

http://l2.espacenet.com/espacenet/bnsviewer?CY=wo&LG=en&DB=EPD&PN=WO02095736&ID=WO++02095736A1+I+

Perhaps those speaking german can give us the gist of enabling design parameters.

Mike

Hi Frank,

I generally try to get the info on the web, as you suggest, before making an open inquiry. Even looked in a couple of physics textbooks. I did not find an answer to the question asked above in either venue.

What manufacturers of neodyium magnets generally do not list is a "lifting strength" number analogous to the number quoted by Hartmut.

Of course, the easy answer is simply to follow Konstantin and get reasonably sized magnets in grades at or above N40.

BTW: Schroeder's patent can be accessed here:

http://l2.espacenet.com/espacenet/bnsviewer?CY=wo&LG=en&DB=EPD&PN=WO02095736&ID=WO++02095736A1+I+

Perhaps those speaking german can give us the gist of enabling design parameters.

Mike

MAGNETISED.

Hi Mike,

You mean what the N# stands for?

Well, it's just a guess, I heard from a cartridge manufacturer that the N stands for North type of magnet and the number the ckass off lifting strenght.

Also, he said that there's more than one standard of classification...seems to make it easier on us.

INTERESTING READ

Cheers,

Hi Mike,

I did not find an answer to the question asked above in either venue

You mean what the N# stands for?

Well, it's just a guess, I heard from a cartridge manufacturer that the N stands for North type of magnet and the number the ckass off lifting strenght.

Also, he said that there's more than one standard of classification...seems to make it easier on us.

INTERESTING READ

Cheers,

- Home

- Source & Line

- Analogue Source

- DIY Schroeder Tonearm???