Hello every vinyl enthusiast's!

For awhile now, I've bee wondering how to build myself a record cleaner.

The reason i want to try this, is because every washer you can buy, are making too much noise.

A buddy of mine came up with an idea of making one by using a ultrasonic washer.(or maybe he had read it somewhere, I don't know)

Any how, the idea turned me on. So I bought one from the US, and got ahead on the drawing board.

Here is what I came up with, as a start:

The washer I bought, and going to use:

This will of course be a fully automatic cleaner (well, almost )

)

The idea is to be able to wash up to 10-15 records at the time.

Lars

For awhile now, I've bee wondering how to build myself a record cleaner.

The reason i want to try this, is because every washer you can buy, are making too much noise.

A buddy of mine came up with an idea of making one by using a ultrasonic washer.(or maybe he had read it somewhere, I don't know)

Any how, the idea turned me on. So I bought one from the US, and got ahead on the drawing board.

Here is what I came up with, as a start:

The washer I bought, and going to use:

This will of course be a fully automatic cleaner (well, almost

The idea is to be able to wash up to 10-15 records at the time.

Lars

Here's more pics:

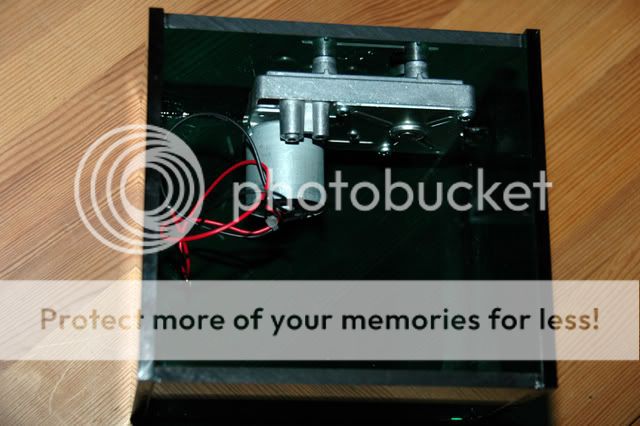

This is the motor I'm going to use to turn it all around:

The transmission make it go around at 26 rpm with a voltage of 24.

I'd like it to go slower than that, so a buddy of mine is going to make a converter, and make it go with approximately 6-8 volt.

I want the large wheel to go with something like 1/4 rpm, so the records stays in water as long as possible at the time.

(Please forgive my poor English)

Regards

Lars

This is the motor I'm going to use to turn it all around:

The transmission make it go around at 26 rpm with a voltage of 24.

I'd like it to go slower than that, so a buddy of mine is going to make a converter, and make it go with approximately 6-8 volt.

I want the large wheel to go with something like 1/4 rpm, so the records stays in water as long as possible at the time.

(Please forgive my poor English)

Regards

Lars

Thank's Netlist!

Well pinkmouse, it's almost done, but I don't want to give you all of it instantly

A little discussion on the project would be nice. Will it work or not?

I forgot to mention, I work as a CNC operator, and mainly work with acrylic, pehd, pom, and further plastic products. So it's natural for me to make this rig in acrylic.

A few more pics :

A simple rubber gasket as a wheel

I don't know the English word for this macine , but it's a "bender". It warms up the acrylic so i can shape it in the angle I want.

So, her's the first"bend":

And we use heavy pieces to hold it in place while it cools down:

Lars

Well pinkmouse, it's almost done, but I don't want to give you all of it instantly

A little discussion on the project would be nice. Will it work or not?

I forgot to mention, I work as a CNC operator, and mainly work with acrylic, pehd, pom, and further plastic products. So it's natural for me to make this rig in acrylic.

A few more pics :

A simple rubber gasket as a wheel

I don't know the English word for this macine , but it's a "bender". It warms up the acrylic so i can shape it in the angle I want.

So, her's the first"bend":

And we use heavy pieces to hold it in place while it cools down:

Lars

Not much interest here , but I keep on posting.

, but I keep on posting.

Made a new set in glossy instead of clear acrylic. much better don't you think?

And a hole to the handle as well

And a wheel in red acrylic placed on my wife's knitting needle for a test

Beginning to get an idea of where I'm going?

regards

Lars

Made a new set in glossy instead of clear acrylic. much better don't you think?

And a hole to the handle as well

And a wheel in red acrylic placed on my wife's knitting needle for a test

Beginning to get an idea of where I'm going?

regards

Lars

Hey, I'm interested! We have a nice deep ultrasonic at work, and I've thought about trying it on a very dirty record. What worries me is that ultrasonics can be very aggressive- try putting a strip of aluminum foil in your cleaner. It should disintegrate or severely pinhole in about 30 seconds. That's actually a manufacturers test for whether the cleaner is working properly. OTOH, vinyl isn't aluminum. Also, most ultrasonic cleaners don't work well if the water is stirred while running, so the records need to rotate quite slowly. Keep posting!

Sclalars said:Not much interest here, but I keep on posting.

Hi,

Don't be discouraged by the lack of responses - a lot of silent observers here. I, for one, am VERY interested.

Keep up the good work.

MJL21193 said:

Hi,

Don't be discouraged by the lack of responses - a lot of silent observers here. I, for one, am VERY interested.

Keep up the good work.

Nice to hear!

I thought I was the only one here

Well, I'll keep posting.

A little test on the placement of the motor:

And this will be the spacers between each record:

Lars

Netlist said:

What liquid will you be using?

/Hugo

One part isopropanol, 7 parts distilled water, and a drop of detergent.

Lars

Sclalars said:

Made a new set in glossy instead of clear acrylic. much better don't you think?

Oops, there should be frosted, not glossy

Lars

I have some thoughts: Will not cause any problem if you clean another set of records in the same dirty water? Could perhaps a VTA-style record cleaner be combined with ultrasonic generator? Are the mist makers of those chinese indoor fountains usable for the purpose? I believe they also work on ultrasonic principle.

Anyway, congratulations for the nice acryl work!

Anyway, congratulations for the nice acryl work!

I agree with a previous poster, ultrasonics are VERY harsh.

They work by having sufficient intensity to cause cavitation in the liquid. Tiny bubbles forms and collapse, and this loosens dirt. But it also damages the surface, even on strong materials like glass or silicon. For example, if you use an ultrasonic cleaner on a substrate for thin film growth, you get a very poor quality film with many defects, as there are damage sites both on the surface and immediately below.

I would only consider ultrasonics for extremely dirty records that milder cleaning methods fail on; for most records the risk of irreversible damage is too great.

They work by having sufficient intensity to cause cavitation in the liquid. Tiny bubbles forms and collapse, and this loosens dirt. But it also damages the surface, even on strong materials like glass or silicon. For example, if you use an ultrasonic cleaner on a substrate for thin film growth, you get a very poor quality film with many defects, as there are damage sites both on the surface and immediately below.

I would only consider ultrasonics for extremely dirty records that milder cleaning methods fail on; for most records the risk of irreversible damage is too great.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- I made myself a record cleaner