kinda late to the original party here...

but to determine the potential damage to the LPs, what I would do is to select a test LP that is of no interest/value for the music, and run it for repeated cycles, like more than 10 and probably up to something like 50.

I'd start with a CLEAN LP, one that maybe has been cleaned or happens to be new or virtually new.

Now note the debris in the tank after 1, 10, 20, 30, N cycles.

Finally collect the total debris.

Inspect the debris under a good microscope to determine the nature of the debris, size and shape. If it is all uniform in terms of color and look it can be presumed to be vinyl. The ultimate test would be to get it into something like a test tube and heat the debris to the melting point of vinyl and see if it indeed congeals into a small blob or not... dirt and dust will not.

To power an ultrasonic element, you probably only need a high power multivibrator circuit. Of course that will not provide variable power, but maybe you don't need that.

Back in the day these things ran off a pair of 811A tubes - I know because I have one...

would be interested to know if anyone runs the test that I suggested and what they find...

_-_-bear

but to determine the potential damage to the LPs, what I would do is to select a test LP that is of no interest/value for the music, and run it for repeated cycles, like more than 10 and probably up to something like 50.

I'd start with a CLEAN LP, one that maybe has been cleaned or happens to be new or virtually new.

Now note the debris in the tank after 1, 10, 20, 30, N cycles.

Finally collect the total debris.

Inspect the debris under a good microscope to determine the nature of the debris, size and shape. If it is all uniform in terms of color and look it can be presumed to be vinyl. The ultimate test would be to get it into something like a test tube and heat the debris to the melting point of vinyl and see if it indeed congeals into a small blob or not... dirt and dust will not.

To power an ultrasonic element, you probably only need a high power multivibrator circuit. Of course that will not provide variable power, but maybe you don't need that.

Back in the day these things ran off a pair of 811A tubes - I know because I have one...

would be interested to know if anyone runs the test that I suggested and what they find...

_-_-bear

My question is, what should I used for an actual cleaning fluid? I was thinking of using my regular home brew record cleaning fluid (3:1 distilled water to 90% isopropyl alcohol w/ Triton X-100 surfactant). Anybody have any better ideas?

Some have reported using simply water. Table 1 on this page Blue Wave Ultrasonics: Manufacturers of Ultrasonic Cleaning Equipment may give further clues to what can be used.

Some have reported using simply water. Table 1 on this page Blue Wave Ultrasonics: Manufacturers of Ultrasonic Cleaning Equipment may give further clues to what can be used.

Thanks. I may just try distilled water with the Triton X-100 surfactant to start with. I only about 10 drops of Triton per gallon of distilled water so waste won't be much of a concern. I just need to think of a way to dry the LPs once cleaned.

Kevin T

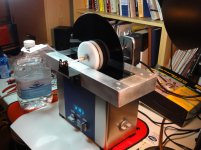

My version using the German made Elmasonic P60H

Great posts everyone! Gotta love DIY!

Decided to try my own version using a state of the art German made Elmasonic P60H with both 37 and 80 KHz modes, sweep mode, pulse mode, and an accurate thermostatically controlled heater. Sure it costs more than the cheap 40KHz machines but when i look at what the Audio Desk costs, this is still only a fraction of the cost. Purchased from Tovatech in the US 973-913-9735

Using the Vinyl Stack solution found on Ebay to separate records and protect the labels. Very well made product but fits on a 1/4" spindle only so I am using 1/4" aluminum rod for spindle.

Using a rotisserie to rotate the records < 2RPM.

Made the top frame from 2" aluminum angle brackets.

Holds up to 4 records at a time.

Using distilled water and a few drops of PhotoFlo and JetDry.

Just starting to use it so results are inconclusive so far. However, visually records come out looking cleaner than new and cleaner than after my VPI HW-17F.

Will post more results as i progress.

Great posts everyone! Gotta love DIY!

Decided to try my own version using a state of the art German made Elmasonic P60H with both 37 and 80 KHz modes, sweep mode, pulse mode, and an accurate thermostatically controlled heater. Sure it costs more than the cheap 40KHz machines but when i look at what the Audio Desk costs, this is still only a fraction of the cost. Purchased from Tovatech in the US 973-913-9735

Using the Vinyl Stack solution found on Ebay to separate records and protect the labels. Very well made product but fits on a 1/4" spindle only so I am using 1/4" aluminum rod for spindle.

Using a rotisserie to rotate the records < 2RPM.

Made the top frame from 2" aluminum angle brackets.

Holds up to 4 records at a time.

Using distilled water and a few drops of PhotoFlo and JetDry.

Just starting to use it so results are inconclusive so far. However, visually records come out looking cleaner than new and cleaner than after my VPI HW-17F.

Will post more results as i progress.

Attachments

check out the other thread

Cbachalo -- if you haven't already discovered it -- all the DIY/US/RCM fun has moved over here: http://www.diyaudio.com/forums/analogue-source/218276-my-version-ultrasonic-record-cleaner.html

Cbachalo -- if you haven't already discovered it -- all the DIY/US/RCM fun has moved over here: http://www.diyaudio.com/forums/analogue-source/218276-my-version-ultrasonic-record-cleaner.html

thanks, have reposted in this other thread

Cbachalo -- if you haven't already discovered it -- all the DIY/US/RCM fun has moved over here: http://www.diyaudio.com/forums/analogue-source/218276-my-version-ultrasonic-record-cleaner.html

I am going to have to agree.

The whole point of the sonic bath is to clean things which you wouldn't want to use much force or an abrasive detergent on. I would imagine that it would be safe for Vinyl.

I've seen a Sonic Cleaner at Bed Bath and Beyond which said it was safe to clean CD's.

I almost purchased it...

Hi Joe!

This is a bit late reply to a page 7 post (I'm just working my way through them).

I'm also following another post about a DIY Ultrasonics cleaner, and it inspired me to buy a machine, it looks very similar to Lars'.

RE: Cleaning CD's in the US cleaner - I sure would STRONGLY advise against that!!

A CD or DVD, unlike a Vinyl record, is a sandwich of plastics and metals, and in the case of a CD/DVD-R or RW is a combination of dissimilar plastics and metal.

One of the main failure points of a CD or DVD is air seeping in the edge and oxidizing the aluminum substrate! If you do some research on this you'll find there are archival CDs & DVDs that are extremely expensive, one of the main factors is close inspection (at high magnification) of the edges.

Putting a CD in an US machine is totally a crap-shoot. The intense vibration would almost certainly force open any edge that was marginal. It could also trigger internal stresses that might do the same. The cleaning fluid could seep in or it could just open the seams slightly allowing air in over time.

I'll state right up front, this is all conjecture as they may well survive fine, but it's so easy to clean a CD/DVD by hand (unlike Vinyl) what's the point of risking it!?!

Joe - I know you were just quoting BB&B's product description, certainly no attack intended here at all, I do get vehement at times ...

. Your point on it being safe for Vinyl is spot on, and proven by a number of people here & elsewhere!

. Your point on it being safe for Vinyl is spot on, and proven by a number of people here & elsewhere!Now back to my job of reading the rest of this fascinating jorney by Lars & the rest (soon to be me - I'm awaiting my machine impatiently. Think my Wife will lose me this weekend!

All the Best, PuterPro

Patent, 1968

This isn't a new idea. There's several decades of prior art for Ultrasonic LP cleaning -- Patent filed in 1966 issued in 1968. Here's a link:

Patent US3401708: Device for ultrasonically cleaning phonographic records

Cheers,

B B

Hi, everyone,

This thread shows that first idea about cleaning LPs in ultrasonic bath was posted by Lars-Norway in 2008.

I would like to know who's idea was this originally. Was it Lars on this forum or idea came from somewhere else.

This isn't a new idea. There's several decades of prior art for Ultrasonic LP cleaning -- Patent filed in 1966 issued in 1968. Here's a link:

Patent US3401708: Device for ultrasonically cleaning phonographic records

Cheers,

B B

Hi all,

Stumbled across this thread a while back and thanks to all you fellas on here, decided to have a go making my own taking what I thought were the best elements of all the interesting designs. I particularly liked the idea of using magnets to attach the motor unit to the UC.

I wanted something compact that I could quickly and simply place on the UC when cleaning records and quickly remove to use the unit for other general cleaning purposes. It also needed to be something I could make with basic tools.

In the end, I based the design around the Vinyl Stack label protector:

They also agreed to supply me the magnetic metal boss from their Sonic Spin Kit:

My parts list as follows:

Turbo Worm Gear Motor 0.6rpm

12v Power Supply

6L Ultrasonic Cleaner

Vinyl Stack Label Protector and magnetic boss

2mm 150x150mm 406 Stainless Steel

130mm right angle stainless steel bracket

6mm coupling & steel rod

Black Plastic Project Box

Panel mount DC Female Jack Plug

Magnets

Pillow Block Bearing

Bolts, Nuts and screws

Total Cost = £256

The end result is a compact integral motor/magnetic record clamp unit that simply rests over the lip of the UC and attaches to a single magnet bonded with Gorilla glue on the back of the unit:

Removed from the unit:

Single magnet bonded to UC:

Closeup:

With magnetic Vinyl Stack kit attached:

Front View:

The hardest part in making the unit, was drilling of the holes in the metal plate to screw mount the motor and project box and the holes to mount the pillow bearing used to support the weight of the Vinyl Stack and records. Fortunately the motor had a technical drawing with the description on Ebay that I was able to use whilst waiting for the motor to arrive from China. Drilling the holes with a cordless hand drill was time consuming. If I were to do it again, I'd get a local engineering firm to do it.

Once the motor was screwed in place to the metal plate, I drilled a hole in the bottom of the black plastic project box, installed the jack plug and soldered two wires between jack plug and motor. I then attached the project box.

Whilst it will take 4 records at a time, I only plan to do a max of 2 for better cleaning efficiency as the distance between the discs is only 15mm. I've cleaned one record so far with filtered water and the results were very good. Looking forward to experimenting with some of the potions suggested on here.

Thanks to everyone for your inspiration and hope I've given you some useful ideas.

Stumbled across this thread a while back and thanks to all you fellas on here, decided to have a go making my own taking what I thought were the best elements of all the interesting designs. I particularly liked the idea of using magnets to attach the motor unit to the UC.

I wanted something compact that I could quickly and simply place on the UC when cleaning records and quickly remove to use the unit for other general cleaning purposes. It also needed to be something I could make with basic tools.

In the end, I based the design around the Vinyl Stack label protector:

They also agreed to supply me the magnetic metal boss from their Sonic Spin Kit:

My parts list as follows:

Turbo Worm Gear Motor 0.6rpm

12v Power Supply

6L Ultrasonic Cleaner

Vinyl Stack Label Protector and magnetic boss

2mm 150x150mm 406 Stainless Steel

130mm right angle stainless steel bracket

6mm coupling & steel rod

Black Plastic Project Box

Panel mount DC Female Jack Plug

Magnets

Pillow Block Bearing

Bolts, Nuts and screws

Total Cost = £256

The end result is a compact integral motor/magnetic record clamp unit that simply rests over the lip of the UC and attaches to a single magnet bonded with Gorilla glue on the back of the unit:

An externally hosted image should be here but it was not working when we last tested it.

Removed from the unit:

An externally hosted image should be here but it was not working when we last tested it.

Single magnet bonded to UC:

An externally hosted image should be here but it was not working when we last tested it.

Closeup:

An externally hosted image should be here but it was not working when we last tested it.

With magnetic Vinyl Stack kit attached:

An externally hosted image should be here but it was not working when we last tested it.

Front View:

An externally hosted image should be here but it was not working when we last tested it.

The hardest part in making the unit, was drilling of the holes in the metal plate to screw mount the motor and project box and the holes to mount the pillow bearing used to support the weight of the Vinyl Stack and records. Fortunately the motor had a technical drawing with the description on Ebay that I was able to use whilst waiting for the motor to arrive from China. Drilling the holes with a cordless hand drill was time consuming. If I were to do it again, I'd get a local engineering firm to do it.

Once the motor was screwed in place to the metal plate, I drilled a hole in the bottom of the black plastic project box, installed the jack plug and soldered two wires between jack plug and motor. I then attached the project box.

Whilst it will take 4 records at a time, I only plan to do a max of 2 for better cleaning efficiency as the distance between the discs is only 15mm. I've cleaned one record so far with filtered water and the results were very good. Looking forward to experimenting with some of the potions suggested on here.

Thanks to everyone for your inspiration and hope I've given you some useful ideas.

Sorry if this has been answered before or elsewhere but for those of you who are using BBQ rotisserie motors in your DIY cleaners, how fid you attach the spindle to the motor? The motor has a square opening to attach the rotisserie "pole" but we'd obviously need a round hole for the shaft that the records will attach to. Thanks for your help.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- I made myself a record cleaner