Hi everybody. This will be my first post to this forum. Perhaps I should identify myself.

name: Steve Clarke

My audiophile interests began in high-school, waxing strong throughout the seventies and into the eighties. Strangely my audiophile bug started waining shortly after purchasing my cd player at around 1985. It started waxing again when I began reading Fremer's "Analog Corner" at around the mid 1990's. I started upgrading my "equipment list" again at around this time.

It started waxing again when I began reading Fremer's "Analog Corner" at around the mid 1990's. I started upgrading my "equipment list" again at around this time.

My first "decent" turntable was a Thorens TD160 MK I. I bought it new in 1975 and I still have it. In recent years I've put some time and energy into gaining a better understanding of correct turntable setup procedures. This has rewarded me in continuously improving sound output from this humble, old and trusty player.

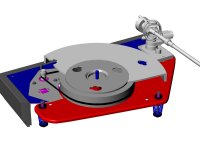

These days I'm listening to Lp's played by a Teres model 135 equipped with the Expressimo RB250 fully modded-out tonearm. I have a Shelter 501-2 mounted at present. With this combo, I would be "shocked" to find any cd or sacd player that could offer me the audio sensory pleasure that this deck gives.

Link here for a view of my current equipment setup:

http://www.theanalogdept.com/user510.htm

I'm still interested in tinkering with old Thorens players however. They respond so positively to correct setting up in addition to damping mods. They gratify...! An excellent specimen for learning. I have documented many of my damping mods at the following website:

http://www.theanalogdept.com/thorens_dept_.htm

Recently I've been out in the shop working on platforms and racks for the Teres. Recognizing that my method may have serious flaws, I have observed how sensitive this Teres player is to siting. It wants to stand on a very rigid platform. Some recent trials I've made with platforms and racks can be found at this link: http://www.theanalogdept.com/shelves_&_platforms.htm

I have been able to quickly assess that there are some knowledgeable folk scanning and posting to these pages. I have many questions I would like to post in an effort to continue my audiophile education. Those will follow. I thought that my first post shoud serve to introduce myself.

This seems like a great forum for audio folks.

-Steve

http://www.theanalogdept.com

name: Steve Clarke

My audiophile interests began in high-school, waxing strong throughout the seventies and into the eighties. Strangely my audiophile bug started waining shortly after purchasing my cd player at around 1985.

My first "decent" turntable was a Thorens TD160 MK I. I bought it new in 1975 and I still have it. In recent years I've put some time and energy into gaining a better understanding of correct turntable setup procedures. This has rewarded me in continuously improving sound output from this humble, old and trusty player.

These days I'm listening to Lp's played by a Teres model 135 equipped with the Expressimo RB250 fully modded-out tonearm. I have a Shelter 501-2 mounted at present. With this combo, I would be "shocked" to find any cd or sacd player that could offer me the audio sensory pleasure that this deck gives.

Link here for a view of my current equipment setup:

http://www.theanalogdept.com/user510.htm

I'm still interested in tinkering with old Thorens players however. They respond so positively to correct setting up in addition to damping mods. They gratify...! An excellent specimen for learning. I have documented many of my damping mods at the following website:

http://www.theanalogdept.com/thorens_dept_.htm

Recently I've been out in the shop working on platforms and racks for the Teres. Recognizing that my method may have serious flaws, I have observed how sensitive this Teres player is to siting. It wants to stand on a very rigid platform. Some recent trials I've made with platforms and racks can be found at this link: http://www.theanalogdept.com/shelves_&_platforms.htm

I have been able to quickly assess that there are some knowledgeable folk scanning and posting to these pages. I have many questions I would like to post in an effort to continue my audiophile education. Those will follow. I thought that my first post shoud serve to introduce myself.

This seems like a great forum for audio folks.

-Steve

http://www.theanalogdept.com

I visited your nice homepage

user510 (Steve)

I was around for awhile at your "department"

I like to have a look at members homepages

I would really like to hear some of my old Vinyls

I would really like to hear some of my old Vinyls

on your analog system

I started buying vinyls in the 60ies

I guess I have a couple of 100red Old goodies LPs & some EPs & singles

My Sony Turntable has a very simple pickup

and my system can't compare with your Super!

--------------------------------------------------

I liked your "canvasbackground.jpg" so much

that I stole that picture (_themes/canvas/cnvbkgrd.jpg)

Hope you do not mind ....

Great with so many nice photos.

I recommend anyone to make Steve a visit...

/halojoy - always among the first ones - around

user510 (Steve)

I was around for awhile at your "department"

I like to have a look at members homepages

on your analog system

I started buying vinyls in the 60ies

I guess I have a couple of 100red Old goodies LPs & some EPs & singles

My Sony Turntable has a very simple pickup

and my system can't compare with your Super!

--------------------------------------------------

I liked your "canvasbackground.jpg" so much

that I stole that picture (_themes/canvas/cnvbkgrd.jpg)

Hope you do not mind ....

Great with so many nice photos.

I recommend anyone to make Steve a visit...

/halojoy - always among the first ones - around

Hi Peter,

thanks for your reply and kind words. The drive string tensioner in that design of yours looks very functional.

The discourse I've been reading here with regard to the DIY Turntable thread has been inspiring. I too have a scheme for making a turntable, although it is not as ambitious as that which is being discussed in the large ongoing thread here at this forum. The goal is to use an existing group of components assembled into an alternate configuration. More to come later.

One attractive thing about turntables is their mechanical simplicity. This makes them accessible to many folks who would like to tinker. Then the real challenge comes when the goal is to achieve a higher sonic quality than existing commercial designs. This I don't pretend to have any talent for but am inspired to work along such goals never the less.

I like to work in 3D cad and graphics. I will post my graphics when I feel I have something to discuss.

Good to read you.

-Steve

http://www.theanalogdept.com

thanks for your reply and kind words. The drive string tensioner in that design of yours looks very functional.

The discourse I've been reading here with regard to the DIY Turntable thread has been inspiring. I too have a scheme for making a turntable, although it is not as ambitious as that which is being discussed in the large ongoing thread here at this forum. The goal is to use an existing group of components assembled into an alternate configuration. More to come later.

One attractive thing about turntables is their mechanical simplicity. This makes them accessible to many folks who would like to tinker. Then the real challenge comes when the goal is to achieve a higher sonic quality than existing commercial designs. This I don't pretend to have any talent for but am inspired to work along such goals never the less.

I like to work in 3D cad and graphics. I will post my graphics when I feel I have something to discuss.

Good to read you.

-Steve

http://www.theanalogdept.com

Attachments

Hi Halojoy

Good to read you.

I too have many Lp's from the 1960's. I've found that finding near mint used replacements is not such an easy task these days. It's more common to find re-issues of an album pressed on flippy floppy seventies or eighties vinyl than it is to find original pressings on nice thick sixties vinyl. The exception seems to be classical music which I can find a-plenty at the local thrift stores in my location, Seattle. What a fun game this is.

The canvas background is part and parcel of the html authoring software package I'm using. Go for it.

best regards,

-Steve

http://www.theanalogdept.com

Good to read you.

I too have many Lp's from the 1960's. I've found that finding near mint used replacements is not such an easy task these days. It's more common to find re-issues of an album pressed on flippy floppy seventies or eighties vinyl than it is to find original pressings on nice thick sixties vinyl. The exception seems to be classical music which I can find a-plenty at the local thrift stores in my location, Seattle. What a fun game this is.

The canvas background is part and parcel of the html authoring software package I'm using. Go for it.

best regards,

-Steve

http://www.theanalogdept.com

Hi Steve!

Welcome here!

Actually your page started me on all this analog stuff, you @#$%^...

Now I am modding my Thorens quite like you did, onely I allso changed the plinth to a far more solid one.

Since you are here, I got a question. Does the TP16-1 arm used to be completely in line or is the headshell slightly pointing downwards (about 3 degrees) from the point the headshell is fixed to the arm? (Hope you can make something out of this...) Mine is though...

greetz,

Merijn

Welcome here!

Actually your page started me on all this analog stuff, you @#$%^...

Now I am modding my Thorens quite like you did, onely I allso changed the plinth to a far more solid one.

Since you are here, I got a question. Does the TP16-1 arm used to be completely in line or is the headshell slightly pointing downwards (about 3 degrees) from the point the headshell is fixed to the arm? (Hope you can make something out of this...) Mine is though...

greetz,

Merijn

Hi Merijn,

the tp16-1 with it's huge honkin' tp60 detachable headshell is adjustable for azimuth. Just loosen the coupling nut and swivel the head with finger pressure. You need the special alignment jig these things came with to set it the Thorens way, however. The user manual covers the details of the adjustment.

Hopefully that's the angular tilt you are referring to. Otherwise, the headshell should be parallel with the arm tube when viewed from the side profile..... No adjustment for that...!

best regards,

-Steve

the tp16-1 with it's huge honkin' tp60 detachable headshell is adjustable for azimuth. Just loosen the coupling nut and swivel the head with finger pressure. You need the special alignment jig these things came with to set it the Thorens way, however. The user manual covers the details of the adjustment.

Hopefully that's the angular tilt you are referring to. Otherwise, the headshell should be parallel with the arm tube when viewed from the side profile..... No adjustment for that...!

best regards,

-Steve

Thorens Arms

Hello Steven, I also have a TD160MK1, the tweakers delight...

I know your web and it's very nice, congratulations! Much inspiration comes from it.

Going back to the 160, thoren's arms aren't the best, are they? Do you think is worth the effort to fit a RB250 in my thorens? Maybe I should wait for a better deck, I don't know, I have also a pro-ject arm, do you think it's a good alternative for the rega? Here the Project9 arm is 280 euros, and the RB250 is 200euro. My project tonearm is now fitted in a complete RPM4, that I'm trying to sell, but don't know if is better to keep just the arm instead of buying a rega and sell the project...

Any experience fitting a rega?

Hello Steven, I also have a TD160MK1, the tweakers delight...

I know your web and it's very nice, congratulations! Much inspiration comes from it.

Going back to the 160, thoren's arms aren't the best, are they? Do you think is worth the effort to fit a RB250 in my thorens? Maybe I should wait for a better deck, I don't know, I have also a pro-ject arm, do you think it's a good alternative for the rega? Here the Project9 arm is 280 euros, and the RB250 is 200euro. My project tonearm is now fitted in a complete RPM4, that I'm trying to sell, but don't know if is better to keep just the arm instead of buying a rega and sell the project...

Any experience fitting a rega?

Hi Raka

I really have no thoughts on the Project tonearms. I do know that there are plenty of people who have swapped an RB250/300 into different Thorens decks. Reports vary.

It is a lot easier to do arm swaps on Thorens decks like the TD150 or TD125 with their large--'open-at-one-end'--arm board. Swapping arms into the TD16x or 14x series will be limited to arms with similar 'pivot-to-spindle' distance rqmts because of the 'captive' armboard opening in the top plate. The Rega arms do fit this opening but just barely. There is a Rega armboard to fit the TD16x tables available from Rega intended for the TD160 Super. Weight of the arm is also very much a consideration. If the arm is too heavy it can destroy the designed-in balance of the light Thorens TD16x suspension assembly. Some folks have done the Rega into a Thorens swap and report great results. Others didn't think much of it.

My thoughts are that cost is a factor. If the cost of the Thorens is less than $200 used, would it make sense to place a new $400 tonearm on it? I'd feel better about it if the arm was acquired for much less money. Keeping the total hardware investment lower. Otherwise, you might just as well get a Linn.

later,

-Steve

I really have no thoughts on the Project tonearms. I do know that there are plenty of people who have swapped an RB250/300 into different Thorens decks. Reports vary.

It is a lot easier to do arm swaps on Thorens decks like the TD150 or TD125 with their large--'open-at-one-end'--arm board. Swapping arms into the TD16x or 14x series will be limited to arms with similar 'pivot-to-spindle' distance rqmts because of the 'captive' armboard opening in the top plate. The Rega arms do fit this opening but just barely. There is a Rega armboard to fit the TD16x tables available from Rega intended for the TD160 Super. Weight of the arm is also very much a consideration. If the arm is too heavy it can destroy the designed-in balance of the light Thorens TD16x suspension assembly. Some folks have done the Rega into a Thorens swap and report great results. Others didn't think much of it.

My thoughts are that cost is a factor. If the cost of the Thorens is less than $200 used, would it make sense to place a new $400 tonearm on it? I'd feel better about it if the arm was acquired for much less money. Keeping the total hardware investment lower. Otherwise, you might just as well get a Linn.

later,

-Steve

Thanks,

Yes, I was thinking about the value ratio of deck/RB250 and seems to be maybe a little crazy...

Anyway, if I sell the project, I will buy the RB250 and try to fit in the 160. As it seems the platform of the arm should be replaced to achieve the pivot spindle distance. I will think about it, doesn't seem to be very difficult to build one.

The tonearm weight can unbalance the subchassis, obviously, but can this be compensated in the springs?

Yes, I was thinking about the value ratio of deck/RB250 and seems to be maybe a little crazy...

Anyway, if I sell the project, I will buy the RB250 and try to fit in the 160. As it seems the platform of the arm should be replaced to achieve the pivot spindle distance. I will think about it, doesn't seem to be very difficult to build one.

The tonearm weight can unbalance the subchassis, obviously, but can this be compensated in the springs?

RB250/TD16x installations I've seen do not replace springs, but work with the stock Thorens parts. In this regard the RB250 seems a good enough candidate. Another idea is to consider the various tonearms known to work well on a LP12. These might also be considered on the TD16x when the pivot to spindle distance works. Perhaps one of the Linn factory arms could be had second hand for next to nothing... Some people report using LP12 springs to replace the Thorens units. I would approach this carefully or not at all as the spring rate of the Linn units are known to be somewhat higher (stiffer).

just a few random thoughts. If you would like to continue this dialog perhaps this forum is not the best place. I can be reached via email directly at: user510@earthlink.net

later,

-Steve

just a few random thoughts. If you would like to continue this dialog perhaps this forum is not the best place. I can be reached via email directly at: user510@earthlink.net

later,

-Steve

Hi Alanb.

The motor in the TD160 is designed to run in synch with the mains frequency. It is this frequency of household electrical current that regulates the speed that the motor turns. The same motor was used for all models including those exported to the UK, Europe and the USA. The motor for the MK 1 and early MK II versions of the table was designed to operate on 110-120 volts AC. It will handle either 50 hz or 60 hz without a problem. The mains terminal inside the cabinetry of the TT offers some connection options. For countries with higher mains voltages, like the UK, the power is routed through a resistor designed to reduce voltage to within the 120 - 110 needs of the motor. For countries like the US and Canada where 110 VAC is the standard, the mains connection option avoids the resistor. This terminal was included on all models and the connection can be altered by simply pulling a wire clip off one spade and onto another.

BTW, later in the production run of the MK II, motors were changed to a low voltage design making use of a "power converter" aka wall wart. These motors allowed the company to avoid the terminal and resistors inside the box. Rather the owner merely has to find the correct power converter for the country he/she is in that has an output of 16 - 18 volts AC. Commonly available for cheap.

Manuals at The Analog Dept.

See the above link to find the "Service Manual" for the TD160. This service manual instructucts on how to make the connection options for different mains currents.

Another important issue:

Remembering that the motor is of the AC synchronous variety and that the speed is regulated by mains frequency we must deal with platter speed for different countries by using a different diameter of drive pulley for 50 hz and 60 hz. You will need to obtain a North American version of the pulley in order to operate it at 60 hz. Rolf Kelch has these pulleys, as well as some other essential supplies and sells them at competitive prices.

Rolf Kelch Electronic GmbH, Hansastrasse 1, D-77933 Lahr, Tel.: 07821 907411, Fax: 07821 42209, e-mail: rolf.kelch@t-online.de ,

Another supplier will be: Technical and General

POBox 53

Crowborough

East Sussex, England

TN6 2BY

Tel: 01892 654534

email: technical-and-general@fsmail.net

hope that helps.

-Steve

The motor in the TD160 is designed to run in synch with the mains frequency. It is this frequency of household electrical current that regulates the speed that the motor turns. The same motor was used for all models including those exported to the UK, Europe and the USA. The motor for the MK 1 and early MK II versions of the table was designed to operate on 110-120 volts AC. It will handle either 50 hz or 60 hz without a problem. The mains terminal inside the cabinetry of the TT offers some connection options. For countries with higher mains voltages, like the UK, the power is routed through a resistor designed to reduce voltage to within the 120 - 110 needs of the motor. For countries like the US and Canada where 110 VAC is the standard, the mains connection option avoids the resistor. This terminal was included on all models and the connection can be altered by simply pulling a wire clip off one spade and onto another.

BTW, later in the production run of the MK II, motors were changed to a low voltage design making use of a "power converter" aka wall wart. These motors allowed the company to avoid the terminal and resistors inside the box. Rather the owner merely has to find the correct power converter for the country he/she is in that has an output of 16 - 18 volts AC. Commonly available for cheap.

Manuals at The Analog Dept.

See the above link to find the "Service Manual" for the TD160. This service manual instructucts on how to make the connection options for different mains currents.

Another important issue:

Remembering that the motor is of the AC synchronous variety and that the speed is regulated by mains frequency we must deal with platter speed for different countries by using a different diameter of drive pulley for 50 hz and 60 hz. You will need to obtain a North American version of the pulley in order to operate it at 60 hz. Rolf Kelch has these pulleys, as well as some other essential supplies and sells them at competitive prices.

Rolf Kelch Electronic GmbH, Hansastrasse 1, D-77933 Lahr, Tel.: 07821 907411, Fax: 07821 42209, e-mail: rolf.kelch@t-online.de ,

Another supplier will be: Technical and General

POBox 53

Crowborough

East Sussex, England

TN6 2BY

Tel: 01892 654534

email: technical-and-general@fsmail.net

hope that helps.

-Steve

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Hello all