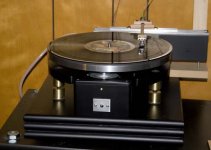

The floppy drive is still working as it should and the pitch sounds correct to my ears. The record anvil weighs 445 grams, I’m thinking about changing to a lighter gripper type.

I’m going to try a 5VDC wall transformer made by Interex that puts out 2000ma. The battery power hasn’t been a problem but I’m always thinking about the charge state.

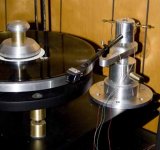

I’ve abandoned the Paul Ladegaard air bearing tonearm in favor of the unipivot. My thoughts on the Ladegarrd would be tonearm wires. The wires can be a real pain to deal with. I think the low compliance cart is the better choice for the Ladegaard arm.

The unipivot makes me smile, it’s so simplistic in design and plays superbly. I’m still in need of a cueing mechanism.

A big thanks to Carlo Morsiani for answering a few questions and for the information he’s posted on this forum about his unipivot tonearm

http://www.morsiani.it/

For now I’m satisfied with my econo tt, it is what it is……

I’m going to try a 5VDC wall transformer made by Interex that puts out 2000ma. The battery power hasn’t been a problem but I’m always thinking about the charge state.

I’ve abandoned the Paul Ladegaard air bearing tonearm in favor of the unipivot. My thoughts on the Ladegarrd would be tonearm wires. The wires can be a real pain to deal with. I think the low compliance cart is the better choice for the Ladegaard arm.

The unipivot makes me smile, it’s so simplistic in design and plays superbly. I’m still in need of a cueing mechanism.

A big thanks to Carlo Morsiani for answering a few questions and for the information he’s posted on this forum about his unipivot tonearm

http://www.morsiani.it/

For now I’m satisfied with my econo tt, it is what it is……

Attachments

BluesMagoos said:

I’ve abandoned the Paul Ladegaard air bearing tonearm in favor of the unipivot. My thoughts on the Ladegarrd would be tonearm wires. The wires can be a real pain to deal with. I think the low compliance cart is the better choice for the Ladegaard arm.

For now I’m satisfied with my econo tt, it is what it is……

My thoughts are the same about a lineair tracking arm:needs a stiff cantilever suspension to avoid "tilting" of cantilever before the whole carriage is moving. A soft suspended cantilever will bend considerately, then creates an even greater error compared to a unipivot/cardanic arm.

(I am planning on a roller bearing lineair arm, but first busy with re-installing my diy arm, did some maintenance on bearings & added new carbon arm tube, and it sounds promising with stethoscope allready)

I am now also switching over to belt drive, discovered a worn bearing in my old modded Akai DD.

Made a MDF base for the belt drive, the former DD had a marble sheet base, rubber suspended. It resonated like hell.

Maybe not that exotic this time but we will see how it sounds:

http://img527.imageshack.us/img527/1285/00013pj8.jpg

Here is the diy arm on the old DD with marble base. It then had still the old aluminium tube. (Takes some time to load)

http://img109.imageshack.us/my.php?image=armoq2.jpg

http://img109.imageshack.us/my.php?image=armoq2.jpg

Yes Jrevillug, the compliance has to fit with the arm.

Just rightnow i am listening to my new carbon tonearm. Sound is warmer compared to alu tube. Less harsch, good detail, less sharp treble. Soundstagehas to open up, just switched it all on.

Elongated the arm somewhat, i build a new TT around it. Used the Linn LP12 values now. A longer arm reduces tracking errors somewhat.

The dynamic weight of the arm is reduced, i guess it's now about 11 grams it was a lot more before: The old armtube (without headshell) weighted 13 gramms, the new Carbon tube 4.8 grams. I did,nt weigh the shell, but can calculate it. But compensated this lesser weight with a more out of the pivot mointing of counterweight. (My arm has a combination of counterweight and spiral-spring adjustment, all diy btw.) The bearings of arm where still perfect, looked at the 60 degr topangle cones turning in the tiny corner ball bearings with powerful diamond loupe, no wear to see after 20 years of use.

The AC Motor is not the best, stray field is enormous, can shield it, but best is to try the floppy motor it think. I use a very flimsy elastic thread (to be braided in socks for elasticity) and il like this solution. The knot is unhearable, the power to drive the used old Lenco platter is very subtle, i think the best solution, a powerful driven platter depends more on the speed fluctuation of the motor. (flutter) And a flimsy belt should give more very subsonic wow. When i turn the platter when it's still, it lasts about a half platter turn before the motor pully starts to turn. The tension on one end of belt is then much greater then on the other. This tiny belt creates a sort of Magnet Drive by itself wich Transrotor invented.

But have a huge hum also on speakers, use 0.4 mV Benz Micro Gold on MM input. Phono amp can amplify it enough, but a pre or step up transformer would be better.

I have to connect the cart better (ground loops)

Any suggestions here? Thanks in advance.

BluesMagoos: do you know at what speed the floppy motor turns? I want to use my floppy motor and calculate a pully for it. Did you use 2 pulleys, or made a speed switch?

Just rightnow i am listening to my new carbon tonearm. Sound is warmer compared to alu tube. Less harsch, good detail, less sharp treble. Soundstagehas to open up, just switched it all on.

Elongated the arm somewhat, i build a new TT around it. Used the Linn LP12 values now. A longer arm reduces tracking errors somewhat.

The dynamic weight of the arm is reduced, i guess it's now about 11 grams it was a lot more before: The old armtube (without headshell) weighted 13 gramms, the new Carbon tube 4.8 grams. I did,nt weigh the shell, but can calculate it. But compensated this lesser weight with a more out of the pivot mointing of counterweight. (My arm has a combination of counterweight and spiral-spring adjustment, all diy btw.) The bearings of arm where still perfect, looked at the 60 degr topangle cones turning in the tiny corner ball bearings with powerful diamond loupe, no wear to see after 20 years of use.

The AC Motor is not the best, stray field is enormous, can shield it, but best is to try the floppy motor it think. I use a very flimsy elastic thread (to be braided in socks for elasticity) and il like this solution. The knot is unhearable, the power to drive the used old Lenco platter is very subtle, i think the best solution, a powerful driven platter depends more on the speed fluctuation of the motor. (flutter) And a flimsy belt should give more very subsonic wow. When i turn the platter when it's still, it lasts about a half platter turn before the motor pully starts to turn. The tension on one end of belt is then much greater then on the other. This tiny belt creates a sort of Magnet Drive by itself wich Transrotor invented.

But have a huge hum also on speakers, use 0.4 mV Benz Micro Gold on MM input. Phono amp can amplify it enough, but a pre or step up transformer would be better.

I have to connect the cart better (ground loops)

Any suggestions here? Thanks in advance.

BluesMagoos: do you know at what speed the floppy motor turns? I want to use my floppy motor and calculate a pully for it. Did you use 2 pulleys, or made a speed switch?

Floppy rpm is 300.

One speed pulley for now. Two-speed pulley is my plan. I ground the convex profile onto my cutting tool, a real time saver

I had planned on leaving my pulley diameter a few thousands over but when I finished it was only .0005 over. I wanted a little fudge margin but it didn’t matter, I believe the pitch is spot on. Two small drops of super glue and it’s locked on.

For your hum problem I would start unplugging everything until you’re down to the bare bones. Powered subs can be a cause. I picked up a hum and it turned out to be a lamp that was plugged into my power strip. It didn’t matter if the lamp was on or off it caused the hum.

What is your carbon wand source? I’m going to go that route. I want to try one of the Easton ACC arrows, they are alum and carbon lined. No luck trying to purchase one arrow. I read a Fremmer review on a turntable that used an alum/carbon-lined wand.

One speed pulley for now. Two-speed pulley is my plan. I ground the convex profile onto my cutting tool, a real time saver

I had planned on leaving my pulley diameter a few thousands over but when I finished it was only .0005 over. I wanted a little fudge margin but it didn’t matter, I believe the pitch is spot on. Two small drops of super glue and it’s locked on.

For your hum problem I would start unplugging everything until you’re down to the bare bones. Powered subs can be a cause. I picked up a hum and it turned out to be a lamp that was plugged into my power strip. It didn’t matter if the lamp was on or off it caused the hum.

What is your carbon wand source? I’m going to go that route. I want to try one of the Easton ACC arrows, they are alum and carbon lined. No luck trying to purchase one arrow. I read a Fremmer review on a turntable that used an alum/carbon-lined wand.

BluesMagoos said:Floppy rpm is 300.

One speed pulley for now. Two-speed pulley is my plan. I ground the convex profile onto my cutting tool, a real time saver

I had planned on leaving my pulley diameter a few thousands over but when I finished it was only .0005 over. I wanted a little fudge margin but it didn’t matter, I believe the pitch is spot on. Two small drops of super glue and it’s locked on.

For your hum problem I would start unplugging everything until you’re down to the bare bones. Powered subs can be a cause. I picked up a hum and it turned out to be a lamp that was plugged into my power strip. It didn’t matter if the lamp was on or off it caused the hum.

What is your carbon wand source? I’m going to go that route. I want to try one of the Easton ACC arrows, they are alum and carbon lined. No luck trying to purchase one arrow. I read a Fremmer review on a turntable that used an alum/carbon-lined wand.

Thanks for reply & tips BluesMagoos, now i can calculate the pulley. Have only one 45rpm 12 inch, but still make a 2 speeder. If yours was only 0.0005 over, you have only a margin of slip. What belt do you use?

For the hum i will check it, but on a regular MM cart it hummed also, because of the high signal not that obvious. Now with a MC problems comes up. I think i will try a separate IC phono stage.

And poweramp is powered by another main connection in the other corner of the room...

BluesMagoos said:

What is your carbon wand source? I’m going to go that route. I want to try one of the Easton ACC arrows, they are alum and carbon lined. No luck trying to purchase one arrow. I read a Fremmer review on a turntable that used an alum/carbon-lined wand.

German make cross woven Carbon diam. 10 mm and 0.5 mm thick wall tube, bought in shop specialised for hobby stuff. (modelmakers) Have been looking in fishing gear shop too, nice that they had some available in conical shape, but this is usual straight woven carbon, i wanted in special the cross woven.

The belt is a flat rubber factory replacement. When I make the two-speed pulley I will add some fudge factor,

I find it hard to stop this modding disease. I’m looking at some Bubinga or Ebony for a new wand. That means a new cart and phono preamp. Then a better platter etc. I’m hoping I can get well, enjoy the music and move on.

Help, I’ve fallen and can’t get up.

I find it hard to stop this modding disease. I’m looking at some Bubinga or Ebony for a new wand. That means a new cart and phono preamp. Then a better platter etc. I’m hoping I can get well, enjoy the music and move on.

Help, I’ve fallen and can’t get up.

BluesMagoos said:The belt is a flat rubber factory replacement. When I make the two-speed pulley I will add some fudge factor,

I find it hard to stop this modding disease. I’m looking at some Bubinga or Ebony for a new wand. That means a new cart and phono preamp. Then a better platter etc. I’m hoping I can get well, enjoy the music and move on.

Help, I’ve fallen and can’t get up.

I thought also that must have been a flat belt.

With a wand you propose a new arm tube? Wood is most natural i think. Maybe a simple pine wood experiment?

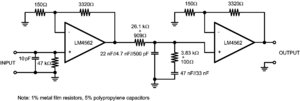

Yes modding never stops. I have build a tube phono and pre, but not perfect satisfied with the sound. To much 2nd harmonic to my taste, it covers up the real ground tones. Am thinking of a simple IC phono stage, balanced, like schematic on the datasheet of LM4562 opamp.

Yesterday i hooked the floppy motor on 4 NiCd batteries of 1500mA capable, runs fine. Want to use a 5V cellphone charger for charging.

Attachments

Well, have the floppy motor running. The motor itself is running smooth. Mounted it on 3 rubber dampers. Calculated two diameters/speeds. Had to emperical resize the 33 rpm again, now i am allmost on the right speed with a strobe.

But the fine filament belt is not the best choice, in the first tracks it's too slow, the later to fast. Have to use a better belt with less slip, it is hearable when diffcult music passages get through, then speeds slows down. For alternative i have a nice soft round silicone belt, but then i have to make a smaller pulley under platter, the silicone belt is smaller. Now the platter is driven on the outside diameter.

I like the Carbon armwand, better detailed sound. Due to hum problems i am forced to let the Benz Gold MC in the box, and have mounted the OM5 ortofon again. This one feels better in the lighter carbon arm now. The leaner sound of it matches good to the carbon arm. I like dynamical carts, the Benz is some laid back. Maybe it's time to get a nice MM cart, Audio Technica or Grado

But the fine filament belt is not the best choice, in the first tracks it's too slow, the later to fast. Have to use a better belt with less slip, it is hearable when diffcult music passages get through, then speeds slows down. For alternative i have a nice soft round silicone belt, but then i have to make a smaller pulley under platter, the silicone belt is smaller. Now the platter is driven on the outside diameter.

I like the Carbon armwand, better detailed sound. Due to hum problems i am forced to let the Benz Gold MC in the box, and have mounted the OM5 ortofon again. This one feels better in the lighter carbon arm now. The leaner sound of it matches good to the carbon arm. I like dynamical carts, the Benz is some laid back. Maybe it's time to get a nice MM cart, Audio Technica or Grado

Very impressive!!!

How do you mount the pully with the floppy motor?

How do you mount the pully with the floppy motor?

BluesMagoos said:Floppy drive

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Floppy drive motor