I think the confusion comes from thinking that this thread involves the Maya passive attenuator system as a whole.

All that is used in this thread is the Maya CPU. None of the Maya's analogue input boards or attenuation boards are used at all.

When you ask Tibi questions about his Maya passive attenuator system, he will be answering you talking about the Maya's analogue boards and the different options with them. His analogue boards only handle 4 inputs. None of that is relevent to this thread however..

As I say, this thread uses ONLY the Maya CPU board (the part with the display and data wheel) and nothing else at all from Tibi .

The Maya CPU is just an I2C controller, albeit one that has many functions. For this project we will be using the I2C commands to control the BPPBP. Hans has created his own board to take the commands from the Maya CPU and to act as an interface for the BPPBP. This is the VolCB.

Hans' VolCB takes the I2C commands from the Maya CPU and can control up to 6 x 5v relays directly from the VolCB for any kind of input relay system you can devise. The VolCB also takes I2C commands from the Maya CPU to control a resistor ladder (?) to adjust level on the BPPBP. Level adjustment on the BPPBP is via the feedback loop and not by any direct audio signal attenuation - that is why the BPPBP requires something more specific to it's design.

There is no need to worry about SE and balanced inputs with the BPPBP. The BPPBP uses differentially wired inputs on XLR sockets. As Bruno Putzey explains in his white paper for the project, SE inputs can easily be used with the BPPBP with nothing more than attention paid to how the connecting cable is wired.

Does this help?

All that is used in this thread is the Maya CPU. None of the Maya's analogue input boards or attenuation boards are used at all.

When you ask Tibi questions about his Maya passive attenuator system, he will be answering you talking about the Maya's analogue boards and the different options with them. His analogue boards only handle 4 inputs. None of that is relevent to this thread however..

As I say, this thread uses ONLY the Maya CPU board (the part with the display and data wheel) and nothing else at all from Tibi .

The Maya CPU is just an I2C controller, albeit one that has many functions. For this project we will be using the I2C commands to control the BPPBP. Hans has created his own board to take the commands from the Maya CPU and to act as an interface for the BPPBP. This is the VolCB.

Hans' VolCB takes the I2C commands from the Maya CPU and can control up to 6 x 5v relays directly from the VolCB for any kind of input relay system you can devise. The VolCB also takes I2C commands from the Maya CPU to control a resistor ladder (?) to adjust level on the BPPBP. Level adjustment on the BPPBP is via the feedback loop and not by any direct audio signal attenuation - that is why the BPPBP requires something more specific to it's design.

There is no need to worry about SE and balanced inputs with the BPPBP. The BPPBP uses differentially wired inputs on XLR sockets. As Bruno Putzey explains in his white paper for the project, SE inputs can easily be used with the BPPBP with nothing more than attention paid to how the connecting cable is wired.

Does this help?

Last edited:

The 6 input board and Maya control with VolCB are kind of universal if you know how they work and know how to integrate them into something else.

Just ask those who have built the BPPBP already - many impressed people out there. Whether it's what you like is another matter although there was time to build the basic preamp and listen to it before spending on the remote control part.

Just ask those who have built the BPPBP already - many impressed people out there. Whether it's what you like is another matter although there was time to build the basic preamp and listen to it before spending on the remote control part.

I was playing with the idea to supplying fully populated VolCB boards, so I requested quotes for 50 Pcs.

But for such a relatively low amount, costs turn out to be prohibitive because of the making of the stencils, the machine programming etc, etc.

So even not having the advantage of buying parts in larger quantities, you will still be a lot cheaper by doing the job of buying and mounting all components yourself.

That's why Tibi and I decided to stay with the original idea and let Tibi supply the bare PCB's.

Sending in one go the Maya controller with the VolCB will also help to save further on shipping costs.

Hans

But for such a relatively low amount, costs turn out to be prohibitive because of the making of the stencils, the machine programming etc, etc.

So even not having the advantage of buying parts in larger quantities, you will still be a lot cheaper by doing the job of buying and mounting all components yourself.

That's why Tibi and I decided to stay with the original idea and let Tibi supply the bare PCB's.

Sending in one go the Maya controller with the VolCB will also help to save further on shipping costs.

Hans

Hans, do you have a BOM for the VolCB board?

Albert

Hi Albert,

Here it is.

View attachment VolCB.bom.txt

Re7 has to be used in case of using the 2 inputs on the BPBP.

When using the 6 input GB board, Re7 will have to be replaced by a connector TE Connectivity 2178710-8 .

The best option is to use thin film resistors, but thick film will be much cheaper.

Thin Film has lower noise and lower distortion.

Hans

I have a very limited range of thin film in both 1% and 0.1%

I have more of the thick film 1% and most are <1p (0.01GBP) each.

All are 805 package.

I lightly tin one pad and leave the other as supplied by the PCB maufacturer.

Place the 805 as accurately as possible sitting with one end slightly high due to the thickness of the hand applied tinning/splodge.

Hold the 805 in place with a darning needle or a cocktail stick or a piano wire clamp.

Apply the iron to the tinned pad and the 805 falls down into place as the solder melts. At this stage I do not add any more solder. This pre-tinning is just enough to hold the 805 in place.

Now solder the other end using cored 26awg or 24awg 63/37 eutectic.

Go back and top up the first end with cored solder.

I have more of the thick film 1% and most are <1p (0.01GBP) each.

All are 805 package.

I lightly tin one pad and leave the other as supplied by the PCB maufacturer.

Place the 805 as accurately as possible sitting with one end slightly high due to the thickness of the hand applied tinning/splodge.

Hold the 805 in place with a darning needle or a cocktail stick or a piano wire clamp.

Apply the iron to the tinned pad and the 805 falls down into place as the solder melts. At this stage I do not add any more solder. This pre-tinning is just enough to hold the 805 in place.

Now solder the other end using cored 26awg or 24awg 63/37 eutectic.

Go back and top up the first end with cored solder.

Thanks for these guidelines, I'll try them out

I have a very limited range of thin film in both 1% and 0.1%

I have more of the thick film 1% and most are <1p (0.01GBP) each.

All are 805 package.

I lightly tin one pad and leave the other as supplied by the PCB maufacturer.

Place the 805 as accurately as possible sitting with one end slightly high due to the thickness of the hand applied tinning/splodge.

Hold the 805 in place with a darning needle or a cocktail stick or a piano wire clamp.

Apply the iron to the tinned pad and the 805 falls down into place as the solder melts. At this stage I do not add any more solder. This pre-tinning is just enough to hold the 805 in place.

Now solder the other end using cored 26awg or 24awg 63/37 eutectic.

Go back and top up the first end with cored solder.

Hi Albert,

Here it is.

View attachment 553605

Re7 has to be used in case of using the 2 inputs on the BPBP.

When using the 6 input GB board, Re7 will have to be replaced by a connector TE Connectivity 2178710-8 .

The best option is to use thin film resistors, but thick film will be much cheaper.

Thin Film has lower noise and lower distortion.

Hans

Hi,

Can I use Fujitsu A5W-Ks for RE1-6? Here is the spec from Mouser:

Manufacturer: Fujitsu

Product Category: Low Signal Relays - PCB

RoHS: RoHS Compliant Details

Product: Low Profile Relays

Type: Miniature

Coil Voltage: 5 VDC

Contact Form: DPDT (2 Form C)

Maximum Switching Current: 2 A

Coil Type: Non-Latching

Power Consumption: 140 mW

Brand: Fujitsu

Contact Material: Silver Alloy (Ag) with Gold Plating

Contact Termination: Solder Pin

Mounting Style: Through Hole

I ask only because I have some I can remove from some equipment.

Hi,

Can I use Fujitsu A5W-Ks for RE1-6? Here is the spec from Mouser:

I ask only because I have some I can remove from some equipment.

The Standard PCF chip can only handle 100mA max. With 6 relays, this means 16mA max per relay.

The IM23 draws 10mA, well within this margin, whereas the Fujitsu draws 28mA.

Having a lower operating current also helps to keep EMI as low as possible.

Hans

I have updated the BOM for the VolCB with some extra information, and also added the BOM for the 4 input board.

Hans

View attachment VolCB.bom.txt

View attachment 4channel.bom.txt

Hans

View attachment VolCB.bom.txt

View attachment 4channel.bom.txt

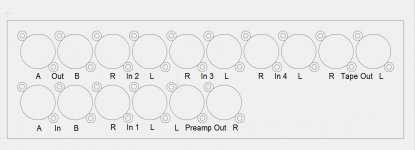

I see 4 pr inputs and 4 pr outputs. It makes more sense to me to put all the inputs on one row and all the outputs on the other row.

Hi Andrew,

From a logistics point of view, you are right (B.t.w. it is 3/5 instead of 4/4)

It would be even nicer to have all left channels on one side and the right channels on the other side.

But I had to follow the layout on the BPBP for those who have the XLR plugs soldered to the PCB.

The can just attach it to the backplate the way it is.

Hans

I have placed all relevant documents for the VolCB and the 4 Input Select board in one dropbox file, that can be updated when needed, thereby keeping the same link.

https://www.dropbox.com/sh/0rxpg5lfxvju9g0/AADqEbF6N7WFk777vFS9e35Ga?dl=0

Hans

https://www.dropbox.com/sh/0rxpg5lfxvju9g0/AADqEbF6N7WFk777vFS9e35Ga?dl=0

Hans

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analog Line Level

- Remote Control for the BPBP