Oh, I never thought about that. Since the topic is of extreme interest in my work, I just downloaded it..Jeez, I only had access to the “Abstracts”

I’ll never confess to you the story of my life. You’ll nail me in a minute with a thousand nails

Well, now that ya mentioned it...

Nah, life is life. And out of bounds with respect to comment..

Technical information, now that's different...tomes setup as technical reference require review and if necessary, revision.

That is NEVER trouble.Yes. And then here I come asking, putting you into the trouble to answer and kindly explain.

Most of the curriculum is based on the aftermaths of such stupid common everyday mistakes.

George

One of my favorite books is Breakdown...Deadly Technological Disasters, Schlager, Neil, 1995 Visible Ink Press, ISBN 0-7876-0478-X

jn

George,

We have a saying for that, stupid is as stupid does. I also worked in aerospace and many of the things I worked on I could only discern what was going on through retained knowledge of the old time employees that had been there since the beginning of a program. We produced the tail and main rotor blades for most major helicopters and my main focus was the Apache tooling. After being there, working with a Boeing rep who came in house we found that every blade produced since the original had left a critical radius out of the manufacturing process. You don't think that we were going to ground every helicopter do you? We quickly rectified the situation on all new production, luckily there had never been a failure due to this oversight. But, when I went back many years into the documents, they were under my purview, there was that radius clearly on the original drawings that Boeing had produced. Could have been a major problem, but at the time we were running production 24/7 just to keep up and so it was overlooked. Historical knowledge can sink you quickly when those people leave any organization, and if nobody ever asks that information isn't ever questioned until that knowledge has already been lost.

Steven

We have a saying for that, stupid is as stupid does. I also worked in aerospace and many of the things I worked on I could only discern what was going on through retained knowledge of the old time employees that had been there since the beginning of a program. We produced the tail and main rotor blades for most major helicopters and my main focus was the Apache tooling. After being there, working with a Boeing rep who came in house we found that every blade produced since the original had left a critical radius out of the manufacturing process. You don't think that we were going to ground every helicopter do you? We quickly rectified the situation on all new production, luckily there had never been a failure due to this oversight. But, when I went back many years into the documents, they were under my purview, there was that radius clearly on the original drawings that Boeing had produced. Could have been a major problem, but at the time we were running production 24/7 just to keep up and so it was overlooked. Historical knowledge can sink you quickly when those people leave any organization, and if nobody ever asks that information isn't ever questioned until that knowledge has already been lost.

Steven

Google for Seebeck effect; The Seebeck coefficient is a material property that depends on temperature (micro volts/ degree C.) From that, EMF can be found....

Some Seebeck coefficients are: copper to silver or gold = 0.5 uv/C; Copper - nickel = 10; Copper to KOVAR = 40.

Strange one is copper to copper is not = 0 [thermal gradients matter].

Also google Thermal EMF of Solders.

Thank you very much RNMarsh

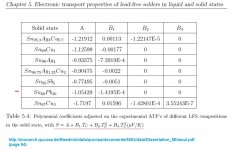

From this paper (some will love it

page 94, the Sieebeck coeff. for Sn60Pb40 solder is –1.06 uV/K at room temperatures

So copper/Sn60Pb40 thermal EMF is 2.6 uV/K

The big problem could be with Nickel/copper (~ -19uV/K) or Nickel/Sn60Pb40 (~ -21 uV/K)

George

Attachments

Last edited:

That is NEVER trouble.

jn

This is encouraging. Thank you.

I’ve read this book. I agree with you.

George,

We have a saying for that, stupid is as stupid does

Steven

Steven, yes. This is the bitter truth.

Fate has it I am now on composite rotors inspection for an OEM manufacturer.

George

George,

I had something to do with the tooling for the composite blade for the \Carson helicopter main rotor blades. Was supposed to be the blade for a new fleet of Presidential helicopters before the costs shut that down. We did install a CAT scanner just for those blades as the requirements were much higher than the commercial blades. What a small world we live in,

Steven

I had something to do with the tooling for the composite blade for the \Carson helicopter main rotor blades. Was supposed to be the blade for a new fleet of Presidential helicopters before the costs shut that down. We did install a CAT scanner just for those blades as the requirements were much higher than the commercial blades. What a small world we live in,

Steven

I don't have that (but it's now on my long list of books to get, despite the one review on Amazon), but I have related books such as "Major Malfunction." I used to read comp.risks a lot many years ago, when I was doing electronic design and embedded programming on products that ... I've got stories that should really have a few more years before I tell ... but anyway, I stopped reading comp.risks because it pretty much started giving me nightmares. There's only so many train wrecks one can read about before finding oneself worrying about everything....

One of my favorite books is Breakdown...Deadly Technological Disasters, Schlager, Neil, 1995 Visible Ink Press, ISBN 0-7876-0478-X

jn

Wasn't it here on DIYaudio that someone posted NASA's analysis and conclusion of the Toyota accelerator problem? It was tin whiskers on the potentiometer connection of the accelerator pedal, one place they SHOULD have used old-fashioned tin-lead solder instead of the RHOS lead-free stuff that had already been known for years to generate tin whiskers.

Back on topic, is there an "accepted" discrete opamp design yet? I think I've seen BJT-only, FET-only and "hybrid" designs so far.

Back on topic, is there an "accepted" discrete opamp design yet? I think I've seen BJT-only, FET-only and "hybrid" designs so far.

Do you want vacuum tubes?

http://wavebourn.com/forum/download.php?id=587&f=7

I don't have that (but it's now on my long list of books to get, despite the one review on Amazon), but I have related books such as "Major Malfunction." I used to read comp.risks a lot many years ago, when I was doing electronic design and embedded programming on products that ... I've got stories that should really have a few more years before I tell ... but anyway, I stopped reading comp.risks because it pretty much started giving me nightmares. There's only so many train wrecks one can read about before finding oneself worrying about everything.

Wasn't it here on DIYaudio that someone posted NASA's analysis and conclusion of the Toyota accelerator problem? It was tin whiskers on the potentiometer connection of the accelerator pedal, one place they SHOULD have used old-fashioned tin-lead solder instead of the RHOS lead-free stuff that had already been known for years to generate tin whiskers.

Back on topic, is there an "accepted" discrete opamp design yet? I think I've seen BJT-only, FET-only and "hybrid" designs so far.

I still have friends who want earnestly to believe that all the Toyota/Lexus problems have been explained away by operator error and trapped floor mats. However, there was a post from someone who afaik had no specific ax to grind, but knew of a number of lawsuits settled out-of-court that indicate a good deal of other very serious issues.

Another friend who might have been agnostic on the subject had his beloved Prius have its brakes fail and he nearly collided with a truck. When he took it in the dealership said Well we'll replace ... (followed a long laundry list) ... and then we'll see if that fixes it

On train wrecks, I know the feeling. One story I will relate before I pass on, in which a powered speaker with a to-that-point enviable reliability record almost burned down a dormitory. It's true that in that very-worst-case, two different components had to fail simultaneously, but the problem revealed a mechanism for overvoltages that was extraordinarily obscure. The only person who was not surprised by the behavior when described (after I had finally figured it out) was Gerald Stanley

Russian Phobos-Grunt failed an year ago, supposedly because of electronics. It was a space ship that had to take soil probe from Phobos, Mars's satellite, and bring it back to Earth. Could it happen because of ROHS regulations?

If the mission was to Mercury, quite plausibly

KOVAR

Also KOVAR, the transistor lead material that you solder to

the pcb. Made more for the thermal coeff of expansion compatibility with the other packaging material. So, here you have many different metals/alloys --the transistor lead metals, the pcb metals and the solder metals.

Then you must consider the thermal gradiants across the parts in the physical circuit layout so as to minimize temp diferences across a part .. like a resistor or other... you want to have same temp at each end of the resistor or part.... For example, when a pcb is mounted vertically or on its edge to conserve chassis space/size you will easliy have different temp from bottom to top of a part if it is also mounted vertically..... better to mount it horizonally. [Am I being clear?]

If you dont control all thermal factors, you wont get absolute best possible performance in terms of dc drift, noise and possibly distortion. These things are all part of making a SOTA amp from a schematic. -RNM

Thank you very much RNMarsh

From this paper (some will love it) http://monarch.qucosa.de/fileadmin/data/qucosa/documents/5563/data/Dissertation_Mhiaoui.pdf

page 94, the Sieebeck coeff. for Sn60Pb40 solder is –1.06 uV/K at room temperatures

So copper/Sn60Pb40 thermal EMF is 2.6 uV/K

The big problem could be with Nickel/copper (~ -19uV/K) or Nickel/Sn60Pb40 (~ -21 uV/K)

George

Also KOVAR, the transistor lead material that you solder to

the pcb. Made more for the thermal coeff of expansion compatibility with the other packaging material. So, here you have many different metals/alloys --the transistor lead metals, the pcb metals and the solder metals.

Then you must consider the thermal gradiants across the parts in the physical circuit layout so as to minimize temp diferences across a part .. like a resistor or other... you want to have same temp at each end of the resistor or part.... For example, when a pcb is mounted vertically or on its edge to conserve chassis space/size you will easliy have different temp from bottom to top of a part if it is also mounted vertically..... better to mount it horizonally. [Am I being clear?]

If you dont control all thermal factors, you wont get absolute best possible performance in terms of dc drift, noise and possibly distortion. These things are all part of making a SOTA amp from a schematic. -RNM

Last edited:

(for audio -- you dont want any nickel in the signal path)

Even in sockets and plugs of professional equipment used to record audiophile quality material?

My best tube amps use nickel alloy for anodes.

Also, speaking of PCBs and their orientation, it is better to orient them such a way so components are better cooled by convection. If you put it horizontally components in it's center will be heated more, and their temperature may be higher than be the PCB mounted vertically. Higher tempco have semiconductor devices, so what's the point in thermocouple effect of joints minimization maximizing overall thermal instability?

No rules of dumbs here. Everything has to be carefully designed. All pros and cons considered and calculated, in each and every different case.

JLH didnt invent that biasing form nor feedback scheme either... used in tube circuits long, long before then. I was just pointing out that the bias scheme was used by myself earlier than was noted ... not that I invented it. I was applying it to a different topology.

[If you dont understand the significant differences of the two topologies, there are plenty of books about the circuit and how it would differe from JLH design. One is: Emerging Techniques for High Freq BJT Amplifier design: A Current-Mode Perspective (1994) by C.Toumazou, J.Lidgey, A.Payne. Covers it so well, its in my reference library I keep. [ International Conference on Electronics Circuits and Systems, Cairo, Egypt.] But there are more contemporary books. -RNM

So what you are saying is add on a cascode and that makes it a different topology ?? I think not. So if I add on a cascode to a LTP its not a LTP anymore ?? Strangely enough another member here experimented with the particular circuit and found that the cascode can actually do more harm than good in the case of BJTs. JLH did invent and was the first to use it in line and phono stages back in 1968. I am too young for the tube era but could you explain how complementary tube circuits were made ??

Also, speaking of PCBs and their orientation, it is better to orient them such a way so components are better cooled by convection.

No rules of dumbs here.

http://www.diyaudio.com/forums/atta...wer-supply-resevoir-size-csa-bigbt-hp-pcb.jpg

(sorry Anatoliy, I live to tease)

You walked into that one, Richard. Of course, I agree that nickel is a lousy connector material. However, Wavbourn don't know that yet. '-)

I know John that nickel, no matter how lousy it is, was widely used in connectors of pro equipment used to record concerts that you enjoy. '-)

I finally got time to simulate Scott's (ggggggggg (9XG) i think) posted here somewhere. I used BF861B instead of BF862.

Attached: the schematic I used, BF861B datasheet and the results.

Cheers

Stein

Attached: the schematic I used, BF861B datasheet and the results.

Cheers

Stein

Attachments

-

20k square.pdf31.3 KB · Views: 88

-

THD 20k.pdf43.1 KB · Views: 111

-

THD 1k.pdf129.2 KB · Views: 124

-

BF861A_BF861B_BF861C.pdf121.4 KB · Views: 131

-

Schematic SW discrete opamp BF861B.pdf27.8 KB · Views: 311

-

HARMDIST 1k 10m-1.5V in.pdf100.4 KB · Views: 90

-

SNR vs Vout.pdf45.9 KB · Views: 97

-

THD vs Vout.pdf43.9 KB · Views: 116

-

THD+N vs Vout.pdf44.2 KB · Views: 116

I finally got time to simulate Scott's (ggggggggg (9XG) i think) posted here somewhere. I used BF861B instead of BF862.

Attached: the schematic I used, BF861B datasheet and the results.

Cheers

Stein

Interesting. Although the harmonic structure is pretty clearly mostly 2nd with a little 3rd, how many harmonics are accounted for in the later plots?

Does your simulator have an option for log scaling?

Brad

- Home

- Source & Line

- Analog Line Level

- Discrete Opamp Open Design