I always work small parts under a stereomicroscope, and I can tell you, 40x is way too much. 4x magnification is more what you'd want. Look for second hand buys of a good brand, and it won't cost you a fortune. One of the best investments in workshop tools I made.

I agree with 40 being too much.

I use one that varies from 7 to 21, and another from 10 to 60. Most of my work is at 7. Whenever I have to solder under the scope, I refrain from drinking any coffee that morning.

I use high mag only when I need to really look at something close. But I cannot do most work at the hi mag. The only exception to that is watch repair, sometimes 7 just isn't quite enough.

A good alternative for a stereo microscope could be an USB microscope, see:

Dino-Lite-- Digital Microscope

Essentially a high magnification real time video camera. it takes just minutes to get used to work watching the PC screen instead of the real circuit board directly. I've learned this from our ECM that routinely does reworking jobs on very hi-tech boards.

Regards

Giorgio

I used one of those, it's really amazing how high those things magnify. But I have to be honest, nothing beats the stereoscopic vision. I find the depthing invaluable for small work.

jn

Depth perception is a good point.I used one of those, it's really amazing how high those things magnify. But I have to be honest, nothing beats the stereoscopic vision. I find the depthing invaluable for small work.

jn

Whenever I have to solder under the scope, I refrain from drinking any coffee that morning.

jn

It's Zen.

I don't think it was me. For short tasks - like replacing just a 0805 resistor or SOT23 transistor - my tri-focaled, super-annuated eyeballs can often get by with just some strong light. My usual practice is to work SMT under a standard office magnifying lamp. Don't know the magnification; I got it at a yard sale or auction several years back. I wouldn't want to go more than about 1 step smaller than 0805/SOT23, though.. . . I didnt mention the need for 40x, that was dchisholm. . . .

I also have a couple of surplus lenses from old copiers that give about 3x or 4x magnification. (E.g., 180mm focal length f/5.6) The image is large enough and the range of focus deep enough to look with both eyes and get good depth perception. The working distance is about 6" so I'm not bumping components as I move it over an assembly.

When I had a job there were a few times I used a stereo toolmaker's microscope to look for manufacturing defects. It's amazing how much more you can see with those things, even compared to a small desk magnifier - almost like the difference between troubleshooting with a Simpson 260 versus a Tek 465. But I can't imagine doing re-work, much less assembly, under that kind of microscope.

Dale

I have a "P2V" USB webcam from IPEVO (see http://www.ipevo.com/prods/Point-2-View-USB-Camera ). It can auto-focus down to about an inch on an object that's essentially planar. The software application can do digital zoom up to 3x.My cam is pretty limited for magnification, but it's a few years old so who knows what's out there. But there is only so much that can be done without good purpose-built optics.

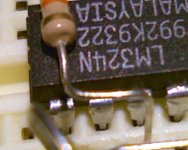

The atch image is a standard DIP package and 1/4W resistor on a solderless breadboard, from about 1.5" and 3x digital zoom.

I think I paid US$60 about 2 years ago. The company runs specials pricing, package deals, etc from time to time. There's now a 2x clip-on lens for it with built-in light that I haven't tried.

Dale

Attachments

my apologies, it was grhughes who first brought it up in post #2726, it seems you and I are both on the same page.I don't think it was me. For short tasks - like replacing just a 0805 resistor or SOT23 transistor - my tri-focaled, super-annuated eyeballs can often get by with just some strong light. My usual practice is to work SMT under a standard office magnifying lamp. Don't know the magnification; I got it at a yard sale or auction several years back. I wouldn't want to go more than about 1 step smaller than 0805/SOT23, though.

I also have a couple of surplus lenses from old copiers that give about 3x or 4x magnification. (E.g., 180mm focal length f/5.6) The image is large enough and the range of focus deep enough to look with both eyes and get good depth perception. The working distance is about 6" so I'm not bumping components as I move it over an assembly.

When I had a job there were a few times I used a stereo toolmaker's microscope to look for manufacturing defects. It's amazing how much more you can see with those things, even compared to a small desk magnifier - almost like the difference between troubleshooting with a Simpson 260 versus a Tek 465. But I can't imagine doing re-work, much less assembly, under that kind of microscope.

Dale

@grhughes: have you actually worked under such an instrument? I can understand it maybe for checking much more complex work than this, but never working on anything

Last edited:

No, I've never used one to solder a circuit board. I have used one on watch and clock parts to situate tiny screws. I'm in my early sixties and have slightly astigmatic vision so I want an instrument that can adjust out astigmatism. I will try to 5x visor first before I opt to buy a stereo microscope. The 3d depth perception is important so I believe trying to hook up my Olympus EP2 camera with a macro lens won't cut it 3d wise. It takes great 2d pics and movies but that's it. There are some good deals on ebone for stereo microscopes with digital camera that are firewire or USB compatible. There needs to be a comfortable working distance between lens and circuit board for drag soldering. And of course the board has to be kept absolutely horizontal, securely clamped down and the part glued down or you chase the part around with the tip of the iron. On a thru hole board the part is kept captive by the holes and you can orient the board any way you want to solder it. Just trying to glean as much info as possible and appreciate all comments. Ray

Ray,

You need to get out of that cubicle more often....... Just kidding. I would think that the visors are the simple way to go for now. I also don't have the vision I used to have and it isn't fun when that happens. With the visors that I know of some even have interchangeable lenses for different magnification and some even have little led side lights on them for lighting up your subject. What I like about the visors is I can still wear my glasses under the visor and work with them on, that way you have your own correction for your eyes. I can only imagine the problems with a microscope having used those long ago in a medical lab setting, nice to look through but you pointed out the room between the lens and the work piece could be rather tight. Perhaps Qusp, my buddy can chime in on that one? With the visor you wouldn't be so locked in to having the board needing to be perfectly horizontal and could use one of those cheap hobby vises to hold the board and allow you to change positions as long as the part was stuck in place first.

Steven

You need to get out of that cubicle more often....... Just kidding. I would think that the visors are the simple way to go for now. I also don't have the vision I used to have and it isn't fun when that happens. With the visors that I know of some even have interchangeable lenses for different magnification and some even have little led side lights on them for lighting up your subject. What I like about the visors is I can still wear my glasses under the visor and work with them on, that way you have your own correction for your eyes. I can only imagine the problems with a microscope having used those long ago in a medical lab setting, nice to look through but you pointed out the room between the lens and the work piece could be rather tight. Perhaps Qusp, my buddy can chime in on that one? With the visor you wouldn't be so locked in to having the board needing to be perfectly horizontal and could use one of those cheap hobby vises to hold the board and allow you to change positions as long as the part was stuck in place first.

Steven

Heat sinking SOT23 transistors when soldering

There is also the issue of heat sinking transistor leads while applying heat to the pad and part appendage. On a thru hole board I use hemastats to heat sink each transistor lead to prevent heat from traveling into the transistor and doing damage and pinching a SOT transistor with a hemastat will unglue it from the board. Also leaving the hemastat pinched on the narrow part appendage could make the solder joint a cold joint if pressure isn't applied very evenly. So I have to re-think that. SOT is really meant for reflow soldering not drag soldering with a hand iron. You young guys may be able to do that. Just my observations. One does what is comfortable! Ray

There is also the issue of heat sinking transistor leads while applying heat to the pad and part appendage. On a thru hole board I use hemastats to heat sink each transistor lead to prevent heat from traveling into the transistor and doing damage and pinching a SOT transistor with a hemastat will unglue it from the board. Also leaving the hemastat pinched on the narrow part appendage could make the solder joint a cold joint if pressure isn't applied very evenly. So I have to re-think that. SOT is really meant for reflow soldering not drag soldering with a hand iron. You young guys may be able to do that. Just my observations. One does what is comfortable! Ray

Back in the old days, docs used an optical endoscope to peep up one's pucker.

Nowadays, digital endoscopes sell around the corner for >>$1k, but also for as little as $50, with USB connector.

Just needs a clamp to hold the bottom handle in position, leaves a 3ft minimum snake to penetrate a board from any angle.

(I had my eyes lasered for long distance a couple of years ago, turned short sight to pucker-peep grade)

Nowadays, digital endoscopes sell around the corner for >>$1k, but also for as little as $50, with USB connector.

Just needs a clamp to hold the bottom handle in position, leaves a 3ft minimum snake to penetrate a board from any angle.

(I had my eyes lasered for long distance a couple of years ago, turned short sight to pucker-peep grade)

Jacco,

A friends father who was an eye surgeon told me long enough ago not to have the eye surgery. Warned me about what you are talking about and also the fact that after a few years when the muscles again age and lose more strength you are back where you started except now your eyes have already been surgically scared. I'll stick with the glasses until they come up with a stem cell solution and can regrow your own eyes.

A friends father who was an eye surgeon told me long enough ago not to have the eye surgery. Warned me about what you are talking about and also the fact that after a few years when the muscles again age and lose more strength you are back where you started except now your eyes have already been surgically scared. I'll stick with the glasses until they come up with a stem cell solution and can regrow your own eyes.

I have used one on watch and clock parts to situate tiny screws.

Fun, no?? You a member of NAWCC?

I'm still able to use very cheap 4x glasses to do the clock work, but for some of the smaller KWM bushings, I use a second pair of 2.5x under the 4x. It does require getting closer to the work however. For scroll work (wooden gears) I use the 4x with a 250 watt halogen worklight 6 inches from the work.

A pair of 4 over a pair of 2.5 is good enough for surface mount work in general, but the small pitch SOIC's I use the stereoscope for.

jn

SMT soldering using a microscope

SMT soldering OT:

Hear is a picture of my latest creation, soldered using a 10x Loupe and my new magnifying head band from Amidon, no stereo microscope needed, although I have used a Leica in the past and they do help to speed things up, make sure to get one with the small circular fluorescent ring lamp.

I think Scott's suggestion of a USB based camera is the way to go.

You need two soldering irons as a must, it is the easiest way to remove/replace a two pad passive SMT part.

Good luck all, I am waiting to see what creations the members can come up with. I liked Scott's prototype as well.

P.S. Was laided off yesterday, any one offering jobs in the Toronto area, send me a PM,

Cheers

Rick

SMT soldering OT:

Hear is a picture of my latest creation, soldered using a 10x Loupe and my new magnifying head band from Amidon, no stereo microscope needed, although I have used a Leica in the past and they do help to speed things up, make sure to get one with the small circular fluorescent ring lamp.

I think Scott's suggestion of a USB based camera is the way to go.

You need two soldering irons as a must, it is the easiest way to remove/replace a two pad passive SMT part.

Good luck all, I am waiting to see what creations the members can come up with. I liked Scott's prototype as well.

P.S. Was laided off yesterday, any one offering jobs in the Toronto area, send me a PM,

Cheers

Rick

Attachments

Last edited:

heatsinking SOT? look where is all this stuff coming from? reflow ovens heat the board and parts slowly up to ~230-240C over a period of a few minutes, then ramp it down. its not hard to beat a reflow oven as far as speed, for heat applied to the part, the parts are designed to deal with heat. just dont use a silly amount of heat and linger on the lead, reposition, heat again, fiddle reflow, fiddle reposition reflow etc, that is what damages parts. work at a sensible speed and you wont damage the part, its as simple as that. no wonder you hate SMD, you are making it far harder than it needs to be.

theres a good chance you are using too small a tip too, you need something with a bit of thermal mass so that you dont take too long making joints, this will prevent all the heat getting sucked out of the tip by the ground plane/copper pour, meaning you turn the heat up and take too long, thus damaging the part.

I use a 2 or 3mm chisel tip for just about everything.

the only time I might heatsink a small sot like that, might be if soldering it to a heavy ground or power plane without thermal relief.

visors, i've only got cheapies, exactly the sort you are talking about Kindhornman, illuminated with LEDs, stereo like protection glasses sort of. I wanted to grab a cheap set to see if they helped before spending a bit and they do, so i'll probably spend 50-100 on a set, i've been meaning to check out the USB endoscope variety too, thanks for the reminder JN

theres a good chance you are using too small a tip too, you need something with a bit of thermal mass so that you dont take too long making joints, this will prevent all the heat getting sucked out of the tip by the ground plane/copper pour, meaning you turn the heat up and take too long, thus damaging the part.

I use a 2 or 3mm chisel tip for just about everything.

the only time I might heatsink a small sot like that, might be if soldering it to a heavy ground or power plane without thermal relief.

visors, i've only got cheapies, exactly the sort you are talking about Kindhornman, illuminated with LEDs, stereo like protection glasses sort of. I wanted to grab a cheap set to see if they helped before spending a bit and they do, so i'll probably spend 50-100 on a set, i've been meaning to check out the USB endoscope variety too, thanks for the reminder JN

Last edited:

I would like to add a note about the facts of possible package breech/delamination due to re-flow ovens and from plastic package moisture absorption issues. Many of the IC parts that I get from the suppliers, are in sealed bags with desiccants, so use the parts ASAP after opening the bags or learn to pre-bake if necessary. Hand soldering does not pose such temp extreme/duration stresses if you are good at it.

long enough ago

But do you like to dive, sail, sportfish at sea on a +40kn yacht, cross-country skiing, shoot a composite bow on a target range, drive 150mph on the German autobahn at night ?

Laser surgery also corrects ocular alignment to 100%, perfect alignment on a 'congenital' basis is quite rare, 20/20 vision at night in particular is awesome.

For steroids hooked on an engineering degree, the $7k was money well spent.

=> Audiohagel - HIFI - Sound of Geeks (me 6'2",18" biceps, and 260lb of lard)

With the expiration date in sight, rather Laserburn up than to Fade away.

Eye laser surgery has come a long way in +2 decades, I've intentionally waited for it to mature.

(my partner is a double-doc, I also have a medical degree, and more 'Amice writers' on a first name basis in the rolodex than I actually care for)

50 buck USB camera endoscopes are a really nice all-in-one deal for those on a budget.

Bought one for generic duty, great items for car & boat related stuff.

Compared to the much higher priced one I already had, bang for the buck of the entry level ones is amazing.

Last edited:

Reminded of scene from Blade RunnerJacco,

A friends father who was an eye surgeon told me long enough ago not to have the eye surgery. Warned me about what you are talking about and also the fact that after a few years when the muscles again age and lose more strength you are back where you started except now your eyes have already been surgically scared. I'll stick with the glasses until they come up with a stem cell solution and can regrow your own eyes.

- Home

- Source & Line

- Analog Line Level

- Discrete Opamp Open Design