Hi Andrew,

The copper plates are all around the chassis (enclosure) i.e on the sides, "roof" etc.

All the AC goes underneath the bottom copper plate while all the DC goes above.

I was told by the Audiomat audiomaker (he is from the Montreal area) and by some audiophile friends that copper was a good EMI/RFI shield.

Therefore, that was the purpose of copper all around.

Whether this is right or not...in any case, that's how I built it.

You'll get a better idea when I'll post the fully assembled pictures in like 2 days.

Regards

Scorpion

The copper plates are all around the chassis (enclosure) i.e on the sides, "roof" etc.

All the AC goes underneath the bottom copper plate while all the DC goes above.

I was told by the Audiomat audiomaker (he is from the Montreal area) and by some audiophile friends that copper was a good EMI/RFI shield.

Therefore, that was the purpose of copper all around.

Whether this is right or not...in any case, that's how I built it.

You'll get a better idea when I'll post the fully assembled pictures in like 2 days.

Regards

Scorpion

I have a question about the DCB1 delay timer. My timer sends earth buzz through my speakers during the delay time (less than ideal for a delay timer) and when I put the wires in to modify as instructed, I got a quiet delay period, but then a noisy signal after (even worse). Has anybody else had this trouble, or is it just me and my particular GND arrangement? My preamp has a lot of different circuit elements working cooperatively, but this is one ground loop (the delay period) that I can't shake.

Thanks

Thanks

Has nothing to do with the timer most likely. Unless you can hear a mechanical chatter. For longer off period change the 47K to 100K 100uF RC. Could be something with the relay rewiring. Having an old series disconnecting board and done the T mod to ground muting? That's the way you do it.

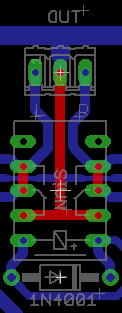

Attachments

OK Salas, I tried to play with some more LEDs I had on hands in order to get better matches (as you suggested).

Here are the final measurements:

LEFT:

LEDs quintet: 9,86V

DC Offset: 1,0 mV

VDrop: 1,28V

RIGHT:

LEDs quintet: 9,94V

DC Offset: 1,4 mV

VDrop: 1,47V

I was not able to increase the LEDs trio on the left channel enough to get real close to the right channel's higher 1,47V Vdrop. The best I could get was 1,28V (from 1,20V).

Should I change something or am I good to go (from a perfectionism stand point)?

Are the Vdrops close enough?

Thanks

Regards

Scorpion

Here are the final measurements:

LEFT:

LEDs quintet: 9,86V

DC Offset: 1,0 mV

VDrop: 1,28V

RIGHT:

LEDs quintet: 9,94V

DC Offset: 1,4 mV

VDrop: 1,47V

I was not able to increase the LEDs trio on the left channel enough to get real close to the right channel's higher 1,47V Vdrop. The best I could get was 1,28V (from 1,20V).

Should I change something or am I good to go (from a perfectionism stand point)?

Are the Vdrops close enough?

Thanks

Regards

Scorpion

1.024A and 1.176A current through the rails CCSs now. You could try drop the 1.47V side a little. Maybe the JFET that current sinks the stronger side LED triplet is bit stronger. So that triplet catches on VF easier. Or VGS forces the difference. Anyway by using a smaller IDSS JFET should tame that dif a bit. The 100 Ohm resistors on each side next to the associated K170's have mV drop which represents the current through each triplet that you can easily check.

Are all the leds the same?

If yes, then I don't know how you get 1.2V drop on the resistor?

Or it is not a IRFP240?

Hi Mr Wagner,

Yes all the LEDs are the same and real close in value (little below 2 volts per).

And it is an IRFP240 from diy member TeaBag.

Regards

Scorpion

1.024A and 1.176A current through the rails CCSs now. You could try drop the 1.47V side a little. Maybe the JFET that current sinks the stronger side LED triplet is bit stronger. So that triplet catches on VF easier. Or VGS forces the difference. Anyway by using a smaller IDSS JFET should tame that dif a bit. The 100 Ohm resistors on each side next to the associated K170's have mV drop which represents the current through each triplet that you can easily check.

Thanks for the useful answer Salas.

I will check mV drop on the 100R resistors to get a better idea of my LED triplets behavior.

Now, I am wondering wether I'd be better off trying to lower the "stronger side (1,47V)" triplet or if it wouldn't be best to change the JFET...

What's your take?

While current is in the 1amp ballpark, it seems a little high at 1,176A, isn't it ? But again, what do I know (limited knowledge).

Oh and yes, I got to retract an earlier comment: heatsinks do not get only warm, they get real hot (I can't leave my hands on them for more than 5 secondes...but they are outside the chassis at this moment so heat can't dissipate throughout the all-aluminum enclosure). I didn't leave my DCB1 "ON" for long enough the first time before making the comment about temperature. Now, it's been "ON" for 2 hours. Sorry, my bad.

Btw, I also sinked the MUR860 equivalent diodes (IXYS 1200v 15A soft- recovery). No choice since these too get real warm. Even while sinked.

Regards

Scorpion

Thanks for the useful answer Salas.

I will check mV drop on the 100R resistors to get a better idea of my LED triplets behavior.

Now, I am wondering wether I'd be better off trying to lower the "stronger side (1,47V)" triplet or if it wouldn't be best to change the JFET...

What's your take?

While current is in the 1amp ballpark, it seems a little high at 1,176A, isn't it ? But again, what do I know (limited knowledge).

Oh and yes, I got to retract an earlier comment: heatsinks do not get only warm, they get real hot (I can't leave my hands on them for more than 5 secondes...but they are outside the chassis at this moment so heat can't dissipate throughout the all-aluminum enclosure). I didn't leave my DCB1 "ON" for long enough the first time before making the comment about temperature. Now, it's been "ON" for 2 hours. Sorry, my bad.

Btw, I also sinked the MUR860 equivalent diodes (IXYS 1200v 15A soft- recovery). No choice since these too get real warm. Even while sinked.

Regards

Scorpion

That current dif won't really influence gfs in that still steep curve region. Its bcs you asked for nice symmetrical reading solutions I tell you how. If the mV across the 100R resistors already indicate close current running through the triplets then the 1.47V side could be better tweaked down in the LEDS than in the JFET.

The resistor also seems a bit small to me for 1 amp.

If there is no load, about 15W heat is generated. The fin of the sink is not ideal as they are horizontal instead of vertical. And in addition the shiny alu sink is not really good for heat radiation.

1.3V across a resistor running 1 Amp gives it 1.3W dissipation. A five Watt resistor will take it on with long time reliability.

Each side sink on 1A CCS has to dissipate 20W more or less assuming a 15VAC feed per side.

In the picture it seems like a 3W resistor to me and it will get really hot.

Especially that the sinks next to it are hot too. It will handle I guess, just really hot.

My 2*3W resistors get 50+ deg with only 120mA.

Mr. Wagner,

The resistors are Mills 1,25R @ 12watts. Still, they do get real hot too.

Regards

Scorpion

- Home

- Source & Line

- Analog Line Level

- Salas hotrodded blue DCB1 build

. Looked at another pic and now I see how huge it is. That will handle

. Looked at another pic and now I see how huge it is. That will handle