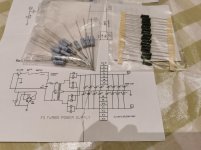

Power Supply Plans

Hi all,

I am in the planning phase of building V3 monoblocks and think I have it mostly figured out except for the power supply.

I am planning on using an Antek AN-10435 transformer (or maybe 1500va equivalent if its worth it) for hopefully ~48v rails. In terms of capacitance, I've heard claims the higher the better and I have very inefficient speakers. I would like to stick with the store's universal board if possible. I've found these two caps readily available on digikey:

Blocked

Blocked

I could either use 8x of the 22,000uf caps per monoblock for a total of 176,000uf, but they only have an 85 C temp rating.

Otherwise, I could use 16x of the 12,000uf caps per block for a total of 192,000uf with a 105 C temp rating. This would come with the difficulty of coupling 2 universal power supply boards since there are more than 8 caps.

Or, I go with 16x the 22,000uf caps for some serious energy storage .

.

Questions:

1.) How crucial is the temp rating? (85C vs 105C)

2.) Does anyone know of information regarding coupling two power supply boards to accommodate more than 8 caps? I've searched these forums but haven't found anything.

3.) Anything else I need to consider for using 48v rails? (I read about one case where someone used 12k ohm for R25/26 instead of 10k)

Anyways, thanks in advance for any input offered. I don't have a technical background in electronics so am constantly learning

Hi all,

I am in the planning phase of building V3 monoblocks and think I have it mostly figured out except for the power supply.

I am planning on using an Antek AN-10435 transformer (or maybe 1500va equivalent if its worth it) for hopefully ~48v rails. In terms of capacitance, I've heard claims the higher the better and I have very inefficient speakers. I would like to stick with the store's universal board if possible. I've found these two caps readily available on digikey:

Blocked

Blocked

I could either use 8x of the 22,000uf caps per monoblock for a total of 176,000uf, but they only have an 85 C temp rating.

Otherwise, I could use 16x of the 12,000uf caps per block for a total of 192,000uf with a 105 C temp rating. This would come with the difficulty of coupling 2 universal power supply boards since there are more than 8 caps.

Or, I go with 16x the 22,000uf caps for some serious energy storage

Questions:

1.) How crucial is the temp rating? (85C vs 105C)

2.) Does anyone know of information regarding coupling two power supply boards to accommodate more than 8 caps? I've searched these forums but haven't found anything.

3.) Anything else I need to consider for using 48v rails? (I read about one case where someone used 12k ohm for R25/26 instead of 10k)

Anyways, thanks in advance for any input offered. I don't have a technical background in electronics so am constantly learning

3) The following will depend on your average mains voltage and its stability along with the voltage loss through your PSU. You could be very close to 50VDC (maybe even a bit over), particularly unloaded. As an example, the specs for the transformer you mention shows 36.6VAC unloaded @ 120VAC.

I've seen a number of recommendations for the a safety margin for the voltage rating on PSU caps. While I don't have the personal knowledge myself to recommend if you should choose higher voltage-rated caps or not, it may be something to consider along with the temp rating.

I've seen a number of recommendations for the a safety margin for the voltage rating on PSU caps. While I don't have the personal knowledge myself to recommend if you should choose higher voltage-rated caps or not, it may be something to consider along with the temp rating.

Folks:

My amp has been repaired and I suspect (to be honest, I pray) this time the repair will prove successful. As I've mentioned before, I jumped into this hobby out of a love for music and not because I had any technical skills, and my learning curve has been (at best) a slow incline. My F5T monoblock could never have been repaired were it not for the support of people like AudioSan, Sangram, Bfpca and nashbap. Many, many thanks!

And in case any other novices are interested, it seems that the first blow-out occurred because of a failed insulator pad. It wasn't until I replaced all of the active components and the insulators that the amp stopped blowing up and, even then, I managed to blow a thermistor that most likely short-circuited against a heat spreader (the lesson there: heat shrink doesn't last forever).

It's a relief to have my V3s back.

Regards,

Scott

My amp has been repaired and I suspect (to be honest, I pray) this time the repair will prove successful. As I've mentioned before, I jumped into this hobby out of a love for music and not because I had any technical skills, and my learning curve has been (at best) a slow incline. My F5T monoblock could never have been repaired were it not for the support of people like AudioSan, Sangram, Bfpca and nashbap. Many, many thanks!

And in case any other novices are interested, it seems that the first blow-out occurred because of a failed insulator pad. It wasn't until I replaced all of the active components and the insulators that the amp stopped blowing up and, even then, I managed to blow a thermistor that most likely short-circuited against a heat spreader (the lesson there: heat shrink doesn't last forever).

It's a relief to have my V3s back.

Regards,

Scott

Thanks for pointing that out - definitely not a good idea to run that close to the limit. I'll go with 63vdc caps to be safe:

Blocked

These are 15,000uf and rated to 105 degrees C and still fit

Now just to figure out what to do with the boards. To clarify, this is along the lines of what I'm thinking, I just can't find much info on it: (Aloha F5 v3 Monoblock build - 8th post down)

Thanks again!

Blocked

These are 15,000uf and rated to 105 degrees C and still fit

Now just to figure out what to do with the boards. To clarify, this is along the lines of what I'm thinking, I just can't find much info on it: (Aloha F5 v3 Monoblock build - 8th post down)

Thanks again!

Scott, good to hear of your success. Reprieve is usually temporary - specially right at the beginning of the hobby.

I've been using mica forever and it never fails. I also never use heatshrink on any component lead, it;s not designed for anything except wire. Teflon tubing is the right thing to be used. Heat gradually softens the heatshrink and causes failures.

mnksoch - the temperature rating while not critical, is significant. A 105C cap lasts 3 times as long and in high ambient temperatures it may be the better option, or you'll need a cap change at some point depending on your case internal temperatures. Note however the cap temperature rating is for internal temperature, not ambient. We usually assume a 30 degree delta, and a doubling of cap life for every 10 degree drop in temperature. The ambient of an F5 is usually 45-50 degrees, give or take.

It is possible to join multiple boards together to increase the capacitor count, but it's probably better to use separate banks for each channel if you have many caps. Do note that the stress on the transformer and rectifiers is increased as you add more caps, due to the higher charging current. This can be quite significant, and may lead to unexpected issues such as buzzing transformers and overheating rectifiers. So make sure your supply can support the additional banks.

I've been using mica forever and it never fails. I also never use heatshrink on any component lead, it;s not designed for anything except wire. Teflon tubing is the right thing to be used. Heat gradually softens the heatshrink and causes failures.

mnksoch - the temperature rating while not critical, is significant. A 105C cap lasts 3 times as long and in high ambient temperatures it may be the better option, or you'll need a cap change at some point depending on your case internal temperatures. Note however the cap temperature rating is for internal temperature, not ambient. We usually assume a 30 degree delta, and a doubling of cap life for every 10 degree drop in temperature. The ambient of an F5 is usually 45-50 degrees, give or take.

It is possible to join multiple boards together to increase the capacitor count, but it's probably better to use separate banks for each channel if you have many caps. Do note that the stress on the transformer and rectifiers is increased as you add more caps, due to the higher charging current. This can be quite significant, and may lead to unexpected issues such as buzzing transformers and overheating rectifiers. So make sure your supply can support the additional banks.

Sangram - Thank you so much for the great information. I will undoubtedly use 105C rated caps (or higher...?). If I understood what you're saying correctly, with caps rated for 3000hrs@105C, I can expect (very roughly) ~10,000 hours of life within a typical f5 chassis (I am planning on using 2x 5U).

To clarify, I meant coupling cap boards within each monoblock (requiring 4 universal boards total for 2 monoblocks). What you said still would be true, however. Using the 15,000uf caps linked above, I would have 120,000uf per channel using one board per block (8 caps/channel total), and 240,000uf per channel using 2 boards per block (16 caps/channel total). I am willing to tackle some of the problems that come with the higher capacitance if it is worth it. I assume it involves perhaps a higher power rated transformer (1500VA) and over-rated rectifiers. Any threads come to mind that document high capacitance supplies? Thanks again for the help - trying to absorb as much as I can.

To clarify, I meant coupling cap boards within each monoblock (requiring 4 universal boards total for 2 monoblocks). What you said still would be true, however. Using the 15,000uf caps linked above, I would have 120,000uf per channel using one board per block (8 caps/channel total), and 240,000uf per channel using 2 boards per block (16 caps/channel total). I am willing to tackle some of the problems that come with the higher capacitance if it is worth it. I assume it involves perhaps a higher power rated transformer (1500VA) and over-rated rectifiers. Any threads come to mind that document high capacitance supplies? Thanks again for the help - trying to absorb as much as I can.

mnkosch:

Take this with a big grain of salt, but I have some experience in this area. My V3s were built in 2013 with a power supply capacitance of 160,000 uF per monoblock (sixteen 10k caps each). The toroids are 1kw with 32V secondaries. The V3s sounded terrific but I missed the deeper bottom end that my prior amps (Pass Labs Aleph 1.2 monoblocks) had in spades. The V3s were faster and a little more delicate but lacked the oomph of the Aleph 1.2. After a couple of years, I added another 90,000 uF to each amp's power supply (six 15k caps each) and the result is far more to my liking. No bloat, great detail and a tight, deep bottom end. Your mileage may vary, of course.

Regards,

Scott

Take this with a big grain of salt, but I have some experience in this area. My V3s were built in 2013 with a power supply capacitance of 160,000 uF per monoblock (sixteen 10k caps each). The toroids are 1kw with 32V secondaries. The V3s sounded terrific but I missed the deeper bottom end that my prior amps (Pass Labs Aleph 1.2 monoblocks) had in spades. The V3s were faster and a little more delicate but lacked the oomph of the Aleph 1.2. After a couple of years, I added another 90,000 uF to each amp's power supply (six 15k caps each) and the result is far more to my liking. No bloat, great detail and a tight, deep bottom end. Your mileage may vary, of course.

Regards,

Scott

Hi Scott,

Great information, thanks for sharing. I have inefficient mirage m3si towers so will target somewhere in the neighborhood of 250,000uf... probably will use 16x of the caps posted above for a total of 240,000uf per block.

Might I ask how you went about adding the additional caps? Sounds like a difficult task

Great information, thanks for sharing. I have inefficient mirage m3si towers so will target somewhere in the neighborhood of 250,000uf... probably will use 16x of the caps posted above for a total of 240,000uf per block.

Might I ask how you went about adding the additional caps? Sounds like a difficult task

Folks:

My amp has been repaired and I suspect (to be honest, I pray) this time the repair will prove successful. As I've mentioned before, I jumped into this hobby out of a love for music and not because I had any technical skills, and my learning curve has been (at best) a slow incline. My F5T monoblock could never have been repaired were it not for the support of people like AudioSan, Sangram, Bfpca and nashbap. Many, many thanks!

And in case any other novices are interested, it seems that the first blow-out occurred because of a failed insulator pad. It wasn't until I replaced all of the active components and the insulators that the amp stopped blowing up and, even then, I managed to blow a thermistor that most likely short-circuited against a heat spreader (the lesson there: heat shrink doesn't last forever).

It's a relief to have my V3s back.

Regards,

Scott

My experience with the thermistor shorting issue is that this happens after you scratch the coating on the thermistor while installing/de-installing.

In my case it took out the trim pot as well.

Hikari1:

Ouch! I do sympathize. Well, I hope you're a better diagnostician than me and were able to figure out what went wrong more efficiently than I did. Sangram's advice seems wise; I'll get a small supply of Teflon tubing in case this situation arises again.

mnkosch:

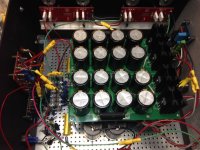

It wasn't very hard, actually. I should have mentioned this in my last post, but the power supply pcbs I used in my F5T build were designed and supplied by Buzzforb, another diyAudio member who years ago hosted an F5T group buy. His power supply boards were large enough to hold sixteen 35mm caps (and he supplied Nichicon KG Super Throughs to boot). I mounted the power supply board on standoffs above the toroid. There was sufficient space under the board and to the rear of the toroid to mount the six additional caps (and I used the Nichicon KG Super Throughs there as well) and a couple of 50W 0.1R power resistors.

You might try reaching out to Buzzforb. He is probably out of those power supply boards, but who knows...

Regards,

Scott

Ouch! I do sympathize. Well, I hope you're a better diagnostician than me and were able to figure out what went wrong more efficiently than I did. Sangram's advice seems wise; I'll get a small supply of Teflon tubing in case this situation arises again.

mnkosch:

It wasn't very hard, actually. I should have mentioned this in my last post, but the power supply pcbs I used in my F5T build were designed and supplied by Buzzforb, another diyAudio member who years ago hosted an F5T group buy. His power supply boards were large enough to hold sixteen 35mm caps (and he supplied Nichicon KG Super Throughs to boot). I mounted the power supply board on standoffs above the toroid. There was sufficient space under the board and to the rear of the toroid to mount the six additional caps (and I used the Nichicon KG Super Throughs there as well) and a couple of 50W 0.1R power resistors.

You might try reaching out to Buzzforb. He is probably out of those power supply boards, but who knows...

Regards,

Scott

Attachments

Slow progress is still progress! I bolted the bridge rectifiers to the chassis today. Steady Steve...think I'd better have a sit down and listen to some tunes to recover.

Also, it looks like past me bought 2 sets of the PSU 0.47 ohm 3W resistors. Panasonic like Mr P and Vishay wire wound. I realise either will be fine but which to chose? Its almost like buying the same record twice and asking which sounds best because my TT is out of action.

Also, it looks like past me bought 2 sets of the PSU 0.47 ohm 3W resistors. Panasonic like Mr P and Vishay wire wound. I realise either will be fine but which to chose? Its almost like buying the same record twice and asking which sounds best because my TT is out of action.

Attachments

Hey all

Im happy to say here that I purchased from the DiyAudio Store

Keratherm Transistor Insulators

F-5T V1/2 Transistor Kit

Linear Systems Matched JFETs - LSK170/LSJ74 ±0.1mA Matched Quad (Grade B)

F-5T Boards

I was wondering if anyone in the UK has any suggestion where best I get the resistors, thermistors and bourns pots for this amp from in one go ?

Im happy to say here that I purchased from the DiyAudio Store

Keratherm Transistor Insulators

F-5T V1/2 Transistor Kit

Linear Systems Matched JFETs - LSK170/LSJ74 ±0.1mA Matched Quad (Grade B)

F-5T Boards

I was wondering if anyone in the UK has any suggestion where best I get the resistors, thermistors and bourns pots for this amp from in one go ?

Hey Diy people

So I've decided Im going to share my whole build here to help others and take on any ideas from other people here. It's a slow build and im in no rush so want to take care making this V2 Turbo.

I have the following 8 heatsinks and was thinking of either using them in to build mono blocks either in horizontal or vertical configuration. I know heat wise Vertical is a good idea which I did for My Jean Hiraga build and somehow I kind of like this tall amplifier.

Im using the Diy Audio F5T boards and the Universe Power supply, the Turbo boards I have seen already will not be easy to fit to the shape of the heatsinks but ill find the way

If anyone has any other ideas let me know! and also anyone know whats best to clean the sinks ?

Here is my Jean Hiraga Amp

https://www.rikibuckingham.com/wp-content/uploads/2018/03/www.rikibuckingham.com_20180328_221553.jpg

https://www.rikibuckingham.com/wp-content/uploads/2018/03/www.rikibuckingham.com_20180328_220019.jpg

The new heatsinks for the Turbo V2

Config 1 Horizontal (one of two mono blocks)

https://www.rikibuckingham.com/wp-content/uploads/2020/11/www.rikibuckingham.com_20201113_120739.jpg

https://www.rikibuckingham.com/wp-content/uploads/2020/11/www.rikibuckingham.com_20201113_120752.jpg

https://www.rikibuckingham.com/wp-content/uploads/2020/11/www.rikibuckingham.com_20201113_120832.jpg

Config 2 Vertical (one of two mono blocks)

https://www.rikibuckingham.com/wp-content/uploads/2020/11/www.rikibuckingham.com_20201113_132526.jpg

https://www.rikibuckingham.com/wp-content/uploads/2020/11/www.rikibuckingham.com_20201113_132529.jpg

Config 3 a crazy Aleph style Vertical stereo amplifier (I think this would just be too heavy and insane ?)

https://www.rikibuckingham.com/wp-content/uploads/2020/11/www.rikibuckingham.com_20201113_132702.jpg

https://www.rikibuckingham.com/wp-content/uploads/2020/11/www.rikibuckingham.com_20201113_132706.jpg

You see two other heatsinks here maybe they are enough for a standard F5 ? they are pretty good!

https://www.rikibuckingham.com/wp-content/uploads/2020/11/www.rikibuckingham.com_20201113_121242.jpg

https://www.rikibuckingham.com/wp-content/uploads/2020/11/www.rikibuckingham.com_20201113_132716.jpg

https://www.rikibuckingham.com/wp-content/uploads/2020/11/www.rikibuckingham.com_20201113_121253.jpg

So I've decided Im going to share my whole build here to help others and take on any ideas from other people here. It's a slow build and im in no rush so want to take care making this V2 Turbo.

I have the following 8 heatsinks and was thinking of either using them in to build mono blocks either in horizontal or vertical configuration. I know heat wise Vertical is a good idea which I did for My Jean Hiraga build and somehow I kind of like this tall amplifier.

Im using the Diy Audio F5T boards and the Universe Power supply, the Turbo boards I have seen already will not be easy to fit to the shape of the heatsinks but ill find the way

If anyone has any other ideas let me know! and also anyone know whats best to clean the sinks ?

Here is my Jean Hiraga Amp

https://www.rikibuckingham.com/wp-content/uploads/2018/03/www.rikibuckingham.com_20180328_221553.jpg

https://www.rikibuckingham.com/wp-content/uploads/2018/03/www.rikibuckingham.com_20180328_220019.jpg

The new heatsinks for the Turbo V2

Config 1 Horizontal (one of two mono blocks)

https://www.rikibuckingham.com/wp-content/uploads/2020/11/www.rikibuckingham.com_20201113_120739.jpg

https://www.rikibuckingham.com/wp-content/uploads/2020/11/www.rikibuckingham.com_20201113_120752.jpg

https://www.rikibuckingham.com/wp-content/uploads/2020/11/www.rikibuckingham.com_20201113_120832.jpg

Config 2 Vertical (one of two mono blocks)

https://www.rikibuckingham.com/wp-content/uploads/2020/11/www.rikibuckingham.com_20201113_132526.jpg

https://www.rikibuckingham.com/wp-content/uploads/2020/11/www.rikibuckingham.com_20201113_132529.jpg

Config 3 a crazy Aleph style Vertical stereo amplifier (I think this would just be too heavy and insane ?)

https://www.rikibuckingham.com/wp-content/uploads/2020/11/www.rikibuckingham.com_20201113_132702.jpg

https://www.rikibuckingham.com/wp-content/uploads/2020/11/www.rikibuckingham.com_20201113_132706.jpg

You see two other heatsinks here maybe they are enough for a standard F5 ? they are pretty good!

https://www.rikibuckingham.com/wp-content/uploads/2020/11/www.rikibuckingham.com_20201113_121242.jpg

https://www.rikibuckingham.com/wp-content/uploads/2020/11/www.rikibuckingham.com_20201113_132716.jpg

https://www.rikibuckingham.com/wp-content/uploads/2020/11/www.rikibuckingham.com_20201113_121253.jpg

Attachments

-

www.rikibuckingham.com_20180328_221553.jpg257.3 KB · Views: 383

www.rikibuckingham.com_20180328_221553.jpg257.3 KB · Views: 383 -

www.rikibuckingham.com_20201113_121242.jpg135 KB · Views: 108

www.rikibuckingham.com_20201113_121242.jpg135 KB · Views: 108 -

www.rikibuckingham.com_20201113_132706.jpg126.9 KB · Views: 116

www.rikibuckingham.com_20201113_132706.jpg126.9 KB · Views: 116 -

www.rikibuckingham.com_20201113_132702.jpg137.2 KB · Views: 116

www.rikibuckingham.com_20201113_132702.jpg137.2 KB · Views: 116 -

www.rikibuckingham.com_20201113_132529.jpg125.4 KB · Views: 89

www.rikibuckingham.com_20201113_132529.jpg125.4 KB · Views: 89 -

www.rikibuckingham.com_20201113_132526.jpg140 KB · Views: 421

www.rikibuckingham.com_20201113_132526.jpg140 KB · Views: 421 -

www.rikibuckingham.com_20201113_120832.jpg150.6 KB · Views: 93

www.rikibuckingham.com_20201113_120832.jpg150.6 KB · Views: 93 -

www.rikibuckingham.com_20201113_120752.jpg131.3 KB · Views: 361

www.rikibuckingham.com_20201113_120752.jpg131.3 KB · Views: 361 -

www.rikibuckingham.com_20201113_120739.jpg137.9 KB · Views: 702

www.rikibuckingham.com_20201113_120739.jpg137.9 KB · Views: 702 -

www.rikibuckingham.com_20180328_220019.jpg229.1 KB · Views: 379

www.rikibuckingham.com_20180328_220019.jpg229.1 KB · Views: 379

Last edited:

Rixsta:

Uhm, if you're building F5 Turbos as monoblocks then I think you may be building (or should consider building) a pair of V3 amps, not a V2. And as a former owner of Pass Labs Aleph 1.2 amps, I'd suggest you consider how you will move the amps you're building. The 1.2s weighed just over 100 pounds apiece and, like all of the Aleph series amps, had a chassis made almost entirely of (sharp-finned) heatsink. Your V3s will very likely weigh far less but moving them may be painful if the heatsinks are sharp.

The rear sink on the 1.2s differed from the other three sides in that a narrow vertical portion lacked fins; that was where Pass Labs located the IEC inlet, fuse holder, single-ended and balanced inputs and binding posts. You might consider a blank (non-finned) panel on the rear of your amps to which you could attach a couple of handles as well. Just a thought.

In any event, good luck with your project!

Regards,

Scott

Uhm, if you're building F5 Turbos as monoblocks then I think you may be building (or should consider building) a pair of V3 amps, not a V2. And as a former owner of Pass Labs Aleph 1.2 amps, I'd suggest you consider how you will move the amps you're building. The 1.2s weighed just over 100 pounds apiece and, like all of the Aleph series amps, had a chassis made almost entirely of (sharp-finned) heatsink. Your V3s will very likely weigh far less but moving them may be painful if the heatsinks are sharp.

The rear sink on the 1.2s differed from the other three sides in that a narrow vertical portion lacked fins; that was where Pass Labs located the IEC inlet, fuse holder, single-ended and balanced inputs and binding posts. You might consider a blank (non-finned) panel on the rear of your amps to which you could attach a couple of handles as well. Just a thought.

In any event, good luck with your project!

Regards,

Scott

F5 turbo v2

Hello All,

Never really posted anything . but read a lot....thanks to all for the information and thanks to Mr. Pass for the wonderful amplifiers and all his help! This is my build. Sounds great....really great! Hope you like the photos!

. but read a lot....thanks to all for the information and thanks to Mr. Pass for the wonderful amplifiers and all his help! This is my build. Sounds great....really great! Hope you like the photos!

Kind regards,

George.

Hello All,

Never really posted anything

Kind regards,

George.

Attachments

Last edited:

- Home

- Amplifiers

- Pass Labs

- F5 Turbo Builders Thread