I don't understand the reason for twisting the headshell of a linear tracker, like on this video:

https://youtu.be/Kfp8KtanP8w

I guess to ease the cantilever of the cartridge at the radial deflection due to record eccentricity

George

I think that video looks just horrible from an alignment point of view, even if nominally it 'works': at any moment alignment could be anything and big errors are guaranteed at least some of the time. It raises the matter of stylus alignment versus noise because, in such an arrangement, I might predict surface noise would vary ?

If friction varies with stylus alignment and surface noise correlates with friction, it should be readily notable one would think ? At least for some pressings, and far more so for fine radius contact styli.......

LD

If friction varies with stylus alignment and surface noise correlates with friction, it should be readily notable one would think ? At least for some pressings, and far more so for fine radius contact styli.......

LD

I think that video looks just horrible from an alignment point of view, even if nominally it 'works':

Is that platter that out of round/off center ?!

Yes, for whatever reason that platter seems to rotate eccentrically to a notable extent.Is that platter that out of round/off center ?!

Eccentricity is yet another elephant in the room. Not least record centre-hole location and run-out versus spindle size, but also spindle location itself, spindle bearing run-out, whether the spindle is dead vertical.

With all the fuss and attention sometimes applied to motor speed stability, it seems amazing IMO that eccentricity seldom gets mention, yet it is by far the largest contributor to pitch instability in normal playback on a healthy turntable. Audibly so, typically.

Unlike that video, normal headshell motion is meant to follow eccentricity in-phase, so that alignment remains true. All part of the miracle of the cart-arm lf resonant system, and it works. However, pitch variation remains.

I suppose pitch variation is, strictly, FM noise and therefore falls within the scope of the thread..........?!

To demo the audible effect, listen to a c 3kHz test tone on vinyl versus a digital source. The prominent effects of eccentricity, arm instabilty and warp are typically very obvious.

LD

Yes, for whatever reason that platter seems to rotate eccentrically to a notable extent.

So I wasn't seeing things. This begs the question, why try to demonstrate mis-tracking effects on a setup where the distortion is visibly correlated to what I would consider the result a broken system? Even the clamp is moving back and forth which would indicate the spindle is off center maybe by a mm or so.

Yup, seems weird. And yet eccentricity is generally ignored, despite typically being the largest contributor to pitch instability even in a healthy TT. My guess is that the spindle shaft is bent on the TT in that video and it's not healthy, but even general slack in centre-hole and centre-hole accuracy in records is enough to swamp motor speed variations, for example, IME.This begs the question, why try to demonstrate mis-tracking effects on a setup where the distortion is visibly correlated to what I would consider the result a broken system? Even the clamp is moving back and forth which would indicate the spindle is off center maybe by a mm or so.

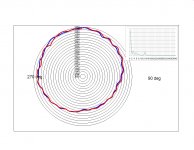

A few years back I wrote a piece of software to help me analyse pitch stability. It analyses a 3.150kHz or so test tone, and is a polar plot of exact frequency versus location on the platter. So once round the chart is once round the platter. Here's a typical example, which I think shows the issue nicely.

Each radial line marks the frequency deviation corresponding to the threshold of pitch audibility, and is calibrated in exact frequency of the test tone in Hz. Red and blue traces are successive platter rotations.

After eccentricity, warp and arm stability, very seldom does motor stability feature IME.

One can see that eccentricity really is the elephant in the room, but also that arm stability and warp contribute significantly. To address pitch stability, which is essentially FM noise, these are the things to address. But, for some reason, it's seldom discussed or even noticed in videos like the one you mention !

LD

Attachments

One such effect has been studied a lot. It was called warp wow and very evident in badly designed uni-pivots with the bearing well above the record surface.Yup, seems weird. And yet eccentricity is generally ignored, despite typically being the largest contributor to pitch instability even in a healthy TT.

.....

After eccentricity, warp and arm stability, very seldom does motor stability feature IME.

One can see that eccentricity really is the elephant in the room, but also that arm stability and warp contribute significantly.

The correct position of the vertical pivot (not just on unipivots) is just above (eg 1mm) the record surface. Otherwise a warp will move the cartridge back & forth causing noticeable wow.

Then there's the correct skew of the vertical pivot which was wrong on SME 3009 but corrected on 'later' models .. but not on M2

A few years back I wrote a piece of software to help me analyse pitch stability. It analyses a 3.150kHz or so test tone, and is a polar plot of exact frequency versus location on the platter.

Lucky, how much for a copy?

The correct position of the vertical pivot (not just on unipivots) is just above (eg 1mm) the record surface. Otherwise a warp will move the cartridge back & forth causing noticeable wow.

Then this is totally off?

https://web.archive.org/web/20110526214839/http://www.sakurasystems.com/articles/rs-a1.html

Then there's the correct skew of the vertical pivot

Can you please explain this Ricardo? I can’t understand it.

George

The correct position of the vertical pivot (not just on unipivots) is just above (eg 1mm) the record surface. Otherwise a warp will move the cartridge back & forth causing noticeable wow.

(

This problem occured with the Revox Tangential arms with very short tonarm, its clearly audible when record is warped and some critical piano tones.

Same with the Souther ( now Clearaudio), here were additional problems with the arm bearings creating ringing noise with some cartridges with limited trackability like Dynavector Ruby and similar. Here we used a soft rubber globb on top of the cart.....

Wrong choosen combos of arm/cart resonances can cause also good audible warp modulation before jumping out of the groove.

(Usually i go for apx.11 Hz with suspension chassis turntables, with heavy non suspension TT, i can go down to 8 Hz, but have to check carefully the combo and acoustical feedback.)

On the other hand to much damping kills the dynamics in my experience.

Thus, i avoid short arms and similar stuff.

I'm not sure I agree with his modulated tracking force stuff and particularly if it makes an audible difference.

But warp wow is certainly very audible.

There may be some justification for his straight arm with no offset.

__________

There's a lot of BS that assumes the old designers were stupid and didn't take into account stuff we do today or didn't listen carefully enough.

I've been privileged to work with Ted Ashley who designed the last of the LEAK valve amps and also Tony Emerson & Dr. Don Barlow who did pickup design for LEAK.

You'd be surprised at what they thought they did wrong and what modern stuff they wished they had in da old days.

They were certainly as bright (and as aware of modern developements) as any designers (& pseudo designers) today and probably better in DBLTs.

J Gordon Holt (founder & first editor of Stereophile) thought 'high end' went down the drain when it started pooh poohing DBLTs.

______________________________

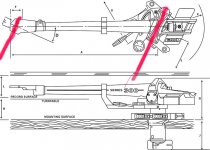

Then there's the correct skew of the vertical pivot

In the pic, the vertical pivots of the Series 300 are parallel to the front of the cartridge.Can you please explain this Ricardo? I can’t understand it.

If the cartridge moves up/down, it will still be vertical as seen from its front.

On the M2 (and early 3009 up to Series 2 improved), the pivots are at right angles to the tube. As the cartridge moves up/down, it will twist so the it is no longer vertical.

Attachments

Last edited:

for those with some money you can fix the SME issue SME Tonearms Upgrades.

Lucky, how much for a copy?

Meantime, I don't mind running a few plots for people now and then on forums just for fun. Needs a 10s or so recording of a 3kHz or so test tone, in any lossless format.

Any mechanical effect that causes the main locus of a groove to vary in velocity as it passes the stylus, will invoke pitch variation. Although warp is more discussed, eccentricity is typically bigger in extent IME, as is the effect of headshell instability.

Looking at pitch instability this way helps to illustrate what is actually important about the cart-arm resonance: its settle time. This is mostly determined by cart suspension damping, typically, as discussed it generally correlates with stiffer suspensions and higher VTFs.

Assuming the cart-arm resonant frequency is well enough clear of warp induced stimulus, then the main effect of choosing frequency is to select at what frequency pitch 'vibrato' will vary, as well as influencing its decay given what damping is available.

Another thesis I have is that the choice of cart-arm resonant frequency, and the vibrato it produces, can be euphonic. As can the quantity or level of vibrato, as applied to programme material. I believe that the often cited 'damping reduces dynamics' may be a result of reducing euphonics due to reducing or eliminating vibrato?

FM noise or pitch stability, such as vibrato, eccentricity and warp wow, is a form of noise, but gets relatively little attention versus the more classic amplitude related forms of noise such as crackle pop.

There are relatively few tools available to analyse pitch stability, and that's why I ended up writing my own. It's a different, and far better IMO, way of looking at the sidebands which show up on spectrum analysers in the frequency domain such as the B&K paper discussed earlier on this thread. Use a 3kHz test tone as a carrier, and FM demodulate it to provide deviation in the time domain.

LD

Last edited:

In case you missed this

I hope you don't mind

https://parttimeaudiophile.com/2017...he-groove-with-the-spoltaire-phono-cartridge/

I hope you don't mind

https://parttimeaudiophile.com/2017...he-groove-with-the-spoltaire-phono-cartridge/

I assume that was a poor attempt at humour.

I assume that was a poor attempt at humour.

Just 2 months early, the banner add on the right for "The Diana Krall Free Zone" was added humor. Multiple copies of the LP version of "Metal Machine Music" would definitely set you back (a fine Bob Ludwig job BTW).

Last edited:

- Home

- Source & Line

- Analogue Source

- Reducing Record Surface Noise - I want to know all Approaches