I have tested thousands of discs using CD-Cats sa3 and other expensive CD test equipment (100,000 US$). I also used NERO DiscSpeed and Opti Drive Control (<30 US$) with different CD/DVD(-R) Drives. The results between different players are always very close and disc related. I would even say that a Plextor CD-R drive will read at lower error correction than the CD-Cats. This is maybe partly because it is able to adapt its read strategy. It is like comparing an old LADA with a new MINI.Not saying that you should not prefer the old LADA.

Doesn't that say that CD-Rom drives all read the same rather than CD audio mechs, from the heavyweight's of the past through to the modern, pressed steel cheap ones of today?

Interesting about Plextor - I've kept Plextor CD-writers for burning CDs over others..

Hi NATDBERG,

Normal mechanisms clamp the CD in the center only. No vibration problems. If it were to vibrate, it would make the RF/eye pattern look unfocused or fuzzy. I guess a motor with bad bearings would do the same, make it vibrate. Normally there is not a vibration problem with a small rotating system.

-Chris

I've opened up many many CD players and watched them play. The clamp's themselves are sources of vibration! Their magnets are rarely centred properly and cause eccentric movement of the disc which can be seen. Subtle but visible.

Also I rarely see the edge of a CD in sharp focus when spinning - it is often blurred meaning it's vibrating. Therefore lots more re-focusing going on and all the resulting extra servo action, EMI potential and ground noise.

Those are real observations which some some sort of clamping of the whole disc would solve.

Of course, arguable whether it improves the sonics aside from anecdotal evidence from some designers that read errors are improved and their own sense of improvement...

It is no longer produced any more and as replaced by the CD-5020A-AT

which uses a Sanyo DV11VFGP traverse mechanism with DL-3150-101 laser.

This already happened in 2010, before Sanyo was bought by Pansonic.

No new information after that. This is why I started this thread -

you simply can´t be sure that those mechs will be around in some years beside some clones.

BTW, another goal of this thread is to swap the often used Sharp LT022 laser diodes against present ones from Rohm. Bigges obstacle is the diffraction grating. But I can only start to play around with that when the math is done

on how to adapt the APC. This is beyond my abilities. Can anyone help me with that.

Datasheets are in post #186 in this thread:

http://www.diyaudio.com/forums/digi...et-us-build-one-ourselves-19.html#post4509547

In the area of reasonable mass i did build the prototype of this stabilizer:

Should be be easily adopted to any top loading mech like CD-Pro2 (have to check wether the eight of 71grams is too much for the CDPro2 Motor) , thus first batch will be for the Sony fixed pickup mechs with Ø6mm shaft.

Those are "used" to stabilizers of double weight. But again, those stabilizers are not about addin mass but doing a litle bit of damping while protecting the mech from wear by heavy mass.

http://www.diyaudio.com/forums/digi...ickup-mechanism-first-prototype-finished.html

All the best,

Salar

Have you thought about the electronics side of things? Laser power boards etc for longevity?

Somewhere I have an 80s magazine with a DIY laser power board for the CDM1 - a much stiffer supply.

Have you thought about the electronics side of things? Laser power boards etc for longevity?

Somewhere I have an 80s magazine with a DIY laser power board for the CDM1 - a much stiffer supply.

Dig it out !!

I'd be interested.

Andy

Hi NATDBERG,

A warp in the CD (defective media - replace) is very unlikely going to be sorted by the stable platter. You can't see it anymore though and that must feel better. The clamping forces required to flatten a warped CD are far beyond the force most clamping mechanisms can apply.

A warped or bent disc table is another actual fault that should be repaired. Again, this is not the normal operating mode for that CD player.

In any event, you are talking about specific special cases.

EMI potential and ground noise is a function of how the electronics were designed. There shouldn't be any EMI generated at all, and ground noise is designed out (or should be)

-Chris

Are you talking about vibration or wobble at once per revolution? If it is vibration, something is broken in the disc motor. The machine is therefore in a fault state and needs to be repaired. A wobble is something the servos are designed to tolerate. A stable platter will not fix an off-center disc.The clamp's themselves are sources of vibration! Their magnets are rarely centred properly and cause eccentric movement of the disc which can be seen. Subtle but visible.

A warp in the CD (defective media - replace) is very unlikely going to be sorted by the stable platter. You can't see it anymore though and that must feel better. The clamping forces required to flatten a warped CD are far beyond the force most clamping mechanisms can apply.

A warped or bent disc table is another actual fault that should be repaired. Again, this is not the normal operating mode for that CD player.

In any event, you are talking about specific special cases.

I think you mean to say that the disc is warped, not vibrating. Within reasonable limits, the focus servo will track properly. However, that disc is defective. If normal CD players cannot track it, a stable platter one will not either. The fix is to replace the defective CD. CD players are not supposed to play everything that can be inserted if they are out of mechanical specification. Again, you are talking about special cases, and a stable platter can not apply enough force to flatten a warped CD.Also I rarely see the edge of a CD in sharp focus when spinning - it is often blurred meaning it's vibrating. Therefore lots more re-focusing going on and all the resulting extra servo action, EMI potential and ground noise.

EMI potential and ground noise is a function of how the electronics were designed. There shouldn't be any EMI generated at all, and ground noise is designed out (or should be)

Counting the C1 flag per revolution or frame would give you the actual error count. This directly leads to an averaged metric that can be used to compare mechanisms.Of course, arguable whether it improves the sonics aside from anecdotal evidence from some designers that read errors are improved and their own sense of improvement...

This would only be an issue in cheaper CD players. A non-issue really, because noise on the laser supply directly modulates the laser beam, and that shows up in the RF / eye pattern. It isn't a problem.Somewhere I have an 80s magazine with a DIY laser power board for the CDM1 - a much stiffer supply.

-Chris

A few of the relevant Red Book specifications:

Eccentricity +-0.2 mm.

Disc unbalance < 11 gmm.

Max. deflection +- 0.4 mm.

Max. deflection over one revolution +- 0.3 mm.

This means that a player must at least be able to play such a disc and in practise a lot worse.

The edge of the disc is transparent and it is the printing and/or the edge of the aluminium layer that gives the impression of deflection and eccentricity.

Eccentricity +-0.2 mm.

Disc unbalance < 11 gmm.

Max. deflection +- 0.4 mm.

Max. deflection over one revolution +- 0.3 mm.

This means that a player must at least be able to play such a disc and in practise a lot worse.

The edge of the disc is transparent and it is the printing and/or the edge of the aluminium layer that gives the impression of deflection and eccentricity.

Hi NATDBERG,

Are you talking about vibration or wobble at once per revolution? If it is vibration, something is broken in the disc motor. The machine is therefore in a fault state and needs to be repaired. A wobble is something the servos are designed to tolerate. A stable platter will not fix an off-center disc.

A wobble at each revolution caused by most magnetic, sprung clamps.

Even if all those CD are warped and all those CD mechs faulty, then in designing a new one you surely want to ensure it has an extrememly robust motor, shaft and bearing (over-engineered) AND you want it to do something about warped CDs - afterall you can't control each CD press plant! And all CDs I've seen playing in real life have blurred edges and so have vibration.. that vibration must be within redbook tollerences and therefore a better designed mech will do something to combat that... surely?

Dig it out !!

I'd be interested.

Andy

I shall! Will Scan and post a link when done..

Hi NATDBERG,

Could be the base of the forcing cone.

Could be the shape of the magnetic clamper.

Could be the shape or size of the CD.

Take your pick, but the magnetic clamp doesn't normally cause these problems, and they don't vibrate!

-Chris

Why? Defective is defective. If the mech can track it, great.Even if all those CD are warped and all those CD mechs faulty, then in designing a new one you surely want to ensure it has an extrememly robust motor, shaft and bearing (over-engineered) AND you want it to do something about warped CDs

Sure you can. Return defective CDs, vote with your dollars. Ask Mark what happens when his quality slides. I'm going to bet he doesn't allow that to happen.afterall you can't control each CD press plant!

No it isn't! Mechanical pressure clamps suffer the same problems.A wobble at each revolution caused by most magnetic, sprung clamps.

Could be the base of the forcing cone.

Could be the shape of the magnetic clamper.

Could be the shape or size of the CD.

Take your pick, but the magnetic clamp doesn't normally cause these problems, and they don't vibrate!

-Chris

Small divesrion: I used to salvage the Drive motors out of CDROM drives . When their crappy plastic mag rings were replaced with discrete Neo mags , their stators rewound .. these made for Surprisingly Good Hobby motors.

For little cost. Some of these motors were multi arm/pole things of a few inches diameter Instant Torque and of Stepper motor rotational accuracy

Why do CDplayers, even bespoke ones?

Still use 25 Cent brushed motors.

Couldn't be costs as CDROM/dvd write drives are ~30$.. at best

For little cost. Some of these motors were multi arm/pole things of a few inches diameter Instant Torque and of Stepper motor rotational accuracy

Why do CDplayers, even bespoke ones?

Still use 25 Cent brushed motors.

Couldn't be costs as CDROM/dvd write drives are ~30$.. at best

Maybe because of multiple speed? Just a guess. But as I wrote before,Couldn't be costs as CDROM/dvd write drives are ~30$.. at best

first generation CD-Rom drives looked "better". I.e a brass platter in an

Apple "Superdrive" (DVR-103 made by Pioneer as far as I remember)

Have you thought about the electronics side of things? Laser power boards etc for longevity?

Let´s assume, the Sharp LT022MC was widely used, APC must be more or less the same?

Anyway, modifying an existing APC or building a new one:

Here i a comparison of the Sharp diode and one from Rohm one one sheet-

(The Rohm uses 2 diodes 660nm and 780, I cut the 660 data for clarity.

But the important data of astigmatism of the Sharp LT022 is missing.

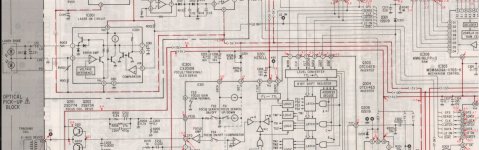

And again, an APC for the Sharp LT022MC in a Sony CDP-502...

Attachments

... Next time you try to copy a music CD, set the software for no errors and see how much extra time it takes! Only with the error correction used for data can they read enough correctly to work. The error correction used for audio CDs isn't robust enough to make that claim about reading at 52X the red book rate. It can, but not error free, not even close...

Eeerrr, 52x CD Red-book reading would be unusual

but ...

52x computer,

is normal and would be ... normal

Couldn't you easily compare them with EAC,

ie a read @ low with real-time CD alorithims

vs

52x speed and

CD-ROM type reading, with multiple passes and amalgamation, CD ROM style,

and way more error correction [CD ROM type] compared to plain Redbook CD ...

better, no?

Last edited:

Hi AudioLapDance,

I haven't a clue when it comes to data CDROMs beyond knowing the error correction is totally different, and more effective. My world stipulates that an CD read is a one shot deal, you either get it or not. The only multiple attempts occur when the player loses lock with the CD itself. The data is already lost when that happens.

-Chris

I haven't a clue when it comes to data CDROMs beyond knowing the error correction is totally different, and more effective. My world stipulates that an CD read is a one shot deal, you either get it or not. The only multiple attempts occur when the player loses lock with the CD itself. The data is already lost when that happens.

Creek did that already. They used computer CDROM drives.CD-ROM type reading, with multiple passes and amalgamation, CD ROM style,

-Chris

A DIY 2012 thread on a similar topic, last page with a post from someone which has auditioned many drives - liked the CD1050-A best.

http://www.diyaudio.com/forums/digital-source/206427-diy-cdplayer-audio-analogue-like.html

2010 review:

UNISON RESEARCH UNICO CD PRIMO

Unison Research Unico CD Primo | Hi-Fi | Review | AVHub

............

Unison Research Unico CD Player Reviewed

By: HomeTheaterReview.com, January 4, 2009

Unison Research Unico CD Player Reviewed

Unison Research's other CD player, the bigger brother to the Primo is the "Due"

Sources - Unison Research - Official Website

http://www.streamunlimited.com/products/optical-storage/8829-cd_specification.pdf

http://www.avhub.com.au/news/hi-fi/unison-research-cd-due-408974

If you are wondering why I'm posting this, it's just an informal inventory of what certain manufacturers were (or are) using.

http://www.diyaudio.com/forums/digital-source/206427-diy-cdplayer-audio-analogue-like.html

2010 review:

UNISON RESEARCH UNICO CD PRIMO

Unison Research Unico CD Primo | Hi-Fi | Review | AVHub

The transport is a Teac CD5010A (CD-ROM transport), which Teac claims is fitted with a low-jitter mechanism it developed specifically for high-end audio applications.

............

Unison Research Unico CD Player Reviewed

By: HomeTheaterReview.com, January 4, 2009

Unison Research Unico CD Player Reviewed

The two settled on a design using a proper CD-ROM mechanism,....................

Sacchetti and Rossetto carried out exhaustive tests on a number of drives before deciding that the only way to go was with a CD-ROM mechanism, especially because of the digital output that this type of transport offers. It required a redesign of the interface between transport and DAC because of the different communication standard, but this in turn allowed the player's performance to be kicked up a notch by inserting a 're-conversion circuit' and PLL circuit, resulting in a significant reduction in jitter. Additionally, the CD-ROM mechanism is more robust, offers superior disc reading accuracy, operates with better quality brushless, low-noise synchronous motors, employs a glass laser lens instead of plastic and the CD tray runs on lapped metal guides. Again: not plastic.

Unison Research's other CD player, the bigger brother to the Primo is the "Due"

Sources - Unison Research - Official Website

Transport

8829CD-KHM DVD-Loader , Only audio CD

http://www.streamunlimited.com/products/optical-storage/8829-cd_specification.pdf

http://www.avhub.com.au/news/hi-fi/unison-research-cd-due-408974

The front-loading disc mechanism is a DVD-loader (8829CD-KHM)—that in this case plays only CDs—whose mechanism is enclosed and shielded by a thick metal cover. Available now, the Unison Research CD Due sells for $7,000 (RRP).

If you are wondering why I'm posting this, it's just an informal inventory of what certain manufacturers were (or are) using.

Last edited:

Hi kach22i,

A computer CDROM has everything going against it. It's very slender and power efficient. That means that the tray fits in there too, as does any vibration control. It runs off a noisy computer power supply and can not be allowed to generate too much heat either. All this for a cost to compete in the computer parts market. The audio section is really an afterthought as most play through the sound chip set on the motherboard. So, forget them spending much on that feature. The main functions will be transferring data on and off DVD discs, so that is where the money goes. So even if you could trick someone into spending $100 on this product, you still do not have enough money to improve audio performance much.

The economics of the situation do not support using a CD or DVD drive for audio CD playback. Besides, I can't think of any problem using a plastic lens for the laser. Even many cameras (with much higher performance requirements) use a plastic lens. None of this supports the supposed superiority of a CDROM drive over purpose built transports. However, for you this might be just the ticket. Go buy one and be done with it.

-Chris

Probably just buffer memory. Teac / Tascam's history for high end audio does not include CDROM drives. They will generally build something massive for that.which Teac claims is fitted with a low-jitter mechanism it developed specifically for high-end audio applications.

Really? In a CDROM drive yet.... but this in turn allowed the player's performance to be kicked up a notch by inserting a 're-conversion circuit' and PLL circuit, resulting in a significant reduction in jitter.

You have got to be kidding! CDROM drives for computers are commodity products that retail between $12 and $35 CDN. Those are mostly plastic and will not use any hand lapped parts at all. If a human hand has to touch anything for finishing, you can expect that product to sell >$100 easily. I just don't see this from a company like Teac / Tascam. Those guys are not afraid to breach >$5,000 for top flight efforts.Additionally, the CD-ROM mechanism is more robust, offers superior disc reading accuracy, operates with better quality brushless, low-noise synchronous motors, employs a glass laser lens instead of plastic and the CD tray runs on lapped metal guides. Again: not plastic.

A computer CDROM has everything going against it. It's very slender and power efficient. That means that the tray fits in there too, as does any vibration control. It runs off a noisy computer power supply and can not be allowed to generate too much heat either. All this for a cost to compete in the computer parts market. The audio section is really an afterthought as most play through the sound chip set on the motherboard. So, forget them spending much on that feature. The main functions will be transferring data on and off DVD discs, so that is where the money goes. So even if you could trick someone into spending $100 on this product, you still do not have enough money to improve audio performance much.

The economics of the situation do not support using a CD or DVD drive for audio CD playback. Besides, I can't think of any problem using a plastic lens for the laser. Even many cameras (with much higher performance requirements) use a plastic lens. None of this supports the supposed superiority of a CDROM drive over purpose built transports. However, for you this might be just the ticket. Go buy one and be done with it.

-Chris

A clone product?

Optical Storage | StreamUnlimited

http://www.streamunlimited.com/products/optical-storage/pb_cd-80_leaflet.pdf

Optical Storage | StreamUnlimited

BlueTiger reference solutions are comprised of a ready-for-manufacturing (RFM) hardware platform, a high quality CD/DVD loader, and a customizable software framework

http://www.streamunlimited.com/products/optical-storage/pb_cd-80_leaflet.pdf

Compatible with a wide range of loaders and OPU’s:

WXD8829C and JPL-2580 tray- and JPSL-33 slot-loader with

Sony KHM313 or Sanyo SF-HD870 OPU.

Hi NATDBERG,

Why? Defective is defective. If the mech can track it, great.

A mech might be able to track it but it will require more error correction and the over-working of focus and tracking servos. And it is actually from your own posts in the past from which I have understood that a hard-working servo has the possibility of effecting sound via EMI interference often transmitted via the laser head ribbon cable and also effect the ground plain.. At least I thought it was you - some experienced CD player engineer here on DIYAudio.

Sure you can. Return defective CDs, vote with your dollars. Ask Mark what happens when his quality slides. I'm going to bet he doesn't allow that to happen.

You think I can return my secondhand CDs? I'll try... You think I'd get very far then returning ALL my hundreds of CDs, even deleted ones and I'd get a brand new collection back from somewhere? I've not bought a brand new CD in a long time..

I want a CD mech which will get the best sound out of my current CDs and not have to search for perfect ones... If that means flattening out tiny warps via a clamp or vacuum system then so be it but the result will be a better sound wihtout having to worry whether the CD is good or bad..

No it isn't! Mechanical pressure clamps suffer the same problems.

Could be the base of the forcing cone.

Could be the shape of the magnetic clamper.

Could be the shape or size of the CD.

Take your pick, but the magnetic clamp doesn't normally cause these problems, and they don't vibrate!

-Chris

I clarified that they pretty much introduce an unballanced spin which causes a wobble, not vibrate. The magnets used are rarely centred within the plastic circle they are mounted in and when the clamp engages rarely do the magnets sit perfectly around the centre of the CD - they just attract in general to the centre of the spindle without much alignment. I'm thinking here of some great CD players like Sony 555es or Marantz CD94 - anything with a sprung, magnetic clamp I've used. As you say, they still manage to read so I guess the designers consider it a cost compromise success...

The clamping methods used in something like the CD701 VRDS is different because it is the mech being brought up to something solid, the VRDS platter, and the two mate together very well. Same goes for heavy pucks which sit perfectly in the centre.

If one is designing a good mech from the ground up, why would you allow compromises? Might as well just use something off the shelf if so.. Being "good enough", to be able read this and that isn't the point . Surely it's about designing and building one which sounds better due to attention to design and taking those extra steps?

I'm here to learn, and you certainly seem to know a lot.A computer CDROM..........runs off a noisy computer power supply.........

The audio section is really an afterthought as most play through the sound chip set on the motherboard. So, forget them spending much on that feature..............

However, cannot any system be designed to circumvent it's shortcomings?

What I mean is, can't the power supplies be split/dedicated and upgraded from those of a computer when designing a CD player?

The audio section a complete redo from that of a computer?

I do not mean to offend with my questions, please keep that in mind. I am not an adversary.

Some people have had the idea to find something cheap and maximize it as part of their exercise/design (that boombox derived project for example).

Some people have the idea of finding a drive used in some high priced CD player which is also used in a much cheaper unit, and using that as their transport (like me).

Others like the originator of this thread, have the idea of starting from scratch, or as near as possible, and making a better mouse trap/CD player.

In each case there is a learning curve, and perhaps something to be shared.

I don't want to hi-jack the thread anymore than I already have, so I'll just grab some popcorn and watch the show from now on. Learned a lot already.

- Home

- Source & Line

- Digital Source

- Quality CD-Mechanisms are long gone - let us build one ourselves!