Hi X This looks like a nice build. I'd like to use 1/2 ply with the PA 130 driver. Any suggestions on the stuffing, lining ? thanks frazier

Line inside behind and to side of driver with felt it open cell foam. Me Clean Magic cleaning pads (BASF professional sound abatement foam) works well too. Put a good block of fiberglass or a wad of polyfill at the top above the driver, it's Ok if some of it touches back of driver frame. Just don't let it block vent. Optional is to line inside of K aperture with felt.

Good luck !

it wound't hurt to make an XKi"X8" with the 2nd "X" denoting use of a K-tube per Karlson's X15 speaker - here's one of Carl's old K8 size testboxes loaded with an 8" woofer and compression driver on a K-tube I made.

regular K8 tend to cut off kinda high

aperture width where the tube reaches or protrudes into the wings should be at least the tube diameter

X15 sounds very "fast" - I'm not sure how a coupler this size would fare

of course a K-tube could be mounted on the top.

regular K8 tend to cut off kinda high

aperture width where the tube reaches or protrudes into the wings should be at least the tube diameter

X15 sounds very "fast" - I'm not sure how a coupler this size would fare

of course a K-tube could be mounted on the top.

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

I wanna make an XKi with my spare PA130's - waiting too long to see you guys make it. I have a feeling it's gonna kick hard.

I also want to try the 5-slits and re-glue the cone trick to see if cone breakup resonance improves. The PA130-8 already has the wet sticky goop at the surround to absorb cone-to-surround reflections (stock surround coating).

I also want to try the 5-slits and re-glue the cone trick to see if cone breakup resonance improves. The PA130-8 already has the wet sticky goop at the surround to absorb cone-to-surround reflections (stock surround coating).

XKi with PA130-8

I had some time for some quick foam core speakers again. I threw this one together pretty fast using the stiffer Elmer's brand foam core with softer foam core for the double thickness baffle board. I have been curious as to whether or not the Dayton PA130-8 would work well in an XKi... I suspected it would based on how great it sounds in a 0.53x Karlsonator. I wanted to try the XKi because it is much more compact - desktop size basically at 7in wide x 12in tall x 7.5in deep.

I did not get a chance to make the K-aperture yet, but I tested the sound without it and it sounds very good. Bass down to about 65Hz and pretty low distortion and balanced overall. I did not even bother to put pads or stuffing inside yet and it sounds very nice already.

This is going to be a classic that I will keep around for a long time - I can tell. It has the great compact size and proportions, sounds balanced, has rich full bass, a great midrange, and it is pretty loud with great dynamics.

This foam core build confirms that the model works and the plans shown in post 315 is good. I set the break point on the front baffle at 5in below the top edge.

I can highly recommend it already.

I had some time for some quick foam core speakers again. I threw this one together pretty fast using the stiffer Elmer's brand foam core with softer foam core for the double thickness baffle board. I have been curious as to whether or not the Dayton PA130-8 would work well in an XKi... I suspected it would based on how great it sounds in a 0.53x Karlsonator. I wanted to try the XKi because it is much more compact - desktop size basically at 7in wide x 12in tall x 7.5in deep.

I did not get a chance to make the K-aperture yet, but I tested the sound without it and it sounds very good. Bass down to about 65Hz and pretty low distortion and balanced overall. I did not even bother to put pads or stuffing inside yet and it sounds very nice already.

This is going to be a classic that I will keep around for a long time - I can tell. It has the great compact size and proportions, sounds balanced, has rich full bass, a great midrange, and it is pretty loud with great dynamics.

This foam core build confirms that the model works and the plans shown in post 315 is good. I set the break point on the front baffle at 5in below the top edge.

I can highly recommend it already.

Attachments

Last edited:

XKi PA130-8 Completed

Here is the XKi with the K aperture. I made the aperture out of 1 sheet of foam core glued to 5mm floor underlayment plywood. It's pretty stiff and gives the speaker a nice look.

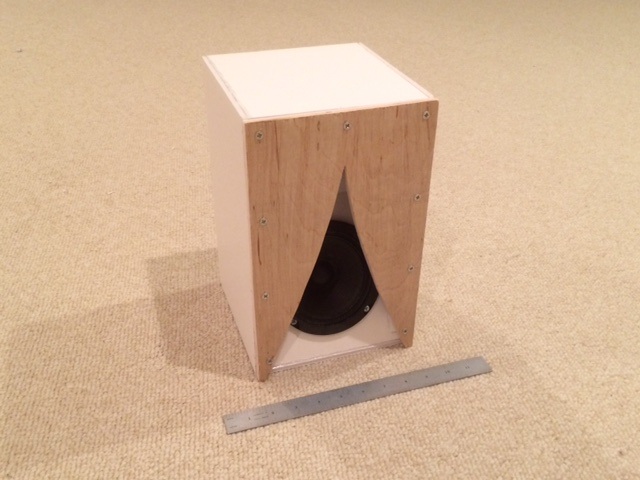

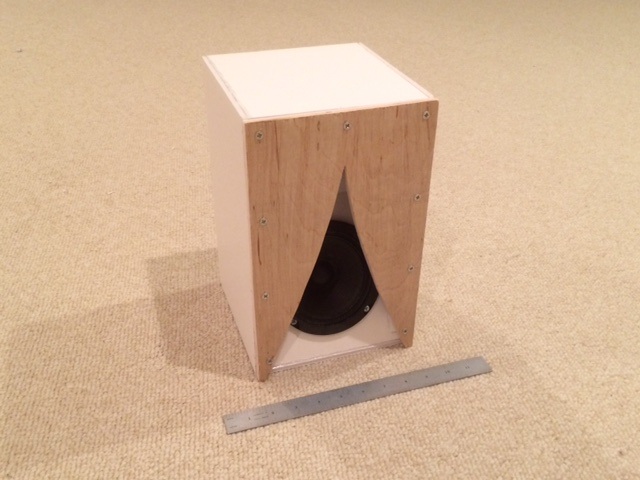

Here is a photo of the new XKi (there is a terminal cup on the back):

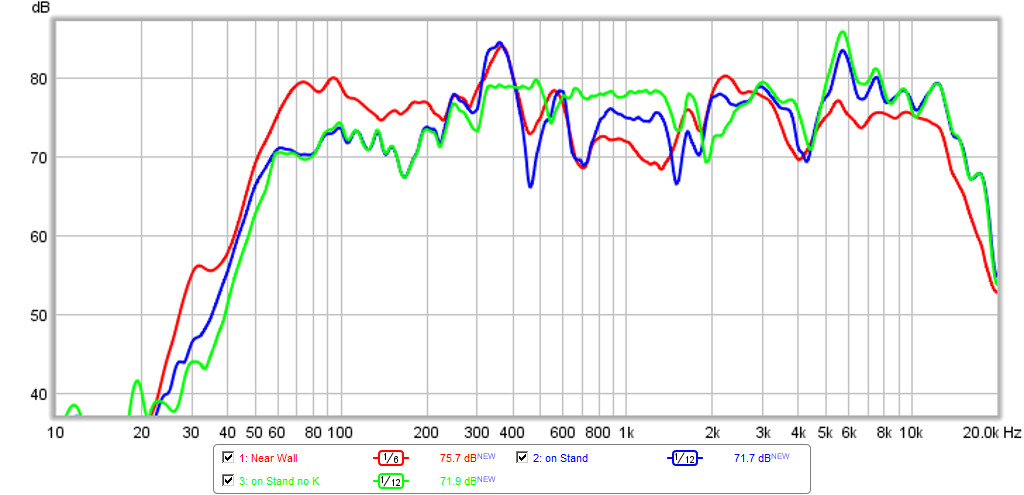

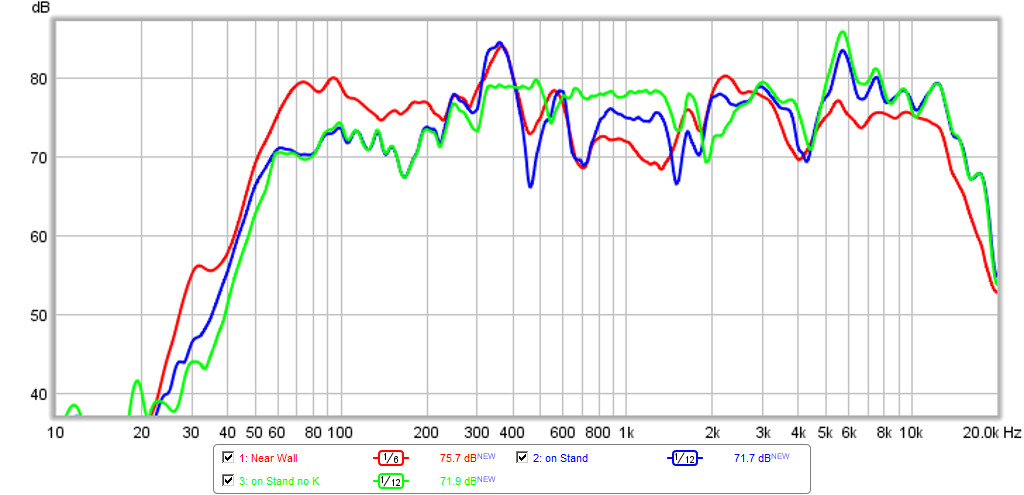

Here is the frequency response up on a stand, 6in from a back wall, and without a K aperture:

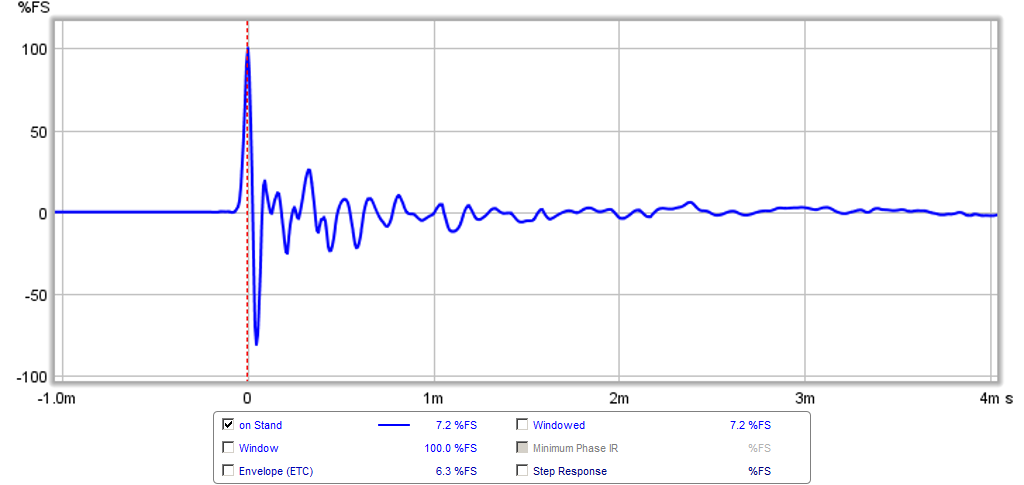

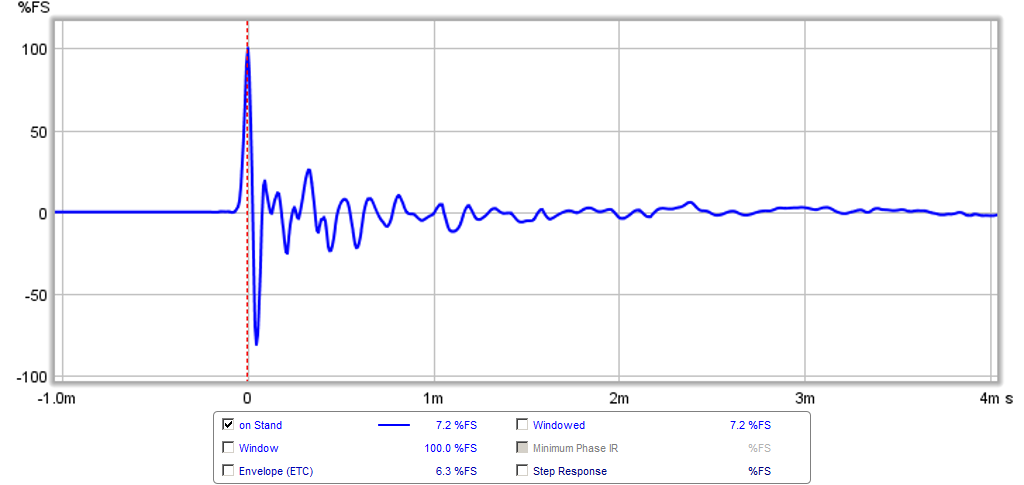

Here is the impulse response for the K-aperture case:

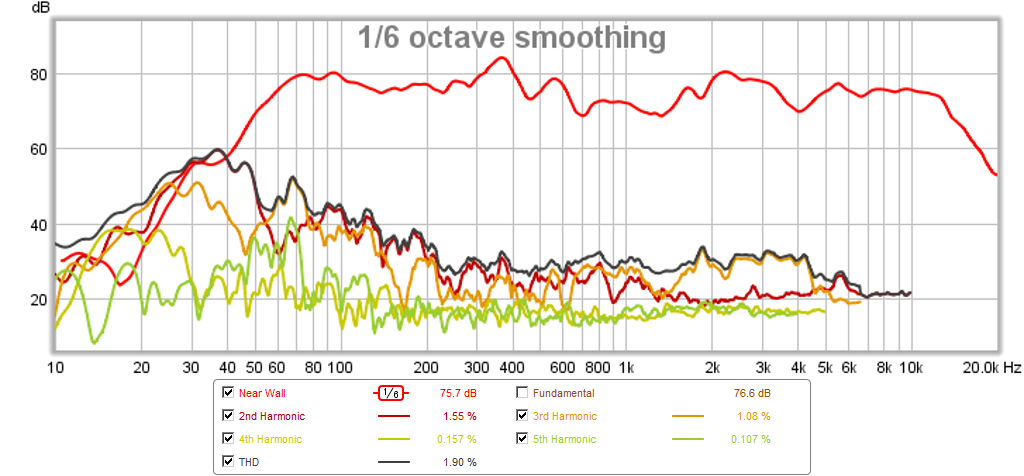

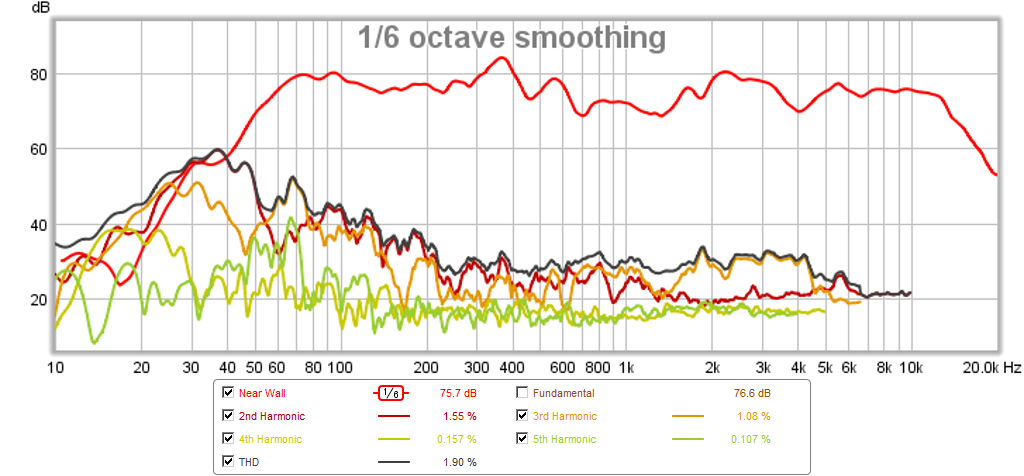

It sounds very good despite the dips and peaks characteristic of many Karlsons. The aperture gives a wider more uniform polar directivity:

It has about a 55Hz -3dB extension.

Here is the XKi with the K aperture. I made the aperture out of 1 sheet of foam core glued to 5mm floor underlayment plywood. It's pretty stiff and gives the speaker a nice look.

Here is a photo of the new XKi (there is a terminal cup on the back):

Here is the frequency response up on a stand, 6in from a back wall, and without a K aperture:

Here is the impulse response for the K-aperture case:

It sounds very good despite the dips and peaks characteristic of many Karlsons. The aperture gives a wider more uniform polar directivity:

It has about a 55Hz -3dB extension.

Attachments

hey X -that came out really well and a good response characteristic - near a wall its really punchy looking and smooth looking  - (its weird and disconcerting to see wood grain in your builds

- (its weird and disconcerting to see wood grain in your builds ) - if a person were using typical pre-cut "12 inch by 12 inch' Baltic birch pieces which are closer to 11 13/16" square, what changes to the plan would you recommend? (those pieces come in 3/6/9/12mm, etc thickness through Amazon)

) - if a person were using typical pre-cut "12 inch by 12 inch' Baltic birch pieces which are closer to 11 13/16" square, what changes to the plan would you recommend? (those pieces come in 3/6/9/12mm, etc thickness through Amazon)

how does it sound in wall position vs some of your other builds?

how does it sound in wall position vs some of your other builds?

Last edited:

If using thicker ply, you just need to adjust dimensions a bit to preserve *internal dimensions* as that is what I have listed. Basic internal volume is 7.75in deep x 7.0in wide x 12in tall. If using 12mm or 0.5in ply then add 0.5in depth for baffle board. The vent should be made of thinner material so it doesn't take up too much volume. Use 5mm and volume difference is not a big deal. Actually all dimensions within 5% is all good. Critical one is vent gap and length - keep that close to specified to make sure tuning is right.

I still have some of that 5mm underlayment around and I figured why not get rid of all the K-wing flex and make it look good while I am at it. The foam core on backside acts kind of like some padding to absorb sound I think. Acoustically a lot less hard than ply - more "cork like" I would expect.

Yes, this thing sounds really good - stand up plucked bass is unbelievably good and you can't imagine coming from a little box with 5in driver. Let me records sample and post.

I still have some of that 5mm underlayment around and I figured why not get rid of all the K-wing flex and make it look good while I am at it. The foam core on backside acts kind of like some padding to absorb sound I think. Acoustically a lot less hard than ply - more "cork like" I would expect.

Yes, this thing sounds really good - stand up plucked bass is unbelievably good and you can't imagine coming from a little box with 5in driver. Let me records sample and post.

Sound Clips of XKi PA130-8

Listen to the detail on the stand up bass - you can hear the finger sliding on the strings. The plucks are very forceful and clear. This speaker does well with vocals too as you will hear. The extension goes clearly to 55 Hz which is a great performance for a PA130 which has an 83Hz fs.

Change .asc extension to .mp3 to listen to 320kbit files.

Listen to the detail on the stand up bass - you can hear the finger sliding on the strings. The plucks are very forceful and clear. This speaker does well with vocals too as you will hear. The extension goes clearly to 55 Hz which is a great performance for a PA130 which has an 83Hz fs.

Change .asc extension to .mp3 to listen to 320kbit files.

Attachments

X Thanks for your dedication to the building and testing of these K aperture speakers. Good work , shoutout to the other posters as well. I really like my .53's and my next build will be this one. Question, it looks like the K- ap is a radius from top to bottom, is there any factor that effects this part of the design?? thanks much frazier

X Thanks for your dedication to the building and testing of these K aperture speakers. Good work , shoutout to the other posters as well. I really like my .53's and my next build will be this one. Question, it looks like the K- ap is a radius from top to bottom, is there any factor that effects this part of the design?? thanks much frazier

The top of the aperture controls bass extension - wider gives more punch and overshoot. Narrow give more extension but reduced amplitude. The lower wider part controls the HF acoustic lens. Wider lets more HF out but less uniform polar. Smaller area of K aperture gives more cone control for higher SPL but at expense of upper extension.

if I block the first few inches of aperture on this particular 41.5 inch tall coupler, it subjectively sounds a bit "slower"

this measures mediocre in LF extension but sounds good and punchy plus has an attractive midrange with 18" woofers and K-tube tweeter

this measures mediocre in LF extension but sounds good and punchy plus has an attractive midrange with 18" woofers and K-tube tweeter

An externally hosted image should be here but it was not working when we last tested it.

If using thicker ply, you just need to adjust dimensions a bit to preserve *internal dimensions* as that is what I have listed. Basic internal volume is 7.75in deep x 7.0in wide x 12in tall. If using 12mm or 0.5in ply then add 0.5in depth for baffle board. The vent should be made of thinner material so it doesn't take up too much volume. Use 5mm and volume difference is not a big deal. Actually all dimensions within 5% is all good. Critical one is vent gap and length - keep that close to specified to make sure tuning is right.

I still have some of that 5mm underlayment around and I figured why not get rid of all the K-wing flex and make it look good while I am at it. The foam core on backside acts kind of like some padding to absorb sound I think. Acoustically a lot less hard than ply - more "cork like" I would expect.

Yes, this thing sounds really good - stand up plucked bass is unbelievably good and you can't imagine coming from a little box with 5in driver. Let me records sample and post.

And now, how about a dual loaded PA130?

That should pack a punch in a friendly sized box!

Cbarth

Oh, ok. Not that small then...

I have found lately that I really enjoy the sound from fullrangers.

Problem is imo the big ones (6,5 - 8) is to shouty and/or beamy, and the small ones just can't do realistic spl levels.

But it looks like this might just be worth a try.

I will try a couple of my ND90's in the mini Karlsonator, if that is as good as you guy's claim, then I will try some bigger ones!

Thanks XRK for all the time and effort you put in all this simulation and engineering for the benefit of the whole community!

Cbarth

I have found lately that I really enjoy the sound from fullrangers.

Problem is imo the big ones (6,5 - 8) is to shouty and/or beamy, and the small ones just can't do realistic spl levels.

But it looks like this might just be worth a try.

I will try a couple of my ND90's in the mini Karlsonator, if that is as good as you guy's claim, then I will try some bigger ones!

Thanks XRK for all the time and effort you put in all this simulation and engineering for the benefit of the whole community!

Cbarth

- Home

- Loudspeakers

- Full Range

- XKi - X's ab initio Karlson 6th Order Bandpass