depending on the whole diameter and plating thickness most PTH holes have more effective copper than the trace that joins them... plating thickness should be between 20-25microns (approx. 3/4 ounce copper)... I presume we are discussing via's here as they are usually the only holes that don't have pins in them.

Again I have not seen this problem in any electronics I have been part of for competently made to the correct specs PCBs and to the required quality, through holes causing distortion, it would be a very big problem on some designs I have worked on... and would be catastrophic for a long term project I am working on... plenty of analogue.....

Again I have not seen this problem in any electronics I have been part of for competently made to the correct specs PCBs and to the required quality, through holes causing distortion, it would be a very big problem on some designs I have worked on... and would be catastrophic for a long term project I am working on... plenty of analogue.....

Company policy or not enough imagination?I never have nor never will put my name on a PCB design, It goes in the border text only (Drawn, checked, approved)...

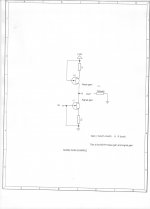

Attachments

ES,

I have a friend who does system design as you do and I can't remember how many times he has talked about how the art of using output transformers has been lost by those doing distributed systems. He also pushes me to look at the loudspeaker as a current device and to stop looking at it as a voltage driven device. This is where reading the book on current drive for loudspeakers has got me thinking again about this selection of voice-coil winding impedance.

Since I am having the coils made to my design requirements it has me wondering about my earlier decisions. It would be trivial to raise the impedance but as you stated it is one thing to add to the moving mass of a bass/ mid driver but when working up higher then things aren't so simple. In my case with a very long gap design adding length to the winding stack isn't going to cost me the same as it would in a design where you have a short gap and how to keep those extra winding in the gap, decreasing wire size isn't something I would want to do to keep the wire in that short gap and adding layers rather than winding stack height makes you widen the gap, it is a very fine line that has to be considered when all the different demands are looked at.

I have a friend who does system design as you do and I can't remember how many times he has talked about how the art of using output transformers has been lost by those doing distributed systems. He also pushes me to look at the loudspeaker as a current device and to stop looking at it as a voltage driven device. This is where reading the book on current drive for loudspeakers has got me thinking again about this selection of voice-coil winding impedance.

Since I am having the coils made to my design requirements it has me wondering about my earlier decisions. It would be trivial to raise the impedance but as you stated it is one thing to add to the moving mass of a bass/ mid driver but when working up higher then things aren't so simple. In my case with a very long gap design adding length to the winding stack isn't going to cost me the same as it would in a design where you have a short gap and how to keep those extra winding in the gap, decreasing wire size isn't something I would want to do to keep the wire in that short gap and adding layers rather than winding stack height makes you widen the gap, it is a very fine line that has to be considered when all the different demands are looked at.

Last edited:

Company policy or not enough imagination?

Which company...

Cobham

BAE

RR nuclear

Knorr Brense

E2V

Zetec

Racal

Northrop Grummon

Shimadzu

and a few more....

Its company policy everywhere I have worked and work now, I can understand why you would want your name in the copper or on the silk, its a product... though for high end audio I think the rules are different as it is a marketing game and having a name associated with a product helps it sell.

Now cool stuff like you have shown would be fun, but the people I work for don't have that sort of humour.

Playing with a power supply this week and next (SMPS) transformer 9" cube with litzs wire, ferrite core 1:1 240V+ rated, fun.

In fact that gets my vote for the coolest text I have seen on a PCB...

Back to the hotel for me, so limited internet again but I can book my drinks to the company credit card so maybe as I get to go home for the weekend I'll treat myself to a skinful of free beer... Its quire cool cos we have loads of climbing types in and got to talk to a childhood hero of mine Sir Chris Bonington, never gone gooey at the knees ever before when meeting someone famous, when I first spoke to him I felt like a little nervous boy, total gentleman though and had time to say hello and have a quick chat, highlight of my year.

Last edited:

PCB artists... never liked that term, its more science than art and always has been,

Well in the days when it was all tape and lightboards you could call it 'art'.

When you step back and look at how PCB design software has improved since the rise of the PC you can how the lines have blurred between the design and the layout. Although I still know RF types who don't trust anyone else with critical layout. Mind you they also have strange habits and dont generally play well with others. Luckily we have imprisoned a lot of them at Roke Manor!

Marce,

Thank you for your earlier answer to my question.

On marking a board like that I would have to agree that when I have worked for others and especially in defense/aerospace it is more about documentation and traceability. Who did what and when and why was it done. I was in charge of document control with my other duties as tooling supervisor of an aerospace company. I could go back years and see every design review, change order and every other thing ever done to say the Apache rotor blade tooling and find whatever was supposed to happened and did. This included machine setups and every other detail of tooling and production. Every part made had a document associated with it, everything is traceable, to do less would have been not following procedure and would have cause some major problems. Nothing can be changed without documentation,, it is the standard in that industry.

Thank you for your earlier answer to my question.

On marking a board like that I would have to agree that when I have worked for others and especially in defense/aerospace it is more about documentation and traceability. Who did what and when and why was it done. I was in charge of document control with my other duties as tooling supervisor of an aerospace company. I could go back years and see every design review, change order and every other thing ever done to say the Apache rotor blade tooling and find whatever was supposed to happened and did. This included machine setups and every other detail of tooling and production. Every part made had a document associated with it, everything is traceable, to do less would have been not following procedure and would have cause some major problems. Nothing can be changed without documentation,, it is the standard in that industry.

You could say this as well for a musician ;-)PCB artists... never liked that term, its more science than art and always has been

Architecture is an art too. With kind of similar requirements, agree ?

Some bring to PCB 'design' a little more than technique: beauty. Often, it is those who are the best on a technical point of view.

I remember my son, when he was a little boy saying, looking at some PCB i just finished to weld "Oh, it looks like a miniature city."

its more science than art and always has been

I take it you never get past R0.

Marce, I beg to differ. True, it necessarily needs to incorporate a lot of science, but there is a point where it goes beyond pure science and technology. It's hard to define, and I suppose it's partly up to the user to feel it or not, but for me there is such a point beyond which I will call a man an artist, not just a PCB designer.

This is why I refer to Alex as an artist. His work is blamelessly neat and ordered, every aspect I can think of is well taken care of, yet it is still wonderfully logical and exceptionally well placed just where it should be. Those who know more about PCB work might not agree with me, and that's all right, every craft has its fine points only another craftsman may readily observe which won't register with me, I don't deny that. Yet, exceptional work is somehow readily appearent to many even outside that trade - that's Alex. Everybody who has seen his work and is in electronics of any type positively commented on his work, as did some of his direct colleagues who have also been at it for 20+ years. It's not very likely all those people are wrong.

As for him signing his work, I have no problem with that, in fact I encourage him to do so. It reflect the truth as it really is. A man's got live, and he does have something to be proud of.

This is why I refer to Alex as an artist. His work is blamelessly neat and ordered, every aspect I can think of is well taken care of, yet it is still wonderfully logical and exceptionally well placed just where it should be. Those who know more about PCB work might not agree with me, and that's all right, every craft has its fine points only another craftsman may readily observe which won't register with me, I don't deny that. Yet, exceptional work is somehow readily appearent to many even outside that trade - that's Alex. Everybody who has seen his work and is in electronics of any type positively commented on his work, as did some of his direct colleagues who have also been at it for 20+ years. It's not very likely all those people are wrong.

As for him signing his work, I have no problem with that, in fact I encourage him to do so. It reflect the truth as it really is. A man's got live, and he does have something to be proud of.

Last edited:

ES,

I have a friend who does system design as you do and I can't remember how many times he has talked about how the art of using output transformers has been lost by those doing distributed systems. He also pushes me to look at the loudspeaker as a current device and to stop looking at it as a voltage driven device. This is where reading the book on current drive for loudspeakers has got me thinking again about this selection of voice-coil winding impedance.

Since I am having the coils made to my design requirements it has me wondering about my earlier decisions. It would be trivial to raise the impedance but as you stated it is one thing to add to the moving mass of a bass/ mid driver but when working up higher then things aren't so simple. In my case with a very long gap design adding length to the winding stack isn't going to cost me the same as it would in a design where you have a short gap and how to keep those extra winding in the gap, decreasing wire size isn't something I would want to do to keep the wire in that short gap and adding layers rather than winding stack height makes you widen the gap, it is a very fine line that has to be considered when all the different demands are looked at.

A good audio band transformer will have at least 1 dB of loss and a bit more if you go for lower frequencies. That is equal to a 250' run of 10 gauge wire. But of course there is also line loss on the transformer wire. Now as 625 watts at 70 volts is 8 ohms, for much of what I do on large systems transformers actually are a bad choice.

The exception of course is distributed ceiling loudspeakers.

Normally going from 8 to 16 ohm voice coils doesn't add mass as you only need one half of the wire area for the reduced current. i think as long as the inductance doesn't get you higher is better.

ES

Architecture is an art too. With kind of similar requirements, agree ?

Architects, at least good ones should be Polymaths. Bad ones should only be allowed to design bus stops! Then there are the rash of celebrity architects and their egos.

But the analogy is wrong. An architect would have a team of (more highly skilled) specialists behind him to do the hard sums to make sure that the building would stay up. If the layout specialist is more skilled than the designer he should be promoted (no offence Marce and sure you have worked with people where that is the case)

The silence is disconcerting!

Actually, here's what I'm curious about- why jFETs for the pass devices in the cap multipliers?

The silence is disconcerting!

However, here as a noise model that we have to address to see what ACTIVE loads do wrong, much of the time.

Interested.... but moving at a snails pace.....

-RNM

I have been using bipolars for the pass devices in cap multipliers mostly because of a limited supply of Toshibas. John any sonic reasons for fets as pass transistors? Nice low noise bipolars available in KSA992 and KSC1845 also.

In reference to the BA LSK pre Nelson did credit JC with the circuit concept.

In reference to the BA LSK pre Nelson did credit JC with the circuit concept.

Distortion and DC drift are secondary to changing the supply voltage. However the supply resistor would have to increase to 600 ohms or more to keep the Idle current of both the first stage and the cascode stage about the same current.

Let's see if any of you can recommend a QUIET 25ma current source, that will replace the supply resistor without adding noise. Any suggestions?

I thought current sources could be made quieter than resistors. Is this a myth?

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II