Well, that is, indeed troubling. Now - if your speed issues disappear once the old bearings are installed . . . Can't wait to hear.

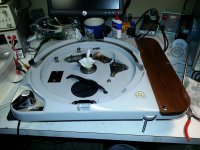

I decided today would be the I would pull apart my TD-124 MKII and see if I could resolve some of the recent issues.

I got ambitious and pulled the motor, I am somewhat miffed to have to report that the motor bearings I installed 4 years ago are not what I thought they were. Be very careful purchasing parts on eBay, particularly ones sourced here in the USA. (Make sure to verify they are made of sintered bronze)

The bearings are also COMPLETELY dry, and study with a loupe is pretty conclusive that these bearings are not made of sintered bronze. Fortunately I kept the original bearings and have cleaned them, heated them to drive out the old oil and they are now sitting in a hot oil bath which is slowly cooling down. These bearings have virtually no wear since the table was not run for 40yrs and I doubt it saw more than a 100hrs of use with its original owner. (I am the second owner of this table)

This explains the massive difference in performance between this motor and the one in my other table where in a fit of cheapness I decided to keep the original bearings.

All I can say is that my knowledge has increased considerably since I got this table and I knew immediately looking at these motor bearings that they were not right.

Fortunately the motor shaft is OK, not a lot of evidence of wear.

Well now, isn't THAT interesting . . . ;-)

Yes, the speed issues have disappeared. The table now gets up to full speed within about a minute, and is rock stable just like the other one. No more prolonged drift.

Is there any synchronous motor suitable in a TD-124 ?

I know, it is not possible to adjust the speed with a synchronous motor (or with a variable frequency generator) but I prefer a stable speed motor vs a continuously unstable speed.

If the motor is working properly and is overhauled using original good parts or proper (reputable) replacements there is no speed stability issue at all..

Everyone replaces the motor bushings wholesale without considering whether the originals are bad, and unfortunately like so many mods and replacement parts for this table not all of them (or many) are good.

The problem with these replacement bushings is that they were not made of sintered bronze and are not self lubricating. I am very lucky that the motor was not damaged. The felt pads were soaking wet with oil which was not getting to the shaft.

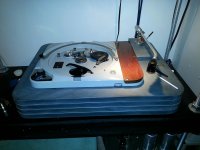

First picture is the reassembled motor, the second those bad bearings, the third is the motor reinstalled. (Yes that is the Hanze Hi-Fi motor suspension - works great)

Attachments

I will report back as the rebuilt motor breaks in, I expect there will be some changes in performance one way or the other and probably some tweaking required.

This table is powered by my recently completed power regenerator project. The voltage can be precisely set along with options for 50 or 60Hz output at 90 - 120V and 180 - 240V. I am currently running it on 110V/60Hz. I expect this will allow me to observe how stable it is over time.

This table is powered by my recently completed power regenerator project. The voltage can be precisely set along with options for 50 or 60Hz output at 90 - 120V and 180 - 240V. I am currently running it on 110V/60Hz. I expect this will allow me to observe how stable it is over time.

What are you showing in that closeup, the original or replacement bushings? Oil in the jar relevant to the re-oil? Looks too dark to be your standard 3 in one electric motor oil, which is why I ask.

Yes, the speed issues have disappeared. The table now gets up to full speed within about a minute, and is rock stable just like the other one. No more prolonged drift.

If the motor is working properly and is overhauled using original good parts or proper (reputable) replacements there is no speed stability issue at all..

Everyone replaces the motor bushings wholesale without considering whether the originals are bad, and unfortunately like so many mods and replacement parts for this table not all of them (or many) are good.

The problem with these replacement bushings is that they were not made of sintered bronze and are not self lubricating. I am very lucky that the motor was not damaged. The felt pads were soaking wet with oil which was not getting to the shaft.

No the oil in the jar is not standard 3 in 1, but it is 3 in 1 SAE 20 WT electric motor oil which is what I normally use, and recommend. Since these bearings are not new and had conventional oil in them previously I did not want to risk a reaction with the Nye oil.

The bushings shown are the replacement bushings I just removed from the motor. The originals look nothing like these in terms of finish.

The bushings shown are the replacement bushings I just removed from the motor. The originals look nothing like these in terms of finish.

That's the oil I meant. Blue can, 20 wt. "specially formulated for 1/2 Hp. motors." I guess I've never seen it in quantity, always thought it was basically clear.

No the oil in the jar is not standard 3 in 1, but it is 3 in 1 SAE 20 WT electric motor oil which is what I normally use, and recommend. Since these bearings are not new and had conventional oil in them previously I did not want to risk a reaction with the Nye oil.

The bushings shown are the replacement bushings I just removed from the motor. The originals look nothing like these in terms of finish.

Boy, I hope you found a larger can that I did! Having to empty out a bunch of those little ones would be a pain!

In any event, unless you find out something different, I'm inclined to go your route and work with the original bearings when I do my E50.

In any event, unless you find out something different, I'm inclined to go your route and work with the original bearings when I do my E50.

I have quite a bit of it lurking around here from the days when I was working on these tables fairly regularly.

Table seems considerably happier, it got up to speed much more quickly and has not drifted around much.

I have a feeling the "right" bushings are what Thorens installed! In the case of my E50 we're talking about a motor that under load came up to speed in a rev., stabilized in 10-15 minutes ( I just had to dial it back a hair after it warmed up) - And I hadn't done a thing to it. I think that says something about overall condition.

I would recommend that unless you can get the right motor bushings, as I recall you bought the same ones I had installed in this motor. I would not use those!

It really should stabilize within a couple of minutes at most and not require much if any touching up on speed once it has settled down.

What you are describing is how my "broken" MKII ran until today, 15 - 20 minutes to come up to speed. The older one once I overhauled the motor never behaved this way.

I would estimate about 2 minutes to be on speed with a small amount of drift possible over the first half hour or so of operation. Getting the bearings aligned properly reduces both noise and the magnitude of speed variation as the table warms up. Some running time after rebuild is required for everything to settle down IMLE.

What you are describing is how my "broken" MKII ran until today, 15 - 20 minutes to come up to speed. The older one once I overhauled the motor never behaved this way.

I would estimate about 2 minutes to be on speed with a small amount of drift possible over the first half hour or so of operation. Getting the bearings aligned properly reduces both noise and the magnitude of speed variation as the table warms up. Some running time after rebuild is required for everything to settle down IMLE.

OK, I'm going on memory and that was a few years ago I suppose, but it's my recollection so I'd best stick to it. Still, if my untouched e50 ran like yours did after the first rebuild, I'm still pretty encouraged. I guess I need to get that workroom finished so I can move in and actually do some work.

It really should stabilize within a couple of minutes at most and not require much if any touching up on speed once it has settled down.

What you are describing is how my "broken" MKII ran until today, 15 - 20 minutes to come up to speed. The older one once I overhauled the motor never behaved this way.

I would estimate about 2 minutes to be on speed with a small amount of drift possible over the first half hour or so of operation. Getting the bearings aligned properly reduces both noise and the magnitude of speed variation as the table warms up. Some running time after rebuild is required for everything to settle down IMLE.

If the motor is working properly and is overhauled using original good parts or proper (reputable) replacements there is no speed stability issue at all..

Everyone replaces the motor bushings wholesale without considering whether the originals are bad, and unfortunately like so many mods and replacement parts for this table not all of them (or many) are good.

The problem with these replacement bushings is that they were not made of sintered bronze and are not self lubricating. I am very lucky that the motor was not damaged. The felt pads were soaking wet with oil which was not getting to the shaft.

First picture is the reassembled motor, the second those bad bearings, the third is the motor reinstalled. (Yes that is the Hanze Hi-Fi motor suspension - works great)

Valuable post.

The bushings in the photo are definitely not oilite bronze. aka sintered bronze. aka porous bronze, aka self lubing bronze bushings, SAE 841, etc.

Where did you source those?

You bring up another valuable thought about replacing bushings without knowing if it is really necessary.

The normal considerations would be to confirm if there has been enough wear in the original bushings to warrant replacing them.

A bore gage should be used in the suspect bushing to confirm uniform cylindricity within the bore. Evidence of wear might take the form of an out-of-round condition within the bushing walls. Also look for taper. A difference of size from one end to the other.

Excessive bushing wear could take the form of these irregularities. But also a poorly made new bushing could also exhibit evidence of out-of-roundness as well as taper.

In any case the bushings in this motor need to be of the sintered bronze variety. Otherwise there would need to be a way to get lube to the bushings on a periodic basis. And there really isn't any. At least not a convenient way.

-Steve

PS: fwiw I re-used the original bushings in my sn 13943 project. Measurements I took with those suggested no need to replace them.

Hey Steve,

These bushings were represented as being replacement bushings for the E50 by a U.S eBay seller. I remember wondering at the time whether they were really sintered bronze or not; now I have enough experience to immediately know the difference.

This motor has always had one sort of problem or another, and always took a long time to achieve stable speed. I complained a lot about it, but comments from others lead me to believe it was "normal" further thought over time caused me realize that no one 50yrs ago was going to wait around for 20 minutes for a turntable to come up to normal operating speed. It would have been a disastrous commercial flop..

When I rebuilt the motor in my second table I elected to keep the original bushings, but I had no way of knowing whether or not they were OK. It's behavior was so immediately different and better than the MKII that it was a confirmation of my worst fears.

Some weeks ago I commented here that I was suspicious of the bushings I had installed in the MKII E50, and after a particularly lousy evening last night I came to the conclusion that today was TD-124 MKII tear down day. The original bearings were reinstalled after reconditioning* and the motor reassembled - I took the opportunity to re-lubricate all of the other moving parts. Some tweaking on the bench and then I reinstalled it. It's been running all evening and has not needed a speed adjustment in about 4 hours, so I am satisfied, best of all it was ready to play a record almost immediately as opposed to some 20 minutes later.

*Reconditioning: Quick soak in alcohol, then 20 minutes in a 200 degree oven to drive out the old oil, then a quick wipe down to get the residue, and then a further 10 minutes in the oven; next into warm oil and left to cool for about 30 minutes; Soaked felts in SAE 20 wt 3 in 1 electric motor oil; reassemble bearings, and motor; align bearings and motor housing shells for quietest running.

A couple things to note, these bearings had probably little more than a hundred hours or so of use, the table then went to sleep for 40yrs and those bushings subsequent to the overhaul sat in a sealed plastic bag for 4 yrs. No visible evidence of wear. (No bore gauge here unfortunately)

The other thing is I had no idea which bushing was top and which was bottom; I have a 50% probability of having put the original bushing back in the right place, and hopefully if not it does not matter too much.

In any case it is running a lot better.

These bushings were represented as being replacement bushings for the E50 by a U.S eBay seller. I remember wondering at the time whether they were really sintered bronze or not; now I have enough experience to immediately know the difference.

This motor has always had one sort of problem or another, and always took a long time to achieve stable speed. I complained a lot about it, but comments from others lead me to believe it was "normal" further thought over time caused me realize that no one 50yrs ago was going to wait around for 20 minutes for a turntable to come up to normal operating speed. It would have been a disastrous commercial flop..

When I rebuilt the motor in my second table I elected to keep the original bushings, but I had no way of knowing whether or not they were OK. It's behavior was so immediately different and better than the MKII that it was a confirmation of my worst fears.

Some weeks ago I commented here that I was suspicious of the bushings I had installed in the MKII E50, and after a particularly lousy evening last night I came to the conclusion that today was TD-124 MKII tear down day. The original bearings were reinstalled after reconditioning* and the motor reassembled - I took the opportunity to re-lubricate all of the other moving parts. Some tweaking on the bench and then I reinstalled it. It's been running all evening and has not needed a speed adjustment in about 4 hours, so I am satisfied, best of all it was ready to play a record almost immediately as opposed to some 20 minutes later.

*Reconditioning: Quick soak in alcohol, then 20 minutes in a 200 degree oven to drive out the old oil, then a quick wipe down to get the residue, and then a further 10 minutes in the oven; next into warm oil and left to cool for about 30 minutes; Soaked felts in SAE 20 wt 3 in 1 electric motor oil; reassemble bearings, and motor; align bearings and motor housing shells for quietest running.

A couple things to note, these bearings had probably little more than a hundred hours or so of use, the table then went to sleep for 40yrs and those bushings subsequent to the overhaul sat in a sealed plastic bag for 4 yrs. No visible evidence of wear. (No bore gauge here unfortunately)

The other thing is I had no idea which bushing was top and which was bottom; I have a 50% probability of having put the original bushing back in the right place, and hopefully if not it does not matter too much.

In any case it is running a lot better.

Is there any synchronous motor suitable in a TD-124 ?

I know, it is not possible to adjust the speed with a synchronous motor (or with a variable frequency generator) but I prefer a stable speed motor vs a continuously unstable speed.

It usually would have more vibration. As TD 124 is a bit marginal on that it might cause problems. Most people can not hear speed variations of <0.1% if not wow and flutter. The thing you should do is have a lower distortion 50 Hz supply. 10 minutes after switch on it should be stable. The instability of typical turntables is dynamic and often called dynamic wow. This is like an underpowered car that slows uphill. Ideal turntables show no preference for uphill or down hill. It is so easy in a bad way to swap something which sceince says you do not need for something you don't understand you need. Sometimes the sound is more real than is typical, this is when the mysterious speed problem is fxed. That is when the dynamic wow is low. The Linn LP12 is not as good to my ears as TD124 on this( and most other belt drives ). The flywheel effect effect does not seem to solve this problem.

If it really matters it would be a nice piece of engineering to have a speed feedback servo using the TD 124 motor. It needs to be a very loose servo to ensure no dynamic problems. The stobe makings if over painted with ultra violet paint might be OK to feed the imformation in .

Is there any synchronous motor suitable in a TD-124 ?

I know, it is not possible to adjust the speed with a synchronous motor (or with a variable frequency generator) but I prefer a stable speed motor vs a continuously unstable speed.

The Papst motor is a synchronous motor but produce extra vibration when used with the so called Steinmetz config.for single fase supply .

I build a three phase power supply special for the Papst motor and the vibrations are minimized and torque almost doubled .In the near future I post the results overhere.

- Home

- Source & Line

- Analogue Source

- Restoring and Improving A Thorens TD-124 MKII