Sagamotto,

Very nice OB build. Can you provide details of the drivers and crossovers? How did you size the baffle? Or it just ended up as 20 x 30 in as default stock size? I think offsetting tweeter and mid slightly to one side reduces diffraction losses. A wood frame is only needed if you feel it is not stiff enough. The foam core is very durable humidity wise if you have three layers. A frame will make it very tough. I like the box made of FC on the back of the woofer. I bet it sounds fantastic.

Very nice OB build. Can you provide details of the drivers and crossovers? How did you size the baffle? Or it just ended up as 20 x 30 in as default stock size? I think offsetting tweeter and mid slightly to one side reduces diffraction losses. A wood frame is only needed if you feel it is not stiff enough. The foam core is very durable humidity wise if you have three layers. A frame will make it very tough. I like the box made of FC on the back of the woofer. I bet it sounds fantastic.

Thks xrk971

A single sheet of FC (20"x30") is a perfect size for OB, I glued 3 layers for the baffle with the help of guerilla glue bought from home depot. It take less then a hour to complete bought speakers and used a total of 7 sheets.

The 15" bass driver is from an Akai SW-177 crossover at 250hz(2nd order), the mid is a 5" dynavox full range cross at 8khz (1st order) to a Philip tweeters (2nd order)

I am very happy with the result of using FC for this OB project and strongly recommend all diyer try the FC for your next OB speakers. It's simple and easy to built.

A single sheet of FC (20"x30") is a perfect size for OB, I glued 3 layers for the baffle with the help of guerilla glue bought from home depot. It take less then a hour to complete bought speakers and used a total of 7 sheets.

The 15" bass driver is from an Akai SW-177 crossover at 250hz(2nd order), the mid is a 5" dynavox full range cross at 8khz (1st order) to a Philip tweeters (2nd order)

I am very happy with the result of using FC for this OB project and strongly recommend all diyer try the FC for your next OB speakers. It's simple and easy to built.

Painting foam board with any type of petroleum based spray paint will warp the paper and dissolve the foam core. The best idea is to use a peel and stick type covering such as Contact paper. It comes in a variety of patterns including wood grain. Latex paint will not hunt the foam but it may warp the paper covering. I would try any latex paint on a scrap piece first.

echo-echo-echo

Some serious diffraction/reflection problems there unless I'm really missreading the plot

I just posted a sim for a 5-horn BLH speaker here:

Some serious diffraction/reflection problems there unless I'm really missreading the plot

The 15" bass driver is from an Akai

Ah, that brings back some memories. Recognized it right away. It's the first woofer I ever used when making a sub and satellite system all those years ago. Long before HT, long before sub/sat became popular. Long before digital cameras, long before plate amps. Long before I knew anything about speakers. Rough lumber, coffin sized box with two 15" passives. Used it as a coffee table with some legs stolen from an old TV stand.

That woofer [not the box] has followed me around through many moves. In fact it's still sitting there in the speaker room holding down a shelf. I went to look for a model number but the sticker has long since left this world but I remember it was a rather pricey one in it's day.

Hey, thanks for the memories there sagamotto!

Some serious diffraction/reflection problems there unless I'm really missreading the plot

I think what you may think is diffraction (10 Hz spaced comb peaks) is not. Those are individual horn resonance peaks and I tuned each horn so they are offset, so that the combined output doesn't have any appreciable dips or holes. With stuffing, the sharp peaks should smooth over. AkAbak has diffraction and baffle step from the baffle accounted for in the model.

This is a sketch of the type of design mod that is required to implement a double uneven length horn. Although not shown, the sims above are for this geometry but somehow with the mouths exiting on the back.

Hi x.

I wonder if you would be able to see if this design would work with the following driver?

THIELE-SMALL PARAMETERS Resonant Frequency (Fs) 102 Hz DC Resistance (Re) 6.2 ohms Voice Coil Inductance (Le) 0.05 mH Mechanical Q (Qms) 5.10 Electromagnetic Q (Qes) 0.89 Total Q (Qts) 0.76 Compliance Equivalent Volume (Vas) 0.03 ft.³ Mechanical Compliance of Suspension (Cms) 0.90 mm/N BL Product (BL) 3.43 Tm Diaphragm Mass Inc. Airload (Mms) 2.56g Maximum Linear Excursion (Xmax) 2.05 mm Surface Area of Cone (Sd) 27.3 cm²

Now, I do have these in the enclosure below, and all I can say is wow!!!! LF down into the 50's, really good imaging. I am sure that my room is enhancing the LF though. I am also building the DNA (bought the plans)

EDIT: These are Peerless 830986 drivers

Attachments

Last edited:

I have used foam core for many years and can tell you it does have a problem with warping and the corners will crush with the slightest bang. Laminating the foam core with 1/8" ply has worked well for me with a Cornu build. It adds support and rigidness without too much weight and can still be cut with a knife.

A couple alternatives to foam core are Gator Board and Sintra. Gator board is a laminate like foam core using much denser foam and tough heavy treated paper on the surface. Sintra is a pvc sheet that comes in many different thicknesses. It's really tough stuff used for years in the sigh business.

A couple alternatives to foam core are Gator Board and Sintra. Gator board is a laminate like foam core using much denser foam and tough heavy treated paper on the surface. Sintra is a pvc sheet that comes in many different thicknesses. It's really tough stuff used for years in the sigh business.

Bcmbob,

I used Guerrilla Glue available from Home Depot. They dried in a few minutes which is good that way it give you enough time to make final adjustment. I also used some painter scotch tape to hold the FC while waiting for glue to dry. No clamp needed!!!

Are you making the baffle for your OB speakers?

I used Guerrilla Glue available from Home Depot. They dried in a few minutes which is good that way it give you enough time to make final adjustment. I also used some painter scotch tape to hold the FC while waiting for glue to dry. No clamp needed!!!

Are you making the baffle for your OB speakers?

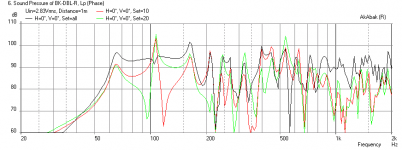

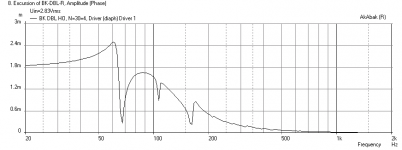

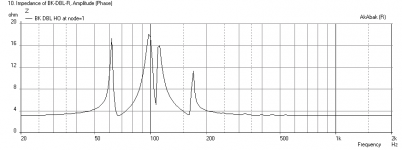

Sim of Double Rear Horn with Dual Peerless 830986

Fringy,

You are in luck! These Peerless drivers work quite well in this design when doubled up. I have them modeled as a parallel connection. The response is quite nice in the 95 dB region with 2.83V at 1 meter away. Below are the frequency response, the cone displacement, and the impedance.

These Peerless drivers work quite well in this design when doubled up. I have them modeled as a parallel connection. The response is quite nice in the 95 dB region with 2.83V at 1 meter away. Below are the frequency response, the cone displacement, and the impedance.

Cheers,

X

Hi x.

I wonder if you would be able to see if this design would work with the following driver?

THIELE-SMALL PARAMETERS Resonant Frequency (Fs) 102 Hz DC Resistance (Re) 6.2 ohms Voice Coil Inductance (Le) 0.05 mH Mechanical Q (Qms) 5.10 Electromagnetic Q (Qes) 0.89 Total Q (Qts) 0.76 Compliance Equivalent Volume (Vas) 0.03 ft.³ Mechanical Compliance of Suspension (Cms) 0.90 mm/N BL Product (BL) 3.43 Tm Diaphragm Mass Inc. Airload (Mms) 2.56g Maximum Linear Excursion (Xmax) 2.05 mm Surface Area of Cone (Sd) 27.3 cm²

Now, I do have these in the enclosure below, and all I can say is wow!!!! LF down into the 50's, really good imaging. I am sure that my room is enhancing the LF though. I am also building the DNA (bought the plans)

EDIT: These are Peerless 830986 drivers

Fringy,

You are in luck!

Cheers,

X

Attachments

Bcmbob,

Are you making the baffle for your OB speakers?

No, I did the Coruns and the DNA horns so far. My main speakers are OB minrange only and all wood. My next FC project will be either a set like your's or the Penta-Horn if X finds a design he likes.

I did find some pictures I downloaded years ago that show a baffle on a OB.

Attachments

Fringy,

You are in luck!These Peerless drivers work quite well in this design when doubled up. I have them modeled as a parallel connection. The response is quite nice in the 95 dB region with 2.83V at 1 meter away. Below are the frequency response, the cone displacement, and the impedance.

Cheers,

X

Hi X. Thank you so much! You are a legend

Hi X. Thank you so much! You are a legendI will get these made at the weekend in ply as foam core is so damn expensive here

You are welcome! Thanks for the kind words but legend is the last thing that comes to my mind

Sorry, I can't do that as you can see from the photo. I do have more than enough woofers, mids and tweeters in the stash to build a set in the format you used. It's on the list

Bob,

You have a lot of nice speakers and amplifiers, I am envious of your stash of supplies. Are those the Sunflowers? What is that white box made of? Looks almost like foam core!

The design of the panpipe pentahorn is pretty good as is - were you waiting for more refinements? Tom Lang is making a nice sketchup model with dimensions so maybe wait for that?

Thanks - I honestly have too much STUFF! Yes those are the sunflowers - best I have owned -period.

I did the low end chamber based on the B&W honeycomb technique. The material is MDF with 6 layer plywood internal web bracing. The corners were routed with a large radius bit and then painted with Krylon satin spray paint. They actually look like metal in real life.

I don't know if anything in FC can totally match a full wood build, but that's not an issue in my mind. The FC projects come together fast and inexpensive and the process is very enjoyable.

And yes, I looking forward to a dimension sketch for the Penta.... sounds like fun.

I got the Panasinic mic working and I'm reading all the user docs (REW & HolmImpulse) as we speak. Measurement info soon.....

I did the low end chamber based on the B&W honeycomb technique. The material is MDF with 6 layer plywood internal web bracing. The corners were routed with a large radius bit and then painted with Krylon satin spray paint. They actually look like metal in real life.

I don't know if anything in FC can totally match a full wood build, but that's not an issue in my mind. The FC projects come together fast and inexpensive and the process is very enjoyable.

And yes, I looking forward to a dimension sketch for the Penta.... sounds like fun.

I got the Panasinic mic working and I'm reading all the user docs (REW & HolmImpulse) as we speak. Measurement info soon.....

Attachments

Last edited:

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?