You don' t really need a 20W 10K resistor to discharge the caps if it is controlled by a switch and will never be in the circuit while power is on. 2W is sufficient as it will withstand the surge, and has a high enough thermal constant such that it will not get very hot.

Be sure to size the resistor for the voltage you are going to apply. You don't want it shorting out due to overvoltage.

Be sure to size the resistor for the voltage you are going to apply. You don't want it shorting out due to overvoltage.

Thank you; the resistor that I use to manually discharge anything that I am working on is actually 10k 50W wirewound so it does not even get warm discharging up to several thousand uF at 300-400V- this is rather impractical for an actual build but I do think that a ceramic body 7w 22k wirewound would be quite convenient switched in with a double throw switch(on-on rather than on-off-on)

I think the bottom line is " you should not have to discharge manually" it means the HT is possibly up after power off. Even though you must test before touching anything. Some sort of controlled power down is needed!

If you put a 1M 2W across the power caps even if the control fails there will be a discharge path all be it a bit slow. So you dont get caught out after a few hours away!

If you rely on the other tubes pulling it down after power off and the HT fuse blows due to a fault you may have a "loaded gun" to put your hands into!

If you put a 1M 2W across the power caps even if the control fails there will be a discharge path all be it a bit slow. So you dont get caught out after a few hours away!

If you rely on the other tubes pulling it down after power off and the HT fuse blows due to a fault you may have a "loaded gun" to put your hands into!

Last edited:

Regardless of whether or not bleeder resistors are present in an amplifier power supply you should always check with a meter that all caps are discharged before touching anything inside the amplifier chassis. Cold solder joints do happen, and resistors can fail. (I've also been guilty of not always showing bleeder resistors in schematics of past designs, although I do strongly recommend them.)

It is also a very good idea to check that the mains are disconnected as well if you are testing/tinkering on the bench with a new design before making changes..

Always be aware of your environment and exactly what you are doing, if you get tired stop!

It is also a very good idea to check that the mains are disconnected as well if you are testing/tinkering on the bench with a new design before making changes..

Always be aware of your environment and exactly what you are doing, if you get tired stop!

The downside of a manual switch is, If you pull the power cord and forget to toggle the swtich, your caps are still charged.

I prefer a resistor fixed across the B+ to insure discharge of the caps when power is removed, either by pulling the plug, or by switching it off AND pulling the plug.

I prefer a resistor fixed across the B+ to insure discharge of the caps when power is removed, either by pulling the plug, or by switching it off AND pulling the plug.

Yes, always use a bleeder resistor. In some cases there may already be a resistive link to ground, such as a potential divider g2 supply, so that will do instead. A few mA is all you need, just enough to light a small LED. If you were really worried about power consumption you wouldn't be using valves anyway.

I've never used a bleeder resistor, I switch off the amp first and let the music discharge my caps. This is also a good way to test if my caps are still healthy, with SE amps the music fades away gracefully others (some PP amps) start distorting it right away. In any case it's not a cause for concern since no-one but me messes with my amps.

Well, I said "music" because I don't hear DC voltage.

Sure. Same cathodes, same capacitance but different caps, different seconds before the music dies off.

Could you say more?

Sure. Same cathodes, same capacitance but different caps, different seconds before the music dies off.

Probably not but maybe 20 or 40 volts. Truth is I have never measured it. But when I do mods I do measure it and never discharge the caps because a few volts don't scare me. I have tasted 320 volts several times when I started building amps (too young and stupid, I know) so 20 volts or so remaining in my caps don't worry me. Note that I rarely use more than 200uf in my power supplies generally less and I don't touch with my hands the B+ rails, also note that it's my life not yours.

also note that it's my life not yours.

Well said! LOL it is. It is everyones choice to do as they wish, however I do believe in good safety it comes from working in the past with 25kV.

Kind regards

M.Gregg

Probably not but maybe 20 or 40 volts. Truth is I have never measured it. But when I do mods I do measure it and never discharge the caps because a few volts don't scare me. I have tasted 320 volts several times when I started building amps (too young and stupid, I know) so 20 volts or so remaining in my caps don't worry me. Note that I rarely use more than 200uf in my power supplies generally less and I don't touch with my hands the B+ rails, also note that it's my life not yours.

The limit for a cattle fence is 1 joule, or about 450V at 1uF, so I guess with 47uF it's gonna count and 100uF in the wrong place it's instant game over;- and you'll never know how the last mod sounded

I usually get down to 12V on the meter before I stick my fingers in - the bleeders then take it to zero in a few more seconds. I think 50V is the limit I heard to take precautions but it all depends on so many factors.

What one also really has to do is use an infra-read thermometer on the devices instead of touching them to see how hot they are, particularly as the heat-tab on my source follower sits at 420V coupled to a 330uF capacitor. I'll put heatshrink over that next I think, it's just too tempting and relies on memory rather than instinct..

Speaking to people even a small belt taken across the chest makes one feel like cr*p for quite a few days so it's really something to avoid.

I think in general an aversion to leaving any 'hot' wires available to touch is a good thing and aids neatness - the anode voltages do not have to be so accessible as the others.

Hmm...What one also really has to do is use an infra-read thermometer on the devices instead of touching them to see how hot they are,

Last edited:

I think we (at work) consider anything over 24V (30V max with tolerances included) to be dangerous. 48V is potentially lethal.

We do too...

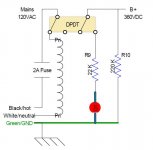

Building on ideas of piano3 and M Gregg, I drew up the circuit in the attached image, but have not implemented it because I can't figure out how to find or design a DPDT switch which can handle the high B+ voltage. Details follow...Would it not be a sensible idea to use a double throw switch on the mains which upon mains switch off switches in a relatively low (10-20k) bleeder which could not be tolerated on the basis of HT current wastage in operation?

As piano3 proposed, this circuit includes a DPDT switch that has the mains power on the first pole, and a high-current bleeder circuit on the second pole, so that when the mains is shut off, the high-current bleeder turns on and illuminates an LED until B+ is drained. (This circuit also includes a second, unswitched, bleeder resistor that lets a slow current through so as to provide some redundancy with minimal current consumption. The redundancy is important in case the power cord is disconnected while the switch is still on or if the LED burns out.) Here's the problem: the second pole in the switch has to be able to handle a voltage of 360VDC. I haven't been able to find any affordable mechanical switches or relays that can handle that spec. Does anyone know a good way to switch that kind of DC voltage, in a way that can be tied in to the mains switch as DPDT?

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- B+ discharge times!