under my stairs,

Where all things dark and scary live.

the ceramic version of the Altec 604. (8H?)

8K, the 8H was the last of the alnico's

1) For the speakers to sound their best, they have to be played loud. And I mean LOUD.

Yes, I have found that with all 15" coax's I have heard.

3) they are a bit forward and with the wrong source material

Aren't they though.

Someday I would like to build a more narrow cabinet with the same liter size and redo the time-aligned crossover... but first I need a bigger house!

Yes, bigger house. Mine are stuffed in a corner downstairs and it's hard to put more than 10 watts into them before things get a little crazy.

On a related note, I've also heard the no-letter UREI 813 with the Alnico Altec 604s and it does sound better to my ears.

Good to know. I have heard that the ceramics are not as good. I will eventually finish the 8H's seen in the pic but not till I have the room to set them up.

Cheers.

Attachments

Hi all,

I have followed GM recommendation and built wings for my 825. I will keep them! They do not significantly extend the bass, but improve linearity around 160 Hz, and I can hear it...

Cool! Thanks for letting us know. Mine have a wrinkle around 160 Hz, so it would be good to fix that. Also let us know what you did with the fiberglass.

As for the Coax drivers, the stock crossovers don't do them justice. A better crossover can make them sound much better. See the Jeff Markwart website for better ideas.

How much more does putting wings on the A7 help the bass?

Also what insulation is best for these cabs?

The wings primarily provide a termination for a too short horn (half size 55 Hz), so smooths out its 'ripple' and by going all the way to the ground it extends its F6 ~an octave or around 70 Hz, so if you either make them wider and/or taller as was originally done with the A800, then you should get solid response down to around 40 Hz even with a HF horn peeking through a gasketed cutout (click to enlarge): 800 VOTT

1" acoustic fiberglass (sometimes 2") as used to damp heating/AC ducts: Owens Corning 703 : Ready Acoustics!, Hear - Sound - Better

If you prefer to stuff, then use polyfil if for no other reason than MJK's MathCAD software will accurately enough plot how different stuffing densities affects performance.

GM

.......how u attached them etc too? and the build of them?

They should be 3/4" (19 mm) no void plywood framed with 2x2s and braced with 2x4s to mimic these much larger ones and all bolted together with 'T' nuts or similar: http://www.lansingheritage.org/images/altec/catalogs/1942/page09.jpg

That said, you can save money by using thinner, cheaper ply and back it with a cheap, lossy insulation board as I did.

GM

Mine have a wrinkle around 160 Hz.......

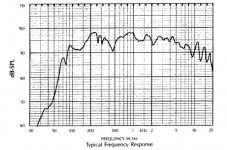

Just a 'wrinkle'? Here's a typical ~free field measurement showing its broadband dip. Then again, this is low enough for the room to help fill it in plus I don't recall ever seeing a large multi-cell A5's response, so maybe there's some fill from it down low also.

GM

Attachments

The wings primarily provide a termination for a too short horn (half size 55 Hz), so smooths out its 'ripple' and by going all the way to the ground it extends its F6 ~an octave or around 70 Hz, so if you either make them wider and/or taller as was originally done with the A800, then you should get solid response down to around 40 Hz even with a HF horn peeking through a gasketed cutout (click to enlarge): 800 VOTT

1" acoustic fiberglass (sometimes 2") as used to damp heating/AC ducts: Owens Corning 703 : Ready Acoustics!, Hear - Sound - Better

If you prefer to stuff, then use polyfil if for no other reason than MJK's MathCAD software will accurately enough plot how different stuffing densities affects performance.

GM

Excellent Links thank you!... So where should I put the 703 in the cab area? Think I will get 2"? Not every wall? Also How High should I go on the top plate above the bass horn when i flip these around? Then I will match the sides to it plus it will cover up the casters too as when i flip these they will just sit on furniture dollies

Last edited:

I am posting the FR before using fiberglass and after. I am using 2 inches on the sides, top and bottom and 4 inches on the back.

The second curve is measured with the wings in place. I made the wings with 19mm MDF. They are 28cm wide.

The second curve is measured with the wings in place. I made the wings with 19mm MDF. They are 28cm wide.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Some of you might remark that the 1505B and the 2405 are attenuated compared to the 825. The microphone was 3 ft from the LP. For time alignment and overall balance at listening point, I use the CSD:

An externally hosted image should be here but it was not working when we last tested it.

Blackson was what I used on the back of the horns in Mr. Hiraga's speakers. It works great. There are now non hardening substances that are water based. YOu might look into that.

Thanks for the graphs. Looks like the wings brought up the bottom end by 6dB or better. Am I reading that right?

Thanks for the graphs. Looks like the wings brought up the bottom end by 6dB or better. Am I reading that right?

Looks good!.. So I understand the graphs correctly, the first one is without no fiberglass or wings correct? the second graph is with glass and wings? also what are the two curves at the bottom of the second graph? What glass did you use? and Is your reflex chamber closed off where the flares are? Pics would be great when u get a chance of the wings ,front and back etc

This is where the horn unloads and transitions to bass reflex. It can be made more gradual by installing baffle 'wings' same as originally used (though it needs to be setting on the floor for max flatness). Ideally, the top baffles would be used also except with a gasketed cutout for the horn: http://www.lansingheritage.org/images/altec/specs/pro-systems/800/page2.jpg

GM

I plan on doing this , now questions are coming ,lol.. My wings on the side are no big deal ,but the top one for the horn to mount flush with the front edge of speaker cab it wont be anywhere near close enough to mount thru top baffle and keep things aligned right, so what do i do here? also in the pic altec shows the port higher up, I was thinking of putting mine right down near the floor for more bass rumble etc what ya think? and for mounting the horn on top too how are u mounting it just use my original mounting stuff?Don't really want to drill holes near the flare tho., so any pics, ideas are welcomed here!! Its all apart just waiting for driver and then build my wings. thanks!

Could someone show me the link to where the measurements are for mounting the horn on top?

Originally, the setback was 4" to the wood angle's mounting holes for the 811 and to mount the angle flush with the front of the cab for the 511, but better to do it acoustically...............

If you're sure the horn was properly mounted originally (which I doubt), then just measure it and mount it on top of the bass horn with the same setback; otherwise, measure/mark a point 19.3" back from the front for the 825/828. This is ~ the center-line of the woofer's VC if a 416, 421 or 515. The center-line of the compression driver's VC is ~ in the middle of the stacked plates at the rear of the driver. Vertically line up the VC center-lines. Wire the horn out-of-phase and using a RTA, slide the horn back n' forth a small amount to find the deepest notch (> 6-8 dB) in the XO's BW. You're done, secure it and swap the horn's leads and it is what it is.

GM

.........the top one for the horn to mount flush with the front edge of speaker cab it wont be anywhere near close enough to mount thru top baffle and keep things aligned right.........I was thinking of putting mine right down near the floor for more bass rumble etc what ya think? and for mounting the horn on top too how are u mounting it just use my original mounting stuff?

If a 511 horn, then dense open cell foam can be used to make a spacer. The 811 would need to be mounted on the baffle and digital time delay used to align it.

High up is better when tuned high (big vent), but smaller vents are better mounted close to the floor.

Original mounting hardware is fine and you can mount it to a sled to help brace the bass horn's mouth and provide more mounting hole location options.

GM

- Home

- Loudspeakers

- Multi-Way

- Altec Lansing