Thanks.

I did all the drywall myself. My very first time doing it. I've worked construction before, decades ago, and saw a lot of drywall go up. But I had never hung a sheet. 11 foot ceilings on the listening room side didn't make it easy. Yes, taping and sanding is awful! Never want to do that again. Painting is a joy compared to that.

I did all the drywall myself. My very first time doing it. I've worked construction before, decades ago, and saw a lot of drywall go up. But I had never hung a sheet. 11 foot ceilings on the listening room side didn't make it easy. Yes, taping and sanding is awful! Never want to do that again. Painting is a joy compared to that.

OK, after the window was removed and patched, the floor poured and the garage door removed, it was time to move on to the walls.

The side walls were covered in cedar singles that had to be pulled down - you can see them in some of the photos. A "shingle ripper" came in handy here.

Once the were singles gone, then up went the furring strips on the wall between my listening room and the living room. Used 2x4 studs on their flat side. This was an exterior wall, but I added the furring to give me room to run wire, install receptacles and put in insulation for sound proofing. The wall is about 8" thick, now. I should have wimped out and bought a framing air gun for all this work, but instead did it all with a nice classic framing hammer - bam, bam bam! Didn't even smash a finger while framing.

I painted the brick and the new floor with DRYLOK paint to keep things warm and dry.

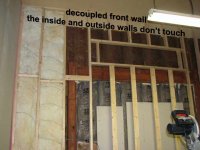

The front wall that faces the street was a big source of noise. Having read in the "Master Handbook of Acoustics" that a decoupled wall could reduce that noise by as much as 52dB, I decided to do that. So a new wall was built about 1.5" from the existing wall (where the garage door was). Only touching at the ceiling and the floor they are nicely decoupled. Insulation went in both walls to about an R30. They look like they touch in the photo, but they don't.

I framed in a space for a glass block window that will go in when the weather gets better. You can see it in the pix.

The decoupled wall really does work. It kills all but the lowest, loudest sounds. Much more traffic noise comes in from the door and window on the back side of the house now.

The side walls were covered in cedar singles that had to be pulled down - you can see them in some of the photos. A "shingle ripper" came in handy here.

Once the were singles gone, then up went the furring strips on the wall between my listening room and the living room. Used 2x4 studs on their flat side. This was an exterior wall, but I added the furring to give me room to run wire, install receptacles and put in insulation for sound proofing. The wall is about 8" thick, now. I should have wimped out and bought a framing air gun for all this work, but instead did it all with a nice classic framing hammer - bam, bam bam! Didn't even smash a finger while framing.

I painted the brick and the new floor with DRYLOK paint to keep things warm and dry.

The front wall that faces the street was a big source of noise. Having read in the "Master Handbook of Acoustics" that a decoupled wall could reduce that noise by as much as 52dB, I decided to do that. So a new wall was built about 1.5" from the existing wall (where the garage door was). Only touching at the ceiling and the floor they are nicely decoupled. Insulation went in both walls to about an R30. They look like they touch in the photo, but they don't.

I framed in a space for a glass block window that will go in when the weather gets better. You can see it in the pix.

The decoupled wall really does work. It kills all but the lowest, loudest sounds. Much more traffic noise comes in from the door and window on the back side of the house now.

Attachments

Pano you lucky dog. I wish I had a place to build a room like that. I did happen to notice in the floorplan sketch that there isn't any door shown from the house to the "man cave". Is this to indicate that one has to go outside to enter your privileged domain?!

"It kills all but the lowest, loudest sounds"

Guess that means when the teenagers with the body panel rattling stereos in their cars go by, the wall doesn't help much!

Peace,

Dave

"It kills all but the lowest, loudest sounds"

Guess that means when the teenagers with the body panel rattling stereos in their cars go by, the wall doesn't help much!

Peace,

Dave

Hey Cal, I thought you might like the photos. And thanks for your advice and help on the project. Also got good help from "Altec Best" who is also in the trades.

Yes, it does feel like a whole different room. I was actually shocked to go back and look at the photos. It's been slow going and there are many other projects around the house, so the old room seems eons ago.

Dave, no, no door directly into the house. My wife and I had planned a door where the window was, but we could never decide on what we wanted. So no door for now. That suits me just fine. Because there is a 3 foot drop that would mean a landing and stairs that would really cramp my speaker placement. And having no door keeps a lot more noise out of the living room - we both like that. I'll put a nice door in when we sell.

The rolling boom boxes on the street can still be heard, along with the rumble of trucks and buses. But I don't know how much of that is my decoupled wall and how much comes thru the storage room doors, the rear window, the roof. But it's much, much quieter than before. I can now hear my tinnitus in the room, and it needs to be very quiet for that (luckily). The least bit of music covers all that up. My Radio Shack SPL meter does not register most of the noise.

The house is one block from the fire station. I still hear the fire trucks, but they don't really bother me. Sound proofing is a big, expensive job. On a noisy street like this, I just do my best and turn up the music.

Yes, it does feel like a whole different room. I was actually shocked to go back and look at the photos. It's been slow going and there are many other projects around the house, so the old room seems eons ago.

Dave, no, no door directly into the house. My wife and I had planned a door where the window was, but we could never decide on what we wanted. So no door for now. That suits me just fine. Because there is a 3 foot drop that would mean a landing and stairs that would really cramp my speaker placement. And having no door keeps a lot more noise out of the living room - we both like that. I'll put a nice door in when we sell.

The rolling boom boxes on the street can still be heard, along with the rumble of trucks and buses. But I don't know how much of that is my decoupled wall and how much comes thru the storage room doors, the rear window, the roof. But it's much, much quieter than before. I can now hear my tinnitus in the room, and it needs to be very quiet for that (luckily). The least bit of music covers all that up. My Radio Shack SPL meter does not register most of the noise.

The house is one block from the fire station. I still hear the fire trucks, but they don't really bother me. Sound proofing is a big, expensive job. On a noisy street like this, I just do my best and turn up the music.

Hi. Nice job. For a better sound proofing it is not enough to decoupled the walls. you need to install on the wood stud a metal bar called 'soundproofing resilient channel' then screw a first sheet of sound absorbing fiber board, then an other bar installed at 90deg, then a first sheet of drywall (3/8''), then a second sheet installed at 90deg. Make sure to install foam ribbon cushion all around the wall before installing the sheet, and apply soundproof sealant. I did that on my second house master bedroom. Kill about 90% of the nearby highway. Even better, I moved away from the noise with my third house, best sound proofing ever

Door, windows, ventilation duck are the main source of noise communication from the outside. Door (Full type, not the usual empty cardboard type found in most houses) needs dropping seal, windows can be improve by a double window installed at a slight angle (ever seen a recording studio sound room, they have such window), ventilation duck are better deal with a separate ventilation system part of the room (I know almost impossible...)

Low frequency (LF) travel through the ground. There is a recording studio in UK, right in London where the complete studio floor is resting on huge springs. LF are also almost impossible to eliminate in a normal house. This is why you still hear the truck and bus.

As for the drywall, I built my first house, contracted the second one, but still did all the basement, and bought a third house fully built. We even kept the curtains. If I see an other sheet of drywall I'll run in the other direction...I know what building construction is in and out. I prefer to keep to electronic projects these days.

Keep on your good work.

Door, windows, ventilation duck are the main source of noise communication from the outside. Door (Full type, not the usual empty cardboard type found in most houses) needs dropping seal, windows can be improve by a double window installed at a slight angle (ever seen a recording studio sound room, they have such window), ventilation duck are better deal with a separate ventilation system part of the room (I know almost impossible...)

Low frequency (LF) travel through the ground. There is a recording studio in UK, right in London where the complete studio floor is resting on huge springs. LF are also almost impossible to eliminate in a normal house. This is why you still hear the truck and bus.

As for the drywall, I built my first house, contracted the second one, but still did all the basement, and bought a third house fully built. We even kept the curtains. If I see an other sheet of drywall I'll run in the other direction...I know what building construction is in and out. I prefer to keep to electronic projects these days.

Keep on your good work.

Last edited:

The Electrics

Since the room is a complete redo, the electrics need to be updated, too.

True to its garage heritage, the electrics were pretty funky. At some point in the past a 220V 30A sub-panel had been run to the area marked "Workshop" on the floor plan. 2 hots and neutral, but no ground - in a simple panel with two 30A fuses. Everything ran off that. Plus later 2 120V circuits had been pulled for a freezer. I"m not using those at the moment.

I have left the main 220V run but installed a new breaker panel. A new ground is run back to the main service panel. The new remote breaker panel in the room has 6 circuits:

Behind the amp rack I have the two separate 20A circuits with 4 receptacles each. I don't need all that power, but it was easy to install. So 8 wall plugs just for the audio. The circuits can not be all run full load, as each leg to the room is breakered at 30A in the main panel, but I can't think I'll ever need that much. I did buy "Professional" grade receptacles for the audio circuits. Not fancy hospital grade, but very sturdy stuff that makes and keeps a good connection. The cheap ones don't.

Also on the same wall there is 1 CAT5 line coming from the router inside the house and another going to the back wall behind the couch. Cable TV is in the same wall box. I doubt I'll use the cable, but you never know. In a box on the right are the two surround sound speaker lines that go to the back of the room about 8 feet up.

Rear wall has 3 receptacles, telephone and CAT5.

The overhead fluorescent work lights have been replaced with 2 nice drum style lights. You can see one in the photos. They give a nice glow to the room.

Tell you what, with the price of cooper what it is, wire is expensive!

Since the room is a complete redo, the electrics need to be updated, too.

True to its garage heritage, the electrics were pretty funky. At some point in the past a 220V 30A sub-panel had been run to the area marked "Workshop" on the floor plan. 2 hots and neutral, but no ground - in a simple panel with two 30A fuses. Everything ran off that. Plus later 2 120V circuits had been pulled for a freezer. I"m not using those at the moment.

I have left the main 220V run but installed a new breaker panel. A new ground is run back to the main service panel. The new remote breaker panel in the room has 6 circuits:

- Wall receptacles

- Main wall 20A

- Main wall 20A

- Lights

- Work shop

- Spare

Behind the amp rack I have the two separate 20A circuits with 4 receptacles each. I don't need all that power, but it was easy to install. So 8 wall plugs just for the audio. The circuits can not be all run full load, as each leg to the room is breakered at 30A in the main panel, but I can't think I'll ever need that much. I did buy "Professional" grade receptacles for the audio circuits. Not fancy hospital grade, but very sturdy stuff that makes and keeps a good connection. The cheap ones don't.

Also on the same wall there is 1 CAT5 line coming from the router inside the house and another going to the back wall behind the couch. Cable TV is in the same wall box. I doubt I'll use the cable, but you never know. In a box on the right are the two surround sound speaker lines that go to the back of the room about 8 feet up.

Rear wall has 3 receptacles, telephone and CAT5.

The overhead fluorescent work lights have been replaced with 2 nice drum style lights. You can see one in the photos. They give a nice glow to the room.

Tell you what, with the price of cooper what it is, wire is expensive!

Wow....

This is kinda weird......I just finished my listening room, it is also a single

attached garage that was a car port at one time. I also decoupled my walls

from the existing...cept the wall that replaced the garage door, there I used

6"steel studs. My floor was also concrete, cracked and uneven, but instead

of concrete I replaced it with a subfloor with R-20 insulation.....I live in northern Canada. For the ceiling I suspended metal furring bar on metal channel then drywall....then sprayed it. The difference is I have been a wall and ceiling mechanic for 30 yrs so the framing drywall and plastering were no problem. What is really coincedental is my house even had the same exterior finish colors.....

My ceilings are only 8'-2" high...yours look great with the added height.

My room finished at about 14'x 25'......your windows are much better situated

also.

Great job and congrats....been enjoying mine for about a week now...no treatments on the walls yet......thats for after X-mass.

Enjoy!!

Perry

This is kinda weird......I just finished my listening room, it is also a single

attached garage that was a car port at one time. I also decoupled my walls

from the existing...cept the wall that replaced the garage door, there I used

6"steel studs. My floor was also concrete, cracked and uneven, but instead

of concrete I replaced it with a subfloor with R-20 insulation.....I live in northern Canada. For the ceiling I suspended metal furring bar on metal channel then drywall....then sprayed it. The difference is I have been a wall and ceiling mechanic for 30 yrs so the framing drywall and plastering were no problem. What is really coincedental is my house even had the same exterior finish colors.....

My ceilings are only 8'-2" high...yours look great with the added height.

My room finished at about 14'x 25'......your windows are much better situated

also.

Great job and congrats....been enjoying mine for about a week now...no treatments on the walls yet......thats for after X-mass.

Enjoy!!

Perry

BTW SY, I fired up the system in the new room with one of your favs, Matt the Electrician.

The Bacon Song? (don't know if I got that album in time to burn it for you)

Hi Perry, funny coincidence, indeed! I'd love to see photos of what you've done. If you've been doing walls and ceilings for 30 years, then you must have gotten a good laugh out of my wall photos. But I'm not unhappy with them.

Nice for you to have the bigger space, that can really help. Tho given my tall ceiling, we are at about the same room volume. I gave serious thought to extending the listening room into the workshop and storage room space, but that would have involved a load bearing wall, installing a ceiling in one of the rooms and removing and installing a ceiling in the other. More work than I felt ready for.

I understand the need for the wood floor and the insulation. Even here that concrete slab can stay pretty darn cold. I did think about doing a suspended floor made out of OSB. I would have been much cheaper than the slab, less than 1/2 the cost, but I didn't know if I'd be able to get the thing level. It would have meant a lot of shimming and trimming of floor joists.

Let me know where you go with acoustic treatment. My plans are for diffusion on the wall behind the speakers, absorption on the wall behind my head and a mix of both on the side wall. I'll be using the UltraTouch cotton insulation in fabric covered panels for the absorption part. Great stuff that Gary Pimm turned me on to. Better acoustically than fiberglass of rock wool.

A Schroeder Diffuser on the speaker wall should work very well for my system. I'd love to use the ready made stuff from RPG, but it's so expensive. So I may have to go DIY on that that.

Nice for you to have the bigger space, that can really help. Tho given my tall ceiling, we are at about the same room volume. I gave serious thought to extending the listening room into the workshop and storage room space, but that would have involved a load bearing wall, installing a ceiling in one of the rooms and removing and installing a ceiling in the other. More work than I felt ready for.

I understand the need for the wood floor and the insulation. Even here that concrete slab can stay pretty darn cold. I did think about doing a suspended floor made out of OSB. I would have been much cheaper than the slab, less than 1/2 the cost, but I didn't know if I'd be able to get the thing level. It would have meant a lot of shimming and trimming of floor joists.

Let me know where you go with acoustic treatment. My plans are for diffusion on the wall behind the speakers, absorption on the wall behind my head and a mix of both on the side wall. I'll be using the UltraTouch cotton insulation in fabric covered panels for the absorption part. Great stuff that Gary Pimm turned me on to. Better acoustically than fiberglass of rock wool.

A Schroeder Diffuser on the speaker wall should work very well for my system. I'd love to use the ready made stuff from RPG, but it's so expensive. So I may have to go DIY on that that.

Awesome !

Hey Michael, Looking Great ! Ahhh it is a Very Merry Christmas, and will be a very Happy New Year !!!

If the furnace doesn't have enough BTU's may I suggest a couple 8' electric base board heaters 240 Volt. They will make that room very toasty.They heat quickly and throw off a lot of heat.Lot easier than running any new ducts.Just have to run a 20-30 amp 240 volt line (cable) with it's own thermostat. You could probably get away with one 8 footer but 2 will be better,don't know how cold it gets there.

You could probably get away with one 8 footer but 2 will be better,don't know how cold it gets there.

But Fantastic Job, Looks Great Michael !

It will be nice to get those A5's breathing again !

Hey Michael, Looking Great ! Ahhh it is a Very Merry Christmas, and will be a very Happy New Year !!!

If the furnace doesn't have enough BTU's may I suggest a couple 8' electric base board heaters 240 Volt. They will make that room very toasty.They heat quickly and throw off a lot of heat.Lot easier than running any new ducts.Just have to run a 20-30 amp 240 volt line (cable) with it's own thermostat.

But Fantastic Job, Looks Great Michael !

It will be nice to get those A5's breathing again !

I understand the need for the wood floor and the insulation. Even here that concrete slab can stay pretty darn cold. I did think about doing a suspended floor made out of OSB. I would have been much cheaper than the slab, less than 1/2 the cost, but I didn't know if I'd be able to get the thing level. It would have meant a lot of shimming and trimming of floor joists.

This is one of my concerns! The floor,not the acoustics but just for comfort reasons.Without some kind of barrior (vapor,etc) it could and will stay cold,damp,etc...

I would lay some plastic sheeting 3 mil minimum and then wood,padding/carpet,on top of that.

In that last picture of the window,what was there before 1 single window ?

Great Job Pano !!

Well too late now! But I did paint the slab with DryLok paint, which should keep the damp out. And it's a new slab over an old, so hopefully not too much damp will seep up. I'm sure I won't mind the cool slab in the summer.

The window you see was already there, I just drywalled around it.

The window you see was already there, I just drywalled around it.

- Home

- General Interest

- Room Acoustics & Mods

- A last! My listening room. A good day.